What is a draft regulator and why is it needed?

Typically, draft regulators are installed in solid fuel boilers.

For this purpose, in the “jacket” of their heat exchanger there is a special hole for installing a draft regulator. The design of this device itself is quite simple. In addition to the drive, the draft regulator body contains a rod and a small submersible sleeve with gas.

When the temperature of the coolant changes, the gas expands or vice versa, and the sleeve pushes out or pushes in the rod to which the lever is attached. When rising or falling down, a lever with a chain automatically adjusts the draft by opening or closing the blower door.

The operating temperature range of the draft regulator is in the region of 30-90ºС, which allows you to effectively control the process of the firebox, boiler or furnace.

Design and principle of operation

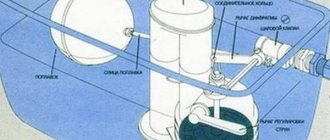

The device diagram is quite simple. The main structural elements are:

- temperature control handle;

- rod and guide;

- actuating mechanism;

- immersion sleeve;

- temperature sensitive element;

- spring;

- drive lever;

- handle and lever mounting screws;

- chain.

The main component is a sensor that responds to temperature fluctuations. It interacts with a spring, which, when heated or cooled, activates the working part (sleeve and rod).

That, in turn, is connected through a mechanical drive to the fuel compartment flap. The draft regulator for solid fuel boilers, under certain conditions, opens and closes the door, maintaining the set temperature.

The principle of operation of the device is banal, but still effective. When the damper opens slightly, more air enters the firebox. Due to this, fuel combustion occurs more intensely, more heat is released, and the room is heated more efficiently. When the valve closes, the fuel is less supplied with oxygen and barely smolders.

If we briefly describe the operation of the draft regulator, based on design features, we get the following diagram:

- when the heat load decreases, the thermostatic sensor reacts to fluctuations;

- the sensor increases the spring tension;

- the spring lifts the lever;

- the damper opens;

- the combustion intensifies.

To reduce the intensity of the process, the steps are performed in reverse order.

The regulator body has a handle with a temperature scale. This sets the required minimum value. The temperature will rise as necessary, but will never fall below the set level.

On the regulator body there is a handle with a temperature scale, so the required minimum value is set.

What is a chimney draft stabilizer and how does it work?

The device is a mechanism that provides dosed air supply for optimal traction in automatic mode. The chimney stabilizer is equipped with a safety valve, which eliminates the risk of overpressure. The operating principle of the regulatory mechanism is as follows:

- if the gas flow rate is excessive, the damper in the draft compensator is activated, which causes partial cutting off of the jet;

- the valve position is maintained until the temperature in the furnace drops to optimal values;

- after the temperature is adjusted, the damper returns to its original position.

The formation of high draft in the chimney is due to climatic and daily changes, atmospheric pressure, significant temperature changes and other factors. The increased intensity of flows in the smoke channel negatively affects the operation of the system - the efficiency of the heat generator decreases and fuel costs increase. To eliminate problems with pressure in the chimney pipe, a draft stabilizer is needed.

Automatic pressure compensators in the smoke exhaust duct are a universal device for all categories of heat generators. The design is made of stainless steel and has compact dimensions. The device is distinguished by its relatively simple mechanism, ease of installation and maintenance. Often, to install autonomous heating systems, they make a draft stabilizer with their own hands.

Chimney draft stabilizers

Setup and calibration

The device built into the case needs to be configured. This is done as follows:

- the ash pan door opens almost completely;

- the locking screw on the regulator handle is loosened;

- the required temperature regime is set on the handle (60° is suitable for a start);

- the chain is attached to the lever;

- the boiler heats up to the set temperature (the boiler thermometer will indicate when it is reached);

- the door is closed, it is necessary to leave a gap of 2 mm;

- the end of the chain is attached to the door handle so that the free play is about 1 mm;

- The fixing screw on the regulator handle is tightened.

You can make sure that the draft regulator is adjusted correctly by changing the temperature conditions. To do this, the thermostat is turned to 80°. If the previously described steps are performed correctly, the damper will open, air will flow in, and combustion will intensify. Having reached the set temperature, the regulator will close the door again, leaving a gap of 2-3 mm.

It is advisable to adjust and calibrate the traction control more often. All devices have an error - this one is 5%. This is a non-critical deviation, but it is still worth checking the correct operation of the device from time to time.

Advantages and disadvantages

Equipping a heat-generating unit with a draft regulator is considered the most effective way to ensure uniform combustion of fuel. This is the key to energy conservation and significant savings in fuel resources. Also, among the advantages of installing a pressure stabilizer in the chimney, the following points are noted:

- the efficiency and safety of the system as a whole is ensured, since the fuel burns evenly and overheating of the chimney is eliminated, which leads to an increase in its service life;

- The efficiency of heating equipment increases, the level of heat loss is leveled, energy savings are up to 15%;

- eliminates the possibility of smoke and fumes entering the room;

- The level of emissions of harmful compounds into the atmosphere is qualitatively reduced.

We are also impressed by the equally impressive capabilities of the chimney stabilizer both with natural draft and with forced draft.

It is noteworthy that the automatic draft force regulator allows you to connect new models of boilers of low-temperature categories to the old chimney system.

Advantages and disadvantages of draft regulators

These devices have both advantages and disadvantages.

We recommend: Carbon heated floor: how it differs from the rest

Among the advantages are:

- Low price for devices. Their cost depends on the manufacturer and model.

- Mechanical draft regulator for solid fuel boilers - the draft regulator functions autonomously, regardless of electricity.

- Fuel for it is available.

- Works for a long time and with high quality.

There are also disadvantages:

- Fuel lasts for a short time.

- Download it yourself.

- Additional space is needed to store fuel.

If you plan to purchase a solid fuel unit, then after connecting it to the heating system, the question will certainly arise of how to configure the draft regulator for solid fuel boilers correctly, since this affects efficiency and fuel consumption. It is better to entrust this to a specialist.

If you adjust the traction manually

The amount of air passing through the solid fuel combustion chamber, and therefore the strength of its combustion (power output), can be adjusted manually by opening or closing the ash cover (air damper). Those. The boiler needs to be constantly monitored.

Without automation, it is quite possible that a lot of fuel was added and maximum air was given so that it flared up faster. Then the boiler was left unattended for any reason, and when attention was paid to it, it was discovered that the temperature of the coolant was already 100 degrees, the safety valve was hissing, there was a roar in the boiler - steam was escaping into the system...

- Monitoring the operation of a boiler is fundamentally different from servicing a large heat-intensive furnace without a water circuit. With a stove, you can forget about an open damper, since all the energy from adding fuel will be spent on heating a large, heavy structure and overheating the air in the house. Any massive oven is designed for this. In the boiler, power is drawn by a moving coolant, and if there is too much heat, the liquid will boil and the boiler will overheat….

Features of choice

Since the boiler is not supplied with a regulator from the factory, when choosing a heating device you need to pay attention to the presence of a sleeve for the accessory on top of the body. The latter is mounted inside the water jacket and can be in three positions - side, front, top.

The second requirement for the boiler is the ability to open the ash pan door upwards. Without this feature, the regulator cannot be configured.

In addition, it is recommended to consider the following parameters:

- the power of the device must be sufficient to easily lift the ash pan door;

- desired range of maintained temperatures (usually 60-90° C);

- the external thread of the regulator matches the internal thread of the sleeve;

- The angle of rotation of the lever allows you to fully open and close the door.

The design of boilers is usually such that the action of the regulator is limited in space, and this must be taken into account when choosing the location for installing the heating system. However, there are heating devices in which it works in any position.

Types of regulators and features of choice

If the solid fuel heater is not equipped with a draft regulator as standard, you will have to install the device yourself.

A prerequisite for this is

- the presence of a special sleeve mounted in the water jacket (the sleeve can be located on the top, front or side of the body);

- ash pan door opening upwards.

The type of device depends on the location of the sleeve - models are available that work only in a vertical position (mounted on top of the body), only in a horizontal position (mounted on the front or side panel) and universal.

On the left is a boiler with the ability to install a regulator, on the right is with manual control

When choosing a model, pay attention to the following parameters

- the force that the drive develops (the value is indicated in the passport, it should be sufficient to lift the ash pan door);

- temperature range for heating the coolant (60-90°C);

- the operating stroke of the drive (it should be sufficient to fully open and close the damper);

- type of threaded connection on the body - it must match the thread in the boiler unit sleeve (usually 3/4″).

The design of the draft regulator may provide for the repair or replacement of the actuator without dismantling the device itself and draining the coolant from the water jacket of the boiler. For such models, the immersion sleeve is removable.

Article on the topic: Mounting for heating radiators made of cast iron, steel, aluminum and bimetallic batteries

How to check traction

Before igniting a boiler, stove or fireplace, the draft force is checked to prevent smoke in the room in the following cases:

- bad weather outside - strong wind, snowfall, fog, rain;

- no one was in the house for a long time, the heating was not used;

- indoor temperature is lower than outside;

- there are doubts about the correct operation of the chimney.

If no sudden smoke occurs after ignition, it is worth observing the combustion for a while. This will allow you to identify problems with the circulation of gases in the chimney, including early detection of weak draft, which can quickly turn into reverse.

Ways to check the direction and force of traction:

- Use an anemometer - a device for measuring the pressure created by the air flow at the inlet and outlet of the chimney. Readings from 10 to 20 Pa are considered normal.

- Bring a sheet of thin paper, a napkin, a thin ribbon or a bag to the open firebox, holding it by one edge. If there is no draft, the object will remain motionless; with good draft, it will deviate towards the heating device, with reverse draft - in the opposite direction.

- Use a burning match, torch or candle to check. With reverse draft, the flame deviates away from the firebox; with correct draft, it bends towards the firebox and goes out; in the absence of draft, the flame remains even.

Note! This method cannot be used to test gas boilers and burners. In the event of a gas leak, a flaming object placed near a heating device may cause an explosion or burns.

- Bring the mirror to the open firebox - if droplets of moisture appear on its surface, it means that the removal of smoke is difficult.

- Look at the color of the flame: a golden-yellow flame indicates normal draft, white – excessive draft, and orange-red – insufficient draft and the possible occurrence of reverse draft.

Excessive draft is not life-threatening, but it reduces heating efficiency - too much air flow draws heat out of the room. In addition to the color of the flame, excess draft can be recognized by humming and humming in the heating device and chimney.

Automatic traction control ensures safety

Almost all solid fuel boilers are equipped with equipment that regulates the amount of air passing through the firebox, maintaining the power level at approximately the same level as set by the consumer.

- Typically, air adjustment is done according to the temperature of the coolant, for example, + 70 degrees C, while the device reduces the boiler power (reduces the amount of air) when such a temperature is reached or exceeded.

This sets the upper power limit; if it is exceeded, the air supply is reduced, and the amount of energy released during combustion is reduced accordingly. The device allows a person not to monitor the operation of the boiler and makes the heating process semi-automatic.

- A draft regulator is required to be used as one of the devices that ensures safe operation. What types of air regulators are there?

Operating principle of the draft regulator

Mount the combustion regulator for a solid fuel boiler directly into the chimney. Its functional purpose is to supply air to the firebox. In the event of a sudden burst, it protects the heating system from blowing out the flame in the firebox. If there is a lack of oxygen, it ensures its supply in order to ensure uniform combustion of solid fuel.

The operation of the regulator is based on the thermomechanical principle. Its design is a sealed cylinder. When the coolant heats up to the desired temperature, a signal is sent to the damper, which leads to a decrease in the volume of supplied air.

After this, the equipment goes into continuous combustion mode. This device is suitable for all solid fuel units. There is no dependence on the type of fuel used.

Function of regulators

The temperature regulator performs a very important function in solid fuel boilers. All units using wood or coal must have a water jacket. If the water temperature is not regulated, it will simply boil, so mechanical or automatic regulators are a very important and necessary element of a solid fuel boiler.

Automatic temperature sensors protect the boiler from overheating and breakdowns, thereby preventing the boiler from exploding.

If water boils, pressure rises and an explosion occurs. Therefore, if a solid fuel boiler has only a manual damper for temperature regulation, it represents a high-risk device. An alternative is to install an additional container where excess heat will go, but this option is not ideal and may malfunction, although it will somehow protect the boiler from overheating.

An automatic draft regulator for solid fuel boilers will do all the work for a person without his direct participation. At the right time, it will close the damper to the required level and prevent water from boiling in the jacket of the device. It is also necessary to take into account that the temperature will continue to increase for some time, but the process of increasing degrees will stop.

In addition to the main advantages of the draft regulator, there are others:

- Using the regulator you can set the maximum temperature. This is especially convenient in autumn or early spring, when the temperature does not necessarily have to stay within +80...+90°C. You can set it to +60°C, and that will be enough.

- When the damper is closed, the combustion rate decreases, which helps save on fuel. But such actions slightly reduce the efficiency of the device.

Sometimes, as an alternative, a safety valve is installed that opens at high pressure. But this method is not a panacea, since after 2-3 operations the valve often begins to leak due to overload, so the ideal option would be to install a draft regulator on the boiler.

Traction regulator functions

The main task will become clear if you look at the name of the device. If you do not regulate the temperature of the coolant (water jacket), it will simply boil. Without an automatic regulator, you will either have to constantly add liquid or manually control the flow of air entering the firebox.

The traction regulator greatly simplifies the life of private home owners. In addition to control, it performs two more useful functions:

- setting and maintaining the maximum permissible water temperature without boiling (up to 90° C; this is especially true in autumn or early spring);

- fuel economy (when the damper is closed, the intensity (speed) of firewood combustion decreases (albeit due to a decrease in boiler efficiency)).

Installing a draft regulator on a solid fuel boiler involves certain costs. To save money, some use a safety valve for similar purposes. For some reason it is considered an analogue of a regulator.

The solution is not the most rational, since after only 3-4 operations (turning off the boiler if there is a risk of overheating and reactivating it if there is excessive cooling), the accessory begins to leak.

Tips for choosing a device

Specialized stores have a huge selection of solid fuel boilers. And, oddly enough, even today you can find models without automation. Most of these “ancient” devices are equipped only with a sleeve mounted inside the heat exchanger. Installation of a draft regulator on a solid fuel boiler of this type is mandatory. This will prevent the temperature from rising to critical levels and will make the structure safer.

In this regard, it is necessary to pay attention to the presence in the design of a sleeve and a flap that rises upward.

When choosing a mechanized draft regulator, you must adhere to the following recommendations:

- the thermostat power must correspond to the weight of the sash in order to successfully lift it;

- it is better to choose the ability to regulate the temperature in the range from +60 to +90°C;

- the angle of rotation of the lever should be enough to fully open and close the sash;

- The threads in the boiler must match the threads of the draft regulator in order to freely fasten the two parts together.

The heating process using modern mechanized and automatic draft regulators has become easy and convenient today

When choosing a regulator, you should also pay attention to the position in which it can operate, since the sleeve can be located on the side or on top. There are models that can work in any position.

Why are regulators needed?

Unlike any wood-burning stove, a hot-water solid fuel boiler is equipped with a water jacket and cannot heat up to too high a temperature, otherwise the water in it will simply boil. In such cases, the resulting steam sharply increases the pressure in the system, causing an explosion. That is, a solid fuel boiler, whose power is manually regulated by the ash pan door, is a source of increased danger.

Note. At the very least, the boiler, without any automation, can work together with a buffer tank - a heat accumulator, whose volume is correctly calculated. Excess heat will go there if you did not close the door in time and did not limit the flow of air into the firebox.

An automatic chimney draft regulator, which you can install on any solid fuel boiler yourself, will supply air for you and much better than you. It will react in time to an increase in the temperature of the water in the boiler jacket and shut off the air supply to the chamber if the firewood gets very hot. Although, by inertia, the temperature will rise for some time, but in general the heating process will stop. In addition to ensuring safety, a mechanical boiler draft regulator helps solve the following issues:

- Does not allow the coolant temperature set by the user to be exceeded. It is not always necessary to accelerate the boiler to 80...90 °C; in spring or autumn, 50...60 °C is quite enough for heating.

- By covering the damper and air supply, the draft regulator increases the burning time of the boiler from one tab. But we must admit that the fuel combustion conditions worsen, and the efficiency of the heater sharply decreases.

Almost any solid fuel boiler can be equipped with 2 types of temperature controllers - mechanical (on the left in the photo) or electronic (on the right).

You can argue that any solid fuel heat generators should be connected to the heating system using a safety valve set to emergency pressure. If it overheats, the valve will work, release steam and no explosion will occur. So the draft regulators seem to be of no use. The statement is only partly true, since without automation the heater will often reach a critical temperature, and the valve will simply leak after 2-3 operations. Yes, and controlling the water temperature manually is quite difficult.

Do-it-yourself installation and calibration of the draft regulator

The simple design allows you to install the device yourself. If we consider the boiler from all sides, in projection, then the front or side surface of the unit is selected to install the regulator. For this purpose, the product has a special hole. The regulator is mounted using a threaded connection. The diagrams show how to install the regulator and how not to install the device.

Note: In this case there can be no middle solution. As indicated in the instructions, this is how the draft regulator is installed on a solid fuel boiler.

Correct installation is determined by aligning the device vertically and horizontally. After the regulator is installed, all rotating elements are tightened, the existing interfaces are subject to sealing with a special heat-resistant compound. The lever is placed in a position so that the hole through which the chain will pass is above the damper, in a vertical position.

If the first stage is quite clear and simple, then subsequent actions require special attention, accuracy and consistency of actions. Calibration of the regulator is the most important step in its functionality.

Stage one

Having installed the regulator on your heating unit, you can start kindling. Having brought the boiler water temperature to 60 0C, record this same temperature on the flywheel (thermostat) of the draft regulator. The lever at this time must be connected by a chain to the damper.

Important! The chain must be taut and free of mechanical interference from the outside. At the time of calibration, the damper is in a slightly open state, at a distance of 1-2 mm from the edge of the exhaust opening contour. At the adjustment stage, the position of the damper is determined manually by lengthening or shortening the chain.

Having fixed the damper in a certain position, with the regulator set at 60 degrees, we do the following.

Stage two

We turn the thermostat to 80 0C. If you have installed the draft regulator correctly and completed all previous steps according to the instructions, when the boiler heats up to the set temperature, the damper will automatically close. Air will stop flowing into the firebox, and the intensity of fuel combustion will decrease accordingly. The error in temperature measurement accuracy can reach +/- 5 0C, which is not critical for ordinary, simple heating devices of heating systems.

It is necessary to adjust the draft regulator as often as possible. Mechanical damage to the chain or a tightly moving damper can cause a malfunction of the device.

The best known manufacturers and models: characteristics and prices

The market for solid fuel boilers is saturated with a large number of increasingly complex systems for automatically controlling the processes of heat production and hot water supply. They are more accurate and do not require user participation in most operations. However, such systems are becoming increasingly dependent on electricity and increasingly expensive to purchase and maintain. Autonomy, simplicity, quality of modern thermostats and low price make them quite popular and competitive.

ESBE ATA 212

One of the best draft regulators for a solid fuel boiler from a well-known Swedish manufacturer. Operates reliably in the range of 35˚-95˚С, operating temperatures from –20°C to +150°C. Can be used with various antifreezes, allows replacement of the thermostatic element. When used in low temperature environments, it requires heating. Can be installed in any position and does not require service. Inserts into a sleeve with 3/4" pipe thread. Weight 0.38 kg.

Cost: from 2800 rubles.

Regulus RT4

The most popular mechanical draft regulator for boilers burning solid fuel, due to its extreme unpretentiousness, ultra-reliability and low price. The body is made of die-cast brass, which guarantees a long service life. The device can be mounted in a vertical or horizontal position; the temperature level scale allows this. Coolant temperature control range 30–90°C, maximum operating temperature +120°C. Coupling for connection with internal thread G3/4”. Device weight 0.42 kg, manufacturer – Czech Republic.

Cost: from 1500 rubles.

Honeywell FR 124

High-quality mechanical thermostat from Germany, compatible with many boilers of domestic and foreign production. Water temperature control range is from +30 to +90°C, maximum operating temperature is +115°C. Chain load from 100 to 600 grams, lift stroke up to 60 mm. Standard installation in a bushing with a G 3/4″ thread. A special feature of this regulator is the presence of a removable immersion sleeve, to replace which it is not necessary to drain water from the boiler. Device weight 0.47 kg,

Cost: from 1900 rubles.

Installation and configuration

When installing a factory or homemade draft regulator for a boiler, it is necessary to drain all liquid from the water circuit. If the system has shut-off taps, then this is easy to do, and no problems with the installation will arise. If there are no such taps, then all the water or antifreeze will need to be drained.

Installing the regulator in the boiler is easy. It is enough to unscrew the plug from the sleeve and screw the regulator in its place.

To configure the design, you must follow these recommendations:

- Light the boiler.

- Open the door without connecting the regulator chain.

- The handle is set to limit the desired temperature, for example, +80°C.

- When the temperature rises to +80°C, it is necessary to attach a chain to the damper, and it must be closed by a maximum of 2 mm.

- Fix the structure.

Next, the operation of the structure is checked from maximum to minimum temperatures.

Thus, we can conclude that it is better to have primitive automation for a solid fuel boiler than not to have it at all. The device is easy to install, costs little, and protects against explosions quite well.

How to install and configure the regulator

In most cases, installing a thermostat yourself entails emptying the boiler's water jacket. This will not create a big problem if the piping of the solid fuel boiler is done correctly and the water heating system can be cut off with taps. Otherwise, you will have to drain all the coolant. After this, the plug is removed from the sleeve, and the device is screwed in instead and the system is filled with water again.

To adjust the draft regulator, you need to light the boiler and follow the instructions:

- Without attaching the chain to the door, open it to allow air to enter.

- Loosen the locking screw on the adjustment handle.

- Set the handle to the position corresponding to the required temperature, for example, 70 °C.

- Watching the boiler thermometer, connect the chain drive to the damper at the moment when it shows 70 °C. In this case, the damper should be slightly open by only 1-2 mm.

- Tighten the fixing screw.

Attention! It is necessary to ensure that the free play of the chain does not exceed 1 mm.

Next, you should check the operation of the thermostat in all modes, up to maximum. In this case, you need to take into account that some time passes between the moment the damper closes and the drop in coolant temperature and do not rush to reconfigure the device. Solid fuel heat generators are characterized by a delay, because the firewood or coal in the firebox cannot go out at once.

Installation rules

Standard sleeve and adjuster threads are typically 3/4 inch. The accessory does not screw in immediately; first, sealing agents are applied to the threads. FUM tape (fluoroplastic sealing material for sealing pipelines) is often used. You will also need an adjustable wrench and a regular Phillips screwdriver for installation.

Before starting work, the liquid (coolant) is drained from the water circuit. Then the shut-off valves are closed and the plug is removed from the boiler sleeve. FUM tape is applied to the external thread of the traction regulator.

The device twists clockwise quite tightly, but without excessive effort. This completes the installation of the regulator. All that remains is to prepare it for work and launch it correctly.

Ways to normalize cravings

This includes methods for enhancing low steam output and preventing tip-over. Depending on the state of affairs, you can use either one or several of them at once.

Construction changes

If the problem is due to incorrect design or unskilled installation, the defects must be corrected. The most common things you need to do are:

- Increase the height of the pipe (if it is small) so that its top is at least 0.5 m above the roof level. And this is for a separate building. For a house located close to trees or adjacent to other real estate, this figure is already 1.5 m.

- Expand the channel - when you don’t know how to deal with backdraft, simply increase the cross-sectional width of the chimney so that it is no less than that of the boiler pipe. Then the air masses will circulate more actively.

- Remove too long (longer than 1 m) horizontal sections of the sleeve, replacing them with inclined sections running at an angle of 30°, get rid of 90° turns in favor of 45° transitions.

Using a regulator (stabilizer)

The configuration of the smoke exhaust system largely depends on the type of heat-generating apparatus with which it is planned to be used. Efficiency is affected by natural temperature fluctuations - time of year and weather. In cold weather, significant temperature changes can lead to high vacuum in the chimney. And this will lead to decreased operating efficiency and increased fuel consumption. The regulator stabilizes the pressure to the optimal value and thereby increases the efficiency of the heating device.

Air pressure can also cause back draft in the chimney. It is determined by location (in the mountains, for example, lower than at sea level) and time of day, weather conditions, season - in summer, air pressure is higher than in winter. Thus, the difference between air pressure on a cloudy April day and a clear day in September can be up to 90 Pa.

Deflectors

These are simple but effective devices that deflect air flows that are reflected by trees, walls of neighboring buildings (and other tall objects), and thus prevent the exhaust gases that escape from reentering the pipe. They help to normalize (usually reduce) pressure and increase the aerodynamic effect, and are easy to install. They give results even in strong winds, but in calm conditions they are practically useless, and this is their main disadvantage.

Ferrum produces both a windproof and a regular umbrella, which will also help cope with precipitation and wind, and prevent the draft from tipping over.

Weather vane deflector device

This is a kind of hybrid of two devices, taking the best from a reflector and an air flow amplifier.

Consists of 3 components:

- the lower cylinder is a pipe that, after assembly, is in direct contact with the chimney;

- the upper glass with racks as a structure - catches and changes the direction of movement of the reflected gas masses;

- cap (umbrella) - can be flat, semicircular, conical, protects the channel from debris and precipitation.

Installing a weather vane deflector is the answer to two questions at once: how to eliminate backdraft in a chimney when there is wind pressure and how to increase the normal draft by 15-20%. Its installation is not difficult: just drill holes in the pipe and secure the device with screws. To prevent it from dangling, you can lay a clamp. It can be really securely fixed even on brickwork - with the help of adapters.

Stainless steel rotary gate device

A mechanical regulator, most in demand when arranging steel channels for the removal of harmful combustion products. It is a section of pipe through the center of which a valve passes, partially blocking the chimney.

It is very simple to use: turn the axis, slightly open the valve, and release steam, reduce the gap, and the gas exit speed decreases.

Gate and valve made of stainless steel

Advantages:

- high anti-corrosion properties;

- smooth surface that does not collect soot;

- light weight with the strength of even a thin plate;

- variety of handles and flaps;

- Possibility of installation in both steel and brick channels.

Cast iron gate

Its design and operating principle are the same as the rotary one. The difference is in the raw material: it is made of metal that is susceptible to corrosion. Therefore, if you are thinking about how to remove back draft in a chimney mechanically, you can give preference to this regulator. Just keep in mind that it will be heavy, which means it will only be suitable for a channel that can withstand significant weight loads. In general, the material is considered obsolete, so if you have a choice, you should pay attention to a stainless steel sample.

Rotary turbines

A rotary turbine is a device installed at the end of a chimney, which consists of either one or several screws. Turbines rotate under the influence of wind, which in turn creates rarefied air to achieve a significant difference between internal and external pressure. The use of turbines is effective only in windy weather; it is also reasonable to use them when the temperature of the smoke emanating from the chimney is up to 200 degrees.

Revision of the ventilation system

It is necessary to analyze how it is organized, eliminate errors and take measures to eliminate drafts and streamline the masses circulating in the room. It usually comes down to the following steps:

- regular ventilation of rooms (especially those where heating equipment operates);

- installation of window and wall supply valves - to constantly obtain fresh air;

- installation of forced ventilation devices - if previous measures do not help.

The chimney is clogged with soot

Perhaps this is the most common and main reason for deterioration in traction.

During the burning of wood, soot is formed. It consists of particles of combustion products that stick together and settle on the inner walls of the chimney, which leads to a narrowing of its diameter. As a result, air movement becomes difficult.

Therefore, soot must be removed regularly. This way you will not only improve traction, but also increase the operating efficiency and fire safety of the heating device. To make the chimney walls less contaminated with soot, you can use ones that contain less moisture and other harmful impurities.

Do-it-yourself stabilizer assembly

To assemble a chimney draft stabilizer, you need a drawing, and you also need:

- semi-automatic argon welding machine;

- argon cylinder;

- grinding wheel;

- stainless steel AISI 304 or 321 at least 8-10 mm;

- 8-10 mm steel rod for the axle, screws, nuts and washers.

The pipe connection is welded so that the internal diameter is 115 mm. At the same time, the weld seams must be thoroughly cleaned from the outside and inside, and a cut for the valve must be made, which is 15% of the cross-sectional diameter of the chimney pipe.

In the valve area there is a clamp and a rotary shaft, which is equipped with a rotary handle that protrudes 120-150 mm from the pipe. From the edges, at a distance of 25-30 mm, roll out the edges for connection with adjacent pipes.

Installation of the stabilizer is best done in the chimney gap. To fix the device at the top and bottom, clamps 50-60 mm wide are used.

How to make a draft regulator with your own hands

It’s up to you to make a compensator yourself or buy a ready-made one. For convenience, it is worth making a drawing with exact dimensions. You can prepare patterns from whatman paper and use them to cut out parts from a metal sheet.

The stabilizer is made with your own hands from a pipe of a suitable diameter, the material is AISI 304 or 321 stainless steel. You can weld a pipe from a stainless steel sheet, you will need argon welding. Sheet thickness – 1 mm. The internal diameter coincides with the diameter of the chimney. Length – 250-300 mm. The seams must be thoroughly cleaned. A cutout is made for the valve - approximately 15% of the cross-section of the chimney hog.

A rotating axis is installed near the cutout - a rod with a diameter of 8-10 mm; a valve plate is attached to it, covering the hole. To fasten the axle, nuts are welded to the pipe and plate, and the axle is inserted into them. To make adjustments, a counterweight is welded onto the plate - a bolt with a high-height nut screwed on. Near the upper and lower edges at a distance of 25-30 mm from the edge of the pipe, it is necessary to flare grooves to fix the stabilizer. The device is attached to the chimney with wide clamps.

The technology for making a homemade regulator can be seen in the video:

Damper

It is an ordinary valve that partially or completely covers the cross-section of the pipe. The simplest option is a transverse valve (as in classic Russian stoves or fireplaces).

Another option is a disk inside the case. The circle is attached to a transverse rod, through which the position of the damper inside the pipe is set. A significant disadvantage of both devices is manual adjustment, which requires almost constant monitoring of the boiler operating mode.

"Fungus"

It is made in the form of a cone-shaped insert into the main pipe. Outwardly it resembles an umbrella. A temperature sensor is installed inside the structure, which monitors the temperature of the gas flow. When reverse draft occurs or during unstable conditions, waste combustion products accumulate under the “umbrella”. There is a general increase in the thermal background. The sensor is triggered and sends a signal to the natural gas supply control device. The boiler turns off.

Ways to increase chimney draft

The purpose of the draft regulator is to extinguish excessive vacuum in the chimney. The stabilizer cannot increase traction. What to do when traction is clearly insufficient?

To increase traction, do the following:

- They check whether the chimney duct is clogged with soot and clean it.

- Check whether there is air access into the room or an air supply from the street to the furnace of the heating unit. If necessary, open a window or install a pipe to take in clean air from the street.

- They analyze whether the pipe is sufficiently insulated and whether the insulation is wet. In the case of modern ceramic or sandwich pipes, the insulation can be considered sufficient; when insulating steel pipes with your own hands, unpleasant surprises are possible. It is also advisable to insulate traditional brick pipes.

- Find out if there is a deflector on the top of the pipe. Often installing a deflector solves the problem.

If all your searches have not led to a solution to the problem, you should invite an experienced heating engineer - family safety comes first.

If you have changed the heating unit to a more modern one (or moved the stove or fireplace), then you must:

- Calculate the minimum length and cross-sectional area of the hog depending on the power of the heating device (see my article about calculating the chimney).

- Consider the required height of the pipe depending on the location relative to the ridge and the zone of wind support of tall buildings and large trees.

- If the chimney is of insufficient height and cross-sectional area, then either build it up or install a smoke exhauster - a special fan. It is installed on the head of the pipe.

- If the old pipe has a cross-section much larger than the design one, this problem can be eliminated by using a gate valve or installing a liner. If the pipe is too long, you can also use a gate.

When replacing an old stove or fireplace with a modern boiler, the pipe will most likely have to be upgraded, since modern boilers have high efficiency, aggressive condensate and low flue gas temperatures. Even modern solid fuel units have a lower smoke point than older wood stoves.

Modernizing chimneys is a very complex process, but with careful attention to the matter, you can calculate the necessary changes and improve the situation.

Afterword

The safe operation and efficiency of stoves and boilers is highly dependent on the presence or adequate draft in the chimney. In case of even minor problems with the smoke removal system, it is necessary to inspect the chimney for permeability and begin to normalize the draft. The presence of carbon monoxide indoors is very dangerous to human life. Carrying out repair work and installing a stabilizer on your own is quite possible.

Sources

- https://zen.yandex.ru/media/id/5b02bffd8c8be3dd3cd115f1/5e39392e5b4a3e23cf825f88

- https://pechiexpert.ru/stabilizator-tyagi-dymohoda-01/

- https://livelyday.ru/teplodom1.ru/kotly/2229-reguljator-tjagi-dlja-kotla-zachem-nuzhen-kak-primenjaetsja.html

- https://www.teplodar.ru/help/articles/detail/regulyator-tyagi-dlya-tverdotoplivnykh-kotlov/

- https://www.tproekt.com/nuzen-li-siber-ogranicitel-tagi-na-dymohode-kotla/

- https://kaminguru.com/kotel/kak-ustanovit-reguljator-tjagi.html

- https://ZnatokTepla.ru/kotly/tverdotoplivnie/regulyator-tyagi-dlya-tverdotoplivnyh-kotlov-ustrojstvo-i-montazh.html

- https://feflues.ru/blog/problemy-dymokhoda/kak-ustranit-obratnuyu-tyagu-v-dymokhode-prichiny-vozniknoveniya-v-pechi-i-chto-delat-chtoby-izbezha/

- https://domsdelat.ru/otoplenie/obratnaya-tyaga-v-dymohode-i-chto-takoe-stabilizator-tyagi-dymoxoda-prichiny-i-ustranenie.html

- https://vseotrube.ru/ventilyatsiya-i-dymohod/stabilizator-tyagi

- https://otoplenie-guide.ru/oborudovanie/pech/stabilizator-tyagi-dlya-dimohoda

[collapse]