The feasibility of purchasing a primer

The primer for metal surfaces contains inhibitors. Their function in this case is the maximum delay or suppression of physical and chemical processes, i.e. development of corrosion. The influence of moisture and oxygen usually becomes the main reason, requiring advance protection of metal structures from imminent destruction. Any surface is susceptible to negative external influences, except when properly treated. Application of any type of primer guarantees the transformation of the emulsion composition into a colorless film that protects the product. This process must precede the finishing decorative treatment of the surface. Its main tasks are: · ensuring adhesion between external metal surfaces and finishing. Thanks to priming, the decorative material will not delaminate or crumble; · antiseptic treatment. The primer contains substances that inhibit fungus and mold; · corrosion protection. The primer prevents the appearance of rust; · reducing the consumption of decorative coatings. Metal primer for exterior work must be chosen wisely, which will reduce its consumption and obtain the expected high-quality result. It can safely be called an indispensable basis for decorative finishing, a budget-friendly way to protect metal from corrosion.

Why do you need a metal primer?

Primer for metal

Metal primer is necessary to increase the level of adhesion of the decor with the functional coating on the surface being treated. It is the intermediate layer of primer that provides strong adhesion.

But, be careful, because most paints and varnishes must be applied without primers, because any layer between the surface and the coating can increase delamination with large changes in operating temperature.

Related article: Proper repair of semi-turn valves

In addition, very often the primer is distinguished by its independent functionality: it forms anti-corrosion protection and does not allow the base to deteriorate from exposure to an aggressive environment.

The main requirement that is put forward for all types of substances is strong adhesion to the metal. Some solutions can only be combined with certain types of paints, while some are considered universal and can be used for work on any surface, even on the surface of a car. For almost all primers, organic-based solvents are used, because the water-dispersion composition does not wet the smooth metal surface.

The optimal technical characteristics that the priming mass should have are shown in the table below.

| Color of the substance | Grey, brick |

| Type of film | Matte or semi-gloss |

| Mass fraction of non-volatile substance | 50-60% |

| Conditional viscosity | Not less than 45 |

| Drying time | No more than 12 hours |

| Flexural elasticity of the film | No more than 1 |

| Film hardness | 0.35 USD |

| Material consumption | 60-120 g/m2 |

| Recommended layer thickness | 15-20 microns |

Features of choice

First of all, anti-corrosion mixtures are selected based on the type and condition of the metal that needs to be treated. The main purpose of a primer when coating ferrous metals is to slow down corrosion. Iron, cast iron, black steel and alloys based on them used for outdoor work are very susceptible to corrosion due to interaction with a merciless environment. For these materials, if they have already begun to rust, a converter should be used as a priority. It will at least partially eliminate traces of corrosion. If the primer mixture is selected for external products made of non-ferrous metal or alloy, for example zinc, copper, brass, aluminum, then its primary function is to ensure maximum adhesion between the treated surface and other finishing material. For this purpose, you can choose compositions based on organic solvents, with a urethane base, and containing zinc. They can be used as a protective coating for galvanized iron or steel. Bronze, brass and copper are best protected with polyurethane or epoxy varnish. On sale you can find types of primers for metal that are applied to hide difficult to remove stains, for example, from grease, soot, etc. This step in the repair cannot be skipped if you do not want the stains to reappear over time or provoke peeling of the decorative finishing. After choosing a primer, you can begin to study the instructions for its external use.

IMPORTANT: 1. pay attention not only to the properties and types of primer, but also to the form of its release. To dilute powder bases and concentrates, it may be necessary to purchase a special solvent; 2. check the compatibility of the selected primer mixture with the planned decorative coating - they may be incompatible.

Types of primers

To maximize the prevention of corrosion, the primer should be selected taking into account its main characteristics, such as: the basis of the composition, adaptability to certain types of metals, feasibility of use in external finishing work. You will have to choose among very different soil mixtures.

Phosphating

Suitable for all metals, but used primarily for coating steel surfaces. The composition is based on a mixture of solvent and phosphoric acid, which has high heat resistance (withstands up to 220°C). Paint adheres well to such a primer; it is preferable to apply it to coatings that are not affected by corrosion. When finishing external structures, it does not always provide the expected protection.

Acrylic

Compositions characterized by safety, absence of unpleasant odor and high drying speed. Acrylic-based primer mixtures allow you to hide minor defects on external metal surfaces, create a durable anti-corrosion coating, and ensure good adhesion. Water-based acrylic primer can be used on various types of metals that are not damaged by rust.

Passivating

Used for aluminum metal structures and products made from other ferrous metals. The main components are chromic acid salts (it is important that their concentration is high). They prevent the interaction of external structures with the environment, which eliminates the development of corrosion processes. The group of these primer mixtures includes alkyd, polyurethane and epoxy.

Tread

They are used for various metals and have enviable anti-corrosion properties. The main components of the mixtures: aluminum, magnesium or zinc powders (their content can reach 90%). They create a strong outer protective film, preventing rust from spreading. Even if cracks appear on the structure, the zinc components of the soil will protect it from corrosion.

Inhibiting (two-component formulations)

Can be used for all types of metals. After application, the mixtures are converted into enamel primer, excellent for its high anti-corrosion properties. They are water- and oil-soluble. They are not suitable for processing external metal structures that may be subject to heating in the future, since the protective film will emit an unpleasant odor.

Insulating

Mainly used for ferrous metals, but can also be used for non-ferrous metals. The main components of the mixtures are neutral pigments and lead white. They are not capable of providing a long-lasting effect, so they are hardly suitable for exterior finishing work. They also cannot be painted.

Transformative

Designed for external metal structures damaged by corrosion. The composition is based on surfactants. They convert existing rust into an anti-corrosion film. To ensure complete protection of the metal, it is necessary to combine this type of primer with a passivating mixture.

Characteristics of primer for metal

A metal primer is a specialized solution that is applied to a metal surface to level it and protect it from corrosion. This material is used for processing metal surfaces both in industrial enterprises and at home. The primer is applied to the surface of any metal and forms a thin protective film that is resistant to moisture and temperature changes.

Important: When using this material, you need to find out what the primer consumption is for metal. On average it is 100 grams per square meter.

Metal primer contains special substances that penetrate deeply into the structure of any metal and prevent its oxidation. The primer is suitable for application to any metal surfaces. It is very often used for high-quality paint and varnish work.

Currently, a large number of primers are produced for processing metal products. Today this is one of the most effective methods of protection against corrosion.

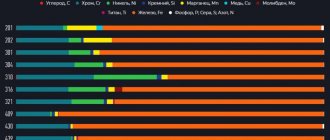

Table. Technical requirements according to GOST

| Indicator name | Meaning | Test method | |

| Organic primers | Water-dispersion primers | ||

| Primer performance. | |||

| 1 Mass fraction of non-volatile substances, %, not less | 13,0 | 48,0 | According to GOST 17537 |

| 2 Conditional viscosity at temperature (20±0.5) °C according to a viscometer type VZ-246, s | 13 — 180 | 30 — 180 | According to GOST 8420 |

| 3 Drying time: for natural drying primers to degree 3 at a temperature of (20±2) °C, h, no more than: | According to GOST 19007 and 9.4 of this standard | ||

| for epoxy primers | 36 | ||

| for everyone else | 24 | 5 | |

| for hot-drying primers, h, no more | 4 | 2 | |

| 4 Viability (shelf life) after mixing the components at a temperature of (20±2) °C, h, not less: | Not defined | According to GOST 27271 | |

| for epoxy primers | 4 | ||

| for everyone else | 6 | ||

| 5 Hazard class and subclass (flash point in a closed cup, °C): | According to GOST 19433 and 9.5 of this standard | ||

| 3.1 | Less than minus 18 | Less than minus 18 | |

| 3.2 | Minus 18 or more, but less than 23 | Minus 18 or more, but less than 23 | |

| 3.3 | 23 or more, but less than 61 | 23 or more, but less than 61 | |

| 9.1 | More than 61 but less than 90 | More than 61 but less than 90 | |

| Coverage indicators: 6 Appearance of cover | After drying, the primer should form a uniform surface without craters, pores or wrinkles. | After drying, the primer should form a uniform surface without craters, pores or wrinkles. | According to 9.6 of this standard |

| 7 Coating adhesion, points, no more | 2 | 2 | According to GOST 15140 |

| 8 Film elasticity when bending, mm, no more | 3 | 3 | According to GOST 6806 |

| 9 Resistance of the coating to static influence at a temperature of (20+2) °C, h, not less than - | According to GOST 9.403, method A and 9.7 of this standard | ||

| water | 24 | 24 | |

| sodium chloride solution with a mass fraction of 3% | 8 | 8 | |

| 10 Resistance of the coating to static exposure to chemically aggressive environments at a temperature of (20 ± 2) °C, h, not less | 2 | 2 | According to GOST 9403, method A and 9.8 of this standard |

Preparation for priming

Before starting to process metal surfaces, they must be cleaned. Dust, dirt, old paint, varnish or enamel - all this can be removed using convenient means at hand (metal brushes, abrasive brushes, spatula, etc.). If the metal structure being treated has already undergone corrosion, then the primer can be applied only after using the converter. Use paint softener to remove dried paint. It also contains anti-corrosion additives. After complete cleaning, the outer coating should be thoroughly washed and sanded. Large metal structures are polished with special machines. For small exterior work, use sandpaper of a suitable grain size and lint-free cotton cloth. The next step is degreasing the surface. It is carried out immediately before the priming process. The most suitable for this purpose are: White spirit, gasoline and other mixtures of similar composition. Degreasing is necessary for uniform coating of the metal and its maximum adhesion to the anti-corrosion mixture. If the surface has few defects with a greasy base, then you can limit yourself to local processing.

Priming process

In order to take into account all the nuances and do high-quality work, you need to master priming “in theory”: application, characteristics and material consumption. You need to prepare convenient tools, take care of your own safety measures, and become familiar with how to store the primer if you don’t use all of it.

Available means

The choice of tool for external application of primer depends on the form of release of the material, the relief of the metal coating, and its area. Possible options:

- · the roller is convenient to use for processing large and smooth products. It is easy for them to distribute the mixture of any consistency. The roller ensures economical application of the material;

- · It is advisable to purchase a brush if you need to prime a small external metal structure or treat hard-to-reach places. In other cases, its use will lead to increased material consumption and time;

- · spray guns come in different sizes and power, so they can be used to apply primer to any surface. They allow this type of external work to be carried out quickly, economically and with the highest quality.

A building materials store may offer you a primer solution in an aerosol can. This is a convenient option, but due to its low capacity it is unprofitable when it comes to covering a large metal structure. Regardless of the type of future work (external or internal), do not forget to purchase gloves, goggles and a respirator.

Applying primer

Correct distribution of the anti-corrosion mixture over the outer surface of the metal structure will avoid its overuse and obtain the required uniform protective layer of primer. Follow these guidelines:

- work at temperatures from -10°С to +27°С;

- Apply the solution in a thin layer. This facilitates its penetration into all irregularities and microcracks, rapid drying, and the creation of a durable film;

- Applying each subsequent layer is possible only after the previous one has completely dried. The number of layers depends on the location of the external metal structure, its operating conditions (the more severe they are, the more material will be needed);

- the final decorative finishing should be carried out within the next few days after the primer has dried. Otherwise, the outer surface of the product will begin to become covered with dust, which will significantly reduce the adhesion of the finishing material to the coating.

Remember: the importance of taking breaks during priming is solely due to the need for the protective material to dry completely. It must be purchased in advance in the required volume to avoid downtime. The information on its packaging will help you calculate the required amount of the selected primer: “Consumption per 1 m2.” By the way, if a frost-resistant composition is used, then its application should be preceded by the distribution of a moisture-repellent primer mixture.

Storage of soil mixture

Any type of paint or primer should be stored in a container with a tightly closed lid. They should not be left near heating systems, electrical appliances, or fire sources. It is recommended to store in places where direct sunlight does not penetrate, the temperature does not exceed average values, and ventilation air flows are provided. The finished mixture will gradually thicken in the container - it can be diluted with a solvent if necessary.

Technology of work execution

We prime metal surfaces

Later in the article we will tell you what technology should be used to prime metal, including removing rust and old coating from a car or surface.

Metal priming is done as follows:

- before painting and performing work on surface treatment of a car or product, it is necessary to clean off loose layers of steel that have been corroded using a spatula;

- the remnants of old paints and varnishes are removed in the same way, but only as a result of softening with a special remover or a hair dryer (if you use a remover, wrap the product in polyethylene, which will prevent the solution from evaporating);

- rust must be removed with a brush with metal bristles or specialized attachments for hand tools (you can also purchase a special rust converter that will transform it into a durable and insoluble coating);

- to perform subsequent work, the steel must be degreased with a rag or solvent;

- metal priming is carried out in 1-2 layers using a brush, rollers, or you can use an aerosol pneumatic spray gun;

Article on the topic: Lighting in the gazebo: the best ideas, photos, diagrams

If you are priming metal from a corrosion-resistant material, it will be enough to clean it from dust and grease.

The approximate consumption of the substance for working on metal surfaces per 1 m2 is about 50-150 g. The consumption of the solution directly depends on its viscosity and the roughness of the surface being treated.