If production requires a large number of metal products or blanks of the same sample, it is advisable to use the stamping method. Metal stamping is carried out from sheet material, which is deformed in a special way to the desired shape by pressure. Stamping of metal products has been used since ancient times: many centuries ago, our ancestors made jewelry, weapons and household items in this way. Then this was done manually and at a much lower speed, but now the process is automated, and the production of one part takes much less time.

History of the process

Initially, everything was done by hand. The first mechanical operations using machines in the metalworking industry began in the mid-19th century. The machines have improved the quality of material processing. Another 50 years later, stamping was used for the first time in the automotive industry - the production of elegant bodies with rounded elements began.

Already in the 1930s, the same technology began to be used in aircraft and shipbuilding, and after another two decades, the production of spare parts for rockets began. The method has gained wide popularity, and is now used to create elements of completely different sizes - from an airplane wing to a small clock hand.

Sheet metal stamping technology

The starting material is a metal sheet, tape or any flat shape. Then it will be subjected to hot or cold processing (we will talk about their differences below), but with any method, the source material acquires additional properties and strength increases.

The essence of the process is the impact of foreign objects on the formation in order to achieve its deformation or separation of a part, that is, a cut. Often these two procedures occur together. The tools that come into contact with the workpiece are selected, then the press operates. He is the main force exerting pressure.

Technological operations

During operation, the machine can perform the following actions:

- Segment. The two parts are separated along a curve or straight line.

- Notching. Only notches and slits are made, but the overall integrity is not violated.

- Trimming. The procedure usually occurs with the edges of the sheet, they detach and go into the trash.

- Punching. Perforation occurs with several or one hole at once, a pattern appears.

- Felling. A closed contour appears from inside the workpiece. A whole fragment is removed along it, without disturbing the fact that the entire part remains closed.

- Cleaning up. Decorative element, corrects unevenness, smoothes ends.

- Piercing. Cones appear on the surface, that is, breakthroughs, but without cutting off any metal layer.

Making metal stamps

It is necessary to construct metal stamps from a metal blank. The first stage involves the development of detailed drawings with interpretation.

Stamps consist of the following elements:

- Poison and matrix. These are working parts that are made from tool steel. After processing under high temperatures, they are hardened to 60 units.

- Punch holder.

- Gaskets. They are made from structural steel with hardening up to 45 units.

- Puller.

- Bottom and top plates. Their thickness depends on the effort expended on stamping.

- Columns and bushings.

- Shank.

Types of stamping of sheet metal parts

All metal products subjected to stamping have a small width, since it is difficult to bend an excessively dense sheet. But depending on its strength, different approaches are used. Let's look at the features.

Cold stamping

The workpiece is processed without preheating. The method is inexpensive and less labor-intensive, as it is a one-step process. Only thin surfaces are processed this way. Procedure steps:

- Increasing the density of steel using a press. This way the material becomes less plastic and more resistant to external influences. The shape remains with the product for a long time.

- Processing through high temperature processing - 550-620 degrees is maintained in the oven. This leads to the destruction of the chemical crystal lattice and the filling of the structure with additional carbon atoms.

- The workpiece is transferred to the workshop for cold metal stamping. Here metal molds are used for long-term use. The dies for them are made of very durable alloys that remain accurate after a long period of use.

Features of cold stamping

It does not happen at home, but exclusively in workshops. Moreover, the advantage is the ability for employees to be in the room while the equipment is operating, because they are not present in an area with high temperatures. The very moment when a stamp is applied using a press takes no more than a few seconds, the mechanism is activated automatically. This option is suitable for:

- alloyed, carbon steels;

- aluminum;

- copper;

- some alloys.

Also, a similar method is used to create products from:

- cardboard;

- skin;

- polymer clay;

- rubber.

Equipment adjustment (weight of the press, steel for knives) will be carried out based on the calculation of the properties of the material.

Hot metal stamping process

It is used to process denser workpieces. They bend and are stamped due to the breaking of bonds between the molecules (they are at a greater distance). The whole procedure has similar preparatory stages as the cold variety, that is, pressing and processing in ovens, hardening. But already at the third step, more modern and complex equipment is required. Here the press is combined with a heating element. The metal initially reaches a red incandescent state. And this is how the main work happens. Peculiarities:

- Automation of the process - people should not stand behind the machines, this is all the more important since it is impossible to work in such an air temperature.

- You must first set the material parameters on the computer.

- The steel for the dies themselves is only alloyed, high-strength.

If automatic heating is not used, then the process is similar, but in two steps - first heating and then stamping. Then there must be a worker in the workshop who uses tongs (for small products as an example) to transfer the workpiece from one place to another. This is a very difficult job, which is why many large enterprises are switching to expensive automation.

After hot metal stamping, no special cooling (water or cold air) is required. The temperature returns to normal depending on the mass and density of the steel. Only after complete cooling can grinding, galvanizing, painting or other finishing work be carried out.

Liquid stamping

The second name, injection molding, is not used very often, since it is expensive and also technologically difficult. But to obtain very durable products, without creases and possible inaccuracies, this particular method is used. It involves melting a metal alloy and then pouring it into a special stamping mold. After cooling, repeated stamping may occur, but as a final feature.

Separation stamping

In fact, this is cutting, punching and cutting. That is, here the material does not bend, but only the excess part is cut off from it. Various patterns and geometric shapes can be produced. This can be either the primary processing of the workpiece, and then the formation of volumes will occur, or the only step necessary for the finished product. Cutting is performed using special tools - knives made of high-strength and well-sharpened steel. The procedure can be either straight or curved. Apply:

- guillotine shears;

- vibration machines;

- disks.

This procedure can also be called cutting, a term used by tailors who cut prepared fabric in similar ways.

Features of the technology

In addition to the division into hot and cold, stamping of metal products is also divided into a number of other categories depending on its purpose and technological conditions.

Thus, stamping operations, as a result of which a part of the metal workpiece is separated, are called separation operations. This, in particular, includes cutting, chopping and punching metal parts. Another category of such operations, as a result of which the stamped sheet of metal changes its shape, is form-changing stamping operations, often called forming. As a result of their implementation, metal parts can be subjected to drawing, cold extrusion, bending and other processing procedures.

As noted above, there are types of stamping, such as cold and hot, which, although implemented according to the same principle, which involves deformation of the metal, have a number of significant differences. Stamping of parts, which involves preheating them to a certain temperature, is used mainly in large manufacturing enterprises.

This is primarily due to the rather high complexity of such a technological operation, for the high-quality implementation of which it is necessary to make a preliminary calculation and accurately observe the degree of heating of the workpiece being processed. Using hot stamping, sheet metal of various thicknesses is used to produce critical parts such as boiler bottoms and other hemispherical products, hulls and other elements used in shipbuilding.

Characteristics and types of parts produced on hot stamping presses

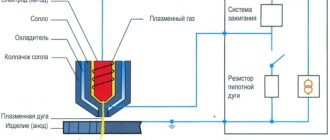

To heat metal parts before hot stamping, heating equipment is used, which is able to provide precise temperature conditions. Electrical, plasma and other heating devices may be used in particular for this function. Before starting hot stamping, it is necessary not only to calculate the heating rates of the parts being processed, but also to develop an accurate and detailed drawing of the finished product, which will take into account the shrinkage of the cooling metal.

When performing cold stamping of metal parts, the process of forming the finished product occurs only due to the pressure exerted by the working elements of the press on the workpiece. Due to the fact that the blanks are not preheated during cold stamping, they are not subject to shrinkage. This allows us to produce finished products that do not require further mechanical modification. That is why this technology is considered not only a more convenient, but also a cost-effective processing option.

If you skillfully approach the issues of designing the size and shape of workpieces and the subsequent cutting of the material, you can significantly reduce its consumption, which is especially important for enterprises that produce their products in large batches. The material from which workpieces are successfully stamped can be not only carbon or alloy steels, but also aluminum and copper alloys. Moreover, an appropriately equipped stamping press is successfully used for processing workpieces made of materials such as rubber, leather, cardboard, and polymer alloys.

Separation stamping, the purpose of which is to separate a part of the metal from the workpiece being processed, is a very common technological operation used in almost every manufacturing enterprise. Such operations, which are performed using a special tool mounted on a stamping press, include cutting, punching and punching.

During the cutting process, metal parts are separated into separate parts, and such separation can be carried out along a straight or curved cutting line. Various devices can be used to perform cutting: disc and vibrating machines, guillotine shears, etc. Cutting is most often used to cut metal workpieces for further processing.

Punching is a technological operation during which parts with a closed contour are obtained from a metal sheet. Using punching, holes of various configurations are made in sheet metal blanks. Each of these technological operations must be carefully planned and prepared so that the result is a high-quality finished product. In particular, the geometric parameters of the tool used must be accurately calculated.

Technological stamping operations, during which the initial configuration of metal parts is changed, are forming, bending, drawing, flanging and crimping. Bending is the most common form-changing operation, during which bending areas are formed on the surface of a metal workpiece.

Drawing is a volumetric stamping, the purpose of which is to obtain a volumetric product from a flat metal part. It is with the help of drawing that a metal sheet is transformed into products of a cylindrical, conical, hemispherical or box-shaped configuration.

Along the contour of sheet metal products, as well as around the holes that are made in them, it is often necessary to form a side. Flanging successfully copes with this task. The ends of the pipes on which flanges need to be installed are also subjected to this treatment, performed using a special tool.

With the help of crimping, unlike flanging, the ends of pipes or the edges of cavities in sheet metal blanks are not expanded, but narrowed. When performing such an operation, carried out using a special conical matrix, external compression of the sheet metal occurs. Molding, which is also one of the types of stamping, involves changing the shape of individual elements of a stamped part, while the outer contour of the part remains unchanged.

Volumetric stamping, which can be performed using various technologies, requires not only careful preliminary calculations and the development of complex drawings, but also the use of specially manufactured equipment, so implementing such technology at home is problematic.

History of the process

It has been known and used since ancient times, since it was invented before the Middle Ages and even then allowed our ancestors to make weapons, jewelry and other things needed in everyday life. It has been steadily improved over the centuries, always distinguished by its comparative simplicity and high productivity, but it was performed manually until the 1850s, after which the level of technological development allowed it to be mechanized in earnest.

From the middle of the 19th century, technical operations began to be carried out on machine tools; from the beginning of the 20th, they began to produce car bodies; from the 1930s, the hulls and mechanisms of sea and river vessels and aircraft; from the 1950s, functional units and elements in rocket science.

Metal stamping has remained popular for centuries due to the following features and advantages:

- Versatility - it can be used to produce parts of any size and shape, both those that require further processing and those that are already ready for use.

- Precision manufacturing, especially at the current level of technology, which makes it possible to ensure the interchangeability of manufactured elements even without finishing.

- A penchant for mechanization and automation - high productivity has always been an obvious advantage, and today it is achieved through the use of rotary conveyor lines.

- Durability of final products, even thin, light, large ones.

This is interesting: Designation and image of the thread in the drawing according to GOST

The process is especially relevant for mass production - both small elements, like gears for watches, and large objects, for example, car bodies.

Areas of use

The method is in demand in various industries where it is necessary to give metals a given shape. The production of parts using stamping is used in the following areas:

- automotive industry;

- production of electronics, watches, etc.;

- construction;

- printing;

- mechanical engineering;

- aircraft manufacturing, etc.

Thanks to high-tech devices during the processing process, it is possible to obtain workpieces of a given shape of different sizes with a minimum of waste.

Equipment according to GOST

There are the following types of machines:

- single crank;

- double crank;

- four-crank.

In any version, they are equipped with a steel matrix and a slider, which is connected to a stamp. The movement begins due to an electric motor, which contains elements of a kinematic chain. To free the worker's hands, the launch is done with the foot; there is a pedal at the bottom, which is connected to the rotation clutch. Next, the force is transferred to all moving elements, the process of metal stamping begins, as you understand, you cannot make such a technologically difficult machine with your own hands.

For complex products

The structure described above is suitable for the most basic workpieces. If the shape has a more complex configuration, a pneumatic press with two or three sliders is used. This is required for more durable fixation of the sheet, as well as for controlling several matrices at once. If the material is very strong and no press can “take” it, then they use an innovative development - an explosion. Its strength helps to penetrate even the strongest alloys.

Equipment and tools

To form metal products, dies are made that are inserted in presses, which are of 2 types:

- Crank-rod. The main element in them is a slider moving along guides. An electric motor is located on top, which gives impetus to the movement of the crank mechanism. There is a plate at the bottom on which the stamp is placed. The equipment is high-speed. The disadvantages include the high impact force when the punch comes into contact with the metal. As a result, the tool becomes chipped.

- Hydraulic presses. They have great power. The advantages include the smooth movement of the slider. Thanks to this, there is no mechanical shock during operation, which leads to long service life of the tool. The amount of travel of the slider provides a large open height of the press space. This makes it possible to perform deep drawing or bending operations on workpieces with high sides.

Metal forming allows you to produce a large number of parts in a short time. In this case, they will all have the same shape. The accuracy of their manufacture is regulated by GOST.

Advantages

- You can make virtually any shape.

- The consumption of metal sheets is reduced.

- There is no loss of mechanical characteristics of the product.

- Can be used in both large-scale and small-scale production.

- High speed.

- The versatility of the machines.

We talked about metal stamping. If you are engaged in metalworking, you can order high-quality equipment from.

To clarify the information you are interested in, please contact our managers by phone;; 8 (800) 707-53-38. They will answer all your questions.

Volume stamping

Volumetric stamping can be performed using both cold and hot methods. Hot - pressure processing, where the forging is formed using a stamp. The blanks are rolled rectangular, round, square profiles, which are cut into dimensional blanks (sometimes they are not cut, but stamped directly from the rod, and then the forging is separated directly by a stamping machine).

Volume stamping is used in mass and serial production, which increases labor productivity and reduces metal waste. The quality of the products also meets high standards. This stamping produces products that are extremely complex in shape and cannot be produced even by free forging.