Main parameters of V-belts

View in the catalog

Profile "A"

- Width (measured on the larger base): 13 mm;

- Height (measurement between the planes of the large and small base): 8 mm;

- Design width value: 11 mm;

- Minimum permissible pulley diameter: 71 mm;

- Length: from 420 to 5300 mm;

- Wedge angle value: 40°.

View in the catalog

Profile "B"

- Width (measured on the larger base): 17 mm;

- Height (measured between the planes of the large and small base): 11 mm;

- Design width value: 14 mm;

- Minimum permissible pulley diameter: 112 mm;

- Length: from 530 to 9000 mm;

- Wedge angle value: 40°.

View in the catalog

Profile "C"

- Width (measured on the larger base): 22 mm;

- Height (measurement between the planes of the large and small base): 14 mm;

- Design width value: 19 mm;

- Minimum permissible pulley diameter: 180 mm;

- Length: from 1180 to 9500 mm;

- Wedge angle value: 40°.

View in the catalog

Profile "D"

- Width (measured on the larger base): 32 mm;

- Height (measured between the planes of the large and small base): 19 mm;

- Design width value: 27 mm;

- Minimum permissible pulley diameter: 315 mm;

- Length: from 1900 to 12500 mm;

- Wedge angle value: 40°.

View in the catalog

Profile "Z"

- Width (measured along the larger base): 10 mm;

- Height (measurement between the planes of the large and small base): 6 mm;

- Design width value: 8.5 mm;

- Minimum permissible pulley diameter: 45 mm;

- Length: from 360 to 2800 mm;

- Wedge angle value: 40°.

Belts for variable speed drives

The applicability of V-belts is determined by the shape and dimensions of their cross-section. That is why the production of different types of products is regulated by their own regulatory documents. CVT belts for industry are manufactured in accordance with GOST 24848.2-81, and for agricultural machines - in accordance with GOST 26379-84. The angle of convergence of the sides is 26°. The summary table of V-belt tension for variators and other main parameters of these products is as follows:

| Regulatory document | Product designation | Sectional width of the product along the larger base W (bo) in mm | Section height T in mm | Estimated length Lp according to external measurement in mm | Amount of effort to control belt tension in kgf | |

| Domestic classification | International classification | |||||

| GOST 24848.2-81 | 1-B16 | W16 | 16 | 5 | 450 – 1 000 | 14 |

| 1-B20 | W20 | 20 | 6,5 | 560 – 1 250 | 18 | |

| 1-B25 | W25 | 25 | 8 | 710 – 1 600 | 22 | |

| 1-B32 | W31.5 | 32 | 10 | 900 – 2 000 | 30 | |

| 1-B40 | W40 | 40 | 13 | 1 120 – 2 500 | 42 | |

| 1-B50 | W50 | 50 | 16 | 1 400 – 3 150 | 60 | |

| 1-B63 | W63 | 63 | 20 | 1 600 – 4 000 | 90 | |

| 1-B80 | W80 | 80 | 25 | 2 500 – 5 000 | 140 | |

| GOST 26379-84 | SV-25 | – | 25 | 12,5 | 800 – 1 600 | 45 |

| SV-32 | – | 32 | 15 | 1 000 – 2 000 | 70 | |

| SV-38 | – | 38 | 17,5 | 1 250 – 2 500 | 100 | |

| SV-45 | – | 45 | 20 | 1 400 – 2 800 | 140 | |

| SV-50 | – | 50 | 22 | 1 600 – 4 000 | 180 | |

In addition, for equipment in operation according to GOST 26379-84, variable speed belts are manufactured with section sizes of 28x16, 40x20 and 45x22 mm. Belts produced in accordance with both regulatory documents can be smooth or toothed.

Application area

Classic V-belts are produced in accordance with GOST 1284.2-89. They have a trapezoidal shape, ensuring uniform contact with the pulley. Thanks to this, the tensile load is evenly distributed, which eliminates changes in the size of the belt during operation and increases its service life. Belts of this type are used in:

- production machines;

- agricultural machines;

- industrial fans;

- construction equipment;

- industrial compressor stations.

Main parameters of narrow-profile V-belts

Profile "SPZ"

- Width at larger base: 9.7 mm;

- Belt thickness: 8mm;

- Design width: 8.5 mm;

- Minimum possible pulley diameter: 63 mm;

- Length: from 500 to 2037 mm;

- Wedge angle: 40°.

Profile "SPA"

- Width at larger base: 12.7 mm;

- Belt thickness: 10 mm;

- Design width: 11 mm;

- Minimum possible pulley diameter: 90 mm;

- Length: from 750 to 2650 mm;

- Wedge angle: 40°.

View in the catalog

Profile "SPB"

- Width at larger base: 16.3 mm;

- Belt thickness: 13 mm;

- Design width: 14 mm;

- Minimum possible pulley diameter: 140 mm;

- Length: from 1250 to 8000 mm;

- Wedge angle: 40°.

View in the catalog

Profile "SPC"

- Width at larger base: 22 mm;

- Belt thickness: 18 mm;

- Design width: 19 mm;

- Minimum possible pulley diameter: 224 mm;

- Length: from 1800 to 10000 mm;

- Wedge angle: 40°.

Application area

Products of the SP(...) series are reinforced narrow-profile belts for operation at high speeds and increased loads. Narrow V-belts differ from classic ones only in overall dimensions; in other characteristics, they are the same belts, only with a reinforced design. The reinforced cord of the belt allows it to be used for:

- various industrial equipment;

- agricultural machinery;

- stationary agricultural machines.

The belts can be successfully operated at temperatures from -30°С to +60°С (for tropical and temperate climates) or from -60°С to +40°С (cold/very cold climates).

Marking features

In the abbreviation of belt designations, the letter indices indicate the following: SP - from the English “super power”. Translated, it means “increased power.” That is, SPA is a reinforced V-belt with profile A. Belts with profiles B, C, Z are designated similarly. For technical parameters, the following designations are used:

- W – width along the upper (larger) part in mm;

- L (Wd) – the value of the estimated belt width in mm;

- H (T) – belt thickness in mm;

- j(40°) is the angle of the wedge-shaped part of the belt, it is the same for all sections.

Classic profile V-belts with wrap

Modern V-belts are approximately the same in design for all manufacturers. They consist of a rubber compound, cord and wrapping fabric. The quality of the belt depends on the materials used and production technology.

Each V-belt has 3 lengths:

- Li

– internal length (belt length along the internal edge) - Lp (Lw, Ld)

– design or working length (approximately equal to the length along the cord line, i.e. the length of the cord) - La

– external length (length along the outer edge)

The relationship between these lengths, as a rule, is in each manufacturer's catalog. There are several options for designating V-belts.

Designation according to GOST 1284-89.

In the USSR and subsequently in Russia, GOST 1284.1-89 - 1284.3-89 was adopted, according to the conditions for the production of classic profile V-belts. Currently, Russian and UZEMIK belts are produced with the GOST designation; also, under the guise of Russian belts, many Chinese products are offered on the market, which are also often marked according to GOST.

| Profile designation | Width, W | Height, T |

| Z (0) | 10 | 6 |

| A | 13 | 8 |

| B (B) | 17 | 11 (10,5) |

| C (B) | 22 | 14 (13,5) |

| D (G) | 32 | 19 (20) |

| E (D) | 38 (40) | 23,5 (25) |

| E0 (E) | 50 | 30 |

In the designation of a belt according to GOST, the calculated length Lp is used to indicate the length for a classic profile belt. Therefore, to select a ContiTech belt, you will need to select a belt according to the design (working length), which is designated in Western catalogs as Lw.

Example notation:

Belt C (B) 2500 GOST 1284.1, where 2500 is the design length in mm.

Belts made in Russia and China are, as a rule, significantly inferior in quality to German ones, therefore, by replacing them with ContiTech, you are guaranteed to get a longer service life and increase the reliability of the drive.

European designation according to DIN 2215

In Europe, the width of the top edge is used to indicate the belt profile:

| Profile designation | Width, W | Height, T |

| 10 | 10 | 6 |

| 13 | 13 | 8 |

| 17 | 16,5 | 11 |

| 22 | 22 | 14 |

| 32 | 31,5 | 19 |

| 40 | 38 | 24 |

The European designation indicates the internal belt length Li.

Example: 22×2500, where 2500 is the internal length in mm.

American RMA designation

In America, letters are used to designate the belt profile and all sizes are in inches:

| Profile designation | Width, W | Height, T |

| A | ½” | 5/16” |

| B | 21/32” | 13/32” |

| C | 7/8” | 17/32” |

| D | 1 ¼” | ¾” |

| E | 1 ½” | 29/32” |

In the American designation, the same as in the European designation, the internal belt length Li is specified. The length Li is given in inches.

Example C 98.0, where 98 is the internal length of the belt in inches, which is equal to Li = 2500 mm.

Designation ContiTech

(all ContiTech classic profile V-belts comply with DIN 2215)

As an international concern, ContiTech sells its products in all countries in the world, therefore universal belt markings are used:

22 x 2500 C 98.0 C 2550 L=L, where

Li=2500mm or 98″, Lw=2550mm, L=L – means that the belt is manufactured with a high length tolerance and is suitable for installation in sets (several belts for one drive).

You can find a list of lengths Ld(Lw) for ContiTech belts on our website in the “V-belts” section in the product cards.

Conversion table from GOST designations:

| GOST designation | Width, W in mm | Height, T in mm | Designation ContiTech, DIN 2215 | Width, W in mm | Height, T in mm |

| Z (0) | 10 | 6 | 10/Z | 10 | 6 |

| A | 13 | 8 | 13/A | 13 | 8 |

| B (B) | 17 | 11 (10,5) | 17/B | 16,5 | 11 |

| C (B) | 22 | 14 (13,5) | 22/C | 22 | 14 |

| D (G) | 32 | 19 (20) | 32/D | 31,5 | 19 |

| E (D) | 38 (40) | 23,5 (25) | 40/E | 38 | 24 |

| E0 (E) | 50 | 30 |

Main characteristics of narrow-profile timing belts

Profile "XPZ"

- Large base width: 9.7 mm;

- Thickness: 8 mm;

- Design width value: 8.5 mm;

- Length: from 630 to 3550 mm;

- Wedge angle: 40°.

Profile "XPA"

- Large base width: 12.7 mm;

- Thickness: 10 mm;

- Design width value: 11 mm;

- Length: from 690 to 3550 mm;

- Wedge angle: 40°.

View in the catalog

Profile "XPB"

- Large base width: 16.3mm;

- Thickness: 13 mm;

- Design width value: 14 mm;

- Length: from 1060 to 4250 mm;

- Wedge angle: 40°.

View in the catalog

Profile "XPC"

- Width of large base: 22 mm;

- Thickness: 18 mm;

- Design width value: 19 mm;

- Length: from 2280 to 5000 mm;

- Wedge angle: 40°.

Application area

Products of the SP(...) series are reinforced narrow-profile belts for operation at high speeds and increased loads. Narrow V-belts differ from classic ones only in overall dimensions; in other characteristics, they are the same belts, only with a reinforced design. The reinforced cord of the belt allows it to be used for:

- various industrial equipment;

- agricultural machinery;

- stationary agricultural machines.

XP(...) series belts are products with a reinforced profile for operation under extreme load conditions. They are used to operate as part of highly loaded industrial drives operated at ambient temperatures from -30°C to +60°C (temperate and tropical climates), from -60°C to +40°C (cold and very cold climates). The use of a molded toothed belt profile without wrapping the side edges allows for a more even distribution of thermal and bending loads. In addition, this profile helps reduce noise levels during belt drive operation.

Marking features

In the designation of narrow-profile timing belts, the XP indices indicate the use of products under extreme load conditions. XP – from the English “extreme power”. XPA (B, C, Z) are belts with a reinforced structure of profiles A, B, C and Z, respectively. For technical characteristics, the following designation is used:

- W – width of the larger base in mm;

- L (Wd) – estimated belt width in mm;

- H (T) – belt height in mm;

- j(40°) is the angle of the wedge-shaped part, it is the same for all sections.

Belt drives

V-BELTS (GOST 1284.1-89)

The description applies to endless rubber-fabric (cord-fabric and cord-cord) drive V-belts of normal sections intended for drives of machine tools, industrial installations and agricultural machines operating at ambient temperatures: from -30

up to

+60oС

- for temperate and tropical climates;

from -60

to

+40oС

- for cold and very cold climates and establishes their sizes and control methods.

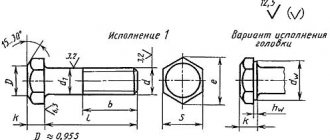

BELT SECTION DIMENSIONS MAIN DIMENSIONS

| Section designation | Wp | W reference | T | α | |||

| Nom. | maximum deviation | Nom. | maximum deviation | Nom. | maximum deviation | ||

| Z (0) | 8,5 | + 0,4 — 0,3 | 10 | 6.00 | + 0,3 — 0,3 | 40° | ± 1° |

| A | 11,0 | + 0,6 — 0,4 | 13 | 8,00 | + 0,4 — 0,4 | ||

| B (B) | 14,0 | + 0,7 — 0,5 | 17 | 11 (10,5) | + 0,5 — 0,5 | ||

| C (B) | 19,0 | + 0,8 — 0,8 | 22 | 14 (13,5) | + 0,5 — 0,5 | ||

| D (G) | 27,0 | + 0,9 — 0,6 | 32 | 20 (19,0) | + 0,6 — 0,6 | ||

| E (D) | 32,0 | + 1,0 — 0,7 | 38 (40) | 25 (23,5) | + 0,7 — 0,7 | ||

| E0 (E) | 42,0 | + 1,0 — 0,8 | 50 | 30,0 | + 0,8 — 0,8 | ||

| 40x20 | 35,0 | + 1,0 — 0,7 | 40 | 20,0 | + 0,7 — 0,7 | ||

| 1. For newly designed drives, do not use EO(E) and 40x20 belts! 2. Belts with dimensions in brackets were manufactured before 01/01/1995. 3. Maximum deviations in the dimensions of belt sections are given only for the design of technological equipment and measuring pulleys. | |||||||

The design width Wp is taken to be the cross-sectional width of the belt under tension at the level of the neutral line.

LEGEND

Belt of section C(B) with a design length of 2500, class IV, used in areas with a temperate climate: Belt C(B) - 2500 GOST 1284.1-89

The same, for high-precision transmissions of moving agricultural machines:

Belt S(V) - 2500 IV PSkh GOST 1284-89

The same, in areas with cold and very cold climates:

Belt S(V) - 2500 IV PSkh HL GOST 1284-89 ESTIMATED BELT LENGTHS MEASURED UNDER TENSION

| Estimated belt length Lp | Belt section GOST 1284.1-89 | ||||||

| Z (0) | A | B (B) | C (B) | D (G) | E (D) | E0 (E) | |

| 400, (425), 450, (475), 500 | |||||||

| (530), 560, (600) | |||||||

| 630, (670), 710, (750), 800, (850), 900, (950), 1000, (1060), 1120, (1180), 1250, (1320), 1400, (1500), 1600, (1700) | |||||||

| 1800, (1900), 2000, (2120) | |||||||

| 2240, (2360), 2500, (2650), 2800, (3000), 3150 | |||||||

| (3350), 3550, (3750) | |||||||

| 4000, (4250), 4500 | |||||||

| (4750), 5000, (5300), 5600, (6000) | |||||||

| 6300, (6700) | |||||||

| 7100, (7500), 8000, (8500), 9000, (9500), 10000, (10600) | |||||||

| 11200, (11800), (13200), 14000 | |||||||

| (15000) | |||||||

| 16000, (17000), 18000 | |||||||

| Difference between design and internal belt lengths | 25 | 33 | 40 | 59 | 76 | 95 | 120 |

Note:

The estimated belt lengths indicated in brackets are used in technically justified cases. By agreement between the manufacturer and the consumer, it is allowed to use belts of other lengths for imported equipment.

A full description of these belts can be found in GOST 1284.1-89 “V-belts with normal sections. Basic dimensions and control methods"

.

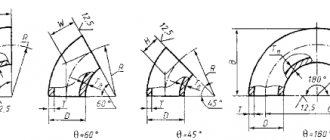

PULLEYS FOR DRIVING V-BELTS (GOST 20889-88) PULLEY GROOVE PROFILE MAIN DIMENSIONS NOMINAL TRANSMITTED POWER

Note:

This table corresponds to one of the methods for determining the transmitted power! (Anuriev V.I. 1978). In Anuriev V.I. for 1999, tables are given that take into account the rotation speed of the smaller pulley and the length of the belt.

Each pulley operating at speeds above 5 m/s must be balanced. Static balancing accuracy standards are given in GOST 20889-88.

| Pulley peripheral speed, m/s | Permissible imbalance, g m |

| from 5 to 10 | 6 |

| from 10 to 15 | 3 |

| from 15 to 20 | 2 |

| from 20 to 30 | 1 |

For small drives we recommend V-belts for compact drives from POLYFLEX

Today, many types of V-belts from different manufacturers are used in our country.

V-belts are mainly used according to the Russian GOST standard and the European DIN standard. For example: classic section (Z, A, B, C, D, E), narrow reinforced (SPZ, SPA, SPB, SPC), narrow reinforced with molded tooth (XPZ, XPA, XPB, XPC), double-sided V-belts (AA , BB, CC, DD), multi-ribbed (PJ, PK, PL, PM), polyurethane V-belts (3M, 5M, 7M, 11M), multi-ribbed V-belts (SPB, SPC, 9J, 15J, 3VX, 5VX), variator , polyurethane V-belts with steel cord (Ferropan). Many belt manufacturers produce belts according to both GOST and DIN standards. Most types of V-belts are interchangeable by these standards. INTERCHANGEABILITY OF V-BELTS FROM LEADING WORLD MANUFACTURERS

| Belt brand type | ContiTech | Optibelt | Gates | Megadyne | Fenner | Goodyear | Bando |

| Classic profile with wrap (Z, A, B, C, D, E) | Conti-V® Standard MultiFlex | Optibelt VB | Hi-Power® VulcoPower™ | Oleostatic® | Fenner® Classic PBV-Belts | Torque-Flex® V | Classic V-belt |

| Narrow profile with wrap (SPZ, SPA, SPB, SPC) | Conti-V® Standard UltraFlex | Optibelt SK Red Power II | Super HC® VulcoPlus™ | SP Kompattex® | Fenner® PowerPlus® wedgebelt | Narrow SP Power Ace® | |

| Narrow profile with molded tooth (SPZ, SPA, SPB, SPC) | Conti-V® Advance FO-Z Advance FO® -Power | Optibelt Super X-Power | Super NS® MN | Jnea X Power-Wedge® | Fenner® CRE PLUS® wedge belt Fenner® Quattro PLUS® belt | Torque Flex® Wedge Hy-T® Wedge | Power Ace® Cog Narrow SPX |

| Narrow profile with molded tooth (XPZ/3VX, XPA, XPB/5VX, XPC) | Advance FO® -Power | Optibelt Super X-Power | Quad-Power® III | Linea X Power-Wedge® | Fenner® Quattro PLUS® belt | ||

| Classic profile multi-ribbed belts with wrap (A, B, C, D) | Conti-V® Multibelt | Optibelt KB | Hi-Power® PowerBand® | PluriBand® | Hy-T® Torque Team® Plus | Power King® Combo Power Scrum | |

| Narrow profile stranded belts with wrap (SPB, SPC, 9J, 15J, 25J/8V) | Conti-V® Multibelt | Optibelt KB Red Power II | Super HC® PowerBand® | PluriBand® | Fenner® Concord Plus® | Hy-T® Torque Team® Wedge | Power Ace® Combo |

| Narrow profile multi-ribbed belts with molded teeth (3VX, 5VX, XPZ, XPA, HRB) | Optibelt KBX | Quad-Power® II PowerBand® | Hy-T® Torque Team®V | Power Ace® Cog Combo | |||

| Classic profile with wrap. Premium class. (AP, BP, CP - aramid cord) | Predator® | ||||||

| Narrow profile with wrap. Premium class. (SPBP, SPCP, 8VP - aramid cord) | CONTI®-V DIN 7753 POWER | Optibelt Blue Power | Predator® | ||||

| Narrow profile multi-ribbed belts with wrap. Premium class. (SPBP, SPCP, 9JP, 15JP, 8VP – aramid cord) | CONTI®-V DIN 7753 POWER | Optibelt Rad Power II | Predator® PowerBand® | ||||

| Double-sided V-belts (AA, BB, SS, DD) | Optibelt DK | Hi-Power® Dubl-V | EsaFlex® | Hex belt | Double V | ||

| Premium belts for power metering drives (3L, 4L, 5L) | CONTI®-V Garden | PowerRated® | XDV | Insta-Power™ | UltraPower AG | ||

| Polyurethane V-belts (60°) (ZM, 5M, 7M, 11M) | Optibelt WR | Polyflex® | Neothane® | Banflex | |||

| Multi-ribbed polyurethane V-belts (60°) (3M-JB, 5 M-J B, 7M-JB, 11M-JB) | PolyflexJB™ | Banflex® Combo | |||||

| Polycline (RN, PJ, RK, PL, RM) | Multirib® +E4 Power | Optibelt RB | Micro-V® | PV | Fenner® Poly Drive Ribbed belts | Poly-V | Rib Ace® |

| CVT | Varispeed® (Varidur, Agridur) | Optibelt SuperVX | Multi-Speed™ | Variable Speed | Power Max® |

Related documents:

Poly V-belts example of a V-belt drive pulley GOST 1284.2-89 - “V-belt drives of normal sections. Technical conditions" GOST 1284.3-80 - "V-belts of normal sections. Transmitted powers" GOST 1284.3-96 - "V-belts with normal sections. Transmitted powers" GOST 23831-79 - "Flat drive rubber-fabric belts. Technical conditions" GOST 24848.1-81 - "Variable V-belts for industrial equipment. Main dimensions and methods of their control" GOST 26379-84 - CVT belts for agricultural machines GOST 5813-93 - V-belts for fans OST 38 05114-76 - Toothed injection molded polyurethane and rubber belts, with metal cord TU 38 105763-89 - Poly V-belts TU 38 405-51 /3-3-236-90 — V-belts with a molded tooth on the lower base TU 38 105349-90 — Fan V-belts, antistatic for car engines TU 38 405-51 /3-3-238-90 — Multi-strand narrow V-belts TU 38 105 1998-91 — Narrow section belts TU 38 305 106-97 — Fan V-belts TU 38 305164-2005 — Antistatic V-belts with cord design TU 2563-430-05011868-98; TU 2563-011-001 52106-97; TU 2563-010-001 52106-96; DIN 7722 - Hexagonal (double) V-belts