Historical reference

The name “zinc” itself was first mentioned in the book “Liber Mineralium” by Paracelsus.

According to some sources, it meant “prong.” The alloy of zinc with copper or brass has been known for a long time. It was used in Ancient Greece, India and Ancient Egypt, and later the material became known in China. The metal was obtained in its pure form only in the first half of the 18th century in 1738 in Great Britain using the distillation method. Its discoverer was William Champion. Industrial production began 5 years later, and in 1746 in Germany, the chemist Andreas Sigismund Marggraff developed and described in detail his own method for producing zinc. He proposed using the method of calcining a mixture of metal oxide and coal in fireproof clay retorts without air access. Subsequent condensation of the vapors had to take place in the refrigerator. Due to his detailed description and painstaking development, Marggraf is often called the discoverer of the substance. At the beginning of the 19th century, a method was found for isolating metal by rolling at 100 C o -150 C o. At the beginning of the next century, they learned to extract zinc using the electrolytic method. In Russia, the first metal was produced only in 1905.

Being in nature

In total, scientists count about 66 zinc minerals or its derivatives. They learned to mix this metal with other elements, thereby obtaining various mixtures and different colors.

The primary mineral is considered to be the so-called zinc blende, which was discovered in Ancient Greece.

In nature, it occurs as a mixture with brown spar.

The earth's crust contains about 10% zinc. It can also be found in igneous earth rocks. The sour ones contain significantly less. Zinc hydroxide also occurs in nature. There are 5 modifications in total.

Zinc tends to migrate in thermal waters. In addition, it can be found in underground and surface waters, where it also migrates successfully.

Scientists have found that living organisms also contain relatively large amounts of zinc. They need it for successful life.

Precautions for using zinc

Excessive intake of zinc can cause serious problems!

Even a completely unbalanced diet cannot provoke a significant excess of zinc. Often, excess of its normal concentration is caused by taking medications, as well as dietary supplements that contain zinc in their composition. A clear excess of zinc is observed in patients who took more than 150 mg of zinc per day.

The second probable reason for excess zinc in the body is a large amount of zinc entering the body, for example, during contact with trace element compounds under production conditions. In some cases, the packaging of certain drinks and foods may pose a hazard. Thus, cases of zinc poisoning have been recorded as a result of eating food that was stored in zinc or galvanized containers.

Excessive intake of zinc may also be harmful. In this case, it is possible to lower the level of good cholesterol (HDL) and, as a result, increase the likelihood of developing cardiovascular disease.

Moreover, excessive amounts of zinc over a long period of time can lead to an imbalance in mineral balance and cause changes in substances involved in calcium metabolism: calcitonin, a hormone that increases calcium stores in bones, and osteocalcin, an essential protein necessary for strong bones.

Symptoms of excess zinc:

- Decreased functioning of the immune system, development of autoimmune reactions;

- pathological conditions of nails, skin, hair;

- pain in the stomach, nausea;

- decreased levels of cadmium, copper, iron in the body;

- dysfunction of the liver, pancreas, prostate;

- pressing chest pain, dry cough;

- chills, drowsiness.

Biological role of zinc

An adult human body contains a certain amount of zinc, namely about 2 g. In the human body it is contained as organic compounds that are found in muscle tissue, pancreas and liver.

Zinc is very useful for humans, and its deficiency usually determines the appearance of various diseases and pathologies. Many enzymes in the human body contain this element.

Biologically, the body needs zinc for:

- production of male sex hormones, in particular sperm;

- proper functioning of the prostate;

- metabolism of vitamins and nutrients;

- synthesis of hormones;

- breaking down alcohol cells and accelerating the elimination of toxins.

The benefits of this element are very important for both adults and children. Vitamins in liquid form are well suited for allergy sufferers and people with certain diseases, as they are easily absorbed and no preservatives are used for their production. There are zinc-containing preparations for both adults and children.

It is important to remember that too much zinc is just as harmful as too little.

Therefore, it is extremely important to ensure the correct proportions.

Zinc and steel

In almost every home you can find galvanized things: buckets, pots, boiling pots, etc. All of them are reliably protected from rust thanks to zinc. Figuratively speaking, of course, this metal is sprayed onto the steel, and logically we are not talking about an alloy. On the other hand, knowing how galvanizing occurs, one can say the opposite. The fact is that zinc melts at a very low temperature (about 400°C), and when it hits the surface of steel in a liquid state, it diffuses into it.

The atoms of both substances bind very tightly to each other, forming an iron-zinc alloy. For this reason, we can safely say that Zn is not “laid” on the product, but “embedded” in it. This can be observed in ordinary everyday situations. For example, a scratch appears on a galvanized bucket. Is it starting to rust at this point? The answer is clear - no. This happens because when moisture gets in, the zinc compounds begin to deteriorate, but at the same time they form some kind of protection for the steel. So, in most cases, such zinc alloys are intended to protect products from corrosion. Of course, other substances, such as chromium or nickel, can be used for these purposes, but the cost of these products will be many times higher.

Interesting Facts

There are a lot of interesting facts related to zinc. It’s worth starting with the fact that zinc is one of the essential microelements in the human body. It plays an important role in metabolism. The daily intake of zinc for adult men is 15 mg, women - 12 mg, children - 10 mg and 5 mg for infants. An overdose of zinc can cause zinc fever. Its symptoms resemble the flu, but after 2 - 3 days the symptoms go away. An interesting note was made at a catering conference in San Diego. Children who took twice as much zinc (about 20 mg per day) significantly improved their mental abilities. This was expressed in increased visual memory and increased concentration.

Another interesting point is that rare plants grow in zinc-rich soil. An example is the Galilean violet. If the number of such violets is large, this may mean that a zinc deposit is located in this place.

Zinc: application

Zinc release forms

Tablets/Lozenges/Capsules/Liquid/

Features of the use of zinc

- As a general supplement, 30 mg per day.

- For acne - 135 mg per day or 1.2% ointment topically

- For gastrointestinal diseases - 300 mg of zinc acexamate per day.

- For taste disorders - 100 mg per day

- For a common cold - 10-23 mg in the form of lozenges every 2 hours, but not more than 150 mg per day. Children should take 10 mg per day or 1 mg per 1 kg of body weight

- For teeth 0.5% zinc citrate.

- Herpes 0.3% zinc ointment

- Take zinc 1 hour before meals or 2 hours after meals. If it causes stomach irritation, take it with a low-fiber meal

- Do not take iron and zinc supplements at the same time

- Take the medicine no earlier than 2 hours after taking antibiotics

- Taking zinc for longer than 1 month may interfere with copper absorption, so for every 30 mg of zinc, add 2 mg of copper.

Zinc toxicity

An excess of this microelement is very harmful to human health, as is its deficiency. An excess of zinc causes intoxication of the body.

Especially with prolonged excessive saturation of the body with this substance, zinc salts and sulfates poison a person with their toxicity.

Zinc sulfates are formed when food is stored improperly. It is especially harmful to store food in closed galvanized containers.

Zinc toxicity even causes infertility, impotence and other health problems. You can become poisoned by inhaling its vapors. Such poisoning will manifest itself in the form of dizziness, loss of consciousness, increased heart rate and the appearance of an unpleasant taste in the mouth.

Properties of zinc alloys

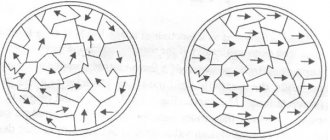

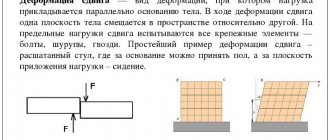

Of course, all compositions with this metal differ from each other in its percentage content. In general, zinc alloys have good casting and mechanical properties. The first and most important thing is corrosion resistance. It manifests itself most of all in an atmosphere of dry, clean air. Possible manifestations of corrosion can be seen in industrial cities. This is due to the presence of vapors of hydrochloric acid, chlorine and sulfur oxides in the air, which, condensing with moisture, make it difficult to form a protective film. Copper-tin-zinc is an alloy characterized by high protective properties. It is this composition that is least susceptible to corrosion, especially in an industrial atmosphere. If we talk about the casting properties of zinc, then, of course, they depend on the alloying elements in its alloys.

For example, aluminum makes their structure homogeneous, fine-grained, refines it, and reduces the negative influence of iron. Another important alloying element is copper. It increases strength characteristics and reduces intercrystalline corrosion. The copper-zinc alloy has high impact strength, but at the same time partially loses its casting properties.

Zinc atom and molecule. Zinc formula. Structure of the zinc atom:

Zinc (Latin Zincum, from German Zinke - “tooth”) is a chemical element of D. I. Mendeleev’s periodic system of chemical elements with the designation Zn and atomic number 30. Located in the 12th group (according to the old classification - a secondary subgroup of the second group ), the fourth period of the periodic table.

Zinc is an amphoteric metal. Belongs to the group of transition metals. Refers to non-ferrous metals.

As a simple substance, zinc under normal conditions is a brittle metal of a bluish-white color (it becomes dull in air, becoming covered with a thin layer of zinc oxide).

The zinc molecule is monoatomic.

The chemical formula of zinc is Zn.

The electronic configuration of the zinc atom is 1s2 2s2 2p6 3s2 3p6 3d10 4s2. The ionization potential (first electron) of the zinc atom is 906.4 kJ/mol (9.394197(6) eV).

Structure of the zinc atom. The zinc atom consists of a positively charged nucleus (+30), around which 30 electrons move through four shells. In this case, 28 electrons are in the internal level, and 2 electrons are in the external level. Since zinc is located in the fourth period, there are only four shells. First, the inner shell is represented by the s-orbital. The second – the inner shell is represented by s- and p-orbitals. The third - inner shell is represented by s-, p- and d-orbitals. The fourth - outer shell is represented by the s-orbital. At the outer energy level of the zinc atom, the s orbital contains two paired electrons. In turn, the nucleus of a zinc atom consists of 30 protons and 35 neutrons.

The radius of the zinc atom (calculated) is 142 pm.

The atomic mass of a zinc atom is 65.38(2) a. eat.

Zinc has been widely used by humans for a long time.

Chemical, physical properties and characteristics of zinc

Zinc is a metal that has a number of properties and characteristics that distinguish it from other elements of the periodic table.

The physical properties of zinc include its state. The main factor is temperature. If at room temperature it is a brittle material, the density of zinc is 7130 kg/m3 (˃ the density of steel), which practically does not bend, then when raised, it easily bends and is rolled into sheets in factories. If you take a higher temperature regime, the material acquires a liquid state, and if you raise the temperature by 400-450 °C degrees, then it will simply evaporate. This is uniqueness - changing your condition. If exposed to acids and alkalis, it can crumble, explode, or melt.

Liquid zinc

The formula of zinc is Zn – zinc. The atomic mass of zinc is 65.382 amu.

Electronic formula: the nucleus of a metal atom contains 30 protons, 35 neutrons. There are 4 energy levels in an atom - 30 electrons. (Fig. structure of the zinc atom) 1s22s22p63s23p63d104s2.

The crystal lattice of zinc is a hexagonal crystal system with tightly pressed atoms. Lattice data: A=2.66U, C=4.94.

Story

An alloy of zinc and copper - brass - was known in Ancient Greece, Ancient Egypt, India (7th century), China (11th century). For a long time it was not possible to isolate pure zinc. In 1738, a distillation method for producing zinc was patented in England. On an industrial scale, zinc smelting also began in the 18th century: in 1743, the first zinc plant, founded by William Champion, came into operation in Bristol, where zinc was produced by distillation. In 1746, A. S. Marggraf in Germany developed a similar method for obtaining pure zinc by calcining a mixture of its oxide and coal without air access in clay refractory retorts, followed by condensation of zinc vapor in refrigerators. Marggraf described his method in great detail and thereby laid the foundations for the theory of zinc production. Therefore, he is often called the discoverer of zinc.

In 1805, Charles Hobson and Charles Sylvester from Sheffield patented a method of processing zinc - rolling at 100-150 ° C. The first zinc in Russia was obtained on January 1, 1905. The first plants where zinc was produced by the electrolytic method appeared in 1915 in Canada and the USA.

Obtaining zinc

It is impossible to find this element alone as a metal in nature. People extract it from ores, and then enrich it and obtain its concentrates. After receiving it, it is fired in special furnaces, further bringing it to the required state.

The main method of obtaining this metal is the electrolytic method.

Concentrates obtained by firing in a furnace are treated with a special solution, after which they are thoroughly cleaned of various impurities and subjected to electrolysis.

Applications of zinc

Zinc has a special place among many industrial metals. It is one of the young metals.

It began to be produced at the beginning of the 19th century. At that time, production volume was no more than 900 tons per year. Today, the largest producers of zinc are foreign countries (USA, Canada, Australia), which account for 60 million tons per year.

So, what are the industrial uses of zinc?

This video will tell you about the use of zinc:

Main areas

The main areas of application of zinc are:

- Production of galvanized steel. This area accounts for half (50%) of the total use of zinc.

- Manufacturing of bronze and brass. This area accounts for approximately 20-25%.

- Production of zinc-based alloys.

- Chemical production. The smallest area of expenditure in terms of volume (only 10%).

Unalloyed zinc is not used as a construction material. For these purposes, it does not have the necessary technological, mechanical and physical properties.

In the case of alloying, the above properties are significantly improved. Therefore, zinc is often used in the manufacture of alloys based on aluminum, copper, lead and brass.

Zinc has several grades. Depending on them, the metal can be used:

- For galvanizing steel.

- For the production of zinc alloys.

- For the production of semi-finished zinc products.

- For the production of zinc compounds.

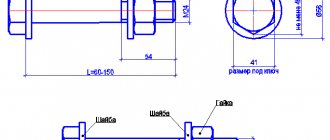

Metal products

- The most popular in construction and industry are zinc sheets. They come in different thicknesses. The thickness of the thinnest sheet can be 0.15 mm, and the thickest - 1.5 mm or more. Zinc sheets are often used in the production of galvanized cookware, gutters and general pipes.

- Zinc sheets are also well used for the manufacture of printing plates for printing houses, for the manufacture of chemical power sources and roofing.

By spraying zinc-containing paints, welded seams are processed on construction sites themselves.

Galvanizing methods

Today, there are different technologies for applying zinc to the surface of products. It is necessary to consider each of them in detail.

Hot galvanizing method

The metal product is degreased, washed and etched in advance. Zinc is melted at a temperature of 450–480 °C. The part is lowered into the liquid metal. The operating principle of this method is based on the fact that iron and its alloys are well wetted. As a result, a coating of significant thickness from 40 to 450 microns is formed, due to which the product is reliably protected from corrosion. However, the hot method also has disadvantages. These include:

- uneven layer thickness;

- it is impossible to use the method for parts with precise tolerances, and in cases where the characteristics of the fastener change under the influence of high temperature.

There is also a possibility that after hot-dip galvanizing, the strength of the fastening will decrease, the so-called embrittlement. To avoid such a situation, the product must be thermally treated after applying zinc, but even this does not provide a complete guarantee. The method under consideration is not suitable for parts coated with paints or powder paints. The reason is the low adhesion between them and hot zinc.

Hot zinc surface treatment

Cold galvanizing method

This method has 2 more names: galvanic and electrolytic. In this case, the technology resembles the process of dyeing a product, but instead of paints, a special composition containing zinc is used. As a result, the part is coated with an anti-corrosion layer. Unlike the previous method, fasteners of any size and painted products can be cold galvanized. Using this method, increased chemical resistance is achieved. The weak points of the method include the small thickness of the layer - 5–35 microns, which leads to a decrease in anti-corrosion properties. The method under consideration, like the previous one, does not exclude the occurrence of embrittlement.

Thermal diffusion galvanizing method

The coating obtained using this method is a positive electrode, while the steel is negative. This is how electrochemical protection occurs. Thermal diffusion galvanizing can only be used for products whose materials are carbon steel, cast iron and low-impurity steel. The galvanizing process occurs as follows. The surface of the product is saturated with zinc, and the medium should be powder and the temperature should be 290–450 °C. The steel grade and product type affect the choice of temperature. In this way, you can achieve any thickness of the protective layer from 6 to 110 microns. With this method, a part is placed in a closed container and a special saturated mixture is added. Final treatment is required to ensure that white corrosion products do not form on the products when they come into contact with salt water and condensate.

The described technology is applicable to workpieces with threads and complex geometric shapes. As a result, a uniform layer is formed over the entire surface; zinc does not accumulate in recesses or joints. Thanks to this advantage, there is no need to remove the coating on the internal threaded part, as is necessary after hot-dip galvanizing. There is also no embrittlement, meaning this technology is suitable for high-strength fasteners. The level of anti-corrosion resistance is 1.5–2 times higher than with galvanic galvanizing, and 3–5 times higher than with the hot method. Also, this technology is characterized by high adhesion of the zinc layer to paints and high accuracy, so the scope of application also extends to structures with precise tolerances. The applied anti-corrosion layer is very wear-resistant and therefore suitable for parts that are frequently assembled and disassembled.

Zinc crystal lattice:

| 500 | Crystal cell | |

| 511 | Crystal grid #1 | |

| 512 | Lattice structure | Hexagonal close-packed |

| 513 | Lattice parameters | a = 2.6648 Å, c = 4.9468 Å |

| 514 | c/a ratio | 1,856 |

| 515 | Debye temperature | 234K |

| 516 | Name of space symmetry group | P63/mmc |

| 517 | Symmetry space group number | 194 |

Metal oxidation reactions

Zinc oxidation occurs in air with the formation of an oxide film, which protects the surface from further destruction under the influence of reagents and prevents the displacement of hydrogen from water.

The oxidation state exhibited by a chemical element in compounds is +2.

- Zinc easily dissolves in dilute hydrochloric and sulfuric acids. As a result of the reaction, sulfuric acid is reduced to sulfur or hydrogen sulfide.

- As a result of the reaction of zinc with nitric acid, various acid reduction products are formed.

- When zinc reacts with a solution of potassium permanganate, the solution becomes discolored.

- The reaction of the metal with potassium vanadate is characterized by the reduction of vanadium with a sequential change in the color of the solution: yellow, blue, green, violet.

- Zinc metal dissolves in high concentration alkali solutions.

- Metal oxides can be obtained as a result of the thermal decomposition of carbonates and the synthesis of simple substances.

- Zinc salts are easily hydrolyzed. As a result of the reaction of zinc metal with a solution of metal chloride, hydrogen is released.

Where and how is Zinc mined?

Zinc is the fourth most widely used metal, after iron, aluminum and copper. Annual zinc production is about 13 million tons. The world's largest zinc production company is Nyrstar. It is a merger of the Australian company OZ Minerals and the Belgian Umicore. About 70% of zinc is obtained from the mining of zinc ore, and the remaining 30% is obtained from the processing of secondary raw materials. Commercial (pure) zinc is known as Special High Grade, often abbreviated SHG

, and has a purity of 99.995%

95% of the zinc produced from mining comes from sulphide deposits. The main mineral for the production of pure zinc is sphalerite. It is almost always found in combination with sulfide of copper, iron and lead. Zinc mines are scattered throughout the world. The leaders in the zinc mining industry are China, Australia and Peru. In 2014, China produced 38% of the total zinc.

Pure zinc is produced in several stages. The mined ore is finely crushed. The powder is then subjected to froth flotation to obtain zinc sulfide. The resulting mixture typically has a concentration of 50% zinc, 32% sulfur, 13% iron and 5% silica. Zinc oxide is then obtained from zinc sulfide by roasting. After this, obtaining a pure chemical element can be achieved in two ways. The first method is pyrometallergic, and the second is the electrolysis method. The pyrometallurgical method involves the reduction of zinc oxide with carbon or carbon monoxide at a temperature of about 970°C. When using the electrolysis method, the solution is first leached with sulfuric acid, and then an electric current is passed through. The output is zinc with a purity of 99.995%.

Read: Cobalt as a chemical element on the periodic table

Production and use of pure metal

Many types of everyday household items are galvanized. For example:

- metal roofs of buildings,

- building gutters,

- water tanks, etc.

A fairly large proportion of zinc is used in the designs of disposable zinc-carbon non-rechargeable batteries. The brass manufacturing process also requires significant amounts of this substance.

A characteristic feature of zinc is the formation of a number of useful compounds:

- Sulfide (phosphor of old TV screens, oscilloscopes, fluorescent lamps and luminous paints);

- Sulfate (weed protectants, use in textile production);

- Oxide (used to make rubber, helps improve the properties of plastics, paints, inks, concrete, cosmetics).

Many well-known alloys are formed on the zinc component. For example, brass, dental amalgam, bronze and some types of solders. Galvanizing not only prevents water tanks from rusting. Almost all types of cough and cold medicines, vitamin tablets and supplements cannot do without this substance.

Common dietary supplement tablets (capsules) include calcium supplements for strong teeth and bones, vitamin C, omega-3 for the eyes, and zinc for a stronger immune system.

Zinc deficiency in the body is accompanied by various problems in relation to the health of the body and leads to the development of diseases. True, this problem is mainly typical for developing countries, where there are factors of malnutrition in the population and a lack of balanced healthy nutrition.

Galvanizing methods

Metallurgical plants are distinguished not only by their equipment, but also by the production methods used. It depends on the pricing policy, and location (natural resources used for the metallurgical industry). There are several galvanizing methods, which are discussed below.

Hot galvanizing method

This method involves dipping a metal part in a liquid solution. It happens like this:

- The part or product is degreased, cleaned, washed and dried.

- Next, the zinc is melted to a liquid state at temperatures up to 480 °C.

- The prepared product is lowered into the liquid solution. At the same time, it is well wetted in the solution and a coating up to 450 microns thick is formed. This is 100% protection against the effects of external factors on the product (moisture, direct sunlight, water with chemical impurities).

Hot galvanizing of metal structures

But this method has a number of disadvantages:

- The zinc film on the product results in an uneven layer.

- This method cannot be used for parts that meet exact standards according to GOST. Where every millimeter is considered a defect.

- After hot-dip galvanizing, not every part will remain strong and wear-resistant, since brittleness appears after passing through high temperatures.

This method is also not suitable for products coated with paints and varnishes.

Cold galvanizing

This method has 2 names: galvanic and electrolytic. The method of coating a product with corrosion protection is as follows:

- The metal part, the product is prepared (degreased, cleaned).

- After this, the “staining method” is carried out - a special composition is used, which has the main component - zinc.

- The part is coated with this composition by spraying.

Cold galvanizing

Thanks to this method, parts with precise tolerances and products coated with paints and varnishes are protected. Increases resistance to external factors leading to corrosion.

Disadvantages of this method: thin protective layer - up to 35 microns. This results in less protection and shorter protection periods.

Thermal diffusion method

This method makes a coating that is an electrode with positive polarity, while the metal of the product (steel) becomes negative polarity. An electrochemical protective layer appears.

The method is applicable only if the parts are made of carbon steel, cast iron, or steel with impurities. Zinc is used in the following ways:

- At temperatures from 290 °C to 450 °C in a powder medium, the surface of the part is saturated with Zn. Here, the marking of the steel, as well as the type of product, matter - the appropriate temperature is selected.

- The thickness of the protective layer reaches 110 microns.

- A product made of steel or cast iron is placed in a closed tank.

- A special mixture is added there.

- The last step is special treatment of the product to prevent the appearance of white efflorescence from salt water.

Thermal diffusion galvanizing

This method is mainly used when it is necessary to coat parts that have a complex shape: threads, small strokes. The formation of a uniform protective layer is important, since these parts undergo multiple exposures to external aggressive environments (constant moisture).

This method provides the highest percentage of product protection against corrosion.

Galvanized coating is wear-resistant and practically indelible, which is very important for parts that are rotated and disassembled from time to time

Reactions with elements

An important goal of zinc interactions with nonmetals is to obtain binary inorganic compounds. A heated mixture of zinc and sulfur results in sulfide (ZnS)

This compound appears externally as colorless crystals. Sulfide is used in the laser industry as a semiconductor material. The passage of phosphorus vapor through zinc plates forms a substance poisonous to living organisms - zinc phosphide Zn3P2. Phosphide reacts well with acids. In this regard, it is used in the fight against household pests, poisoning the acidic environment in the stomach of rodents.

When heated to 600 °C, the reaction of zinc in a stream of ammonia produces Zn3N2 nitride. This compound is refractory and is often used in air refractory materials. However, it is extremely unstable to water, which quickly decomposes it. There are a number of elements with which zinc reacts only in the presence of water vapor: bromine, fluorine, chlorine. Does not interact in principle with hydrogen, nitrogen, carbon, silicon and boron.

Interaction with acids

The good reaction of zinc with most acids is due to its position relative to hydrogen in the electrochemical activity series of metals. This produces many important zinc salts. These salts are predominantly colorless, they are hygroscopic crystals, the solutions of which, due to hydrolysis, have an acidic environment. In the case of salts of other metals, it will also displace them from solution if they are in the voltage series to the right of the element.

When interacting with acids, zinc salts are formed.

In a solution of the element with sulfuric acid at temperatures below 38 °C, zinc sulfate is formed, the scientific name of which is ZnSO4 sulfate. It is used in the production of viscose, some branches of metallurgy, and in medicine as a disinfectant. ZnCl2 chloride is obtained from a solution of hydrochloric acid with zinc. It is used in the production of batteries, antiseptic impregnation of wood and paper fiber.

Derived compounds

- Zinc and its amphoteric properties are transferred to zinc hydroxides Zn (OH)2. These substances exhibit the chemical behavior of acids and bases at the same time. The hydroxide can be obtained in the form of a white precipitate by the action of an alkali on the sulfate. In its natural state, hydroxide is a crystalline substance that decomposes at temperatures above 130 °C. Used for the synthesis of zinc salts.

- The old method of extracting ZnO oxide, previously referred to as the “French process,” can be called effective. In the presence of highly heated air around the cell plate, zinc vapor will begin to be released, which will then ignite with a bluish light, forming an oxide. In large-scale production, it is extracted from the natural mineral zincite. In addition, thermal decomposition of more complex compounds, such as hydroxide, is widely used to produce oxide.

- The colorless white oxide powder, insoluble in water, expresses its chemical duality. By fusing zinc oxide with alkalis, zincates are obtained. When fused with oxides - silicates. Its own thermal conductivity allows it to be a semiconductor, the band gap of which is 3.36 eV. The oxide has a wide range of uses in the chemical industry, becoming a filler in many plastics. In electronics, not a single TV beam tube can do without it. It is also included in most dermatological ointments.

Mercury Hg

Mercury is the only metal that is in a liquid state at ordinary temperatures (melting point - 38.8°). Mercury is white. It has less reducing activity than zinc. In the voltage series, mercury is located to the right of hydrogen, i.e., it does not displace it from water and acids. The radius of a mercury atom is almost equal to the radius of a cadmium atom, and the charge of the atomic nucleus is much greater, so the electrons of the outer layer are held by mercury much more firmly. ■ 30. Draw the electronic configuration of the outer and pre-outer layer of the mercury atom. Explain why mercury exhibits the least reducing activity among the zinc group metals. (See Answer) Mercury readily forms alloys with other metals called amalgams. Mercury is chemically inactive and can be stored unchanged in air for quite a long time. However, with prolonged low heating it can oxidize, forming mercury oxide: 2Hg + O2 = 2HgO When ground in a mortar, mercury very easily interacts with sulfur, forming black mercury (II) sulfide: Hg + S = HgS Mercury does not react with water, but it reacts well with nitric and concentrated sulfuric acids, which have a strong oxidizing effect. In this case, depending on the temperature at which the reaction is carried out, salts of both monovalent and divalent mercury are formed. Mercury in compounds can be monovalent or divalent. Compounds of both monovalent and divalent mercury are quite stable, although they can transform into each other. It should be noted that mercury is highly toxic, which evaporates easily even at room temperature and can cause severe poisoning that has a strong effect on the heart. When mercury compounds get inside, a disorder of the digestive organs and kidneys occurs. Mercury compounds, such as sublimate, are also very poisonous. Both metallic mercury and some of its salts are used in industry. Metallic mercury is used in the manufacture of thermometers, barometers and some measuring instruments, as well as in the mining of gold to purify it from impurities, since mercury easily forms amalgams with gold and some other precious metals. This property is also used in dental practice to make fillings.

Mercury salts also find some use. For example, sublimate HgCl2 is used as a disinfectant, calomel Hg2Cl2(Cl - Hg - Hg - Cl) - as a mild laxative. In nature, mercury is rarely found in a native liquid state, but more often in the form of compounds, such as cinnabar HgS. To obtain mercury from it, cinnabar is first burned: 2HgS + 3O2 = 2HgO + 2SO2 and then the resulting mercury oxide HgO is decomposed by heating: 2HgO = 2Hg + O2 Usually both reactions occur simultaneously in a single process. ■ 31. What are amalgams? Which amalgam are you already familiar with? (See Answer) 32. List the features of the chemical properties of mercury. 33. What is the physiological effect of mercury? 34. Indicate where metallic mercury is used. 35. What do you know about mercury compounds? 36. In what form can mercury occur in nature and how can it be obtained from natural compounds? Support your answer with reaction equations. 37. Based on the position of mercury in the metal stress series, describe the relationship of mercury to water, hydrochloric acid, dilute and concentrated sulfuric acid, dilute and concentrated nitric acid. (See answer)

Zinc salts

Almost all salts that are not double and complex, that is, do not contain foreign colored ions, are colorless crystalline substances. The most popular in terms of human use are the following.

- Zinc chloride – ZnCL2. Another name for the compound is soldering acid. Externally, it appears as white crystals that absorb air moisture well. Used to clean the surface of metals before soldering, to obtain fiber, in batteries, to impregnate wood before processing as a disinfectant.

- Zinc sulfide. White powder, quickly turning yellow when heated. It has a high melting point, unlike pure metal. It is used in the production of luminescent compounds applied to screens, panels and other objects. Is a semiconductor.

- Zinc phosphide is a common poison used to get rid of gnawing animals (mice, rats).

- Smithsonite, or zinc carbonate – ZnCO3. Colorless crystalline compound, insoluble in water. It is used in petrochemical production, as well as in silk production reactions. It is a catalyst in organic synthesis and is used as a soil fertilizer.

- Zinc acetate – (CH3COO)2Zn. Colorless crystals, highly soluble in all solvents of any nature. It is widely used in the chemical, medical and food industries. Used to treat nosopharyngitis. Used as a food additive E650 - freshens breath, prevents the appearance of plaque on teeth when included in chewing gum. It is also used for pickling dyes, preserving wood, producing plastics and other organic syntheses. Almost everywhere it plays the role of an inhibitor.

- Zinc iodide is a white crystal used in radiography, as an electrolyte in batteries, and as a dye for electron microscopy.

- Black or dark green crystals that cannot be obtained by direct synthesis, since zinc does not react with nitrogen. Formed from metal ammonia. At high temperatures it decomposes with the release of zinc, therefore it is used for its production.

- Zinc nitrate. Colorless hygroscopic crystals. Zinc is used in this form in the textile and leather industries for treating fabrics.

Zinc alloys

Zinc-based alloys with the addition of copper, magnesium and aluminum have a low melting point and have good fluidity. They are easy to process, weld and solder.

Brass

There are two-component and multi-component brasses.

Two-component brass is a zinc alloy with a high copper content. There is yellow brass with copper in the amount of 67%, golden copper or tombac - 75%, and green - 60%. Such alloys can be deformed at temperatures of 300 °C.

Multicomponent brasses, in addition to the 2 main metals, consist of other additives: nickel, iron, lead or manganese. Each of the elements affects the properties of the alloy.

TsAM is a family of zinc alloys. They contain magnesium, aluminum and copper. Such zinc alloys are used in foundries. They contain aluminum in the amount of 4%.

The main area of application of TsAM alloys is zinc die casting. Alloys of this family have low melting points and good casting properties. Their high strength allows the production of durable and complex parts.

Virenium

The alloy consists of zinc (24.5%), copper (70%), nickel (5.5%).

The greatest amount of zinc is found in oysters, meat, liver (other offal), fish, eggs, hard cheeses, cocoa, cereals, and nuts.

Signs of zinc deficiency include:

- loss of smell, taste and appetite

- brittle nails and the appearance of white spots on the nails

- hair loss

- frequent infections

- poor wound healing

- late sexual content

- impotence

- fatigue, irritability

- decreased learning ability

- diarrhea

Zinc is actively used in modern life:

- Zinc is often used to create a special coating that makes the product less susceptible to rust and degradation. Such things are called galvanized. This method of corrosion protection is actively used in the construction and automotive industries.

- Zinc is used to make alloys with other metals, which are actively used in mechanical engineering.

- This metal is part of batteries.

- Zinc is added to paints. Zinc white is available for sale, which is used by artists to paint pictures and painters to paint rooms. This white paint is also used for mixing with other colors to create new shades.

- In the chemical industry, metal is used when it is necessary to carry out an organic synthesis reaction.

- Zinc is part of the electrodes that are found inside household appliances.

- The metal, ground to a powder (called an oxide), is used in the pharmaceutical industry. It is included in ointments, creams and powders that have an anti-inflammatory and drying effect.

- Zinc is a filler for rubber.

Attention! Zinc plays an important role in the body as it maintains homeostasis. It is also responsible for the formation of primary sexual characteristics and maintains normal metabolic processes.

This metal actively interacts with oxygen, water, acids and alkalis, hydrogen, and is used in various spheres of human life.