Species that make up

A balanced alloy based on the dominant metal for creating permanent connections between metal parts by introducing a fusible connector with local heating is solder.

Soldering methods, limiting the effect of temperature on parts, mechanical strength of the connection, and resistance to corrosion determine the variety of types.

Technological requirements for filler:

- Free flow after passing the liquidus temperature.

- Wetting of joint surfaces.

- Mechanical stability, limited shrinkage, heat tolerance, immunity to external influences in the solid state, electrical conductivity.

Soft fusible

Domestic solders are named in accordance with GOST . The marking corresponds to the names of the dominant chemical elements that determine the properties of the material. Release form: wire, rods, foil, powders, combined pastes, tubes filled with rosin.

Low-melting solders are alloys with a melting point of 60–4500 C. Low-temperature tin-lead ones have low strength. Used to connect parts that are afraid of overheating. POS compositions are common.

Deciphering the abbreviation: “tin-lead solder.” The digital display indicates the percentage of tin. Common chemical elements in the composition of solders and tinols in addition to lead: antimony, copper, bismuth, arsenic, zinc.

Fusibility of soldering compounds, area of application:

- Wood's alloy - 600 C (tinning boards).

- D'Arsenval alloy - 790 C (radio equipment and electronics).

- Rose alloy – 950 C – (temperature restrictions).

- POSV 33 – 1300 C – (fuse links).

- POSK 50 – 1450 C (semiconductors, copper alloys).

- POS 61 – 1900 C (requirement of increased electrical conductivity).

- POS 30 – 2600 C (soldering, tinning of steel, copper).

- P 250 – 2800 C (aluminum and alloys).

Refractory

Scope of application – industrial soldering of cast iron, dissimilar steels, copper-containing alloys, tombac. Melting point in the range of 400–8000 C. Solder components: copper, silver, nickel, magnesium. The connections are durable.

Abbreviated as PMC (copper-zinc solder), the number indicates the copper content. In total, 3 brands are used, approved by GOST 1534-42: PMC-36, PMC-48, PMC-54. In addition to the main component, zinc is present, 5–7% is iron, tin, and antimony. Melting point 800–9000 C.

There are restrictions on use due to burnout of ligatures . Zinc burns out when leaving the liquid phase, which causes porosity. Destructive consequences threaten:

- Products subject to internal pressure.

- Vibration and dynamic loads.

In this case, soldering is carried out with refined copper at an increase in temperature. Another way is to use low-temperature tin alloys that improve fluidity. Or silicon additives. Silicon prevents the evaporation and oxidation of zinc.

PMCs are produced in rods, strips, and granules. Fluxes for soldering - borax.

PSR (copper-silver) are expensive, high-strength, refractory additives. Unique in maintaining connection flexibility. The range of operating temperatures between the initial PSr-10 in the series and the 92% silver PSr-92 is 720–9500. PSR 72–92 have found application in connecting operations on high-frequency elements.

An alternative to silver is phosphorus . Plastic copper-phosphorus solders, while maintaining similar properties, have the following advantages:

- Cheapness.

- Resistance to corrosion and aggressive environments.

- Fluidity.

- Melting point 700–8500.

- Suitable for joining dissimilar metals, such as copper and steel.

Aluminum soldering is carried out in a narrow temperature range under a layer of oil to restrain oxidation, using ultrasonic soldering irons . Silumin, 34A, P590A, P 575 are used. Alloying elements are silicon, copper, zinc.

Solders and fluxes

To solder, just a soldering iron is not enough. Here I will tell you what else you need to stock up on before starting work.

Solder Solder is a low-melting alloy of metals. In other words, a metal that melts at a relatively low temperature - usually 200...300 degrees. Solder serves as a kind of electrically conductive glue that holds metal parts together. Unlike welding, where bonding occurs due to the interaction of the molten masses of the parts themselves, when soldering the parts are not damaged: only the solder melts. It requires less temperature, less time, consumes less energy and is safer.

There are different types of solders. When installing electronic circuits, soft tin-lead solders are used. The most popular of them is POS-61. The first three letters of the name are translated as Tin-Lead Solder. Next comes a number indicating the percentage of tin in the solder. In POS-61, respectively, 61% is tin, the remaining 39% is lead. Its melting point is 180 degrees.

Below are the melting temperatures of various PICs:

POS30 – 240 POS40 – 210 POS61 – 180 POS90 – 310

In addition to native domestic ones, today there is a lot of bourgeois solder in the bazaar (i.e., market). Don't be afraid of him, he's good too. You just need to consult the seller which one is more suitable for your purposes.

Solder is usually sold in wire form. The thickness of the wire may vary, but I recommend thin: it is more convenient to dose the amount. However, this is not important. If you know how to solder well, then you will not have problems with such trifles.

However, what looks like a wire is not always what it actually is. Very often there is a cavity inside such a wire. This cavity contains some kind of flux, for example, rosin. This is necessary to slow down the oxidation of the solder during the soldering process, but this does not mean at all that a separate flux is no longer needed.

Well, since we’re talking about fluxes, let’s continue about them.

Flux The second material needed for soldering is flux. Note that it has nothing to do with teeth in general and diseased teeth in particular. That's just what it's called.

Flux is a substance that helps remove a layer of oxide from the surface of a metal. On the other hand, flux protects the metal from oxidation during the soldering process and promotes uniform spreading of solder over the metal surface. In general, without flux - nowhere.

Fluxes, like solders, are very diverse. It is more convenient for us to divide the entire variety of fluxes into two large groups: acidic and acid-free. From these two groups we will choose acid-free ones.

The most common acid-free flux is everyone’s favorite rosin. In the north of our Leningrad region, in the kingdom of consumptive pines, rosin can be extracted with your own hands. After all, rosin is nothing more than processed (purified) pine sulfur. I don’t remember that rosin was somehow classified by type. The truth differs by grade (by degree of purification). The purer the rosin, the less it smells when soldering, and the slower the soldering iron tip becomes dirty. However, the smell of rosin is quite pleasant, but the tip will still become dirty, whether slowly or quickly, no matter how much it cracks. Therefore, the purity of rosin is not a parameter worth chasing.

Rosin is quite cheap, so get more. Believe me, it ends very quickly (if you solder correctly).

How to use it? Rosin can be used both dry and diluted. Rosin is usually “diluted” in alcohol, in the proportion rosin: alcohol = 1:3 (parts by volume). If the idea of diluting something in ALCOHOL seems blasphemous to you, you can dilute it in acetone. True, it smells strong, and some people get headaches from it. Also, don’t be surprised if, after using acetone for some time, little green men start running around the wall. Don't try to catch them: they are extremely fast.

Typically, liquid fluxes, such as alcohol-rosin, are used to coat large surfaces (for example, a printed circuit board). For trivial soldering of elements, they still use solid rosin.

To avoid being accused of bias, I’ll drop a few lines about other fluxes. Well, first of all, it’s worth returning to the rejected acid fluxes. Why don't we like them? But because after soldering they must be thoroughly washed off the parts: otherwise the remaining acids will slowly and surely gnaw at the structure, and one fine day everything will fall apart. In addition, if a drop of hot rosin gets on your finger, you swear loudly and get a thermal burn that goes away in a couple of days. If you drop hot acid on your finger, then in addition you will get a serious chemical burn that will heal for a long time and painfully. And yet, acid flux can be very, very useful, for example, when soldering iron (steel, cast iron, etc.). It is very difficult to solder iron using rosin, but it is easy to solder with acid. Personally, for such purposes I use... aspirin. Aspirin is acetylsalicylic acid. Take an aspirin tablet and go ahead: now you are not afraid of iron surfaces!!! Just try to inhale acetylsalicylic acid vapor as little as possible - it is very unpleasant and extremely harmful.

There are also various specialized fluxes, such as aluminum soldering flux. You buy this flux and you can safely solder aluminum, stainless steel and other metals that you cannot use with rosin.

This is probably all about fluxes. Now we need to prepare the soldering iron for work.

https://radiostudy.narod.ru

Tweet Like

- Previous post: CHARGER FOR NICKEL-CADMIUM BATTERY WITH CURRENT REGULATOR AND TIMER

- Next post: What is an integrated circuit (IC)

- MOTORCYCLE HEADLIGHT DISCONNECT INDICATOR (0)

- WHEATSTON BRIDGE DIAGRAM (0)

- CURRENT/VOLTAGE CONVERTER WITH AMPLIFIER HA TRANSISTOR (0)

- Again about the IR barrier (0)

- How to choose an electric lock (0)

- How to choose a video camera (0)

- About printed circuit boards (0)

Related posts:

Flux in solder, what is it and why?

By analogy with welding self-shielding wire, fluxed solder is produced . There is no need to separate operations to clean the surface being treated or improve adhesion.

An example of a material for domestic use is the 7-component combination HTS2000, manufactured in the USA, for joining a wide range of aluminum alloys.

An oval tube 460 mm long, Ø 2.1 mm melts without entering the burner flame zone, when it touches the heated metal. The melting point of the rod 3900 implies separate heating. The instructions state that melting and filling of the seam space occurs when the heating zone is rubbed with a filler rod.

Not applicable for loaded seams . The technology of separate heating is complicated and requires mastery of the burner. In order not to burn out the previously applied contact layer over an extended area, tricks are needed to maintain an equal temperature of the treatment zone.

During this period, the heating surface is defenseless and oxidizes. The filler rod follows the brush, which scrapes off the oxide film. Filling micropores at a temperature far from liquefying the base is safe: the transition of aluminum from a solid to a fluid state is difficult to determine by eye.

Low tightness was noted due to the formation of pores on the surface of the seam. But the HTS2000 is one of the inexpensive ones in its niche. Provides decent mating strength.

We check how good the advertised patented products are and the feasibility of their use on forums based on reviews from experts.

Solder with flux HTS-528 with a temperature threshold of 7600 according to the same scheme is used for ferrous metal with cast iron, copper and nickel alloys. The manufacturer recommends that you use the color of the heated part to determine whether the required temperature has been reached.

What is solder, soldering, flux

There are two ways to join metals - welding and soldering. When welding, the metal at the junction of the parts melts, resulting in an inextricable connection. This type of connection is the most reliable, but not all metals can be welded. For metals that cannot be welded, soldering is used.

What is solder solder - it is the material that makes the connection

What is solder and why is it needed?

Soldering is the process of joining metals using an auxiliary compound - solder. This is an alloy that has a lower melting point than the parts being joined. During the process, the parts being connected only heat up, but do not begin to melt. Only the solder melts. It turns into a liquid state, spreads and fills the capillaries of the parts being connected. The result is a reliable connection, although less strong than welding. When welding, we essentially get a monolith. It is impossible to achieve this effect when soldering.

Solder for soldering is an alloy of metals with a melting point lower than that of the parts being joined.

So, solder for soldering is an alloy with a melting point lower than that of the parts being joined. With its help we get a strong connection. Some types of solder provide sealing, others provide good electrical conductivity. It is this group of solders that is used in the repair and manufacture of devices and connecting wires.

What is flux and what does it do?

When soldering circuit boards, wires, and electronics, it is important to achieve good electrical contact, i.e. with minimal resistance. This is only possible when connecting pure metals without contamination and oxide film. And copper and aluminum, which usually have to be soldered, are actively oxidized. Oxides can be removed mechanically, but it takes time, and the result is too dependent on the person. Therefore, flux is usually used - this is a substance that dissolves oxides and, at the same time, improves the spreadability of solder. The simplest flux is rosin dissolved in alcohol.

It's all solder for soldering

There are fluxes that also serve to protect against environmental influences. But, in most cases, they are too active and, after soldering, cleaning of the boards and parts is required. Otherwise, flux residues will corrode the shell, the board itself, and the connection. There are special washes for this. Usually these are alcohols and alcohol solutions, but some compositions are washed off with water. The method of removal is usually indicated in the description of the composition.

Solder release forms for soldering

Most often, solder is found in the form of wire of various thicknesses - from 0.3 mm to 3 mm. These are the sizes that are used when soldering electronics and wires. Solder in the form of a wire is wound onto reels (reels). The length of the solder wire is several meters, but it is sold by weight - in grams and kilograms. Standard packaging options on a reel are 50, 100, 200, 250 and 500 grams. For production purposes, coils with solder weights of 1 kg or more are produced.

Wire solder in reels is the most convenient form for use. The products of the German company Stannol are popular

Small packaging can be without a reel.

Solder POS-61 with a rosin channel. Sold without reel as it weighs only 10 grams

Please note that solder wire can have flux/rosin - a tube of solder filled with flux. The amount of flux is 1-8%. This option is ideal, since the components are optimally selected (from good brands) and provide good soldering quality.

Tubular solder with flux - there is rosin inside the tube

The percentage of flux is indicated on the sticker.

According to the information on the label, the flux content is 2.2%

There are also the following types of solder release:

- Rods. Diameter is 5-10 mm, but they are also sold by weight.

- Powder. Typically for industrial applications.

- Granules. Also more often for production.

- Foil. This form of release is good for thin-film (SMD) parts.

- Solder paste. Solder paste is also convenient for working with ordinary, but small parts. But it was developed for SMD electronics.

Solder in the form of paste in a tube, foil and granules. These are more convenient to work with when soldering SMD components.

The most common form of solder release is wire. Different thicknesses allow you to take the amount of material that is required for a given type of part. And it’s easier to store a reel than, say, a skein, powder, etc. Solder paste, which is sold in tubes, is also convenient. But this form of release is many times more expensive. So it is usually used purposefully - for thin-film parts.

Specifications

When soldering parts, it is important that the liquid solder is not so hot that it damages the part or melts the insulation. The second important point is that it fits well on the parts to be joined. Well, the third thing is that the contact at the soldering point is reliable. They also often pay attention to the shine - this is evidence that the soldering was carried out in compliance with the technology. The following technical characteristics of solder are responsible for all these parameters:

- Wettability. When soldering, it is important that the solder spreads well and envelops the joined fragments and does not flow off them. This is possible with good wettability. This is precisely the property of spreading, remaining at the same time on the details.

The ability to spread and “adhere” to parts is called solder wettability.

- Melting temperature . Everything is clear here. The solder must be selected so that it melts before the parts begin to melt or overheating becomes critical.

These are all the technical characteristics by which solder is selected for home use. And it is these two points that are noted when a particular company is recommended or not. They focus more on temperature. And what’s strange is that the same composition, but from different companies, needs to be heated differently. Wettability can be adjusted using flux - it improves this indicator. But there is no way to fight the melting point. Therefore, the ease of soldering is determined by how easily the solder melts.

In general, strength, elasticity, hardness, and electrical conductivity are taken into account. Strength and elasticity are important where mechanical stress may occur. This applies more to soldering copper pipes and other similar products. Hardness indicates how easily the soldering area is damaged. Conductivity is important to ensure electrical contact.

What is soldering flux?

The quality of soldering is based on the correct selection of flux components and additives. Flux function:

- Creation around the solder, on the surface of the metal, an easily evaporated film that dissolves oxides in the working area.

- Create conditions for solder spreading by reducing surface tension.

- Improve adhesion to the base, reduce environmental impact.

- Evaporate at the threshold of the melting point.

The variety of proposals with simple and complex liquid, powder and paste compositions are divided into two technologically dissimilar types of soldering fluxes: passive and chemically active. Solder pastes made from a flux-solder combination, alternative tubular solders with the internal cavity filled with flux, are sold.

Chemically active

These are mainly acid-containing reagents . Oxide films and greasy deposits are successfully removed. But the question arises of neutralizing the activity of aggressive substances by washing: metal and textolite boards are destroyed by corrosion.

Phosphoric acid, hydrochloric acid after pickling, borax, and ammonia are available and actively used. The effects of vapors on the respiratory system are toxic, and the skin is also vulnerable.

Soldering acids are used in soldering nickel and steel. Easily remove oxidation products. They require neutralization with slightly alkaline solutions with the obligatory procedure of immersion in running water. Application temperatures 250–3300 C.

When using aggressive agents, the workroom needs ventilation; the minimum measure is ventilation . Contact with the skin of the hands requires rinsing with detergents without delay.

Organic

Chemically passive fluxes remove fatty films, partly unstable oxides . These organic, non-corrosive substances provide protection against oxidation. Pine rosin, wax, stearin and alcohol rosin solutions do not emit vapors harmful to health. Used with low-melting solders in radio engineering.

FLUX FOR SOLDERING

Flux

- substances (usually a mixture) of organic and inorganic origin, intended to remove oxides from the surface for soldering, reduce surface tension, improve the spreading of liquid solder and/or protect against environmental influences. Soldering flux should not interact with solder, except for fluxes for reactive flux soldering. Depending on the technology, flux can be used in the form of a liquid, paste or powder. There are also solder pastes that contain solder particles along with flux; sometimes the solder tube contains a filler flux inside.

*****************************************************************************************************************************************************

To order flux, you must send a request to email. email: [email protected] or [email protected] The application can be in free form.

*****************************************************************************************************************************************************

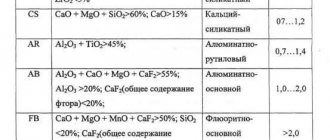

Classification

According to GOST 19250-73 “Soldering fluxes. Classification", soldering fluxes are divided according to the following criteria:

— by temperature range of activity: low-temperature (up to 450 °C) and high-temperature (over 450 °C);

- by the nature of the solvent: aqueous and non-aqueous;

- by the nature of the activator of the determining action: rosin, acid, halide, hydrazine, fluoroborate, aniline, stearic (low-temperature) and halide, boride-carbon dioxide (high-temperature);

— by mechanism of action: protective, chemical action, electrochemical action, reactive;

— according to the state of aggregation: solid, liquid and paste.

Fluxes for soldering with POS type solders

1) Fluxes for soldering ferrous metals

* Strongly acidic fluxes (“active fluxes”) - Zinc Chloride

* Fluxes of medium and low activity - Ammonium chloride

2) Fluxes for electrical engineering

The main requirements for such fluxes are low leakage current and low corrosiveness.

The simplest fluxes of this type are created on the basis of rosin - for example, solutions of rosin in alcohol - ethanol or other alcohols or an alcohol-gasoline mixture. Acid fluxes are also often used - various acids and their salts, but due to high acidity, it is necessary to wash the soldering area. Even a flux such as glycerin must be washed from the printed circuit board, since it has good hygroscopicity, as a result of which the soldering area quickly oxidizes. An exception is rosin and its alcohol solutions due to the fact that it covers the surface and is a kind of neutral protective coating.

3) Fluxes for aluminum alloys

Although aluminum alloys can be soldered with lead-tin solders, better results are achieved with multi-component solders containing zinc, cadmium, bismuth and other metals. A “binary” flux is used: concentrated orthophosphoric acid (often called simply phosphoric acid) until whitening, then 20% eutectic (50 mol.%, a.i. 8:11.5) NaOH-KOH in glycerin.

4) Fluxes for soldering stainless steels - Phosphoric acid

Fluxes for high-temperature soldering with copper-phosphorus solders

When soldering with refractory solders, sodium tetraborate (borax) is used as a flux.

Fluxes used for soldering

1) Fluxes must satisfy the following basic requirements:

2) The melting point of the flux and its specific gravity must be lower than the melting point and specific gravity of the solder.

3) The flux must completely melt and have good fluidity at the soldering temperature, but at the same time it should not be too fluid so as not to “leave” from the soldering site.

4) The flux must promptly and completely dissolve the oxides of the base metal, and the flux must act at a temperature several degrees below the melting point of the solder.

5) Flux should not form compounds with the base metal and solder, nor be absorbed by them.

6) The flux should cover the surface of the base metal in a uniform layer at the soldering site, protecting it from oxidation throughout the entire soldering process. However, in order for the solder to cover the surface of the base metal in a continuous layer, it is necessary that the adhesion of the flux to the base metal (i.e., the adhesion force between the flux and the base metal) be weaker than the adhesion of the solder (i.e., the adhesion force between the solder and base metal).

7) Flux should not evaporate or burn out at soldering temperature, and its decomposition products and oxides should be displaced by solder, easily removed after soldering and not cause corrosion.

For soft soldering

Acid or active, anti-corrosion, acid-free, activated fluxes are used. Acidic or active fluxes - based on chloride compounds - intensively dissolve oxide films on the surface of the base metal and thereby ensure good adhesion and, consequently, high mechanical strength of the joint. The flux residue after soldering causes intense corrosion of the joint and the base metal, and therefore after soldering the soldering area must be thoroughly washed. It is strictly prohibited to use acid fluxes for soldering conductors when installing electrical and radio devices.

Acid fluxes

Acid fluxes include zinc chloride (usually in the form of a 30% aqueous solution with the addition of 0.6-0.7% free hydrochloric acid; approximately 263˚ C), flux paste (zinc chloride or ammonium chloride with an appropriate filler: lanolin, petroleum jelly, glycerin, etc.; tm = 263° C), flux “Prima I” (solution of zinc ammonium chloride in a mixture of water and ethyl alcohol with the addition of glycerin, tm = 170˚ C).

Anti-corrosion fluxes

Anti-corrosion fluxes are fluxes based on phosphoric acid with the addition of various organic compounds and solvents, as well as fluxes based on organic acids. Fluxes of this group do not cause corrosion of ferrous metals and therefore there is no need to remove flux residues after soldering.

Flux VTS

VTS flux (a mixture of technical petroleum jelly with salicylic acid, triethanolamine and ethyl alcohol) is used for soldering copper, brass, bronze, constantan, silver, platinum and platinum group alloys. This flux is especially suitable for soldering electrical connections, as it ensures clean and reliable soldering and does not cause corrosion, even if it remains in the soldering areas.

Acid-free fluxes

Soldering of connections when installing electrical and radio devices is carried out, as a rule, with acid-free fluxes based on rosin.

Pine rosin is basically a mixture of resin acids. When stored in air, rosin absorbs oxygen, and the higher the temperature, the greater the absorption. Ground rosin mixed with air can explode. The melting (softening) temperature of rosin ranges from 52˚ to 83° C; at 125˚ C, rosin turns into a liquid state. The main advantage of rosin is that in the molten state (at a temperature of 150 ° C) it is capable of dissolving oxides, and after solidification on the solder joint, the flux residue does not cause corrosion. The rosin residue is not hygroscopic and is a good insulator, which is also one of the advantages of rosin as a flux for soldering assembly joints. As a surfactant, rosin significantly improves the spreading of solder.

Rosin is a low-chemically active flux and can be used provided that the parts are carefully prepared for soldering, that is, they are cleaned or tinned.

Natural rosin (GOST 797-64), as well as solutions of rosin in alcohol (CE and glycerin-rosin flux) are used as fluxes for soldering assembly joints.

Activated fluxes

Activated fluxes based on rosin are used for soldering metals and alloys that are difficult to solder with rosin flux; they also speed up the soldering process of copper and copper alloys.

As activators, aniline hydrochloride, aniline phosphate, phenolic anhydride, diethylamine hydrochloride, salicylic acid, etc. are introduced into rosin in small quantities.

The best flux for soldering assembly joints from this group of fluxes is flux with aniline.

For brazing

Acid fluxes are mainly used, the residues of which must be removed after soldering. Depending on the melting point, they are divided into: fluxes with a melting point above 750 ° C, used for soldering with refractory solders, and fluxes with a melting point below 750 ° C, used for soldering with relatively low-melting silver solders. The most widely used refractory fluxes are borax and boric acid. The active group of these fluxes is boric anhydride B2O3, which, when reacting with metal oxides, forms borates.

Borax is used in the form of anhydrous salt Na2B4O7 and in the form of crystalline salt Na2B4O7 • 10H2O.

Crystalline borax decahydrate begins to melt at 75˚ C; as the heating temperature increases, the borax loses water, strongly swelling and splashing, and gradually turns into anhydrous salt Na2B4O7 (fused or burnt borax); melting at a temperature of 783° C. To avoid boiling storms during soldering, it is usually used in a calcined form. Crystallization water is removed by heating borax to 400 - 450 ° C. The active action of borax begins at a temperature of 800 ° C; at lower temperatures, borax does not spread well. Borax in the molten state can be heated to high temperatures without noticeable evaporation; it is very fluid and vigorously dissolves the oxides of many metals, especially copper.

Boric acid is a less active flux than borax. The active temperature of boric acid is higher than that of borax and is 900° C. Boric acid alone is rarely used as a flux. Mixtures of borax and boric acid are the basis of most fluxes.

To increase the activity of a mixture of borax and boric acid when soldering stainless steels and heat-resistant alloys, calcium fluoride and other additives are added to the flux composition.

As low-melting fluxes for soldering with silver and copper-phosphorus solders, mixtures of holoid salts of alkali metals with borate salts are mainly used. Halide salts flux oxides mainly by physical dissolution, while borate salts have a chemical effect.

Fluxes are used in paste, powder and liquid form.

Sometimes the fluxing effect is produced by the solder itself with appropriate additions of deoxidizing agents (for example, copper-phosphorus solders).

Names and applications

Pine rosin is the simplest, cheapest and most accessible type of flux with low leakage current. Belongs to the class of chemically passive fluxes. It is freely available on the market due to its popularity. It is used in a wide range of radio applications. It is moderately soluble in alcohol with the addition of glycerin, which is why alcohol-rosin fluxes have become popular among radio amateurs.

Solder fat - exists in two types: active and neutral . Used for oxidized parts consisting of ferrous or non-ferrous metal. Active solder fat is not used in radio design. Neutral solder fat does not contain active components, so it can be used for soldering radio components.

- Borax – necessary for high-temperature soldering of high-carbon metals: cast iron, copper, steel, etc.

- TAGS is a glycerin-based flux for radio installation. Due to residual resistance, it needs to be washed with alcohol.

- ZIL fluxes are well suited for soldering steel, brass, and copper with low-melting bismuth-based solders.

- F-38N PET is a highly chemically active flux. Used for soldering metals that quickly oxidize in air at temperatures above 300 degrees. They solder nichrome, manganin, and bronze. Mandatory use of personal protective equipment when using it. Washing with alkali is also required.

- Active fluxes FIM - soldering of oxidized silver, platinum. Requires washing with an aqueous solution containing soda. The flux contains phosphoric acid.

- FCDT and FKT PET are a popular inactive flux widely used for tinning wires and copper contacts in electronic equipment.

- FTS is a rosin-free passive flux without smoke. Designed for soldering radio components.

- Soldering paste "Tinol" is a special chemical flux for soldering SMD radio components using a hot air gun at a soldering station.

- TT flux-gel is a flux with a reddish tint indicator of chemical activity for a wide range of soldering. When exposed to temperature, it discolors, indicating the absence of active components. Does not require washing.

- ST-61 – passive solder paste. A – melting point +200 degrees, B – for computer and mobile radio spare parts, C – rosin.

Soft solders

Soldering printed circuit boards, wires and other work requires a low temperature. Many radio components simply cannot withstand high temperatures and fail due to overheating. Does not tolerate heat and wire insulation. Therefore, solder for soldering in this category is chosen from soft and fusible ones. Moreover, it is desirable that the solder melts at 200°C or slightly lower.

Externally, solders for soldering with a high lead content can be distinguished by their gray color

POS: types. types, application

The most common soft solder for soldering is PIC (Tin-Lead Solder). It consists of tin and lead in different proportions. The percentage composition is displayed in the name - after the PIC there is a number indicating the percentage of tin. For example, POS 40 contains 40% tin. In POS 61 - 61%, in POS 90 - 90%, etc.

Kilogram coil POS 40 - for large volumes of work. Produced according to GOST 21931-76

To improve/change characteristics, additives can be added to the composition in small quantities. The type of additive and its percentage is indicated at the end of the solder label. For example, the addendum to PIC 61 Sn61Pb37Ag2 indicates that the solder consists of the following components:

- Sn61 - 61% tin;

- Pb37 - 37% lead;

- Ag2 - 2% silver.

This solder flows well and gives an almost mirror-like shine. But silver is not a cheap addition, which will be reflected in the price.

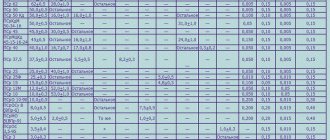

POS and POSSu: technical characteristics

There is one popular variety of POS - POSS. And it means “tin-lead solder with the addition of antimony” (the last two letters “Su” indicate the presence of this additive in the composition). Antimony increases soldering strength, so such compounds are used where increased joint strength is required.

| Solder grade | Tin Sn in % | Antimony Sb in % | Copper Cu in % | Silver Ag in % | Melting point solidus/liquidus | Temporary tensile strength, kgf/mm2 | Application |

| POS-90 | 89-91 | 0,05 | 0,05 | 0,02 | 183/220 | 4,9 | Food utensils and medical equipment |

| POS-61 | 59-61 | 0,05 | 0,05 | 0,03 | 183/190 | 4,3 | Electro-radio devices |

| POS-40 | 39-41 | 0,05 | 0,05 | 0,03 | 183/238 | 3,8 | Electro-radio devices, galvanized steel |

| POS-10 | 9-10 | 0,05 | 0,05 | 0,03 | 268/299 | 3,2 | Tinning of contact tracks, soldering of devices, relays |

| POSSu-61-0.5 | 59-61 | 0,05-0,5 | 0,08 | 0,03 | 183/189 | 4,5 | Equipment and parts with strict temperature requirements |

| POSSu-40-0.5 | 39-41 | 0,05-0,5 | 0,08 | 0,03 | 183/235 | 4,0 | Sheet metal, windings, cables, installation of electrical elements, radio components, copper tubes |

A few words about the characteristics reflected in the table. The melting point is given in two numbers - solidus and liquidus. The first is the beginning of melting. When heated to this degree, the most fusible components of the composition transform into a liquid state. Liquidus is the temperature of complete melting. This is exactly what is needed when soldering - the tip should be a little “hot”. For example, to solder POS 61, the soldering iron must be heated to 190°C or so. The exact heating of the soldering iron is selected experimentally, since the fluxes, parts, and heat losses are different. But the general principle is the same: slightly higher than the melting point.

How can you tell which type of solder is used? According to the degree of gloss of the contact pad. The more tin in the composition, the more shiny the surface. Lead gives a dull gray color. And this is visible to the naked eye.

| Solder grade | Melting point solidus/liquidus | Density, g/cm3 | Electrical resistivity Ohm*mm2/m | Temporary tensile strength kgf/mm2 | Relative extension % | Impact strength kgf/cm2 | Brinell hardness, HB |

| POS 90 | 183/220 | 7,6 | 0,120 | 4,9 | 40 | 4,2 | 15,4 |

| POS 61 | 183/190 | 8,5 | 0,139 | 4,3 | 46 | 3,9 | 14,0 |

| POS 40 | 183/238 | 9,3 | 0,159 | 3,8 | 52 | 4,0 | 12,5 |

| POS 10 | 268/299 | 10,8 | 0,200 | 3,2 | 44 | 3,2 | 12,5 |

| POS 61M | 183/192 | 8,5 | 0,143 | 4,5 | 40 | 1,1 | 14,9 |

| POSK 50-18 | 142/145 | 8,8 | 0,133 | 4,0 | 40 | 4,9 | 14,0 |

| POSSu 61-0.5 | 183/189 | 8,5 | 0,140 | 4,5 | 35 | 3,7 | 13,5 |

| POSSu 50-0.5 | 183/216 | 8,9 | 0,149 | 3,8 | 62 | 4,4 | 13,2 |

| POSSu 40-0.5 | 183/235 | 9,3 | 0,169 | 4,0 | 50 | 4,0 | 13,0 |

| POSSu 35-0.5 | 183/245 | 9,5 | 0,172 | 3,8 | 47 | 3,9 | 13,3 |

| POSSU 30-0.5 | 183/255 | 8,7 | 0,179 | 3,6 | 45 | 3,9 | 13,2 |

| POSSu 25-0.5 | 183/266 | 10,0 | 0,182 | 3,6 | 45 | 3,9 | 13,6 |

| POSSu 18-0.5 | 183/277 | 10,2 | 0,198 | 3,6 | 50 | 3,6 | — |

| POS 95-5 | 234/240 | 7,3 | 0,145 | 4,0 | 46 | 5,5 | 18,0 |

| POSSu 40-2 | 185/229 | 9,2 | 0,172 | 4,3 | 48 | 2,8 | 14,2 |

| POSSu 35-2 | 185/243 | 9,4 | 0,179 | 4,0 | 40 | 2,6 | — |

| POSSu 30-2 | 185/250 | 9,6 | 0,182 | 4,0 | 40 | 2,5 | — |

| POSSu 25-2 | 185/260 | 9,8 | 0,185 | 3,8 | 35 | 2,4 | — |

| POSSu 18-2 | 186/270 | 10,1 | 0,206 | 3,6 | 35 | 1,9 | 11,7 |

| POSSu 15-2 | 184/275 | 10,3 | 0,208 | 3,6 | 35 | 1,9 | 12,0 |

| POSSu 10-2 | 268/285 | 10,7 | 0,208 | 3,5 | 30 | 1,9 | 10,8 |

| POSSu 8-3 | 240/290 | 10,5 | 0,207 | 4,0 | 43 | 1,,7 | 12,8 |

| POSSu 5-1 | 275/308 | 10,2 | 0,200 | 3,3 | 40 | 2,8 | 10,7 |

| POSSU 4-6 | 244/270 | 10,7 | 0,208 | 6,5 | 15 | 0,8 | 17,3 |

This table contains tin-based solders that can be found in stores. As you can see, the most fusible one - POSC 50-18 - melts at 145°C. The most durable and rigid is POSSU 4-6, the most “ductile” is POSSU 50-0.5, and slightly less tensile POS 40.

Solder for soldering POS 61

Based on the totality of characteristics, radio amateurs, and even professionals, most often use POS 61 or its imported analogue Sn63Pb37. Their melting point is 183/189. But it is often called POS 60. But look, the alloy with exactly this composition - Sn60Pb40 - melts at 191°C. So don't be fooled by the name. You need 61% tin, although according to GOST 59-61% is acceptable. This is why “identical” solders from different companies melt differently. They have different percentages, although they are made according to GOST. Well, and because of the additives, of course.

POS 60 has a melting point higher than POS 61

Here are the additives that can be added to POS 61:

- Antimony - no more than 0.1%;

- Aluminum - no more than 0.002%;

- Copper - no more than 0.05%;

- Sulfur - no more than 0.02%;

- Arsenic - no more than 0.02%;

- Iron - no more than 0.02%;

- Bismuth - no more than 0.02%;

- Nickel - no more than 0.02%;

- Zinc - no more than 0.002%.

The most popular solder for soldering is POS 61

Tin makes up 59-61%, and lead "everything else" (38.7-40.7%). A specific “set” of additives determines the final properties of the solder. This is precisely what distinguishes products from different companies - the number and composition of additional elements. Although everything is called POS 61, it “works” differently.

Low melting point solders

Heating some components to temperatures above 100°C is contraindicated. Others can barely tolerate heating up to 80°C, and there are even more “tender” ones. For these, especially low-melting types of solders are used. This is an alloy of Rose (melts at 94°C), Wood (60.5°C), D'arsenval (79°) and some others.

| Name or brand of solder | Bismuth Bi, % | Lead Pb in % | Tin Sn in % | Cadmium Cd in % | Melting temperature |

| Wood's solder | 50 | 25 | 12,5 | 12,5 | 60,5 |

| Solder Rose | 50 | 25 | 25 | — | 94 |

| D'Arsenval solder | 45,3 | 45,1 | 9,6 | — | 79 |

| Lipovitsa solder | 50 | 26,67 | 13,33 | 10 | — |

| POSV 33 | 33,3 | 33,4 | — | — | 130 |

| POSK 50-18 | 32 | 49,8 | 18,2 | 145 |

The highest melting point of this group is POSC 50-18. It contains a lot of cadmium (the letter K in the labeling indicates exactly this), which makes it toxic. It can only be used with good suction. POSV-33 heats up a little less. This is tin, lead and bismuth in equal parts. Melting point - 130°C. Both of these compositions are used for tinning PCB tracks and soldering components sensitive to overheating.

Wood and Rose solder are used for mounting/disassembling SMD components. They melt at temperatures below 95°C. They are also used for tinning paths, but the cost of these compounds is high.

Imported

- IF 8001 Interflux is one of the best fluxes for lead-free soldering of SMD components, including work with BGA chips. Quite expensive. Does not require rinsing.

- IF 8300 BGA Interflux (30cc) – for soldering BGA packages. It is a gel. Free from harmful halogen.

- IF 9007 Interflux BGA is a no-clean soldering paste for soldering with lead solder. After work, it leaves a barely noticeable layer of flux with high resistivity.

- FMKANC32-005 – mildly activated no-clean cream. Shows good results when soldering BGA chips and working with infrared soldering stations.

Classification

You can often find marking symbols in the labeling of imported fluxes. Let's look at their designation below:

- “R” is rosin, which comes either in pure form or in the form of a solution (alcohol-rosin). It is a chemically passive flux, so before use it requires manual cleaning of the surface of the components being soldered to remove oxides. After finishing work, it requires washing with alcohol or acetone.

- “RMA” is a rosin-based flux with a small addition of activators (organic acids and their compounds). During heat treatment, acid-containing activators evaporate. To use them, a hood is required. Optimal soldering is achieved using hot air.

- "RA" - activated rosin. According to the manufacturers, due to the low activity of acids, it does not cause corrosive processes at the soldering site, and therefore does not require cleaning. We would still recommend using a weak alkali solution or alcohol for cleaning after working with it, if we are not talking about BGA soldering!

- "SRA" - active acid fluxes for soldering stainless steel and nickel. They are practically not used in electronics due to the destructive effect of acids. After soldering with such a flux, the product needs to be thoroughly washed with alcohol or acetone.

Also, imported fluxes often have the inscription “no clean” added to their name, which means that this flux does not require washing . Such fluxes are often used when soldering radio components, where cleaning the parts after soldering is physically difficult. For example, when soldering BGA chips.

For aluminum

Fontargen F 400 M powder for alloys with a small percentage of magnesium rods for argon welding.

Provides tightness. Requires extensive washing - actively corrodes. Castolyn FBK 192, flux cored solder. Recommended for thin-walled structures with preliminary tinning and creating a gap around the perimeter of 0.2 mm. Shell composition Zn-98%, Al-2%. Advantages of the material:

- No residual corrosion;

- Stability of wettability and fluidity at t 4400;

- Acceleration of crystallization;

- Reliable fusion of aluminum with stainless steel, galvanized ferrous metal, copper.

Castolin 192 is suitable for restoring internal threads in body parts, repairing and sealing surface holes, including without applying patches. Overlapping connection.

For brass and copper alloys

Refractory coaxial tubular fluxes for soldering are copper-phosphorus and copper-phosphorus with the addition of silver BrazeTec complexes for gas-flame melting . Temperatures range from 645–8900 C. The joining of closely related metals is adjacent to brass-steel soldering. Large selection of solder pastes of combined composition for various purposes.

BrazeTec is chosen for particularly demanding work, reasons:

- The declared composition does not change in different batches.

- The quality certificate guarantees the effectiveness of the work.

PET soldering acid - the optimal temperature for the soldering process with its use is 150 - 320 degrees. Used for soldering carbon steels, brass, copper, nickel.