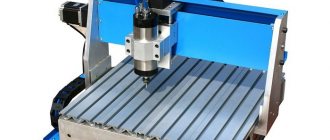

A desktop CNC milling machine, which has a fairly high functionality, can be successfully used for processing workpieces made of ferrous and non-ferrous metals, stone, ceramics, plastics and wood. Thanks to the control system that this mini-machine is equipped with, the part can be processed accurately and efficiently.

Compact desktop milling machine equipped with CNC

CNC milling machines. Tabletop and small-sized.

Even in the recent past, on small-sized machines, all processing of metal parts was done manually. A little later, machines appeared, where most of the operations were already performed automatically. But nowadays, mini-machines equipped with program control have become increasingly common and automatically perform almost all metal processing work. The workpiece is rigidly fixed on the deck of the machine's work table, then a certain program is entered, after which the machine performs almost all milling operations, maintaining all the specified parameters for processing parts.

Operating principle of mini milling machines

Working with a mini milling machine is not difficult; anyone who works with a computer can handle CNC. Before starting work on this equipment, the operator must properly secure the workpiece, and then download and run the program on the computer. After all manipulations, all operations are performed automatically without operator participation.

With mini CNC machines for home production, users can easily design any product made of metal or wood, then manufacture it. Previously, it took craftsmen a lot of time and effort to make hand-carved wooden objects, but now with the help of milling machines the process is much easier.

If a person has purchased CNC equipment for milling, he must understand software issues and learn how to work with the CNC device. Then he will be able to use the program to create drawings and model three-dimensional products from different materials.

Desktop mini CNCs are equipment controlled by a computer using a special program or DSP controller, equipped with numerical control. They have the ability to produce products from different materials:

- plastic and plexiglass;

- metal and composite;

- wood and acrylic.

Such milling machines are multifunctional and versatile, since operations on slotting, drilling, and engraving machines are not required.

Milling machines that process metal products are produced in two types:

- With console

- Not having a console.

The most popular of them are console machines. The convenience of using such a machine lies in the location of the workpiece being processed, which is rigidly fixed on the console, and all operations to move it along the cutter are performed by the console. In this case, the spindle with the attached cutter remains motionless.

On machines that do not have a console, the workpiece is attached to a work table, which can move both along the machine and across it. In this case, the cutter is also in motion along the horizontal or vertical axis.

Certain information is pre-entered into the machine’s memory, according to which the program control carries out almost all technological processes for milling workpieces. To carry out certain metal milling operations, especially for such small-sized machines, several software programs have been developed.

What are the advantages of mini CNC woodworking machines for a home workshop?

Mini machines take up a small area and can even be placed on the balcony of your home. They are great for carving and making custom wood products.

The equipment is characterized by:

- ease of use;

- high performance;

- easy maintenance;

- equipped with a security function;

- economical since it operates from a single-phase network.

In addition to these advantages, we can note the quiet operation, low weight (at any time you can move it from one place to another if necessary), and low cost.

Advantages of milling machines.

If you compare automated drilling and milling installations and small-sized milling machines with program control, it will immediately become clear that the latter have a number of positive advantages:

- Small dimensions.

- Low cost.

- Creates little noise.

- Minimal vibration during operation.

- Simplicity of design.

- Versatility.

Such machines provide high precision when processing parts with a rather complex geometric shape. At the same time, the processing process occurs quite quickly and efficiently.

The process of operation of a machine equipped with a CNC is monitored by only one operator, who launches the computer program. That is, it is possible to operate several machines simultaneously, under the control of one person.

If at one time equipment equipped with CNC was used only for industrial purposes, now it is actively used in the processing of metal parts and workpieces from other materials in private workshops.

It is quite possible to make a desktop milling machine with PU on your own directly in a garage. There are quite a few such home craftsmen, and a CNC milling machine is quite expensive compared to conventional equipment.

CNC machines for steel

Equipment modernization is a natural and necessary process, since it allows you to increase the dimensional accuracy of parts, reduce their processing time and improve quality. All this has a positive effect on the competitive ability of the enterprise. Every reasonable business owner comes to these conclusions sooner or later. Therefore, an excellent solution would be to purchase a CNC machine for metal,

capable of functioning in 5D modes, quickly processing even very hard alloys. This unit is equipped with software numerical control, and allows you to create unique contours. Today, almost every milling machine of this type allows you to perform: turning of external cylindrical surfaces, drilling, reaming and countersinking of holes, milling of curved as well as cylindrical planes and surfaces. The machine is indispensable in industrial enterprises for the mass production of high-quality metal products.

There is a large selection of such machines on the market. If you are interested in metal CNC router,

then “CNC Modelist” is ready to tell you more about this group of products, provide detailed information (including photos) about each model that is included in our online catalog. This also applies to tabletop metal equipment used in the processing of steel parts. All our products are distinguished by an excellent level of quality, and prices are characterized by loyalty to customers, because we are extremely attentive to cooperation with each organization or individual and value our reputation. By the way, in addition to the production and sale of goods, we provide services for setting them up and provide customers with training articles and videos that reveal the nuances of the correct operation of certain devices.

Let's move on to the benefits of using a tabletop metal milling machine

. So, if this equipment is installed at the factory and is used for processing small parts and milling, then the business owner will, at a minimum, save energy costs. It is also ideal for use at home. Its small dimensions allow it to be placed even in limited spaces, and thanks to its light weight, you can easily move the unit to another location. The machine produces a low noise level during operation, so it will not disturb others. Simple operation means that even a non-specialist can handle such work after training. In addition, due to its dimensions, the machine has a fairly low cost. Thus, it is available to a wide range of consumers. At the same time, electronically controlled milling units are much more productive than manually controlled models. Therefore, we can firmly say that they are indispensable for small businesses.

When choosing the right desktop CNC machine for metal,

We recommend taking into account a number of parameters. Among them: the dimensions of the table holding the workpiece; type of cooling of the working area; a method of providing the user with data about the work process (on a computer or monitor); number of axles; spindle unit power. In addition, find out what size parts it can process and whether it is possible to quickly restore the equipment if necessary. Experts advise giving preference to machine models whose parameters suit your specific conditions and are capable of meeting production needs. At the same time, just in case, you need to take into account the possibility of upgrading the car in the future.

On our website you will find detailed information regarding the CNC machine for metal price,

image, technical specifications, description. Choose the model that best suits you and order it. We sell products throughout the CIS and Russia.

Homemade metal milling machine with your own hands

You can make the simplest type of milling machine yourself. To do this, you will need a drive for the equipment, a cover, a homemade elevator, and a stop. You need to buy an electric motor with the required power indicators, a guide and a durable table.

Drive for machine

The electric drive for a small machine is made independently. Craftsmen prefer to use Russian and foreign-made motors, the power reaches 500 V. But this option is only suitable for a low-power unit, since it stalls when operating at high speeds and does not justify the human resources. It is much more effective to choose a motor with power characteristics of 1100 V or more. The milling cutter can be used of any design, there are bearings, thanks to which the device can withstand heavy loads.

The issue of the drive is decided individually depending on what power indicators they want to obtain. For some types of work, electric motors with a power of up to 2 watts will be optimal, for others - with a conventional drive, which is used in hand tools (about 500 watts).

How to make a homemade elevator for a router?

Special attention is paid to the control elevator. The best option is to use plywood sheets. They are assembled and secured to the table (do not use straps). The cutter is put on the rotating shaft. It is important that the drive provides a high rotation speed and does not interfere with the elevator. The elevator consists of a body, reins, carriage, axle and screws. A self-assembled elevator allows the carriage to move up and down the axis, and the screw to control the movement.

Creating a cover

The cover is a part of the body that holds the structure together. It is responsible for ensuring that the engine and carriage do not become loose. Plywood with a thickness of 19 millimeters is taken, the standard length is 0.5 m, the width is 0.5 m. The cladding is carried out with textolite with a thickness of 0.2 mm (allowances of 2.5 centimeters). The edge coverings are glued.

Installation of the stop

After assembling the above parts, the joints are examined at the corners. The stop is mounted with an overlay of 25 centimeters made of wood. Space is left for edges and tongues.

Milling machine assembly

A small machine can be assembled independently in 2-3 evenings (the time spent searching for parts is not taken into account). Finishing is important because it ensures clear and safe work. Check if the drive has enough power. Try moving the slider and the stop. It should move progressively and not press down.

General information

When working with a tabletop milling machine, a standard set of cutting tools is used. The unit itself is compact in size and suitable for use in a home workshop. At the same time, in terms of functionality it may not be inferior to its large-sized counterparts.

There is no need to connect an electrical drive to such equipment and the unit occupies very little space during installation. The only limitation for the equipment in question is that the dimensions of the work table cannot be smaller than the dimensions of the workpiece.

How the machine is designed

The design of any machine is almost identical, if the essence is based on the main components. But the small details differ - this determines the functionality and scope of use.

bed

The bed is the stable base of the machine on which the main structural parts are located - the gearbox and the spindle shaft. It is designed in such a way as to be as convenient to use as possible.

Gearbox

The feed box of the milling machine ensures rapid movements of the axis, console and slide. Depending on the type of equipment, the features and number of feeds vary.

Console

The console is the main part of the machine. The console moves when the device is turned on along the guide frames. The gearbox is mounted on the latter.

Gearbox

The gearbox is controlled by the electrical part of the unit. This device transmits rotation to the spindle, and it transmits rotation to the cutters. At the same time, the efficiency and safety of work also depends on the unit, since it determines the speed of movement and stopping.

Table and slide

Depending on the type of machine, the table may not have the ability to rotate, or it may have it (vertical, horizontal, circular, translational, cross and other types of movement). The most convenient sleds are those that have a rotating device.