By default, AISI 304 and 430 stainless steel have differences in metal production costs, characteristics and areas of use, respectively. Both construction materials are corrosion resistant. 400 series steel is cheaper, but is used in less aggressive environments. Stainless steel 300 series is more expensive due to the nickel it contains, but it is more resistant to intergranular and pitting type corrosion.

The high mechanical characteristics of AISI 430 304 steels allow them to be processed with minimal labor costs. There are no restrictions on weldability, magnetic properties are completely absent. Ferritic 430 steel is more often used for general purpose pipelines, instrument making and automotive manufacturing. Austenitic 304 steel is used in medicine, food, and chemical industries.

Chemical composition

The differences between AISI 304 and 430 steels are due to the composition and amount of useful additives - alloying chemical elements:

| Steel | C | Mn | Si | P | S | Cr | Ni |

| 304 | 0,08 | 2 | 0,8 | 0,035 | 0,025 | 17 – 19 | 9 – 11 |

| 430 | 0,12 | 0,8 | 0,8 | 0,035 | 0,025 | 16 – 18 | – |

According to the generally accepted classification, steels containing more than 12.5% chromium automatically become stainless. However, they do not rust only in the rain without heating, in the absence of serious loads, and with an extremely low degree of environmental aggressiveness.

To further increase corrosion resistance, it is necessary to increase the percentage of chromium and/or introduce additional alloying additives into the steel composition. All of them are divided into two categories - passivators, which increase the electrode potential of steel, and cathode additives, which increase the potential of the metal solid solution.

In 430 steel, up to 18% chromium is added, and in 304 steel, it is slightly less, but an additional 10% nickel is present, and the carbon content is reduced. These steel grades do not contain cathode additives - palladium and platinum metals.

Both alloys belong to the groups of corrosion-resistant and heat-resistant steels. That is, they are by default resistant to electrochemical, salt, acid, alkaline, soil and atmospheric corrosion, and operate reliably at temperatures below +550°C in gaseous environments in a lightly loaded state without the formation of scale.

At the same time, stainless steel AISI 304 and AISI 430 have a difference in nickel content. This chemical element increases resistance to intergranular corrosion. Therefore, it is not dangerous for 304 steel, but 430 steel has no protection from it.

Analogs

In the American standard designation, AISI 430 and 304 steel are difficult to compare. The closest analogues of these stainless steels in the standards of different countries are:

| Standard (Country) | Austenitic steel | Ferritic steel |

| AISI (USA) | 304 | 430 |

| GOST (RF) | 08Х18Н10 | 12Х17 |

| BS (UK) | 304S31 | 430S15, 430S18 |

| DIN (Germany, for internal use) | X5CrNi18-10 | X6Cr16 |

| DIN EN (Germany, for external use) | 1.4301 | 1.4016 |

| PN (Poland) | 0H18N9 | H17 |

| JIS (Japan) | SUS304 | SUS430 |

| UNI (Italy) | X5CrNi18-10 | X8Cr17 |

| AFNOR (France) | X5CrNi18-10 | Z8C17 |

| ISO (European Union) | Type 11 | Type 8 |

| EU (European Union) | X5CrNi18-10 | X6Cr17 |

| CSN (Czech Republic) | 17240 | 17040, 17041 |

| GB (China) | 0Cr18Ni9 | 1Cr15 |

| SS (Sweden) | 2333-02 | 2320 |

Thus, the encrypted designations of the United States, the Czech Republic, Japan and Great Britain are absolutely uninformative. The markings of all other countries immediately indicate the ratio of the important components of steel.

That is, in Europe and the Russian Federation, experts initially see the percentage of alloying additives in a steel grade. And they can evaluate their influence on the chemical, physical, mechanical, technological and operational properties of the structural material.

In America and Japan, a different approach to the problem has been adopted. When comparing AISI 304 and 430 steel, which is better for specific operating conditions, experts use a different algorithm:

· three numbers without a letter indicate that the steel belongs to the category of stainless steel;

· three classifies stainless steel as the austenitic class, and four classifies it as ferritic;

· The last two digits determine the position of the alloy within its class.

In this case, analogs of steels 304 and 430 are available in all foreign standards, since they are the most popular in their classes.

Scope of application

Practice shows priority products:

- AISI 304: furnace equipment, pipes for transporting solutions of acids and steam, heat exchangers and collectors, electrodes of automotive spark plugs, parts of welding and thermal power systems, chemical industry vessels. Permissible operating temperature is up to six hundred degrees. The chemical aggressiveness of the environment should be within average values; for maximum values, there are other solutions.

- AISI 430: fasteners and auxiliary parts for various devices and devices used in combination with moderate solutions of acids and salts. It can also often be found in everyday life: kitchen utensils and parts of kitchen and bathroom appliances.

Comparison of AISI 430 and AISI 304 allows you to choose the most suitable material. Some sources do not distinguish much difference between these materials, which is incorrect. Arbitrary replacement can have unpleasant consequences, expressed in design defects - up to fatal non-compliance.

Corrosion resistance

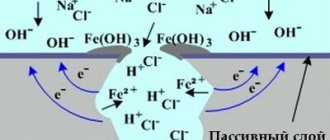

The budget alloying component of stainless steels is chromium. A high percentage of carbon content of 0.12% in steel 430 can lead to excessive formation of chromium carbides, which, on the one hand, reduce the saturation of steel with carbon, on the other hand, bind chromium molecules necessary for the formation of a protective oxide film of chromium with oxygen on the metal surface .

Therefore, in steel 430, the chromium content has been increased to 17%, so that about 12% of it is always in the unbound state in the metal structure. However, with sudden cooling or intense heating, chromium depletion occurs at the ferrite grain boundaries. In aggressive environments, intergranular corrosion can occur.

Intense heating is observed during welding work. Therefore, after welding, the seams of steel 430 are additionally treated by passivation.

Nickel is more expensive than chromium because it is a strategic raw material. However, in terms of the importance of alloying elements, nickel is in second place after inexpensive and accessible chromium. Nickel improves the weldability, ductility and mechanical strength of the metal.

The simplest way to distinguish AISI 304 from AISI 430 at home is a magnet. Food grade steel 304 does not have magnetic properties. And 430 steel has too much iron and a ferritic structure, so the magnet sticks to it.

It is possible to determine which is better for a specific project - AISI 40 or 304 - only taking into account the characteristics of the working and external environment, temperature range, pressure, and other operating conditions. In their classes (austenitic and ferritic stainless steels) AISI 304 430 are the undoubted leaders.

Types of stainless steel corrosion

Based on the type of development, cause of appearance and symptoms, several types of stainless steel corrosion are distinguished.

Crevice corrosion of stainless steels

Crevice corrosion is a widespread type of rusting of stainless steel. It develops where there is a small gap in the structure, for example, when water penetrates under the fasteners into the product. The second surface is usually a rubber seal, a gasket, and sometimes a metal element.

The mechanism of formation of crevice corrosion is as follows:

- Accumulation of aggressive ions in the gap, displacing oxygen.

- The appearance of an anode in the gap (the material outside the gap plays the role of a cathode).

- The formation of corrosion due to changes in the acidity of the environment and electrochemical reactions.

To prevent crevice corrosion, structures must be designed correctly. It is important to provide cathodic protection, which will reduce acidity, as well as improve the fluidity of the medium.

General surface corrosion

General corrosion is the uniform destruction of the metal structure in part of the surface layer. It causes the destruction of the oxide film on most of the product or over its entire area. Usually the cause is contact with strong alkalis, acids, compounds of iodine, fluorine, bromine. The main “enemy” of stainless steel is considered to be chlorine, which is why chlorine-containing detergents should not be used to clean it.

Pitting

Stainless steels, as well as alloys based on aluminum and nickel, are most susceptible to pitting corrosion. Unlike ordinary steel, which more often suffers from general surface corrosion, such materials in most cases are covered with pitting - small defects. Local destruction of the passive layer occurs in the following situations:

- scratching, mechanical damage,

- local change in steel composition,

- point exposure to chlorine, sulfur, halide ions,

- temperature increase.

Spot rusting is considered the most common among different types of stainless steel. Because of it, holes appear in tanks and small cracks appear in pipes and tanks. Usually their diameter is no more than 1 mm, while the depth can be significant - this is the insidiousness of this phenomenon. As in the case of crevice corrosion, the specific pitting will act as the anode, and the remaining (undamaged) surface will become the cathode. Adding molybdenum to stainless steel during its production increases the product's resistance to pitting corrosion.

Intercrystalline corrosion

This process has another name - intergranular corrosion of stainless steels (ICC). It occurs when the temperature rises sharply, which happens, for example, during welding. Rusting begins if, with the participation of heating, chromium urea appears along the grain boundaries, that is, the structure of this alloying additive changes radically. For ferritic steel, the sufficient temperature for the formation of corrosion foci is +900 degrees, for austenitic steel – +450 degrees.

Contact corrosion

This type of corrosion develops when dissimilar metals come into direct contact with each other under the influence of electrolytes. For example, this happens when joining different metal products in an aggressive conductive environment - sea water. As a result, the steel locally deteriorates, and less noble metals may even dissolve.

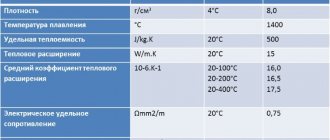

Properties

Initially, AISI 304 and 430 steel grades do not have the same properties.

By default, AISI 430 stainless steel is considered to have “increased resistance to corrosion in chemically active environments.” The presence of chromium in the composition ensures the metal's ability to passivate. However, it is very important to select the proper operating conditions to maintain the stability of this passive state.

By default, food grade stainless steel AISI 304 430 is superior to the steel grade in several respects. Chrome-nickel steels have high technological properties:

· increased creep resistance;

· increased machinability;

· high scale resistance threshold +800°С ... +900°С.

Therefore, food grade 304 stainless steel is easily polished, making it easy to clean and maintaining the highest hygienic requirements in food processing and medicine.

Chromium-nickel corrosion-resistant heat-resistant steel AISI 304 is prone to pitting. This disease is inherent in the entire 300 series of austenitic stainless steels according to the American standard classification. Inexpensive ferritic steel AISI 430 is also often used at high temperatures, but never at elevated pressure.

Application of sheet steel

In most cases, kitchen equipment is made of sheet steel. Its cutting and thickness may be different for AISI 430 and AISI 304. During the production process, they are characterized as flexible and easy-to-cut materials that can be easily stamped. The smoothness of the surface depends on the degree of processing and is not related to the grade of steel.

Inspection of products made from AISI 430 and AISI 304 reveals a difference in color. 304 is a yellowish tint, and 430 is blue-white, somewhat reminiscent of aluminum.

According to the conclusion of the Department of State Sanitary and Epidemiological Supervision of the Russian Federation No. 77.95.5.140.P.14626.9.00 dated January 1, 2001, AISI 430 steel was named the best for use in the food and processing industries. It is suitable for making products for the meat, alcohol, confectionery, and fat-and-oil industries. The material retains all its characteristics at all stages of raw material processing (sorting, heat treatment, mixing, grinding, packaging, etc.).

AISI 304 is commonly used for the production of washing baths, deluxe and cleaning tables for vegetables, serving lines, display cases and profiles for fast food.