04/15/2021 Author: VT-METALL

Issues discussed in the material:

- Operating principles of semi-automatic welding

- 5 basic parameters for setting up welding equipment

- Tables of semi-automatic welding modes

A high-quality output product can only be obtained by correctly setting up semi-automatic welding modes. And if experienced specialists do not experience any problems with this, then for beginners such a task can cause certain difficulties.

However, not everything is so sad. In the vast majority of cases, everything is solved with the help of “cheat sheets” - special tables that contain the necessary data. Although both practice and theoretical knowledge in this matter are also of great importance.

Operating principles of semi-automatic welding

Semi-automatic welding is a type of arc welding and differs from it in that the process is carried out by automating the supply of electrode wire into the weld pool and the simultaneous exposure of it to shielding gas. The remaining operations are performed manually. The gas used in welding is intended to completely protect the heated and molten base materials and electrodes from exposure to air, which can not only slow down the process, but also stop it completely.

When welding metals, the key task is to maintain a certain temperature regime. Insufficient heating of the seam will not ensure high-quality melting of the edges of the workpieces being welded and mixing them with each other and with the filler material. When the temperature rises, the metal boils and evaporates, which causes chemical reactions with atmospheric gases. What complicates the situation is that for some metals and alloys such processes can begin to occur even at temperatures below those required for the formation of a high-quality weld.

We recommend articles on metalworking

- Steel grades: classification and interpretation

- Aluminum grades and areas of their application

- Defects in metal products: causes and search methods

When using different types of welding equipment, this problem is solved in different ways. The semi-automatic welding we are considering today, which is also called MIG/MAG, has two technological distinctive points. The first is that the shielding gas is supplied directly to the melting zone, and the second is that the installation is equipped with automatic adjustment to regulate the feed rate of the filler material and change the strength of the welding current.

The welding wire is fed using a broaching mechanism, for which, before performing the operation, it is necessary to calculate the semi-automatic welding modes, taking into account the correct ratio of speed and melting temperature, in order to ensure uniform filling of the seam and high productivity.

The function of a protective medium can be performed by active gases (hydrogen, nitrogen or oxygen) or inert gases - argon or helium. In industrial production, a mixture of carbon dioxide and argon is predominantly used in a ratio of 1:4, which is quite sufficient for standard processes. When welding specific materials, for example, duralumin, brass or high-alloy tool steels, it is necessary to vary the ratio of the mixture composition.

Despite the fact that consumables (welding wire and gas) are expensive, mastering semi-automatic welding is the best option for beginners for two reasons. The first advantage is the ease of performing the weld; to do this, you just need to read the reference documentation and use it to set the required technological parameters of the inverter for a specific type of welding joint.

The second advantage is ergonomics, that is, complete visual control of the condition of the seam, the ability to use any spatial position and, most importantly, the feasibility of the weld even on very thin-walled parts.

Stationary arc welding

Random fluctuations in the electrode wire feed speed and arc length can disrupt the stability of the process and lead to short circuits. arc breakage. To avoid this, it is necessary to change the melting rate of the electrode, i.e. Vary the welding current accordingly.

The current-voltage characteristic of the arc (volt-ampere characteristic of the arc) in protective gases with a consumable electrode has an increasing character.

At a certain point in the stable welding process, the electrode wire feed speed Vп1 is equal to the melting speed Vpl1. In this case, the current and voltage parameters were determined by the operating point A1 with arc length ld1. Let us assume that due to malfunctions in the wire feed mechanism, the feed speed has decreased. Then a relative melting rate ΔVmel = Vmel1 - Vп2 arises, which leads to the movement of the operating point to a new position - A2. It is characterized by a decrease in welding current (Δl), which leads to a decrease in the initial melting rate. The welding process returned to point A1 with arc length ld1. This process is called self-regulation along the arc length. It becomes more intense with a more rigid voltage-ampere characteristic of the power source.

When welding from a source with a rigid characteristic, the welder adjusts the current mode by adjusting the wire feed speed. However, this changes the length of the arc and the voltage on it. To maintain the required arc length, when setting the mode, you should adjust the current-voltage characteristic of the power supply, moving from one (I) to another (II).

The stability of the arc, especially in the ceiling position, as well as the size of the weld and its quality depend on the type of transfer of electrode metal through the arc gap. There are three types of transfer.

1. Large droplet transfer with arc short circuits. Droplets are formed 1.5 times larger than the diameter of the electrode wire. The process is accompanied by short circuits with a natural pulse-arc process determined by the mode parameters. The voltage on the arc periodically decreases to 0 and at the moment of drop separation it increases to the operating value. The current at the moment of a short circuit increases, which leads to the detachment of a drop of electrode metal.

The process proceeds with metal spattering, which worsens the appearance of the welded joint, leading to lack of penetration and excessive convexity of the seam.

2. Medium drop transfer without short circuits.

The arc burns continuously, and the electrode metal is transferred through the arc in droplets whose diameter is close to the diameter of the wire.

Welding occurs with periodic changes in arc voltage and welding current.

The pulse-arc process depends on the parameters of the welding mode and is also accompanied by spattering, which reduces the quality of the weld.

3. Jet transfer.

The arc burns continuously, the melted end of the electrode is extended into a cone, from which drops measuring less than 2/3 of the electrode diameter flow into the weld pool. The mass of the drop is small, so the electrode metal is easily transferred to the pool during welding in all spatial positions.

Spattering during jet transfer is negligible. Productivity is high. Jet transfer can be obtained in argon. In carbon dioxide, this transfer is achieved at high welding current densities or with wires activated by rare earth elements

Controlled transfer of electrode metal with the required droplet sizes is successfully achieved using a pulsed-arc process, when the arc voltage and welding current are periodically changed.

Tables of semi-automatic welding modes

As mentioned above, the experience and knowledge of experienced welders will allow them to set the correct welding modes without hesitation. But what about those who have only recently begun to master this specialty? There are special tables for setting modes for each type of welding. But you shouldn’t always use ready-made data; you need to experiment in practice and not be afraid to apply your accumulated experience and knowledge.

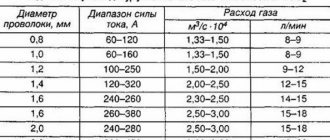

Table No. 1. Preferred settings for the formation of a butt weld in the lower spatial position, as well as for welding low-carbon and low-alloy steels in a shielding gas environment (carbon dioxide, a mixture of carbon dioxide with oxygen and carbon dioxide with argon) using reverse polarity current.

Table No. 2. Recommended semi-automatic welding modes for forming rotary butt joints using carbon dioxide, a mixture of carbon dioxide and argon; argon with carbon dioxide and oxygen, in relation to a current of reverse polarity.

Table No. 3. Preferred semi-automatic welding modes for forming an overlap weld using carbon dioxide or a mixture of carbon dioxide and argon with a reverse polarity current.

Table No. 4. Preferred parameters of the semi-automatic welding mode for carbon steels in a vertical spatial position with reverse polarity using carbon dioxide or a mixture of carbon dioxide and argon.

Table No. 5. Preferred semi-automatic welding modes for horizontal connections using reverse polarity with protective carbon dioxide.

Table No. 6. Recommended semi-automatic welding modes for forming ceiling seams with reverse polarity using carbon dioxide.

Table No. 7. Recommendations for setting semi-automatic welding parameters in a carbon dioxide environment when working with carbon steels.

In conclusion, I need to give one piece of advice. If you unconsciously copy the average parameters of equipment settings given in tables and reference technical literature, you may encounter some inaccuracies and even typos. It is important for a welder not only to blindly duplicate recommendations, but also to approach each specific task creatively, with the necessary scrupulousness and increased attention to detail. This will be a guarantee of high-quality work.

Synergetic management

Inverter power supplies allow you to accelerate changes in current parameters up to 1000 A/ms. The high speed of the source contributes to the optimal choice of pulse and pause currents, pulse and pause time, pulse frequency depending on the wire feed speed. This ensures stable transfer of a drop of electrode metal in one pulse.

In modern semi-automatic machines, microprocessor technologies have been introduced to control pulsed welding processes, depending on the steel grade, wire diameter, and type of shielding gas. Such systems are called synergetic.

Thanks to the pre-programming of pulse modes, only two parameters are regulated during welding: welding current and arc length . Synergetic equipment easily adjusts welding modes depending on the grade of steel being welded, the diameter of the electrode wire and the type of shielding gas.

In the synergetic equipment system, optimal welding mode parameters are programmed for various material combinations: carbon steel, stainless steel, aluminum alloys; diameters of solid electrode wire: 1.0; 1.2; 1.6 mm; crater filling time.

For each wire diameter there is a wide range of current mode values, which allows you to weld materials of different thicknesses and in all spatial positions. Synergic systems increase productivity by 20% compared to conventional MIG/MAG welding.

Main settings

The first stage of work is to set up the modes for semi-automatic welding in a protective gas environment. To do this, let’s look at the main components of a semi-automatic machine.

Let's go through the main modes, after studying which you can easily set up semi-automatic welding correctly and avoid making annoying mistakes.

We start with the diameter of the wire. Its size can vary from 0.5 to 3 millimeters. Most often, the wire size is chosen depending on the size of the material you will be working with.

But, regardless of this, each thickness has its own characteristics. For example, if you want to achieve a more stable arc and less metal spattering, professionals recommend working with thinner wire.

It is important to take into account when working with thick material - the voltage will be required much more.

Please note that to work with low-alloy steel, be sure to use wire that contains manganese and silicon. The wire must be with deoxidizers. The same applies to low carbon steel.

Unfortunately, a common mistake beginners make is precisely insufficient attention to the company that manufactures this material, as well as the metals that make up its composition.

Still, it is worth noting that steel in a protective gas environment is most often alloyed, or highly alloyed. The way out in this situation is simple - you need to take a wire that is made of the same material that you are working with.

This is very important, because in case of an error the seam will be fragile, and this will certainly affect the entire result of the work.

Semi-automatic welding

A semi-automatic welding machine is a device in which the role of an electrode is played by a wire fed to the welding site automatically. When welding with a semi-automatic machine, it is necessary to set two speeds. Both are installed by a welder. The first of these is the speed at which the wire is fed. The right choice will ensure a stable burning of the welding arc.

Second, the welding speed depends on the speed at which the torch moves. Thick-walled joints are welded at high speed to form narrow seams. At high speeds, it is necessary to ensure that when the gas leaves the protection zone, there is no oxidation of the end of the wire and the metal surface. Just as with manual arc welding, the current strength and feed speed of the electrode, in this case the wire, must be set by the welder himself, guided by his experience and qualifications. You have to start, in particular, from the type of metals being fused.

Using a semi-automatic welding machine, you can join two metal parts quickly and efficiently. This machine can weld metals of various widths. Compared to manual welding, semi-automatic welding has significant advantages.

Before starting the process, it is necessary to calculate the main characteristics - current, arc voltage and welding speed. The last parameter can be calculated knowing the selected current and voltage, since the semi-automatic welding speed depends on them.

Current and voltage, in turn, are selected in accordance with the thickness of the metal. It turns out that the speed of semi-automatic welding depends on the thickness of the metal.

First, the current strength is calculated using the formula. It is calculated depending on the diameter of the electrode and the current density. Knowing the calculated current strength and the diameter of the electrode, using the formula, you can determine the value of the welding arc voltage. After this, you can select the optimal welding speed.