The range of rolled metal products includes a standardized list of profile types indicating technical parameters in accordance with GOST. The product range of metallurgical plants is classified according to several criteria:

- types of profile;

- sizes;

- varieties;

- types, quality and grade of steel.

The rental nomenclature is contained in several directories:

- metallurgy;

- mechanical engineering;

- textbooks on strength of materials;

- in the plant supply directory;

- collection of GOSTs.

The information is collected by type and presented in the form of rolled metal tables indicating the main dimensions and characteristics of rolled metal. For ease of calculations, a separate column provides information on the weight of 1 linear meter in kilograms.

Based on the weight of the assortment, the total weight of the order is determined and the necessary transport for transportation is selected, the weight of the metal structure and the load on the foundation are calculated, the weight of the finished product is calculated, and strength calculations are carried out.

Nomenclature of the manual

The main assortment includes:

- corner is equal and unequal;

- fittings;

- steel circle;

- channel;

- channel (bent);

- Sheet steel;

- pipes;

- seamless and electric-welded pipes;

- profile pipes (rectangular and square);

- I-beam;

- square and hexagon.

The range of rolled metal products is classified into two directions: black and stainless steel. The division occurs in accordance with the type of material used for manufacturing.

According to the production method, a distinction is made between cold-rolled and hot-rolled steel, bent from sheet material.

Hot-rolled profiles are made on special rolling mills, through the profile rolls of which a hot billet is passed under pressure. Rolling mills are included in process equipment lines that are several hundred meters long.

The hot rolling method is used to produce thick sheets, circles, angles, channels, I-beams, and thick-walled pipes.

The range of cold-formed profiles is produced by bending on special profile bending machines. This group includes bent angles, channels, and special profiles.

Hot-rolled profiles have greater strength and resistance to various types of loads than cold-rolled or bent sections.

Types of channels

The most popular type of assortment is channel.

Channel

This is explained by high strength indicators, good weldability, low weight with significant load-bearing capacity. It is used on construction sites for floors, in the manufacture of metal structures such as trusses, columns and reinforced concrete products. For all its advantages, the channel has an affordable price.

Manufacturers offer profiles of various sizes and types. The directory of rolled metal products contains a large list of several dozen items that differ in type, size, symbol, and marking.

In the construction industry, the use of channels helps to strengthen the structure, increase rigidity and performance characteristics. This is explained by the fact that concrete itself is resistant only to compressive stresses. The channel remains stable under the influence of bending load, pressure in the longitudinal and transverse plane.

The main method of obtaining a profile is hot rolling. The raw materials used are blanks produced by forging or continuous casting. The material for production is structural steel grade St 3 or 09G2S, carbon construction steel C 235, C 245.

MetalPromContinent

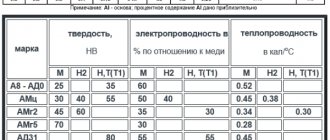

Directory: Steel marking

Steel marking is done with indelible paint, regardless of the steel group and degree of deoxidation.

By agreement of the parties, paint marking is not performed. Letters and numbers for steel: Grades of carbon steel of ordinary quality are designated by the letters St and number (StO, St1, StZ, etc.). High-quality carbon steels are marked with two-digit numbers showing the average carbon content in hundredths of a percent: 05; 08; 10; 25; 40, etc. The letter G in the steel grade indicates a high Mn content (14G; 18G, etc.). Automatic steels are marked with the letter A (A12, A30, etc.). Carbon tool steels are marked with the letter U (U8; U10; U12, etc. Here the numbers indicate the steel content in tenths of a percent).

The designation of the alloy steel grade consists of letters indicating which components are included in its composition and numbers characterizing their average content: A - nitrogen Y - aluminum P - boron F - vanadium B - tungsten K - cobalt C - silicon D - manganese D – copper M – molybdenum N – nickel B – niobium C – selenium T – titanium U – carbon P – phosphorus X – chromium C – zirconium

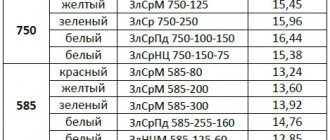

The first digits of the grade indicate the average carbon content in steel (in hundredths of a percent for structural steels and tenths of a percent for tool and stainless steels). Then the letter indicates the alloying element. The numbers following the letter indicate its average content in whole units. When the alloying element content is less than 1.5%, numbers are not placed after the corresponding letter. The letter A at the end of the brand designation indicates that the steel is high quality. Letter Ш – especially high quality. Ordinary quality steel St0; VSt0, BSt0 – Red and green St1, VSt1kp – Yellow and black St2, VSt2kp – Yellow StZ, VStZkp, VStZ, BStZkp, BStZ – Red St4, VSt4kp, VSt4, BSt4kp, BSt4 – Black St5, VSt5 – Green St6 – Blue

Quality carbon steel 08, 10, 15, 20 – White 25, 30, 35, 40 – White and yellow 45, 50, 55, 60 – White and brown

Alloy structural steel Chrome - Green and yellow Chrome-molybdenum - Green and purple Chrome-vanadium - Green and black Manganese - Brown and blue Chrome-manganese - Blue and black Chrome-silicon - Blue and red Chrome-silicon-manganese - Red and purple Nickel-molybdenum - Yellow and purple Chrome-nickel - Yellow and black Chrome ony-nickel-molybdenum – Purple and black Chrome-aluminium – Aluminum

Corrosion-resistant steel Chrome - Aluminum and black Chrome-nickel - Aluminum and red Chrome-titanium - Aluminum and yellow Chrome-nickel-silicon - Aluminum and green Chrome-nickel-titanium - Aluminum and blue Chrome-nickel-niobium - Aluminum and white Chrome-manganese-nickel - Aluminum and brown Chrome-nickel-molybdenum Ethane – Aluminum and Violet

High speed steel P18 – Bronze and red P9 – Bronze

Hard sintered alloys VK2 – Black with a white stripe VKZ-M – Black with an orange stripe VK4 – Orange VK6 – Blue VK6-M – Blue with a white stripe VK6-V – Purple VK8 – Red VK8-V – Red with a blue stripe VK10 – Red with white stripe VK15 – White T15K6 – Green T30K4 – Blue

Types of profile

The nomenclature is represented by the following profile types:

- hot rolled according to GOST 8240–89;

- special purpose according to GOST 19425–74;

- bent equal flange according to GOST 8278–75;

- bent unequal flange according to GOST 8281–80;

- Available in measured lengths from 2 to 12 meters.

The assortment is necessary for the construction of interfloor slabs, bridge spans, and roofing at production facilities. In architectural construction, channel bars are used to strengthen and reinforce walls. It is indispensable for the reconstruction of construction sites and installation of partitions.

In addition to the construction industry, the profile is in demand in the carriage building, many branches of mechanical engineering, shipbuilding and the automotive industry.

The profile is widely used in mechanical engineering

All profile sizes are standardized and comply with GOST:

- h – channel height;

- b – shelf width;

- s – profile wall thickness;

- t – flange thickness;

- R – radius of internal conjugation;

- r – radius of the flange rounding.

Channels with a slope should have a bevel of internal edges of 4–10%.

Hot-rolled steel channel GOST 8240–89

A hot-rolled steel channel looks like a beam with a section profile like the letter “P”. At the edges of the vertical wall there are two shelves perpendicular to it.

The channel designation encodes the size of the wall length, measured in centimeters from one outer edge of the shelf to the other.

For example, channel No. 20. This means that the distance between its edges or height is 20 cm (200 mm).

In terms of shape and size, rolled metal products are characterized by the following series:

- with a slope on the inner edges of the shelves - U;

- has parallel edges - P;

- with parallel arrangement of shelf edges, economical - E;

- light series with parallel shelves - L;

- special purpose - S.

The dimensions of the assortment and the characteristics of the section are summarized in tables, the distribution is made in accordance with the types of profile. The permissible maximum deviations of profile dimensions are also standardized depending on the size range.

There is a table for determining the weight of each part.

| Serial channel by number | Part dimensions in mm | Nominal weight, kg | Meters per ton of product | ||

| height | width | thickness | |||

| P5 | 49–50 | 30–32 | 4,3–4,4 | 4,79–4,85 | 206,74 |

| P6.5 | 65–66 | 36–37 | 4,4–4,6 | 5,93 | 169,78 |

| P8 | 65–67 | 36–37 | 4,3–4,4 | 7,99 | 141,79 |

| P10 | 97–100 | 44–46 | 4,4–4,5 | 8,57–8,6 | 116,42 |

Manufacturing accuracy ensures compliance with the actual dimensions specified in the standard. The following accuracy classes are defined:

- high level of accuracy - class A;

- increased level of accuracy – class B;

- standard – class B.

The designation of the accuracy class is indicated in the marking.

Requirements for the chemical composition of steel

The chemical composition of steel (main elements) according to the analysis of the ladle sample must comply with the standards in accordance with GOST 380-2005, indicated in the table below

| steel grade | Mass fraction of chemical elements, % | ||

| carbon | manganese | silicon | |

| St0 | No more than 0.23 | — | — |

| St1kp | 0,06-0,12 | 0,25-0,50 | No more than 0.05 |

| St1ps | 0,06-0,12 | 0,25-0,50 | 0,05-0,15 |

| St1sp | 0,06-0,12 | 0,25-0,50 | 0,15-0,30 |

| St2kp | 0,09-0,15 | 0,25-0,50 | No more than 0.05 |

| St2ps | 0,09-0,15 | 0,25-0,50 | 0,05-0,15 |

| St2sp | 0,09-0,15 | 0,25-0,50 | 0,15-0,30 |

| St3kp | 0,14-0,22 | 0,30-0,60 | No more than 0.05 |

| St3ps | 0,14-0,22 | 0,40-0,65 | 0,05-0,15 |

| St3sp | 0,14-0,22 | 0,40-0,65 | 0,15-0,30 |

| St3Gps | 0,14-0,22 | 0,80-1,10 | No more than 0.15 |

| St3Gsp | 0,14-0,20 | 0,80-1,10 | 0,15-0,30 |

| St4kp | 0,18-0,27 | 0,40-0,70 | No more than 0.05 |

| St4ps | 0,18-0,27 | 0,40-0,70 | 0,05-0,15 |

| St4sp | 0,18-0,27 | 0,40-0,70 | 0,15-0,30 |

| St5ps | 0,28-0,37 | 0,50-0,80 | 0,05-0,15 |

| St5sp | 0,28-0,37 | 0,50-0,80 | 0,15-0,30 |

| St5Gps | 0,22-0,30 | 0,80-1,20 | No more than 0.15 |

| St6ps | 0,38-0,49 | 0,50-0,80 | 0,05-0,15 |

| St6sp | 0,38-0,49 | 0,50-0,80 | 0,15-0,30 |

In steel grades St3kp, St3ps, St3sp, St4kp, St4ps, St4sp, St5ps, St5sp, it is allowed to reduce the lower limit of the mass fraction of manganese by 0.10% for rolled thin sheets and thick rolled sheets up to 10 mm thick, provided that the required level of mechanical properties is ensured.

In steel grades St3kp, St3ps and St3sp, intended for the production of long and shaped rolled products, except for those supplied for shipbuilding and carriage building, it is allowed to reduce the lower limit of the mass fraction of manganese to 0.25%, and the lower limit of the mass fraction of carbon is not standardized provided that the required level is ensured mechanical properties.

In steel grades St2kp, St3kp and St4kp, intended for the production of long and shaped steel, it is allowed to increase the mass fraction of silicon to 0.07%.

When deoxidizing semi-quiet steel with aluminum, titanium or other deoxidizing agents that do not contain silicon, as well as several deoxidizing agents (ferrosilicon and aluminum, ferrosilicon and titanium, etc.), the mass fraction of silicon in the steel is allowed less than 0.05%. Deoxidation with titanium, aluminum and other deoxidizing agents that do not contain silicon is indicated in the quality document.

The mass fraction of chromium, nickel and copper in steel of all grades, except St0, should be no more than 0.30% each. In steel grade St0, the mass fraction of chromium, nickel and copper is not standardized.

In steel produced by the scrap process, a mass fraction of copper up to 0.40%, chromium and nickel - up to 0.35% each are allowed. At the same time, in steel grades St3kp, St3ps, St3sp, St3Gps and St3Gsp, the mass fraction of carbon should be no more than 0.20%.

The mass fraction of sulfur in steel of all grades, except St0, should be no more than 0.050%, phosphorus - no more than 0.040%. In steel grade St0, the mass fraction of sulfur should be no more than 0.060%, phosphorus - no more than 0.070%.

The mass fraction of nitrogen in steel should be no more than:

- smelted in electric furnaces - 0.012%;

- open hearth and converter - 0.010%.

It is allowed to increase the mass fraction of nitrogen in steel to 0.013%, provided that the norm of the mass fraction of phosphorus is reduced by at least 0.005% for each increase in the mass fraction of nitrogen by 0.001%.

The mass fraction of arsenic in steel of all grades, except St0, should be no more than 0.080%. The mass fraction of arsenic in steel grade St0 is not standardized.

Maximum deviations for the chemical composition of finished rolled products, ingots, billets, forgings and further processing products must comply with the standards specified in the table below

| Name element | Maximum deviation for chemical composition, % | |

| boiling steel | semi-quiet and calm steel | |

| Carbon | ±0,03 | +0,03 -0,02 |

| Manganese | +0,05 | +0,05 |

| -0,04 | -0,03 | |

| Silicon | — | +0,03 -0,02 |

| Phosphorus | +0,006 | +0,005 |

| Sulfur | +0,006 | +0,005 |

| Nitrogen | +0,002 | +0,002 |

Up