How do ferrous metals differ from non-ferrous metals?

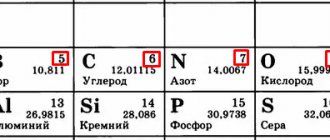

The above list is exhaustive for magnetic chemical elements (ferrous metals). If you make a combined list of non-ferrous and ferrous metals, it will include 78 chemical elements of the periodic table. At the same time, three types of ferrous metals, with the exception of iron, are also classified as non-ferrous according to certain characteristics. They are divided into types:

- heavy - copper, zinc, lead, tin, this also includes nickel;

- light – aluminum, titanium, magnesium and others (12 elements in total);

- refractory – manganese, tungsten, molybdenum, chromium and others (8 elements in total);

- noble, etc. (total 8 groups of non-ferrous metals).

It is much more difficult to list everything that relates to ferrous metals from a technical point of view. The total number of steel and cast iron grades includes several hundred product items. Moreover, some of them do not have magnetic properties, which allows, based on the combination of characteristics, to classify such alloys simultaneously as ferrous and non-ferrous metals.

Is brass a non-ferrous or ferrous metal?

Brass, along with bronze, is one of the main types of copper-based non-ferrous alloys. The range of products made from brass and bronze is almost identical. It includes:

- sheet metal, tapes, foil;

- pipes and tubes;

- wire, rods;

- casting, etc.

Brass and bronze are superior to copper in strength, but unlike it, they are not used for alloying carbon and producing other non-ferrous alloys. Copper-nickel alloys, which are also classified as non-ferrous metals, deserve special attention.

Classification of ferrous metals

In most cases, the classification of ferrous metals is based on the division of elements according to their chemical composition and properties . The content of alloying elements determines the iron and its alloy. In turn, a certain percentage of carbon in the alloy indicates whether it is cast iron or steel. Thus, cast iron contains more than 1.7% carbon, and steel contains from 0.2 to 1.7% carbon. Classification of ferrous metals involves division into the following classes:

- iron metals;

- refractory;

- uranium;

- alkaline earth;

- rare earths.

Also, the classification of ferrous metals implies the separation of alloyed and unalloyed steels, which are also called carbon steels. Carbon steels include steels in which carbon is the main component, and impurities do not have much effect on the properties of the metal. Alloyed steels have one or more alloyed elements, which have a huge impact on the properties of steel. /Alloy steels are very widely used for the manufacture of critical parts that bear heavy loads, experience different temperatures, and strong frictional effects. The use of such steel is widespread in mechanical engineering, tractor manufacturing, heavy industry and other areas.

Physicochemical characteristics

Aluminum is the 13th element in the periodic table and is a light metal.

Its color is silvery white. In nature, it occurs in the form of compounds due to its strong chemical activity. Under normal conditions, there is an oxide film on the surface of aluminum, which makes it impervious to oxidizing agents and corrosion. When it reacts with alkali and solutions of ammonium salts, it is destroyed, and then this metal is used as a strong reducing agent. The main physical properties include:

- High strength characteristics due to connections with other metals;

- Light weight - much lighter than copper and iron;

- Corrosion resistance;

- Rapid heating, like iron;

- Excellent electrical and thermal conductivity;

- Resistance to fire, temperature changes;

- Possibility of secondary processing;

- Not susceptible to rust, unlike iron;

- Easy to mold due to softness and plasticity - you can bend, crush and roll into a tube.

To increase strength, this metal is alloyed with magnesium, copper, and silicon. Aluminum alloys remain strong in low temperatures. They are all divided into casting and deformable. Aluminum-bronze - superior to bronze in chemical resistance.

Ferrous metals - what are they?

This class includes:

- iron and all its alloys;

- manganese;

- chromium;

- vanadium;

- titanium;

- actinides and uranium (thorium, plutonium, neptunium and others);

- tungsten;

- alkali metals.

That is, of the entire variety of these substances, ferrous metals account for a minority. Moreover, generally not the most common ones (with the exception of iron) are found in the earth’s crust and subsoil.

But despite the fact that ferrous metals are represented by such a small number of elements, they are very common and voluminous in production and processing. A lot of products, parts, and accessories are made from iron and its alloys.

Ferrous metallurgy is quite extensive and in demand all over the world. Iron mining and processing is one of the most advanced technical and economic problems in many countries of the world, including Russia.

Main types of alloys

The division is based on the composition and acceptable uses. In addition to the amount of carbon, the percentage of other substances is taken into account. Today, ferrous metal is presented on the market in the following types:

Cast iron. It can be used for household, commercial and industrial purposes. The latter is used for the production of durable metal structures, the first two for the manufacture of parts and products with unique properties. They are divided into four types:

- white (standard carbon);

- gray cast iron (with globular graphite);

- malleable (soft and viscous, intended for firing);

- high-strength (spheroidal graphite is used in the composition).

Gray cast iron is in demand in the industrial sector. Malleable and ductile are variations of gray cast iron.

Steel. The most common metal widely used in the construction industry. It is used for the manufacture of metal structures, parts and household products. Carbon alloy steel provides high strength and durability of structures. Its most popular variations are:

- chromium;

- molybdenum;

- tungsten;

- Nickel

Alloy steel is also represented by copper, magnetic, zinc and other types of alloys. The types and ratio of substances are indicated in the labeling. The letters indicate the type of substance in the composition, and the numbers indicate the percentage.

Our production company offers to sell cast iron and steel in any variations. Purchases are carried out in unlimited quantities in four districts of Moscow, which ensures convenient delivery. You can also use our transport to remove scrap metal on favorable terms. If there is a wholesale volume, export is free of charge.

Is steel a ferrous or non-ferrous metal?

The question of whether steel belongs to ferrous or non-ferrous metals should be considered based on the classification of carbon alloys, which is provided for by many GOSTs.

According to various regulatory documents, steel is divided into the following types of ferrous metals:

- low-carbon, carbon and high-carbon alloys with a carbon content of up to 0.25; 0.25–0.6 and over 0.6%, respectively;

- low-alloy, medium-alloy and high-alloy grades of alloys with a controlled content of alloying additives up to 2.5; from 2.5 to 10 and over 10%, respectively;

- structural, tool, high-speed, corrosion-resistant, heat-resistant and other types of steel for various applications.

Of the entire extensive range of steel grades, only seven items form the group of non-magnetic alloys. We remind you that the absence of magnetic properties is the main characteristic of non-ferrous metals. At the same time, non-magnetic steel grades contain iron, which is one of the defining characteristics of ferrous metals.

Taking into account the small number of non-magnetic steels, they can be considered an exception to the general rule with an unclear status. From an ordinary point of view, it is generally accepted that ferrous metals are alloys that are susceptible to corrosion from atmospheric influences. Although high-alloy alloys can also rust.

Is lead a non-ferrous or ferrous metal?

Lead is part of the group of heavy non-ferrous metals. Currently, its use in its pure form is extremely limited. Examples include radiation protection devices at radioactive sites and the production of bullets. But it is widely used in the form of various alloys in the production of explosives, batteries, dyes and other products.

Special steel grades

When considering what scrap metal is, it is necessary to pay attention to another, separate category of steel waste. This is scrap stainless steel and quick cutters. Stainless steel waste is accepted based on the nickel content in the metal. For example, stainless steel with Ni inclusions at the level of 8% is estimated at 42,000 rubles per ton. Increasing the concentration to 18% increases the cost to 70 thousand.

The most popular among waste tool steel (high-speed cutters) are the domestic grades P6M5, P18, as well as the imported grade - HSS. In essence, this is the same alloy steel, where the main impurities are refractory metals: tungsten, molybdenum, vanadium and rhenium.

The role of ferrous metallurgy in industry

As already mentioned, iron and steel products are the basis for heavy industry.

Ferrous metallurgy enterprises produce the bulk of finished products in the form of cast and pig iron, open-hearth and converter steel, as well as finished rolled products, steel and cast iron pipes.

The production of ferroalloys is also included in the ferrous metallurgy industry and is important for further use in the composition of alloy steels.

Pig iron is subsequently smelted and decarburized to produce steels with different carbon contents.

Most steel is produced in the form of ingots, which are subsequently forged and rolled to produce profiles of various sections:

- blanks;

- sheet metal;

- long products;

- seamless pipes;

- special types.

Long rolled steel profiles are used directly in structures (bridges, building floors, railway rails). The most common long products for direct use are:

- brand;

- I-beam;

- channel;

- corner.

All of the listed long products are produced in a wide range of standardized sizes.

Classic steel pipes of welded structure are produced from rolled sheets.

Special types of rental include such complex elements as:

- axles and wheels of railway equipment;

- gear wheels for various purposes.

Shaped casting of cast iron is used for machine beds for a wide variety of purposes (metal and woodworking machines).

Conversion plants are engaged in the processing of pig iron, metal scrap, and metallurgical waste. Currently, more than half of the output of the metallurgical process is pigment metal obtained by melting and refining scrap metal.

What is made from ferrous metal?

The boundary separating ferrous and non-ferrous metals does not always look clear and unambiguous. Therefore, at the ordinary level, ferrous metals include carbon and low-alloy steel grades, as well as unalloyed cast iron. We can name the following examples of ferrous metals, or more precisely, products made from them:

- construction fittings of all classes;

- sheet, long and shaped rolled products from the listed steel grades, including those with galvanized coating;

- pipes;

- general purpose steel and cast iron castings - for example, pipeline valve bodies.

The detailed list of ferrous metal products can be continued almost indefinitely. However, do not forget: not everything that rusts is ferrous metal.

Use in mechanical engineering

Steel and cast iron objects, parts, and various devices are widely used in mechanical engineering. They are in demand not only in the automotive industry, but also in the chemical and aviation industries, as well as in shipbuilding. All this is due to the special strength of these materials, their heat resistance and corrosion resistance. Ferrous metals are becoming the base material for the production of many types of products. Among the most common are the following:

- side covers of gearboxes;

- bearings;

- valves;

- fitting;

- bushings;

- pipes;

- cylinders of cars and other vehicles;

- gears;

- chain links on tractors;

- brake drums;

- carriages;

- casings and so on.

This list can be continued endlessly, because there are really a lot of products made of ferrous metals and their alloys.

Non-ferrous and ferrous metals

All metals and alloys are divided into non-ferrous and ferrous metals. Ferrous metal is an alloy of iron and carbon, which may include silicon, manganese, phosphorus, sulfur, and other chemical elements added during the smelting process to improve the quality of the metal. To give ferrous metal specific properties, alloying additives are introduced into its composition - copper, nickel, chromium, silicon. Non-ferrous metal is also an alloy - aluminum, magnesium, copper, nickel, zinc, tin, lead. As you can see, non-ferrous and ferrous metals differ in their composition: ferrous metal contains iron, non-ferrous metal does not have it.

Non-ferrous and ferrous metals are different in their structure, which is clearly visible under a microscope. The grains of the metals are closely adjacent to each other, which is especially noticeable at the fracture of the metal rod. And although the differences, as they say, are obvious, sometimes it is difficult even for a professional to determine whether they belong to the group of non-ferrous and ferrous metals with the naked eye. Non-ferrous and ferrous metals are consumed all over the world, thanks to which metallurgy and industry develop. Products - cast iron, steel, wrought iron from ferrous metals occupy about 90% of the total volume of metal production.

- Cast iron is an iron-carbon alloy with a carbon content of more than 2.14% - 3.8% used in industry. It has good casting properties and fragility. But cast iron has poor weldability, as well as a low ability to undergo plastic deformation, which cannot be ignored. Cast iron products are manufactured mainly by casting, after which they are processed by cutting or rolling the cast iron. Modern production technologies are designed for the production of cast iron products of any level of complexity and modifications. These include lift loads, balls, drums, flanges, etc.

- Steel is an alloy of iron with a carbon content of 0.02 to 2.14%. It has hardness, high strength, ductility, toughness, and good weldability, which determined the scope of its use. Mild steel, carbon steel, stainless steel are indispensable in mechanical engineering and production, including construction. To improve the mechanical, strength, physical and chemical properties, chromium, molybdenum, nickel, tungsten, titanium or vanadium are added to the steel melt. In this way, the steel is alloyed and then processed by cutting, pressing and casting. Finished steel is divided into grades, taking into account the percentage of carbon content, after which it is used for its intended purpose - in the production of metal structures, elements and parts, such as washers, gaskets, instruments, coils, bushings, connecting rods, crankshafts and flywheels.

- Wrought iron is an alloy of iron that is flexible and durable. This type of metal is rarely used in structural and commercial applications due to its very dark appearance. Wrought iron is used for fences, street railings and furniture. When used outdoors, wrought iron products are painted black, which generally not only improves the appearance of the product, but also protects it from rust.

Non-ferrous and ferrous metals independently resist oxidation. If you see rust on metal, rest assured that you are looking at ferrous metals. Most ferrous metals have magnetic properties, useful in making large motors and electrical appliances. Ferrous metals are easily processed without losing their strength properties. Because of their tensile strength, which makes even the tallest skyscrapers and longest bridges in the world stable, ferrous metals have become popular in various types of construction. The steel has proven itself successfully in industrial containers, large-scale pipelines, automobiles, and fastening tools. Non-ferrous and ferrous metals have different weights. Non-ferrous metals are lighter, which made them indispensable in the aviation and canning industries. As we have already said, non-ferrous metals do not contain iron, so they have a higher resistance to corrosion and rust than ferrous metals. Non-ferrous metals are used for gutters, plumbing, roofing and road signs. Due to its “non-magnetic” nature, non-ferrous metal has become an ideal material in electronics and electrical applications.

In our production, we use ferrous metal, from which we manufacture lightweight metal structures in our own workshop, which are often abbreviated as LMK. Prefabricated buildings and structures made from LMK are used in various sectors of activity, economy and production. If you want to save on construction, take advantage of our commercial offer - which you can find out about in the “Special Offers” section. For all questions regarding production, construction, design and installation, call 209-09-40! We'd love to hear from you!

Raw materials used in iron and steel industry

The main resource used to obtain products is iron ore. In Russia, its reserves are quite large and almost completely satisfy domestic needs. Separately, several ore mining areas should be highlighted.

Thus, the development of this mineral on an industrial scale began in the Urals. Large metallurgical plants, which were among the first in the country, still operate here. Also, large reserves of iron ore are located in Siberia (we are talking about the deposits of Kuzbass).

In the European part of Russia there is the so-called Kursk magnetic anomaly. According to some data, this is the largest iron ore deposit on the planet. However, development began only in the 30s of the last century and was interrupted due to the war. The deposit is located on the territory of the Kursk and Belgorod regions.

In addition to iron ore, the metallurgical industry requires coking coal. It is used as a high-quality fuel for smelting iron and loosening iron ore.

The main deposits of coking coal in Russia are concentrated in the Kuznetsk and Pechora basins.

Why recycle scrap metal?

Recycling is important for:

- economics;

- ecology.

For a long time it was believed that the planet's mineral resources were limitless .

In fact, many of them are close to exhaustion.

Metal ore is from this category.

Industrialization , which continues to accelerate, requires more metal for industrial use.

Recycling various metal products gives the material a second, or even a third, life. Recycling of metal recyclables has existed in the world for more than a hundred years .

Scrap metal is accepted at special points and sent to metallurgical plants.

After melting, recyclable materials do not lose their properties and are thus reused many times.

Repeated use of non-ferrous scrap metal is much more economical and safer for the environment than extracting it from the ground.

Metals are not found in nature in their pure form; ore contains a lot of waste rock and impurities (up to 95 percent). To extract, for example, copper from ore, you need to spend a lot of energy .

It is difficult and expensive to separate this or that non-ferrous metal from alloys, which is done in processing plants. But this process is also more economically profitable than ore mining.

The difference in price is explained by the fact that it is not necessary:

- develop a deposit;

- process ore;

- concentrate.

The main advantages of recycling recyclable materials:

- Severely depleted deposits of metal ores are “resting”;

- fuel required for extraction and processing is saved;

- ecology is preserved;

- There is less metal sputtering and scattering.

Some types of non-ferrous metal are harmful to the environment when released into:

- soil;

- water.

To prevent accumulations of waste metal, and to put waste into use means taking care of:

- nature;

- health of compatriots.

This point is also important: by clearing the Earth of rubbish in the form of scrap metal, collectors earn money.

And in the case of non-ferrous metals, they earn good money.

Arguments for selling scrap metal:

- scrap metal prices are rising;

- the range of in-demand scrap metal is expanding ;

- cutting is carried out by numerous receiving points.

Types of ferrous metal scrap according to GOST

Classification occurs according to the following criteria :

- Carbon content.

- Presence of alloying elements that improve the appearance and properties of products. In turn, alloyed scrap is divided into 67 groups.

- Quality . Depending on the quality indicators of waste, 28 groups are distinguished.

About 90% of all metal products produced by humans are iron and its alloys . The carbon content in the metal allows us to understand whether this is steel or cast iron.

Each of these alloys has its own characteristics and is used for the manufacture of various products. Let's look at them in more detail.

Heavy metals

Heavy non-ferrous metals, the list of which is very wide, are obtained from sulfide and oxidized polymetallic ores. Depending on their types, methods for obtaining metals differ in the method and complexity of production, during which the valuable components of the raw material must be completely extracted.

Metals in this group are hydrometallurgical and pyrometallurgical. Metals obtained by any method are called rough. They undergo a refining procedure. Only after this can they be used for industrial purposes.

Ferrous metal scrap classes

From the standpoint of the mentioned standard, two classes of ferrous scrap are distinguished. The division is based on the proportion of carbon content in the metal:

- steel scrap and waste (contain less than 2.14% carbon, which is true for iron-carbon alloys with a low percentage of impurities);

- cast iron waste and scrap (characterized by high carbon content in iron).

Sometimes a third class is added to these classes - stainless steel. But its position in the classification cannot be decided unambiguously. On the one hand, stainless steel is the result of the interaction of iron and carbon (which is also structural steel and cast iron), and on the other hand, during its production alloying elements are added - impurities (mainly non-ferrous metals), which significantly change the properties of steel.

In addition to the listed classes, secondary ferrous metals are distinguished outside the class: blast furnace additive, scale, welding slag.

Conditions for accepting galvanized metal waste

Reception points accept all types of galvanized steel at the price of the base metal. The category of metal waste is determined in accordance with GOST 27-87-75, in which:

- 3A is lumpy dimensional scrap metal, at an average price of 8,000 rubles/ton;

- 5A – oversized steel scrap, at an average cost of 7600 rubles/t;

- 12A – thin-sheet and lightweight waste, at a price of 7,000 rubles/ton.

At some collection points for ferrous metals for recycling, you can see clearly reduced prices for galvanized steel. Therefore, carefully choose a place to dispose of metal waste; our company usually makes the best offers. As additional services, we are ready to offer dismantling work and removal of large quantities of scrap using specialized company transport.

Galvanized scrap of category 3A in some cases can be accepted at a higher cost than regular black. However, large beams, channels, circles, etc. are quite rare. Therefore, it is always possible to find a solution that is right for both parties.

Scope of application of recycled ferrous metals

Thanks to modern processing technology, high-quality products are produced from recycled ferrous metal that are in no way inferior to analogues made from ore .

Remelted raw materials are no worse than primary ones (obtained from ore), so remelted metal is used everywhere.

Almost any product can be made from recycled materials , which is very beneficial for the entire metallurgical industry.

Craftsmen often use scrap ferrous metal to make useful household items . To learn how to give a second life to metal waste at home, read our article What can be made from ferrous metal waste - iron, steel, stainless steel, cast iron.

Deposits in Russia

In Russia, ferrous metals are found in almost all large federal districts.

- Central Federal District (Kursk Magnetic Anomaly) – over 59%.

- Ural Federal District – 14%.

- Siberian district - 13%.

- Far Eastern – 8%.

- Northwestern Federal District – 4%.

- Privolzhsky – 0.5%.

In each of the listed districts there is an enterprise that produces ferrous metals. Russia occupies a clear leading position in the world in this indicator, and, judging by its reserves, this will continue for a very long time.

Sources

- https://ajax-metall.ru/chto-otnositsya-k-chernym-metallam

- https://metallsmaster.ru/chernye-metally/

- https://TheMineral.ru/metally/chernye

- https://FB.ru/article/164704/chernyie-metallyi-mestorojdeniya-hranenie-metallurgiya-chernyih-metallov

- https://metallolom-msk.ru/chto-takoe-chernyij-metall.html

- https://BaikalHangkai.ru/othody/chernye-metally-spisok.html

- https://stankiexpert.ru/spravochnik/materialovedenie/chernaya-metallurgiya.html

- https://fabricators.ru/article/chernaya-metallurgiya

- https://rcycle.net/metally/chernye

- https://lomvtormetalla.ru/stati/vidy-loma-chernyh-metallov/

- https://promzn.ru/metallurgiya/chernaya.html