What do the rules of PB 03-273-99 establish?

Certification of welders based on the provisions of PB 03-273-99 (industrial safety standards) establishes the level of knowledge of those being certified, their training, and ability to perform work at a certain level.

To carry out certification, the Welding NAKS association was created . It develops methodological documents for training welders and creates certification standards based on industrial safety requirements.

Responsibilities of the Association:

- selection of experts to the commission for certification;

- development of manuals;

- providing practical assistance to certification centers;

- formation of new centers;

- consultations on various issues;

- analysis of the work experience of commissions;

- generalization of international experience;

- development of new certification requirements;

- development of technical policy;

- coordination of actions and requirements of SASv - welder certification system.

The NAKS Association is considering changes or exclusions of individual points of rules or regulations that are not included in the list provided for in the SASv.

Certification according to PB 03-273-99 develops rules and determines the timing of certification according to the methods developed by NAKS and the commissions created by it, preparation time and rules for recertification.

Examinations according to PB 03-273-99 are conducted according to the rules for certification of welders and welding production specialists . They divide performers and managers into 4 levels of training.

- Welder . It is examined for the ability to cook efficiently and to carry out work using a certain technology, including gas, manual and electric arc welding. Possession of semi-automatic and automatic welding equipment.

- NAKS 2nd level master welder . Workers must follow his oral and written instructions. The master must have knowledge of welding methods and be able to select equipment operating modes.

- Welding technologist . The specialist must have a higher education and be able to write technological processes for workers to carry out. The technologist controls the welding process and the quality of the seams.

- A welding engineer is tested for his ability to manage welding production, knowledge of equipment and welding modes, and knowledge of technology.

Separate certification of workers as HDPE welders is carried out. The connection of polyethylene pipes is made by heating the plastic to relatively low temperatures. The equipment differs from metal welding. The currents and voltages used in operation are significantly lower. Specialists are certified to be able to choose the right modes and make a high-quality connection.

NAKS certification levels

There are four levels of certification:

- Level I – a certificate of a certified welder is issued,

- Level II – a certificate of a certified master is issued,

- Level III – a certificate of a certified technologist is issued,

- Level IV – a certificate of a certified engineer is issued.

Level 1 welder certification

— training of welders who perform welding (electric and gas) work for further work in the field of welding production;

— training of welders on new methods and objects;

— checking the level of knowledge and skills of workers performing welding work;

The following levels of enterprise specialists are also subject to certification by NAKS:

Level 2 - specialists who control the implementation of welding work (give instructions and control the process and result of welding). This category includes foremen and foremen;

Level 3 - heads of divisions and departments that ensure the performance of work in the field of production welding. They determine the welding technology at the enterprise and sign technological maps for the welding process. This category includes technologists (heads of departments, heads of working groups);

Level 4 - managers of the welding production service. They approve all documents on the basis of which welding work is carried out. This category includes technologists and engineers.

Special training

At least 3 months before certification, special training is carried out. Her goal:

- familiarization with the certification procedure;

- mastering the technological features of welding;

- work methods for repairing or installing specific equipment;

- methods and new methods of quality control;

- requirements for safe work.

During the training process, workers master a new welding machine and acquire skills to operate it . Managers are introduced to new technologies and their application in the manufacture of products typical of the enterprise where they work.

Applications for special training before the examination are handled by enterprise managers, simultaneously with the certification of products manufactured by welding. Welders and specialists themselves can submit an application on their own and undergo retraining if their certificate expires or if they are introducing new technologies and installing modern equipment at the site where they work.

Special training is carried out when an enterprise transitions to the production of other products.

If a worker wants to increase his grade, he undergoes special training and acquires practical skills in performing more complex types of welding.

Specialists planning to move to a higher position, for example from a foreman to a technologist, must first study the theory in courses. Then, during certification, they demonstrate their knowledge and ability to use it.

Recruitment of groups is carried out at the location of the enterprise or residence of the specialist, if he himself declares his desire to undergo special training.

Magnetographic method for checking welding work.

The magnetographic method is a method that is based on the ability of a magnetic force flux to deviate from weld defects. Such magnetic lines of force emerge on the surface of the metal and create magnetic flux dispersion fields. The stray fields are recorded on ferromagnetic film and then analyzed by specialists. Each defect has its own characteristic image of the scattering field. Quality control of welded work using this method is carried out using reproducing devices: a magnetizing device PNU or a magnetographic flaw detector MGK-1 and MDU-2U.

The magnetizing device is an electromagnet with a constant voltage source (3 - 12 V). With its help, a magnetic force flow is created in the weld, followed by fixation on a ferromagnetic film.

All of the above methods for monitoring welding work are the most popular inspection methods and provide a high-quality inspection of welding work.

After the quality control of welding work has been carried out, the results of the checks are recorded in welding logs and on welding diagrams and drawings.

Organizational structure

SASv is an independent and independent structure. It reports to RosTechnadzor, has a presidium and an extensive system. The Directorate manages federal and regional representatives, as well as groups of NAKS experts.

The second branch of the organization is the technical council. It consists of 10 committees in different areas of activity.

Certification is carried out in several directions. Materials, equipment and technologies used must be checked.

Each direction has certification centers. The responsibilities of the personnel certification branch include organizing commissions and retraining personnel.

general information

Welder is one of the most in-demand working professions at the moment. Professional welders easily find work, receive decent pay and additional benefits for health risks.

Yes, welding is not the easiest job. Sometimes you have to work in difficult conditions that negatively affect your health. In addition, welders often experience vision problems, despite the use of a protective mask.

However, with full compliance with safety precautions and the Labor Code, such work causes minimal harm and at the same time provides a stable income in any country. There are more and more cases when our compatriots move abroad and get jobs there in welding production.

Training requirements

Welders are certified in 3 disciplines:

- general educational theory;

- professional knowledge;

- practical skill.

If a worker has a secondary or higher education, he is exempt from the general theory. A higher education in welding allows you to avoid taking theory in a practical subject. Knowledge of safe work methods and fire safety is taken by all workers and specialists regularly.

The ability to cook products of a certain complexity is mandatory tested by the commission on several samples of different types.

The welder undergoes a special training course in order to know all the requirements that may be placed on his ability to work. For example, is it allowed to weld the semi-perimeter of a joint during certification? For a worker certified to work with pipelines, it is permissible to weld only half of the joint, provided that the pipe has a diameter of more than 1020 mm. At the same time, he must partially capture the bottom and top and demonstrate his ability to work the ceiling.

If the pipe diameter is 25 - 100 mm, at least 2 circumferential welds are made. For pipeline connections up to 25 mm, the number of connections made is 5.

Quality control of joints: visual, physical and mechanical tests.

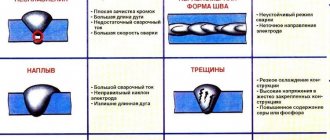

A visual inspection is carried out after cleaning the welded product from splashes and slag. The criterion for the quality of visual inspection is that the seams have a fine-scale texture with a convex surface and a smooth transition to the parts of the metal being welded. The height of the convexity of the weld should be no higher than 1-3 mm. If welding technology is not followed or welding materials are of poor quality, weld defects occur.

Visual inspection reveals the following defects:

- external cracks;

- seam porosity;

- seam slagging;

- excessive seam force;

- low seam force.

Physical tests reveal the following defects:

- lack of penetration of the root, more than 10% deep;

- lack of penetration along the cross-section of the seam;

- lateral lack of penetration;

- burn;

- internal cracks of any size and direction.

A joint with an identified defect must be cut out or a small part (uncooked, slag) cut out if the welding seam is long enough.

Mechanical tests confirm the tensile strength of the welded joint and a bend angle of at least 120 degrees for electric arc welding and at least 100 degrees for gas welding. If deficiencies are identified in any test, a re-inspection is carried out on twice the number of joints. If unsatisfactory results are obtained, the welder is removed from work and sent to advanced training courses.

Certification of welders

For college graduates who have just completed their specialty training, certification must be carried out . They pass the initial examination for proficiency in the profession and receive a certificate. They must clearly explain the essence of the welding process, answer theoretical questions, and demonstrate knowledge of the subject and skill. After 2–3 years, to extend the validity of the document, the certification procedure provides for a periodic examination.

If a worker’s behavior does not comply with generally accepted rules, or managers doubt the quality of his work, the welder may be subject to extraordinary recertification.

When upgrading your qualifications, additional certification must be carried out . The procedure for passing theory and practical skills has been approved and corresponds to the general scheme. The worker passes the theory and cooks a sample corresponding to the new category. Thus, he confirms the status of a highly qualified specialist.

All types of certifications contain the same requirements for passing theory and practice.

The ticket is a technological map and must include:

- surfacing or welding method;

- surfacing materials;

- additives;

- combinations of consumables;

- Type of equipment;

- edge cutting shape;

- welding mode;

- heating temperatures.

All data contained in the certification flow chart must correspond to that used directly at the enterprise where the person being certified works.

Head of Quality Control Department, member of the certification commission of the AMZ plant V.P. Tverdokhlebov: “Periodic certification can be postponed if, for example, the welder’s shift has not yet ended and he is on a business trip. When manufacturing products with increased requirements for strength, tightness and other parameters, periodic certification of performers can be included in the technology. For example, the frequency is 3 months. Then everyone who works in this operation, regardless of the validity of the certificate, undergoes certification every 3 months. The samples they weld are cut, undergo mechanical tests and laboratory studies of macro and microstructure.”

Certification of welders

12.1. General provisions

1. These Rules for the training and certification of welders on federal railway transport (hereinafter referred to as the Rules) define:

- the procedure for preparing for certification and certification of welders of the second and higher categories and welding production specialists engaged in welding work on federal railway transport;

- the procedure for conducting theoretical and practical classes;

- requirements for the composition of certification commissions;

- requirements for test results and the form of documents drawn up during certification.

Welding work refers to both welding itself and surfacing, spraying in various ways, cutting and soldering of metal.

2. Certification of welders is carried out in order to establish the sufficiency of their theoretical and practical training, test their knowledge and skills and grant them the right to perform work at federal railway transport facilities.

3. When certifying welders engaged in manufacturing, reconstruction, installation and repair of facilities under the jurisdiction of the Gosgortekhnadzor of Russia, one should be guided by the Rules for the Certification of Welders and Welding Specialists, approved by the Gosgortekhnadzor of Russia on October 30, 1998 No. 63.

12.2. Organization of work on certification of welders on federal railway transport

1. Certification of welders is carried out by certification commissions created temporarily, for the period of certification, or permanently operating: at linear enterprises of railways and railway departments, at rolling stock repair plants and other repair enterprises of JSC Russian Railways; in road certification centers of railways and their certification points of railway departments, in certification centers created at educational institutions and research organizations of JSC Russian Railways (hereinafter referred to as organizations).

2. Certification commissions of organizations check the theoretical knowledge and practical skills of certified welders in accordance with the requirements of these Rules.

3. Road and other certification centers and points are created in accordance with the legislation of the Russian Federation and are guided in their activities by the regulations on certification centers approved by JSC Russian Railways.

4. The certification commissions must include at least one certified welding technologist or welding engineer, i.e. a specialist of at least III level of professional training in accordance with the certification system for welders and welding production specialists (CASW), provided for by the Rules for Certification and Specialists welding production of the Gosgortekhnadzor of Russia dated October 30, 1998 No. 63.

5. The composition of the certification commissions includes:

- The chairman of the commission is the chief engineer of the organization. In the absence of the position of chief engineer, the head of the organization, his deputy or chief welder (if there is such a position in the organization) is appointed as the chairman of the commission.

- The secretary of the commission is a personnel training engineer or technologist appointed by order of the enterprise to be responsible for welding production.

- Members of the commission: head of the technical department or specialist of the technical department responsible for welding technologies; chief welder of the organization; receiver of rolling stock (or other objects) of JSC Russian Railways; quality control worker; occupational safety engineer.

In addition, the certification commission may include: a foreman supervising welders; head of a workshop or section; a representative of the technical department of the relevant railway service, in charge of welding production issues; representative of the fire safety authority.

6. If an organization does not have the necessary production base for the certification of welders or does not have welding engineers on staff, then welders are certified in any of the certification centers, in organizations in other sectors of the economy where a similar system for certifying welders operates.

7. Responsibility for compliance with these Rules rests with the head or chief engineer of the organization.

12.3. The procedure for admitting welders to certification

1. Welders at least 18 years of age who have a certificate of completion of a special educational institution or welding course, a qualification category corresponding to the nature of the work for which certification is being carried out, are allowed to undergo certification for all types of welding work.

2. Welders who transferred to work from other organizations, graduates of specialized educational institutions or courses and who have a certificate or insert card issued in accordance with these Rules or certified in accordance with the rules of Gosgortekhnadzor, when entering work may be exempt from initial certification if admission to for critical welding work is not expired and corresponds to the type of work that the welder will perform in this organization.

3. Certification of welders is divided into primary, additional, periodic and extraordinary.

All welders who re-enter the organization and do not have access to welding work undergo primary certification. At the same time, they pass theoretical and practical exams.

4. Welders who have previously passed primary certification undergo additional certification before being allowed to perform welding work not specified in their certification certificates, as well as after a break of more than 6 months in performing welding work specified in their certification certificates. During additional certification, welders pass theoretical and practical exams.

5. All welders undergo periodic certification every 2 years in order to extend the validity of their certification certificates for performing relevant welding work. During periodic certification, welders pass theoretical and practical exams.

6. Welders must undergo extraordinary certification by decision of the head of the organization before they are allowed to perform welding work after their temporary suspension from work for violation of welding technology or repeated unsatisfactory quality of the work they perform, as well as for violation of safety rules. During extraordinary certification, welders pass a theoretical and practical exam.

7. If the welder has experience in manual welding, then his experience in manual welding is allowed to be counted in his work experience when certifying for welding using mechanized or automatic welding methods.

8. If the welder has experience in mechanized welding methods, then his work experience in certification for welding using automatic welding methods is allowed to include work experience in mechanized welding methods.

9. A certified welder must be able to perform welding work in compliance with the requirements of technological documentation and safety rules.

12.4. The operating procedure of certification commissions of organizations

1. Work on the certification of welders is carried out according to a schedule approved by the head of the organization or his deputy.

2. Accounting for the timely completion of recertification by welders after the expiration of the certificate, preparation of documents for sending to the commission is carried out by a person appointed by order of the head of the organization.

3. All members of the organization’s certification commission must be notified of the start of the commission’s work, while commission members working in this organization are notified at least five days, and commission members of other organizations - at least ten days before the start of the commission’s work.

If it is impossible to participate in the work of the organization’s certification commission, members of the commission must notify the chairman no later than three days before the start of the commission’s work.

4. The certification commission of an organization is authorized to conduct theoretical tests if the meeting is attended by: the chairman of the commission, the secretary, the receiver of rolling stock (or other objects of JSC Russian Railways) or a quality control department employee, a labor protection engineer. In the absence of any of the above persons, theoretical tests are postponed to another time.

5. Welders admitted for certification must be notified by members of the organization’s certification commission at least two weeks in advance about the place and time of theoretical tests, as well as control questions.

6. Theoretical training classes for welders are conducted by specialists with a special secondary technical or higher education in welding production or specialists with a higher technical education and at least 5 years of experience in welding.

7. Theoretical training of welders is allowed in specialized educational institutions that provide training in welding specialties. In this case, the organization’s application or contract for theoretical training of welders must specifically indicate:

- the nature of the work performed;

- on what points of the theoretical training program of these Rules (Section 7) should the welder be trained?

8. The protocols of the certification commission, together with the protocols of laboratory tests of samples, must be stored for 3 years in the technical department or human resources department of the organization.

Updated: 11/22/2011 16:02

Career

A welder can have career growth, and quite a lot. It all depends on the aspirations and skills of the master. The higher your rank in welding, the better the salary and the more in demand your candidacy is.

Graduates of vocational schools, colleges and technical schools do not have to look for work for long. And all because welders are needed in many industries. At first, your earnings will be small, but as your career develops, you can achieve a very good financial position. Especially if you work abroad.

The lowest salaries are for welders in the housing and communal services sector, the highest are for craftsmen in private industries, where highly qualified workers are required.

To begin with, you can get a job in the housing and communal services or construction. This is a dusty job, low paid and often not the most comfortable. But over time, you can gain higher qualifications and get a job in modern production.