Copper-plated welding wire SV08G2S ChZSM. Photo Welding Technologies

Welding wire SV08G2S (spelling Sv-08G2S is also acceptable) is one of the most common brands of filler materials. This brand is often called universal, since it is used for welding and surfacing. In addition, it is used in the manufacture of electrodes. Full information is provided below.

Scope, purpose

SV08G2S wire is used for welding low-alloy and carbon steels, which are widely used in various industries: machine, aircraft and shipbuilding, construction, repair of products made from carbon materials.

Copper-coated wire SV-08G2S-O (18 kg; 1.6 mm) CEDAR. Photo VseInstruments.ru

SV082S wire - along with other materials - is used for argon arc welding using automatic machines, as well as when working with semi-automatic machines. It is used for manual welding in argon or a mixture of argon and carbon dioxide.

The wire can be used as an additive to form flux when performing pool welding.

Application area

Sv08g2s wire is used for welding carbon and low-carbon steel grades, which have a wide range of applications. They are used in the mechanical engineering industry, shipbuilding, as well as in construction, for the repair of various products made of carbon steel.

Copper coated wire is especially in demand. This coating significantly increases current conductivity by reducing contact resistance. This makes it possible to maintain a uniform welding arc and improve the quality of the weld due to the absence of oxidation.

VIEW Welding wire on AliExpress 708 rubles → Thanks to the production of products of different diameters, you can select the desired wire section for welding both thin parts and large structures. For example, a 2 mm section is often used when repairing small metal objects and is the most popular in everyday life. Products with a cross-section of up to 6 mm are used primarily in the mechanical engineering field for welding structures.

Copper-plated welding wire SV08G2S is used:

- As a connecting material when carrying out argon arc welding using semi-automatic welding machines, as well as during manual welding in argon or its mixture with carbon dioxide. The wire is introduced into the area of the welded joint, where it melts under the action of the burner flame, and after hardening it forms a single whole with the metal of the parts being connected. Non-consumable tungsten electrodes are used for argon arc welding.

- As an additive for the formation of flux when performing welding. When the wire and welded ends of the metal melt, the slag that rises up after the melt cools forms a protective film and protects the weld area from oxidation. In addition, with the help of welding wire, an improvement in the weld can be achieved through additional alloying.

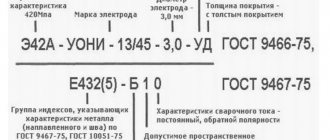

Decoding the brand

SV08G2S stands for as follows:

- SV – welding;

- 08 – carbon content, % – 0.08;

- G – presence of manganese in the composition;

- 2 – amount of manganese, in% – 2;

- C – the presence of silicon in the composition, since there is no number after the letter “C”, this means that the silicon content does not exceed one percent.

Reference. Manufacturers produce two modifications of wire: copper-plated and uncoated. The marking of the first variety contains the letter “O”.

Copper-plated welding wire is also in high demand, since its use results in slight wear of copper tips and an increase in conductivity, which ensures arc stability and increases the strength and durability of the weld. It is important not to confuse copper coated steel wire with all copper consumables.

Characteristics

Copper-coated wire SV-08G2S BARS. Photo VseInstruments.ru

Technical characteristics are determined by several parameters depending on the further use of the wire (welding, surfacing or electrode production):

- The tensile strength varies from 882 to 1030 MPa, depending on the diameter of the material. If the wire is used for the production of electrodes, then this figure is reduced by about 10%.

- Heat treatment , the most common method is quenching in oil at a temperature of 880-920 degrees and gradual cooling in air. As a result of this procedure, the wire becomes more elastic , the tensile strength is reduced to 430-450 MPa, which makes it possible to produce electrodes of complex configurations from the material.

- Any surface defects of the material are not allowed, with the exception of dents and scratches formed during drawing. But they should not occupy more than 5% of the surface area.

Mechanical

After manufacturing, the wire must undergo a tensile test . The following tensile strength indicators are allowed (Sv kgf/mm2):

- value Sв for wire with a diameter of up to 1.5 mm. should be in the range from 90 to 135;

- for 1.6 mm. – 90-130 (for surfacing) and 70-100 (for electrodes);

- for 2.0 mm. – 80-120 (for surfacing), 70-100 (for electrodes);

- for wire with a diameter over 2.0 mm. – 70-105 (for surfacing), 65-95 (for electrodes).

also include :

- relative elongation rate – at least 30%;

- yield strength value – from 415 to 440 MPa;

- impact strength indicator: at 40° degrees – 56 J/cm2, at 20° – 69.

Reference. Characteristics of other types: titanium, stainless steel, powder, aluminum, as well as wire grades: VT1-00Sv and PANCH-11 are presented in separate articles.

Chemical composition

Welding wire JULI SV08G2S. Photo Welding Technologies

The chemical composition of materials for welding is determined by GOST 2246–70. In accordance with Gosstandart, the wire contains the following elements:

- carbon (C) – 0.05-0.11;

- silicon (Si) – 0.7-0.95;

- manganese (Mn) – 1.8-2.1;

- chromium (Cr) – no more than 0.2;

- nickel (Ni) – no more than about.25;

- sulfur (S) – no more than 0.025;

- phosphorus (P) – no more than 0.03.

Wire without copper coating may contain copper, no more than 0.25%. GOST allows for a nitrogen content of no more than 0.01.

Alloyed wires containing vanadium, aluminum and other elements are not produced.

Why should you know the deposition rate?

When performing surfacing work, the specialist must know what the welding coefficient of the wire he is using is. It should be understood as a value that describes the metal deposited over a specific time at a certain current strength. The deposition rate of hardware is usually at least 8.5 g/A*h . Its usual value depends on:

- chemical composition of hardware;

- type of product coating;

- polarity and type of current used to perform surfacing.

The productivity of surfacing operations largely depends on the surfacing coefficient of SV08G2S hardware. This indicator also affects the number of weld losses due to evaporation, as well as spatter and oxidation. Another indicator under consideration determines the melting coefficient of the base metal, as well as a number of other important characteristics and welding operations.

Deposition rate indicator

When performing surfacing work, it is important to know the surfacing coefficient of a certain grade of material. This indicator demonstrates the amount of deposited metal formed over a certain period of time - per hour and at a specific value of welding current.

Welding wire SV08G2S has a deposition rate of at least 8.5 g/A*h. This indicator depends on the composition of the chemical elements of the wire, its type (copper-plated or uncoated), the nature of the current during the work; in the case of alternating current, its polarity is also important. This parameter is fundamental when calculating the consumption of materials for welding.

Deposition coefficient indicator sv08g2s

When welding, the success of the work and its speed largely depend on the wire deposition coefficient.

It denotes the amount of metal deposited per unit time at a given current value. For sv08g2s it can be at least 8.5 g/Ah and depends on the composition of the chemical elements of the wire, its type (copper-plated or uncoated), as well as the nature of the current during the work (direct or alternating, in this case its polarity is important) . The deposition rate of the wire affects the speed of welding, the loss of the consumable electrode during evaporation (evaporation rate), spattering of the melt, as well as the oxidation of the alloy.

The value of the melting coefficient of the metal being joined also depends on this indicator. And this affects the quality of the weld and its strength.

Certification, GOST

The chemical composition and properties of the wire must comply with GOST 2246-70 . Materials for welding undergo mandatory certification and certification by the Welding Association NAKS. Some manufacturers provide certificates on official websites, thereby demonstrating compliance with the standard and high quality of the filler material.

Welding wire Sv-08G2S-O Fubag. Photo VseInstruments.ru

Requirements for delivery conditions

In addition to the requirements for the chemical composition, properties of the wire and packaging, which are presented above, “claims” are also made regarding the conditions of supply of filler materials.

- Finished products are packaged in skeins. If there is permission from the consumer, then the welding wire is supplied in coils or cassettes . Large diameter products are sold in sealed packages without being wound onto reels.

- At the same time, an important requirement is that the wire should not have breaks .

- Winding is done in tightly even rows. The possibility of unwinding or unraveling of the material during transportation must be eliminated.

- The surface of copper-plated products may sometimes have processing residues in the form of soapy grease upon delivery. This, in accordance with GOST requirements, is permissible in small quantities, but the lubricant should not contain sulfur and graphite.

Requirements for welding wire SV08G2S

State standard 2246-70 records the technical characteristics and chemical composition of products for welding with this hardware. Regulatory documents regulate the content in this material of the following elements in percentage:

- nickel - the amount of this element is up to 0.25;

- chromium – its content does not exceed 0.2;

- manganese - its value can reach 2.1;

- silicon – the content of this element can reach up to 0.95;

- sulfur – in hardware the content of this component can reach 0.025;

- phosphorus - it is contained in this hardware in the amount of 0.03;

- carbon - its value varies from 0.05 to 0.11.

Copper-bonded alloyed wire SV08G2S is usually not alloyed with elements such as aluminum, vanadium and a number of others. Acceptable is the presence of manganese in an amount from 0.65 to 2.1%. Note that this requirement applies only to hardware whose diameter does not exceed 1.4 mm . If ordinary wire is produced, then its copper content cannot be more than 0.25%. Standards allow up to 0.01% nitrogen content. Such hardware is used not only for welding, but also for surfacing.

Currently, hardware of this brand is produced with a cross-section from 0.3 to 12 mm. Finished products are packaged in skeins. The maximum weight of a skein can be up to 30 kg. Copper-clad wire can be formed into coils rectangular in cross-section. Their height is 50-90 mm. The internal diameter of this hardware can vary from 100 to 400 mm. As for the outer diameter, it varies in the range from 175 to 600 mm.

If there is permission from the consumer, then alloyed welding wire can be supplied in coils or cassettes . Moreover, it should consist of segments without breaks. The product is wound in tightly even rows. The possibility of unwinding or unraveling of the material during transportation must be eliminated.

Important Features

For alloyed welding wire SV08G2S, the tensile strength value should range from 882 to 1372 MPa.

Such requirements apply to welding hardware with a diameter of 0.3 to 0.5 mm. For welding wire with a diameter of 2 mm, this requirement is expressed in resistance from 686 to 1029 MPa. Regular and copper-plated wire can be heat-treated if these indicators are not provided by the production technology. residues of a soapy lubricant on its surface . It is worth saying that its presence does not violate the requirements of government regulations. Please note that the presence of substances such as sulfur and graphite is acceptable in the lubricant.

Distinctive features, advantages and disadvantages

Wire ESAB SV-08G2S. Photo 220Volt

Welding wire SV08G2S has the following features that can be considered advantages:

- ensuring a stable welding arc;

- eliminating the possibility of the electrode “sticking”;

- positive mechanical properties, including toughness, high tensile strength

- used in a wide range of welding modes;

- suitable for working with any class of welding machines;

- provides slight splashing of the melt in a gaseous environment;

- allows you to economically use copper tips and re-ignite the arc;

- provides an even, high-quality seam with good edge weldability of the parts being joined, without the presence of pores and foreign inclusions, as well as with a uniform chemical composition;

- low cost;

- absence of copper vapor;

- used for welding in all positions.

There is no information about shortcomings.

Deposition factor

We recommend reading our other articles

- Rules for installing a toilet with your own hands: steps and recommendations

- Tips for purchasing inexpensive furniture

- What is responsible cargo storage

- Differences between pile foundations

During surfacing, the welder must know the welding coefficient of the wire that he is using. After all, this indicator depends on:

- quality of the final product,

- loss of the weld due to evaporation, oxidation, spattering,

- amount of melting of the base material, etc.

Important!

Works with SV08G2S wire in most welding modes.

This coefficient indicates the value that describes the metal deposited in the allotted time at a specific current strength. Wire SV08G2S has a deposition rate within 8.5 g/A*h, however, it may differ for different materials, because this value is influenced by:

- components used during wire creation;

- polarity and type of current used in the work;

- product coating.

Recommendations

When purchasing welding wire, you should remember some rules that will reduce the likelihood of purchasing counterfeit or low-quality products:

- you should purchase materials from manufacturers and suppliers who have certificates that indicate what standards the wire meets and whether it is even genuine;

- It is recommended to buy consumables in large stores; from trusted sellers who are able to provide storage under appropriate conditions.

Assortment, release form, packaging, packaging

Welding wire SV08G2S is available in diameters from 0.3 to 12 mm. The materials are packaged in skeins, the weight of which can reach 30 kg. Copper-clad wire can be formed into coils rectangular in cross-section. Their height is 50-90 mm. The internal diameter of the wire can vary from 100 to 400 mm, the external diameter - from 175 to 600 mm. Reels and cassettes are another type of packaging, their weight is 5 and 15 kg. Sealed packages without winding weigh 80 or 250 kg.

Copper-coated wire SV-08G2S-O KEDR, cassette 15 kg. Photo VseInstruments.ru

Price and release form

Welding wire SV08G2S is made in accordance with GOST 2246-70. The permissible cross-section is from 0.3 mm. It is collected into coils (bundles) weighing 5 and 15 kg. Large-section material is sold in coils and coils weighing 80-250 kg. If the wire is copper-plated, then the coils are most often produced rectangular, up to 50-90 mm in height. Internal diameter – 100-400 mm, external – 175-600 mm.

If there is a certain permission, SV08G2S alloyed wire can be supplied in cassettes or reels. It is wound carefully so that there are no breaks in the thread. The wire is wound in straight rows, one to one, to eliminate the chance of unwinding and tangling during transportation.

The price is affected by the size of the skein, coil, type of wire, and it can range from 100 rubles per kilogram. If you take packs with a large weight, then, for example, wire weighing 250 kg is sold on average for 30,000-40,000 thousand rubles. And, of course, this material can be purchased in bulk. It will be much cheaper, but such a purchase is practiced only in large productions.

Analogs

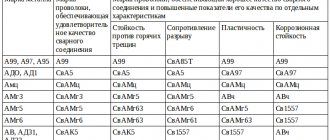

Analogues of SV08G2S include such well-known brands as:

- ER-70-S Fubag;

- ER-49 Bri;

- W10 Weld-Team KFT;

- Novofil G3Si1;

- OK 12.51 ESAB;

- SM-70 HYUNDAI;

- ER 70-6 Prima.

Analogues of SV08G2S-O are ER70S-6 wire, produced by several companies: Prima, DEKA, BARS and others, as well as OK 12.51.

Manufacturers

Several manufacturers, Russian and foreign, produce SV08G2S welding wire:

- ESAB;

- Oliver produces polished welding wire, marking SV-08G2S-P;

- LINCOLN ELECTRIC produces a copper-plated version;

- Golden Bridge.

Application of wire SV08G2S

Also check out these articles

- Advantages of modern vibrating plates

- Features of wildflowers for bouquets

- Professional verification of water meters

- Features of monitoring parameters when drilling a well

In industry, this welding wire is used very often. Moreover, these can be a wide variety of types of industry. It is often purchased for semi-automatic and automatic welding machines. The wire is suitable for welding joints and surfacing.

Most often it is taken:

- when sewing holes between parts of the workpiece;

- to form a bead on the seam.

Often this alloy wire is used as a filler material.

Due to the optimal amount of silicon and manganese in the composition, welding wire SV08G2S is also used for surfacing. It allows:

- obtain a higher level connection;

- reduce the cost of manufacturing welded material;

- achieve a strong seam.

Where can I buy

Suppliers and manufacturers of Sv-08G2S wire, as well as other consumables, are collected in a separate section of our website.

Sections: Welding wire

Tags: alloyed welding wires, wire for argon arc welding, copper-plated welding wire, polished welding wire, steel welding wire

Previous: Deca Welding Wire Next: ER70S Welding Wire