Is it possible to degrease with white spirit? Certainly. Read how

Often when repairing a car, the question arises whether it is possible to degrease the parts to be painted or glued with white spirit. The interest, one might say, is correct, since the design of the machine contains both metal and plastic parts. Sometimes you have to work with glass - when replacing a windshield, mirrors or cracked glass on headlights and lanterns. And all of the above materials have varying degrees of density and interaction with adhesives.

Nobody wants to worsen the situation by deforming spare parts – purchased or those to which they are attached. People are especially sensitive to the paintwork of a car - repainting the entire body is expensive, time-consuming and troublesome if you do it with your own very skillful hands. But the body has to be degreased not only during repairs, but also if you are lucky enough to pick up water-insoluble contaminants along the way, such as drops of bitumen, rubber crumbs, all sorts of lubricants and oils that are quite difficult to wash off from the body or glass.

Is it possible to degrease with white spirit?

– the answer is first of all broken down into separate options based on the material from which the degreased surfaces are made.

Applications: degreasing, diluting, cleaning

Nefras has a number of features. The advantages of this solvent:

- the pungent odor goes away quickly (in particular, this applies to Tikkurila brand products);

- inexpensive;

- relatively low consumption compared to other solvents.

Application of the substance:

- production of paints and varnishes;

- production of various mastics, polishing pastes and drying oils, materials for priming;

- cleaning of various equipment parts in industry;

- degreasing of various surfaces, mainly metal;

- fighting rust and removing bitumen stains from the body;

- production of antibacterial substances for wood;

- removes paraffin from the surface and fibers of fabric.

This list is not exhaustive. It is expanding with the development of various technologies.

Expert opinion

Ilya Vyacheslavovich

Consultant for body repair at krasymavto.ru

Ask a Question

Disadvantages of the solvent: explosive and flammable when accumulated in the room where it is used, the presence of an unpleasant odor and some toxicity at high concentrations.

Is it possible to degrease with white spirit? Certainly. Read how

Based on this, we will describe these possibilities and the feasibility of using this solvent in practice.

All modern chemicals used for degreasing are essentially solvents for organic matter and, accordingly, should not affect inorganic surfaces (primarily metal ones). Antique and proven degreasers - gasoline with kerosene and acetone - would cope with their role, but are rejected by the modern automotive community due to their increased flammability. White spirit is also not devoid of it, but it is much less volatile, and therefore is more correct from the point of view of safety in use.

It does not react with metals, so there is no danger of using it to make a hole in the side of your iron friend.

White spirit does not dissolve body coatings, even if they are no longer solid and have scratches and abrasions. Taking into account its low price - 50 rubles per liter - most car owners prefer to use it for garage needs. The only drawback of the substance is its rather strong and persistent characteristic odor. With caution, white spirit can only be applied to aluminum parts and alloys containing this metal. Aluminum is easily corroded by certain organic compounds.

In theory, white spirit should not damage such parts, but who knows what is mixed into the source material. In any case, in folk auto practice there have been cases of deformation of aluminum parts.

The situation with him is much more complicated. There are quite a few types of plastic used in the automotive industry. Some bubble and warp from benzene or acetone, others are driven in all directions by gasoline, and some even dissolve in dichloroethane. A number of plastic parts are quite indifferent to white spirit, and they can be degreased with it. But it’s better not to experiment and buy a special, mild preparation like PiTon

or

APP WK900

. And it’s better to first test them on some inconspicuous area and in a microscopic dose.

Glass is also indifferent to more aggressive liquids than white spirit, and here it is unnecessary to be careful. The question is: why is degreasing carried out? If its purpose is bonding (for example, when replacing a cracked rear view glass), then white spirit is quite suitable. But if you wash the windshield from oily substances before tinting or gluing the film, then it is better to turn your attention to other solvents.

The fact is that white spirit leaves behind quite noticeable, slightly oily stains. It is especially undesirable to use it under film - such patterns will remain with you forever. And even if they are not too noticeable, visibility will still be somewhat impaired.

If we summarize the experience of many generations of car enthusiasts, then the question of whether it is possible to degrease with white spirit can definitely give a positive answer. You just need to do this necessary and painstaking process in a well-ventilated garage or even on the street, in the open air. And it wouldn’t hurt to wear a special protective mask or respirator.

Signs of poisoning and first aid

The causes of nefras poisoning can be:

- inhalation of fumes;

- contact with skin;

- accidental contact with the mucous membrane of the eyes;

- accidental or deliberate ingestion.

Symptoms of poisoning:

- gradually increasing dizziness;

- confusion of speech, hallucinations, delusions;

- impaired psychomotor reactions, gait, decreased physical activity, muscle spasms;

- pain or burning sensation in the throat, ears, nose, lips;

- blurred vision and weakening of other senses

These symptoms usually appear in people prone to allergic reactions and occur quite rarely - if they occur, you must stop using white spirit in your work.

First aid

Anyone needs to know what to do before the ambulance arrives in case of poisoning or a severe allergic reaction to a solvent.

- The person is taken out (in severe cases, taken out) into the open air to prevent further entry of the chemical into the respiratory tract.

- Open the windows to ventilate the room.

- If white spirit gets on the skin or mucous membranes and causes an allergic reaction, the affected areas are washed with plenty of water.

- Call an ambulance immediately.

- Rinse the stomach with plenty of water if the victim is conscious.

- Give activated carbon to drink (1 tablet per 10 kg of weight).

The listed cases and consequences of poisoning are rare and, as a rule, are caused by individual intolerance to the substance or accidental ingestion of white spirit into the body.

Recently, new generations of solvents have appeared on the market. There is a deep cleaning nefras without a pungent odor. However, the low price of the usual white spirit, its consumer qualities and functionality make the classic solvent an indispensable assistant in everyday life.

Welcome to our site!

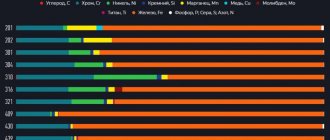

When comparing solvent and white spirit, you must immediately make a reservation that these are two solvents with similar properties, which are produced mainly from crude oil by distilling it in cracking columns at oil refineries. Without access to oxygen, at temperatures from 130 to 150C, hydrocarbons are evaporated, from which a solvent (solvent) is produced. In the same cracking columns, mixtures of hydrocarbons called white spirits are evaporated at temperatures from 155 to 200C. Aromatic hydrocarbons are evaporated from oil at low temperatures and in solvent form up to 56% of the total mass. The mass of such hydrocarbons in white spirit should not exceed 16%.

In addition to oil cracking, the production of solvent is established when producing coke from coal, when light aromatic fractions of hydrocarbons are released when heated in the form of coke oven gas, collected when passing through an exhaust pipe, condensed while passing through coolers, and the output is xylene, quite suitable for consumption, toluene and solvent. This coke oven gas contains up to 60% light aromatic hydrocarbons. Due to the higher content of aromatic hydrocarbons, the solvent, unlike white spirit, has a sharper characteristic odor, which evaporates quite quickly, however, when working with the solvent for a long time in a closed, unventilated room, it can cause a headache and even hallucinations in a person.

The content of hydrocarbons of different volatility gives both solvents slightly different properties, for example, solvent may have a yellowish tint, white spirit is always transparent, solvent dries within 10-20 minutes, white spirit dries within 1-2 hours, solvent gives paints a glossy surface , and White Spirit makes the paint matte with an additional film on top. Solvent has found application not only for diluting paints, it is also actively used for cleaning metal parts (including car bodies) before painting them. White spirit is more actively used by paint manufacturers and consumers at home. Similar properties include the ability of both solvents to dissolve oil paints and fats. In addition to oil paints, the solvent dissolves nitro paints well. Both solvents are used in the production of glyphthalic, pentaphthalic, alkyd and bitumen paints and varnishes, when removing old dried paints and when removing grease stains before painting. Due to its low odor and low drying speed, white spirit is more actively used in the production of paints. Using solvents, rubbers, bitumens and polyesteramides are dissolved. Sometimes solvent is used to obtain poison from rats and beetles, but this is rather an exception.

Read also: DIY car repair cart

Both solvents are flammable substances with a low flash point, and both have the ability to accumulate static electricity, which can cause an explosion. The density of the solvent is higher than the density of white spirit, and they are 0.86 and 0.79, respectively.

Despite assurances of development and improvement of the quality of both solvents, at the moment not a single oil refinery in the Russian Federation produces solvents that comply with GOST 1978 and 1979, which determine their regulatory compliance. This happened for a number of reasons:

- GOST allowed the presence of aromatic hydrocarbons, which made both solvents so odorous that they did not find their use abroad, that is, they are not sold for export. Western analogues do not have the smell and color, which is provided for in the regulations of these countries, so our solvents are very inferior to them.

- Increasing consumer demands for solvents has led to an increase in the flow of imported solvents. Transparent and completely odorless solvent produced at coal processing plants in Alsace and White Spirit distilled in Norway greatly displaced the production of domestic solvents, making its production unprofitable.

- The deepening of the oil refining process created conditions when it became possible to distill the fraction of solvents and white spirits with a boiling point from 120 to 200C into more expensive benzenes and gasolines, replacing solvents with inexpensive orthoxyols and toluenes. Today, the production of solvent and white spirit according to GOST standards is not economically profitable, and all oil refineries that sell solvents produce them based on their own specifications. Such solvents do not have the density of the declared solvents and have overly strong odors.

- Modern developments in chemistry have made it possible to obtain solvent and white spirit by simply mixing various hydrocarbons. As a result, it turned out to be much easier and cheaper to achieve the properties of solvents by adding various hydrocarbons than to carry out complex and costly oil refining processes.

- Many manufacturers are trying to replace solvent and white spirit with various kerosene-based solvents. Such attempts are quite successful and will probably soon make it possible to completely abandon the centuries-old dependence on petroleum solvents.

The need to prepare metal products for painting is due to an increase in the adhesion characteristics of the substrate to the paint and varnish material and the resistance of the metal to corrosion processes. All this will have a positive effect on the service life of the painted products. However, most owners are much more concerned about the presence of rust, which must be removed during the metal preparation process, than about degreasing, which is why painting work is carried out without this important and mandatory operation.

Advantages of using it before painting

Due to tightening production standards and the need to comply with GOST, the appearance of improved versions of materials has become the norm. This trend has also affected nefras. Consumers should pay attention to a solvent such as white spirit 1050.

The production of this substance is carried out, in particular, by. A certificate confirming quality determines the highest class of its products. The features of the solvent white spirit 1050 are the following:

- Effective. It is also used for diluting various paints and varnishes of the Tikkurila brand.

- The shelf life of white spirit 1050 solvent in the original container is at least 10 years, even at low temperatures.

- Contains paraffin and various compounds containing this substance in smaller quantities relative to analogues. This became possible due to the optimization of the chemical composition of the solvent by employees. Since paraffin is contained in smaller quantities, white spirit becomes safer for use.

- Less solvent consumption per nominal weight of paint and varnish material.

- Use for degreasing a larger list of surfaces compared to analogues.

- De-scented (odorless white spirit).

- Certificate guaranteeing the quality of the product.

- The specific gravity for 1050 nefras is 0.780 g/cm 3, which is less than the standard weight of a substance made in accordance with GOST requirements.

Information! There are different types of solvent, their technical characteristics, such as weight, volume of paraffin-containing additives, consumption, differ, but not too much.

What is defatting

The essence of the procedure is to remove fatty substances from the surface of the substrate, which are often present in cooling emulsions, mineral oils, preservative lubricants, and polishing compounds. Degreasing of the metal surface before painting also has to be done to remove residues from washing and etching, traces of sweat and fingers. All these contaminants can extremely negatively affect the quality of surface wetting with paints and varnishes, as well as harm film formation and other properties of the coating.

Depending on the amount of fatty impurities present per square meter, several degrees of surface contamination can be distinguished:

- Weak - up to 1 g;

- Medium - from 1 to 5 g;

- Increased - more than 5 g.

When processing fats with chemical reagents, several sequential processes occur on the surface:

Depending on the ability of fats to be destroyed under the influence of solvents, several types of contaminants are distinguished:

- Non-destructible - for example, emulsions.

- Pollinated - polishing materials, lubricant residues.

Chemical methods

The main type is organic solvents, which allow you to quickly remove grease and oily areas from metal parts. They are most widely used in individual production, although sometimes they are used in serial production, but not often due to their high explosion and fire hazard. The desired effect, namely the dissolution of oil and fat deposits, is achieved at the moment of contact of organic solvents with them.

The quality of surface degreasing is directly affected by the degree of solvent contamination, since the more fats are contained on the surface, the worse the chemical’s ability to dissolve existing deposits becomes. Most often, aliphatic and chlorinated solvents are used to remove fat and oil areas. Despite their high efficiency in metal cleaning, they have a serious drawback - these compounds are not able to remove abrasive materials and other mineral contaminants from the surface.

Aqueous solutions

As is known, water has poor purification ability, which is associated with significant surface tension and incompatibility with fats. Therefore, when it wets greasy surfaces, stable emulsions are not formed. To increase the cleaning properties of an aqueous solution, manufacturers resort to various techniques - increasing the pH acidity level, increasing the temperature regime of use to the range of 50-65 degrees Celsius, and introducing surfactants into the composition.

Alkaline degreasers

These compounds have a lot of positive properties. These include high cleaning ability, fire safety, environmental friendliness, and a wide selection of application methods. When treated with aqueous solutions of saponified fats and oils, the latter are inevitably destroyed, and unsaponifiable contaminants are emulsified. The latter case can be described as the process of detachment of fatty layers from the surface with gradual transformation into a working liquid and removal along with the working solution. The main disadvantage of these compositions is the need for anti-corrosion treatment of the surface after cleaning.

Read also: How an electromagnetic all-wheel drive clutch works

Among the components present in cleaning solutions, surfactants - surfactants - deal best with fatty and oily areas. Once on the surface, they form foam on it, simultaneously reducing interfacial and surface tension, increasing wettability and destroying solid and liquid contaminants, transforming them into a more convenient form for removal. The surfactant content in grease cleaners , as a rule, fluctuates within 10%.

If the need arises, along with degreasing, to remove thin oxide or hydroxide films, acidic solutions containing 1-3% phosphoric acid are used.

After treating surfaces with cleaning compounds, they must be washed with water. The presence of salt residues is unacceptable, since they can destroy the properties of paint films, increasing moisture permeability and accelerating the development of under-film corrosion.

Emulsion compositions

In cases where there is a need to remove oil deposits, grease, and difficult-to-remove contaminants from the surface, emulsion degreasing is used. This method is combined and has the advantages of organic solvents and aqueous alkaline solutions. These compositions contain emulsions of solvents and surfactants diluted with water. Chlorinated or aliphatic hydrocarbons can be used as solvents.

Ultrasonic and electrochemical methods

To increase the cleaning ability of detergent compositions, special baths with an ultrasonic field are used. This method is most relevant for small-sized products with a highly complex surface, for which it is important to remove contaminants with the highest quality possible. For large parts, it is not practical to use this method due to economic considerations, since there is a need to increase the output power of the device.

When preparing metal products using the electrochemical degreasing method, specially equipped baths are also used, and the process itself is carried out due to the action of gas bubbles formed on the electrodes. This makes it possible to reduce the consumption of components of chemical compositions and improve the quality of surface treatment.

Ultrasound and other processing methods

Degreasing methods:

- Use of ultrasonic baths.

- Electrochemical method. To clean metal you need to use industrial equipment. Therefore, electrochemistry is not suitable for domestic use.

Since the degreasing process involves not only removing the fat film, but also cleaning the surfaces from contamination, it is permissible to use a mechanical processing method. To do this, you can use various power tools - an angle grinder, a grinder, a drill with a special attachment. Complex contaminants are removed with coarse abrasives. Gradually the grains are reduced to create smoother surfaces.

Before you start painting metal parts, you need to prepare them. To do this, you need to remove contaminants. After rough cleaning, you need to start removing grease stains, which can reduce the adhesion of paint to metal.

How to degrease metal before painting

In domestic conditions, owners, as a rule, use proven “old-fashioned” products - gasoline, kerosene, acetone, alcohol.

But today more modern and technologically advanced formulations are available. Among them, Nefras (White Spirit), Solvent 646 are quite popular. They have a lot of advantages - affordable price, increased level of environmental friendliness, the ability to form films that are more resistant to paintwork, which helps prevent the development of corrosion processes.

The problem for many owners is that the substrate after degreasing does not match the chosen paint. This can be avoided by purchasing a solvent suitable for the coating being treated. But more often than not, such problems do not arise when using solvent No. 646 . Consumer reviews talk about its versatility, so there is no need to carry out additional operations.

Another popular type of solvent is Antisilicone. These compounds are in high demand among craftsmen, who use them to degrease the car body before subsequent painting. However, safety rules must be observed during operation. In the room where degreasing work is carried out, windows and doors must be opened. Such solvents can be used as far as possible from sources of ignition and always wearing personal protective equipment.

The most effective are special concentrated solutions - Chistomet, Docker Dekamet and others. The main active component in these products is alkali. They also contain additional substances - inhibitors, surfactants, additives, etc. Before use, the concentrate is mixed with water in pre-calculated proportions. It all depends on the degree of contamination of the surface being treated. The advantages of these solutions are their high environmental friendliness and safety. They can be used not only to degrease the surface, but also to increase the anti-corrosion resistance of the metal. Can be used in industrial enterprises.

Alkaline degreasers

Alkali-based degreasing solutions are characterized by a number of advantages:

- high efficiency, including against high levels of pollution;

- low harmfulness;

- no fire hazard;

- environmental friendliness;

- various methods of application to the surface.

During interaction with alkaline solutions, saponified fatty compounds are destroyed. Unsaponifiables form an emulsion and are removed along with it. A significant disadvantage of alkaline solutions is that after treatment they must be protected against corrosion.

Surface-active substances very effectively dissolve fatty contaminants. When it comes into contact with dirty areas, foam is formed, which reduces surface tension and the adhesion force of molecules to each other. Contaminants in solid and liquid form are destroyed and turn into solutions and emulsions, which are then easy to remove. Surface degreasing products contain up to 10% surfactants.

If, in addition to fatty contaminants, it is also necessary to remove thin films of oxides from the surface, then weakly concentrated acid solutions are used. This treatment is carried out, for example, before welding non-ferrous metals and their alloys.

Popular solvents

How to degrease a metal surface before painting is a pressing question for many owners. To degrease metal surfaces, today you can use not only affordable and time-tested compounds, but also modern solvents.

White spirit

Among degreasers, white spirit is most often used. It looks like a transparent, colorless liquid with a characteristic odor of fuel and lubricants.

It is sold in stores under the name “Nefras-S4” and is available in various modifications. The main reason for its popularity is due to its versatility.

This solvent can easily remove any oils and fats, as well as many organic compounds. It is often used to dilute oil paints, enamels and varnishes. White spirit also has one more positive property - after treating the surface, you do not need to wait for it to dry; you can immediately proceed to applying a primer or paint material. The solvent evaporates very quickly, and this is what gives it superiority over other cleaning compounds.

Solvent 646

This type of degreaser is widely used when preparing for painting. It is a yellowish liquid with a strong characteristic odor. It has a fairly wide range of applications.

With this composition you can not only dilute paints, but also degrease metal surfaces. It is especially effective when you need to remove old layers of paint. Can be used for washing painting equipment and tools.

Best suited for diluting the following types of enamels:

- nitrocellulose NC;

- glypthal GF;

- melaninoamide MPs;

- acrylic;

- epoxy.

When using the degreaser, it is necessary to observe the temperature recommended by the manufacturer from + 5 to + 30 degrees Celsius, while the air humidity should not be higher than 85%. Then, after treatment, the metal surface will acquire a shiny, glossy appearance without stains or streaks.

Please remember that Solvent 646 is a flammable and explosive product. You can work with it only while wearing respiratory, eye and skin protection. When carrying out work indoors, it is necessary to ensure the supply of fresh air through windows and doors or through working exhaust ventilation.

Acetone: classic

Another fairly common metal degreaser. In terms of its composition, it is a transparent liquid with a strong characteristic odor. Excellent for removing oil and grease stains, as well as tar.

Acetone can be used to dilute varnishes, enamels, paints and primers. Sometimes it is added to the composition of some solvents. The main component is alcohol, which is highly volatile.

To protect metal surfaces from corrosion processes, they must be specially treated before applying paint. Dyeing technology requires an operation such as degreasing. It can be performed using various solvents and degreasing compounds.

Read also: Lead sheathed cable marking

Among them there are both traditional and more modern and technological ones. The choice of the most suitable composition for degreasing should be made taking into account the nature and scale of the tasks at hand, as well as the purpose of the metal product.

At the same time, it is important not to forget about safety rules during degreasing work. Many formulations are unsafe due to the content of compounds harmful to health. Therefore, when carrying out work indoors, it is necessary to ensure constant access to fresh air. You also need to remember that there are no flammable sources nearby.

Degreasing the metal surface is a must before painting it. This is done in order to improve the adhesion (adhesion) of the paint to the metal. Carrying out preparatory work before painting, various contaminants, primarily fatty ones, will still appear on the surface. It’s enough to touch the oily overalls and that’s it; painting the contact area no longer makes sense. The paint won't stick.

Safety precautions

When working with white spirit, it is necessary to observe safety measures that reduce the negative impact on the human body and the objects being processed.

- Wear only protective clothing. Prolonged exposure to the skin and mucous membrane during breathing can cause allergic reactions and drug addiction to inhaled vapors (GOST 3134-78).

- The room in which work is carried out must be ventilated.

- Keep container tightly closed, away from direct sunlight. A substance that is self-igniting and may catch fire when heated. An increase in temperature causes accelerated evaporation of the solvent.

In case of nefras fire, extinguishing is carried out by any means except water.

- It is prohibited to use white spirit near open flames, machines and tools that are a source of sparks.

We recommend: Preparing an analogue of gold eye patches at home

White Spirit

The most common degreaser is white spirit. It is a transparent liquid with the smell of fuels and lubricants.

It was distributed under the trade name "Nefras-S4" of various modifications. It has gained wide popularity due to its versatility.

Easily neutralizes any oils and fats, many organic compounds. In addition to these purposes, it is used as a thinner for oil paint, enamel, and varnish. Another remarkable quality of white spirit is that after treating the surface, you can immediately apply primer or paint to it. The evaporation of this solvent occurs instantly, as they say “before our eyes.”

What's better?

Which is better - white spirit or kerosene degreaser? Is it possible to ensure high-quality adhesion by replacing materials? Let us remember the fundamental differences between one fraction and another - volatility and viscosity. Kerosene is low-volatile and “heavy” compared to the “white spirit”. It is an excellent solvent, but due to its low volatility it forms a thin, oily film after degreasing, which, of course, does not contribute to better adhesion of the paintwork and the body surface.

Kerosene does not react with fabric dyes and does not damage wool pile. Why? Because it cannot interact with the smallest oxide compounds that cover all objects in contact with the atmosphere. We live in this very atmosphere! The surface of the car is also covered with exactly the same oxide film, which means that it must either be gotten rid of or made safe and “obedient”.

Nefras, like kerosene, is not able to rid the surface of the car of this film, but it is able to react with it and turn the harmful oxide into a stable chemical compound that does not interfere with adhesion.

Nefras “Galosha” - another version of white - is applicable not only for automotive iron, but also for vulcanizing its “shoes”.

The oxide film can be completely removed only with pure alcohol C₂H₅OH, but can you imagine the consumption of “spiritus” on a car body? The conclusion suggests itself: white spirit for degreasing before painting has clear advantages over kerosene and alcohol.

Solvent 646

The next popular degreaser will be solvent 646, which is often used in preparation for painting. The liquid is slightly yellowish in color with a sharp, specific odor. The spectrum of its action is quite extensive.

Excellently dilutes paints, degreases metal surfaces well, is indispensable for removing old layers of paint, and is used for washing painting equipment and tools.

It is recommended to use for thinning the following enamels:

- nitrocellulose NC;

- glypthal GF;

- melaninoamide MPs;

- acrylic;

- epoxy.

When working, it is necessary to maintain the temperature within +5…+30ᵒ C, and air humidity should not exceed 85%. In this case, the painted surface takes on a shiny, glossy appearance without spots or streaks.

Acetone

Acetone, as a degreaser, is also widely used. Colorless transparent liquid with a sharp specific odor. Excellently dissolves oil and grease stains, various resins.

Used to thin primers, paints, enamel and varnish. Included in some solvents. It is made on an alcohol basis. Has high volatility.

When working with acetone, it is imperative to take measures to protect the skin, eyes and respiratory organs. It is strictly prohibited to use open fire or be near operating electrical appliances. For ease of working with acetone, it is best to use a spray bottle.

Vershina universal degreaser

The Vershina universal degreaser has confidently begun to gain popularity among drivers. It degreases well any surfaces made of metal, ceramics, glass and plastic. Easily removes various contaminants from the surface before painting or applying any anti-corrosion coatings.

Recommended by the manufacturer for treating surfaces before gluing them. It is very convenient to use with a spray nozzle on the bottle. When dry, it leaves no traces.

Compliance with safety precautions when working with degreaser guarantees complete safety.

This is interesting! Alkyd enamel: what is it and how is it different from alkyd paint

Metal Degreaser

For longer service life, any metal structure must be treated with appropriate paints and varnishes. This will prevent the appearance of pockets of corrosion. One of the first manipulations when working with metal is the process of applying a degreaser to the surface, regardless of the complexity of the design. High-quality treatment with a degreaser will ensure reliable adhesion of the surface of the product to the layer of paint and varnish that will be applied subsequently.

Solvent

Can also be used as a degreaser. In the retail chain it may go under the name "Nefras F-130/150". Transparent colorless or slightly yellowish liquid. It is made on the basis of petroleum fractions. Less often - coal. When painting a car, it can be used not only as a degreaser, but also as a paint thinner. Excellently removes all auto-preservatives.

At the same time, rubber bitumen and oil shale automotive mastics are diluted with a solvent. Solvent-based paints have unique properties. Thanks to their high adhesion, they create a durable coating. When working with solvent, it is necessary to strictly observe safety precautions.

Types and composition of degreasers

Degreasing agents can be divided into three groups according to their chemical composition:

- Based on organic solvents - organic degreasers;

- Emulsion degreasers based on emulsions of organic solvents in water;

- Based on aqueous solutions of alkalis and acids - alkaline and acidic degreasers.

Organic degreasing agents are based on solvents - petroleum products (petroleum solvents), saturated and aromatic hydrocarbons, alcohols and esters, chlorinated hydrocarbons (methylene chloride, tri- and tetrachlorethylene, chlorofluorocarbons), white spirit and others. The degreaser may contain one or two solvents, as well as components to reduce the rate of evaporation of solvents, stabilize them, etc.

Traditional degreasers

Often, when servicing a car, the most common degreasers are used. For the initial treatment of small areas of contamination, you can successfully use gasoline, kerosene and even diesel fuel.

Primary treatment consists of preparing the surface of the iron for degreasing. For example, the manufacturer recommends using BR-2 solvent, also known as Galosh gasoline, for washing metal products.

This recommendation can be successfully applied to kerosene and diesel fuel (“diesel fuel”). By the way, gasoline or kerosene can be used to thoroughly clean and degrease leather and fabric products. The only drawback is that the smell will take a long time to dissipate.

This is interesting! What is drying oil: types, composition, technical characteristics and application features

Glass degreasers

Compared to plastics, glass practically does not react to any solvents except the strongest acids. Therefore, you can use any available composition for it. It is important to remember that the properties of glass do not apply to rubber seals - rubber or plastic frames. They will have to be dismantled or protected from the effects of the solvent composition.

To degrease the glass surface, use alcohol, acetone, license solvents, alkaline solutions, white spirit - whatever is at hand.

Ammonia

Ammonia is also a solvent for oil paints. It is contained in small quantities in ammonia. A stain of oil paint on clothing can be removed with a piece of cotton wool soaked first in turpentine, then in ammonia. It removes stains and other compounds using it well.

Although ammonia has solvent properties, its use is not recommended. If necessary, it is better to replace it with other, less toxic products.

Degreasing any metal surface before painting it is a must. Otherwise, the paint will simply begin to peel off and all the work will have to be done again. To prevent this from happening, you first need to prepare all the materials for work. Selected solvents and degreasers, protective equipment, tools, a first aid kit, clean water and rags should be the basis of this preparation. All that remains is to degrease the metal correctly, in compliance with the manufacturer’s recommendations and without violating safety measures.

Watch the video in which a specialist talks about how to degrease metal before painting a car and about the properties of degreasers:

This is interesting! Copper sulfate against fungus on walls: method of application and processing tips

See inaccuracies, incomplete or incorrect information? Do you know how to make an article better?

Would you like to suggest photos on the topic for publication?

Please help us make the site better! Leave a message and your contacts in the comments - we will contact you and together we will make the publication better!