Story

In the ancient world they knew brass (copper-zinc alloy). The Englishman William Champion managed to obtain zinc as a metal by the 18th century. He founded the first plant. Later, his compatriots developed a method of rolling metal.

However, the pioneer in history was the German Andreas Marggraff. He worked out a similar method, describing the technology in detail.

In Russia, a trial batch of zinc was received by 1905.

Ten years later, zinc was mined electrolytically in North America.

The terms zincum, zinken were first used by the chemist and physician of the Middle Ages Paracelsus. It is similar to the German word for "prong". This is what zinc metal fragments look like.

Physico-chemical characteristics

When exposed to air, the shiny metal becomes coated with an oxide film. Due to this chemical property it looks dull.

| Properties of the atom | |

| Name, symbol, number | Zinc / Zincum (Zn), 30 |

| Atomic mass (molar mass) | 65.38(2) a. e.m. (g/mol) |

| Electronic configuration | [Ar] 3d10 4s2 |

| Atomic radius | 138 pm |

| Chemical properties | |

| Covalent radius | 125 pm |

| Ion radius | (+2e) 74 pm |

| Electronegativity | 1.65 (Pauling scale) |

| Electrode potential | -0.76 V |

| Oxidation states | 0; +2 |

| Ionization energy (first electron) | 905.8(9.39) kJ/mol (eV) |

| Thermodynamic properties of a simple substance | |

| Density (at normal conditions) | 7.133 g/cm³ |

| Melting temperature | 419.6 °C |

| Boiling temperature | 906.2 °C |

| Ud. heat of fusion | 7.28 kJ/mol |

| Ud. heat of vaporization | 114.8 kJ/mol |

| Molar heat capacity | 25.4 J/(K mol) |

| Molar volume | 9.2 cm³/mol |

| Crystal lattice of a simple substance | |

| Lattice structure | hexagonal |

| Lattice parameters | a=2.6648 c=4.9468 Å |

| c/a ratio | 1,856 |

| Debye temperature | 234K |

| Other characteristics | |

| Thermal conductivity | (300 K) 116 W/(m K) |

| CAS number | 7440-66-6 |

Interaction with metals begins at 450°C.

The main disadvantage of the metal : the increase in fragility by several times from a small amount of impurities.

When bending a zinc plate, you can hear a cracking sound. It is generated by the lattice structure.

[edit] Literature

- Glossary of terms in chemistry // J. Opeida, O. Shvaika. Institute of Physical-Organic Chemistry and Coal Chemistry named after. L. M. Litvinenko NAS of Ukraine, Donetsk National University - Donetsk: "Weber", 2008. - 758 p. ISBN 978-966-335-206-0

- Small mountain encyclopedia. In 3 volumes / Ed. V. S. Beletsky. - Donetsk: Donbass, 2004. - ISBN 966-7804-14-3.

- R. Ripan, I. Certeanu. Inorganic chemistry: Chemistry of metals: In 2 vols. - M.: Publishing house. "Mir", 1971. - T. 1. - 561 p.

- Chemical properties of inorganic substances: Textbook. manual for universities. 3rd ed., Rev. / R. A. Lidin, V. A. Molochko, L. L. Andreeva; Ed. R. A. Lidin. - M.: Chemistry, 2000. 480 p.: ill. — ISBN 5-7245-1163-0

Electrochemical activity series of metals

, , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , , H2

, , , , , , , , , , , , , , , , ,

| Periodic table of chemical elements by D. I. Mendeleev | |||||||||||||||||||||||||||||||||||||||||||

| Zn | |||||||||||||||||||||||||||||||||||||||||||

| Uue | Ubn | Ubu | Ubb | Ubt | Ubq | UBP | Ubh | ||||||||||||||||||||||||||||||||||||

| Alkali metals | Alkaline earth metals | Lanthanides | Actinoids | Superactinoids | Transition metals | Other metals | Semimetals | Other non-metals | Halogens | Noble gases | Properties unknown | ||||||||||||||||||||||||||||||||

Being in nature

The presence of native zinc in nature has not been recorded, only almost seven dozen minerals.

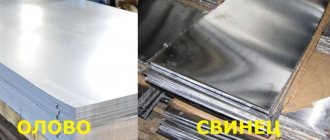

The most popular one is sphalerite. This is zinc sulfide plus impurities that give it different colors.

Sphalerite

The second name - zinc blende - is due to the difficulty of identifying the element (from the ancient Greek σφαλερός - deceiver). It is classified as the primary, “parent” of other minerals: smithsonite, zincite, calamine. And also “chipmunk” ore. This is how the inhabitants of Altai dubbed the motley conglomerate of zinc blende with brown spar.

Physical properties

In its pure form it is a rather ductile silvery-white metal. Has a hexagonal lattice with parameters a

= 0.26649 nm,

s

= 0.49431 nm, space group

P

63/mmc, Z = 2. At room temperature it is brittle; when the plate is bent, a crack is heard from the friction of crystallites (usually stronger than the “tin cry”). At 100-150 °C zinc is plastic. Impurities, even minor ones, dramatically increase the fragility of zinc. The intrinsic concentration of charge carriers in zinc is 13.1⋅1028 m−3.

Reserves

Markers for zinc mining are acidic or basic rocks of volcanic origin.

The average metal content in the planet's crust is 8.3x10-3%.

This is a mobile active element: rivers, thermal waters, and groundwater transport it with lead, hydrogen sulfide, and clays. As a result, a precipitate of zinc sulfides is formed.

Australia, Bolivia, Kazakhstan, and Iran have large reserves.

In Russia it is Taimyr, Krasnoyarsk Territory. Reserves are estimated at half a million tons.

Receiving technology

Due to its chemical and physical properties, the metal is the fourth most popular in the world (only iron, aluminum, and copper are ahead). World production amounts to millions of tons annually.

It is mined from polymetallic ores (0.9-3.9% zinc). Ores are enriched by separation flotation. The resulting concentrates are: zinc (52-61%), lead, copper.

Electrolytic (hydrometallurgical) method

The main method for obtaining pure zinc:

- The concentrates are fired and treated with sulfuric acid.

- The result is dissolved sulfate, which is removed from impurities by precipitating with zinc dust.

- The product is loaded into baths with an internal lead or plastic coating.

- The current is started (electrolysis process).

- Zinc is accumulated on cathodes.

From there it is scraped off and sent for smelting in a furnace.

Pyrometallurgical (distillation) method

The concentrate is fired, sintered, and then reduced with coke or coal. The resulting metal vapors are converted into condensate and poured into molds.

Liquid metal is purified from iron and lead by settling at 500°C. Impurities remain at 1.3%. Purity of 99.994% (plus cadmium extraction) is achieved by rectification.

[edit] Description

Simple substance. Zinc alloys (brass) have been known since ancient times (2400-2000 BC). The production of zinc was described by Strabo (1st century BC). Industrial production of zinc in Europe began in 1743, in China 400 years earlier. Pure zinc was obtained only in the 16th century. Plastic malleable bluish-gray metal with a density of 7.13 g/cm3. tmelt 419.88 °C; boiling point 907 °C. Reacts with acids, alkalis, ammonia and ammonium salts, in the presence of water vapor - with chlorine and bromine, and when heated - with oxygen.

Galvanizing methods

Metals rust in water and humid air. To solve this problem, they are coated with a protective layer. The most common material is zinc. At the same time, protection against exposure to current and chemicals is provided.

Various methods of galvanizing metal create a coating with a thickness of 0.005 - 1.5 mm.

The metal layer is applied in several ways.

Cold

Can be used on any materials except magnesium alloys and high-strength steel.

The surface is cleaned of dust, dirt, rust, and scale. Apply the composition for cold galvanizing.

Cold galvanizing is the only method that can be carried out in a home workshop.

Hot

The sample is cleaned, washed, etched, and immersed in a bath of molten zinc. A coating of 0.035-0.097 mm is formed on the surface.

The hot galvanizing method is optimal in terms of price – reliability – versatility.

Galvanic

A layer of zinc is applied to the cleaned surface by electrolysis. The electrolyte is a water-zinc medium.

The impact of direct current on the surface of the workpiece (cathode) deposits zinc ions (released by the electrolyte). The anode is zinc material.

The technology allows you to create a layer of 0.005 - 0.5 mm.

Advantages of the method:

- High performance.

- Low cost.

- Uniform coverage.

- Work with forms of any structure, including porous ones.

- Creation of decorative galvanization.

These characteristics have made the method the most popular.

Disadvantages: harmful to the environment, fragility of the product if the technology is violated.

Gas-thermal

A jet of zinc suspension is sprayed onto the surface of the product at an angle.

Minuses:

- Uneven layer thickness.

- Difficulty of process control.

- Expensive (three to four times) compared to other methods.

Plus: suitable for processing products of any shape and size. Thermal diffusion

The retort with the charge and samples is placed in a chamber equipped with an inductor. The heat from the retort and products heats the charge.

In the magnetic field of the inductor, currents are formed in the products, heating them to 500-800°C in half an hour.

Result: 98% of the top coating layer is pure zinc.

The thickness of the metal layer in the thermal diffusion method is determined by the parameters of the products, the charge, heating time, and temperature.

Zinc compounds.

Zinc forms numerous binary compounds with nonmetals, some of which have semiconducting properties.

Zinc salts are colorless (if they do not contain colored anions), their solutions have an acidic environment due to hydrolysis. Under the action of solutions of alkalis and ammonia (starting from pH ~ 5), the main salts precipitate and transform into hydroxide, which dissolves in an excess of the precipitant.

Zinc oxide

ZnO is the most important industrial zinc-containing compound. As a by-product of brass production, it became famous before the metal itself. Zinc oxide is obtained by burning zinc vapor in air, which is formed during the smelting of ore. A purer and whiter product is produced by burning vapors obtained from pre-purified zinc.

Typically, zinc oxide is a white, fine powder. When heated, its color changes to yellow as a result of the removal of oxygen from the crystal lattice and the formation of a non-stoichiometric phase Zn1+ x

O(

x

Ј 7.10–5). Excessive amounts of zinc atoms result in lattice defects that trap electrons, which are subsequently excited when visible light is absorbed. By adding a 0.02–0.03% excess of metallic zinc to zinc oxide, you can get a whole spectrum of colors - yellow, green, brown, red, but the reddish shades of the natural form of zinc oxide - zincite - appear for another reason: due to the presence manganese or iron. Zinc oxide ZnO is amphoteric; it dissolves in acids to form zinc salts and in alkalis to form hydroxinates, such as [Zn(OH)3]– and [Zn(OH)4]2–:

ZnO + 2OH– + H2O = [Zn(OH)4]2–

The main industrial application of zinc oxide is in rubber production, in which it reduces the vulcanization time of the original rubber.

As a pigment in the production of paints, zinc oxide has advantages over traditional lead white (basic lead carbonate), due to the lack of toxicity and darkening under the influence of sulfur compounds, but is inferior to titanium oxide in terms of refractive index and hiding power.

Zinc oxide increases the life of glass and is therefore used in the production of special glasses, enamels and glazes. Another important area of application is in neutralizing cosmetic pastes and pharmaceutical preparations.

In the chemical industry, zinc oxide is usually the starting material for the production of other zinc compounds, in which soaps (ie fatty acid compounds such as stearate, palmitate and other zinc salts) are the most important. They are used as paint hardeners, plastic stabilizers and fungicides.

A small but important application of zinc oxide is the production of zinc ferrites. These are spinels of the ZnII x

MII1–

x

FeIII2O4, containing another doubly charged cation (usually MnII or NiII). At x = 0 they have an inverted spinel structure. If x = 1, then the structure corresponds to normal spinel. A decrease in the number of FeIII ions in tetrahedral positions leads to a decrease in the Curie temperature. Thus, by changing the zinc content, it is possible to influence the magnetic properties of ferrites.

Zinc hydroxide

Zn(OH)2 forms as a gelatinous white precipitate when alkali is added to aqueous solutions of zinc salts. Zinc hydroxide, like the oxide, is amphoteric:

Zn(OH)2 + 2OH– = [Zn(OH)4]2–

Used for the synthesis of various zinc compounds.

Zinc sulfide

ZnS is released as a white precipitate when soluble sulfides and zinc salts react in an aqueous solution. In an acidic environment, zinc sulfide precipitate does not form in an acidic environment. Hydrogen sulfide water precipitates zinc sulfide only in the presence of weak acid anions, for example, acetate ions, which reduce the acidity of the medium, which leads to an increase in the concentration of sulfide ions in the solution.

Sphalerite ZnS is the most common zinc mineral and the main source of the metal, but a second natural, although much rarer, form of wurtzite is also known, which is more stable at high temperatures. The names of these minerals are used to refer to crystal structures, which are important structural types found for many other AB compounds. In both structures, the zinc atom is tetrahedrally coordinated by four sulfur atoms, and each sulfur atom is tetrahedrally coordinated by four zinc atoms. The structures differ significantly only in the type of close packing: in wurtzite it is cubic, and in sphalerite it is hexagonal.

Pure zinc sulfide is white and, like zinc oxide, is used as a pigment; for this purpose it is often prepared (as lithopone) together with barium sulfate by reacting aqueous solutions of zinc sulfate and barium sulfide.

Freshly precipitated zinc sulfide easily dissolves in mineral acids with the release of hydrogen sulfide:

ZnS + 2H3O+ = Zn2+ + H2S + 2H2O

However, calcination makes it less reactive and is therefore a suitable pigment in children's toy paints as it is harmless if swallowed. In addition, zinc sulfide has interesting optical properties. It turns gray when exposed to ultraviolet radiation (possibly due to dissociation). However, this process can be slowed down, for example, by adding traces of cobalt salts. Cathode, X-ray, and radioactive radiation produce fluorescence or luminescence of various colors, which can be enhanced by adding traces of various metals or by replacing zinc with cadmium and sulfur with selenium. It is widely used for the production of cathode ray tubes and radar screens.

Zinc selenide

ZnSe can be precipitated from solution as a lemon-yellow, difficult-to-filter precipitate. Wet zinc selenide is very sensitive to air. Dried or prepared dry, it is stable in air.

Zinc selenide single crystals are grown by directional crystallization of a melt under pressure or by vapor deposition. Zinc sulfide is used as a laser material and a component of phosphors (together with zinc sulfide).

Zinc telluride

ZnTe, depending on the production method, is a gray powder that turns red when rubbed, or red crystals, and is used as a material for photoresistors, infrared radiation receivers, dosimeters and radiation counters. In addition, it serves as a phosphor and semiconductor material, including in lasers.

Zinc chloride

ZnCl2 is one of the important zinc compounds in industry. It is obtained by the action of hydrochloric acid on secondary raw materials or roasted ore.

Concentrated aqueous solutions of zinc chloride dissolve starch, cellulose (which is why they cannot be filtered through paper) and silk. It is used in the production of textiles, in addition, it is used as an antiseptic for wood and in the manufacture of parchment.

Since zinc chloride easily dissolves oxides of other metals in the melt, it is used in a number of metallurgical fluxes. Using a solution of zinc chloride, metals are cleaned before soldering.

Zinc chloride is also used in magnesium cement for dental fillings, as a component of electrolytes for electroplating and in dry cells.

Zinc acetate

Zn(CH3COO)2 is highly soluble in water (28.5% by weight at 20° C) and many organic solvents. It is used as a fixative for dyeing fabrics, a wood preservative, an antifungal agent in medicine, and a catalyst in organic synthesis. Zinc acetate is a component of dental cements and is used in the production of glazes and porcelain.

When zinc acetate is distilled under reduced pressure, the basic acetate [Zn4O(OCOMe)6] is formed; its molecular structure includes an oxygen atom surrounded by a tetrahedron of zinc atoms connected along the edges by acetate bridges. It is isomorphic to basic beryllium acetate, but unlike it, it quickly hydrolyzes in water, this is due to the ability of the zinc cation to have a coordination number above four.

Organozinc compounds

. The discovery in 1849 by the English organic chemist Edward Frankland (1825–1899) of zinc alkyls, although not the first synthesized organometallic compounds (Zeise's salt was obtained in 1827), can be considered the beginning of organometallic chemistry. Frankland's research pioneered the use of organozinc compounds as intermediates in organic synthesis, and his measurements of vapor density led him to the proposition (crucial in the development of the theory of valency) that each element has a limited but definite strength of affinity. Grignard reagents, discovered in 1900, have greatly supplanted zinc alkyls in organic synthesis, but many of the reactions in which they are now used were first developed for zinc compounds.

Alkyls such as RZnX and ZnR2 (where X is halogen and R is alkyl) can be prepared by heating zinc in boiling RX under an inert atmosphere (carbon dioxide or nitrogen). Covalent ZnR2 are non-polar liquids or low-melting solids. They are always monomeric in solution and are characterized by linear coordination of the zinc atom

C–Zn–C. Organozinc compounds are very sensitive to air. Low molecular weight compounds spontaneously ignite, producing zinc oxide smoke. Their reactions with water, alcohols, ammonia and other substances proceed similar to Grignard reactions, but less vigorously. An important difference is that they do not react with carbon dioxide.

Where is it used?

The properties of the metal, its alloys, and compounds determined their use in metallurgy, electrical engineering, and medicine.

Pure metal

Main directions:

- Negative electrode of batteries, accumulators.

- Reducer of precious metals.

- Protective coating of steel against corrosion.

- Component of hard solders to increase fusibility.

- Metal extractor from rough lead.

Until the mid-20th century, a popular area of application for zinc was printing. The zincography method was used to create black and white illustrations in newspapers or books. An image was etched onto a zinc plate with acid. Then impressions were made from it on a printing machine.

Zinc ingots

Alloys

Zinc is in demand as a component of metal alloys. For example, brass.

It is used by machine builders for precision casting:

- Automotive accessories.

- Carburetor box shell.

- Bolts of traumatic pistols.

A fifth of the raw materials are used for the production of tires and oil paints.

Connections

Metal compounds created by nature or man have found application:

- Chloride – metal soldering, fiber production.

- Telluride, selenide, phosphite are semiconductors.

- Selenide is used in the manufacture of special types of glass for lasers.

- Oxide is the source material for zinc white.

- Sulfide is a component of phosphors (flexible panels, screens).

Metal phosphite is used to kill rodents.

Mixtures and alloys

To enhance strength and increase the melting point, the metal is mixed with copper, aluminum, tin, magnesium and lead.

The most famous and sought after alloy is brass. This is a mixture of copper with the addition of zinc, sometimes tin, nickel, manganese, iron, and lead are also found. The density of brass reaches 8700 kg/m3 . The temperature required for melting is kept at around 880 C o - 950 C o: the higher the zinc content in it, the lower it is. The alloy perfectly resists unfavorable external environments, although it turns black in air if not varnished, it is perfectly polished and welded by resistance welding.

There are two types of brass:

- Alpha brass: more ductile, bends well in any condition, but wears out more.

- Alpha+beta brass: deforms only when heated, but is more wear-resistant. Often alloyed with magnesium, aluminum, lead and iron. This increases strength, but reduces ductility.

Zamak or Zamac alloy is composed of zinc, aluminum, copper and magnesium . The name itself is formed from the first letters of the Latin names: Zink - Aluminum - Magnesium - Kupfer / Cuprum (Zinc-Aluminum-Magnesium-Copper). In the USSR, the alloy was known as TsAM: Zinc-Aluminum-Copper. Actively used in injection molding, melting begins at low temperatures (381 C o - 387 C o) and has a low coefficient of friction (0.07). It has increased strength, which makes it possible to produce products of complex shapes that are not afraid of breaking: door handles, golf clubs, firearms, construction fittings, fasteners of various types and fishing tackle.

A small percentage of zinc (no more than 0.01%) is contained in hart alloys used in printing for casting typographic fonts and rulers, printing forms and typesetting. These are outdated mixtures, replaced by pure zinc with a small addition of impurities.

The low temperature required to melt zinc is often compensated for by alloys with other metals, but it also happens vice versa. If the temperature required to melt a “pure” metal is 419.5 C o , then the alloy with tin is reduced to 199 C o, and with tin and lead - to 150 C o. And although such alloys can be soldered and welded, most often mixtures with zinc are used only to seal existing defects due to their weak strength. For example, an alloy of tin, lead and zinc is recommended for use only on nickel-plated products.

Most often, zinc alloys are used to create carburetors, speedometer frames, radiator grilles, hydraulic brakes, pumps and decorative elements, parts for washing machines, mixers and kitchen equipment, watch cases, typewriters, cash registers and household appliances. These parts cannot be used in industrial production: when the temperature rises to 100 C, the strength of the product decreases by a third, and hardness by almost 40%. When the temperature drops to 0 C, zinc becomes too brittle, which can lead to breakage.

Meaning for humans

Zinc is an essential component of body tissue. The second most abundant microelement after iron. Without it, proteins and nucleic acids are not synthesized.

Life processes

The metal is involved in the following processes:

- Tissue regeneration.

- Metabolism of vitamin E.

- Synthesis of testosterone, insulin, growth hormones, etc.

- Alcohol breakdown.

- Functioning of the prostate, sperm production.

The human body of average build contains up to 2 g of zinc compounds.

Places of metal accumulation are muscle tissue, liver, pancreas, prostate.

Nutrition

The daily “standard” of zinc for women/men is 9/12 mg.

Rich in zinc:

- Pumpkin and sunflower seeds.

- Meat.

- Hard varieties of cheese.

- Oysters.

- Oatmeal.

- Peas, beans, chickpeas, mung beans.

- Bitter chocolate.

Zinc deficiency causes irritability and depression. On the physical plane – anemia, unmotivated exhaustion, amnesia, weakened vision, allergies.

The use of metal in medicine is zinc oxide (zinc ointment). This is a popular antiseptic and anti-inflammatory agent.

Warning

Uncontrolled entry of metal into the body causes poisoning. It is generated by sulfates or chlorides. They can form when storing food in galvanized containers.

Symptoms of zinc vapor poisoning:

- Intense thirst.

- Sweetish taste in the mouth.

- Loss or decrease in appetite.

- Dry cough.

The person feels overwhelmed and tired. Feels drowsy, chest pain.

For severe poisoning, 1 gram of zinc sulfate is sufficient.

You need to remove toxins immediately. Their presence provokes anemia, growth inhibition, and infertility.