Centrifugal casting is a special technology that uses centrifugal forces to form castings by freely pouring molten metal into rotating molds. Using centrifugal casting technology, castings are made from steel, cast iron, as well as alloys based on aluminum, copper, titanium, magnesium, zinc and some other metals.

Since with this method of forming castings, centrifugal forces act on the metal or alloy, which is the starting material, the finished products acquire increased density and improved mechanical characteristics.

Horizontal centrifugal casting

To produce castings using the centrifugal casting method, centrifugal machines with vertical and horizontal axes of rotation are used. They are equipped with investment casting molds and shell molds.

Centrifugal casting with horizontal axis of rotation

This method is the most widely used centrifugal casting method. It consists in the fact that the formation of a casting with a free surface occurs in a field of centrifugal forces. In this case, the inner surface of the mold plays the role of a forming surface. The melt is poured into the mold from the ladle through a special pouring chute. During the production process, the melt spreads over the inner surface of the mold, and under the influence of centrifugal forces it forms a hollow cylinder. After the metal or alloy has hardened, the mold stops and the finished product is removed from it.

Production of iron castings

| 3.4 Centrifugal casting |

Centrifugal casting is a promising method for the production of shaped products with the shape of bodies of rotation, mainly for large-scale production. This casting method is used to produce water and sewer pipes, blanks for cylinder liners of internal combustion engines, linings of ship shafts, drying cylinder bodies of paper-making machines, pipes for power engineering and other critical products.

Centrifugal casting has the following advantages compared to casting in one-time molds. Labor productivity when working on a centrifugal machine increases several times; there is no need for molding areas, mixtures, binding materials for cores, as well as equipment for drying molds and cores.

The centrifugal casting process can be fully mechanized or automated, which reduces scrap losses and reduces the need for highly skilled labor.

Centrifugal castings are characterized by increased mechanical properties of the cast metal. At the same time, significant technical and economic advantages of centrifugal casting are achieved due to savings in metal, energy and the duration of the production cycle.

However, centrifugal casting also has disadvantages: special machines are required; the molds must be of increased strength and tightness; strict dosing of metal is necessary to obtain the desired size of the internal hole of the casting; the segregation of alloy components by density increases. The casting itself can only have the shape of a body of rotation.

The peculiarity of centrifugal casting is that metal is poured into a rotating mold, most often metal. During pouring and crystallization, the metal experiences centrifugal forces.

The axis of rotation of the mold can be horizontal, vertical, inclined, or moving in space during the casting process.

Metal, freely poured into a mold rotating around a horizontal axis, spreads along it under the influence of the kinetic energy of the jet and is drawn into rotational motion due to the friction forces of the metal on the mold. However, such a speed of metal particles when rotating around a horizontal axis cannot be constant due to the pulsation of the resulting force during the rotation of the form, since it consists of a force of gravity that is constant in magnitude and direction and a constant in magnitude, but changing in direction, centrifugal force . This leads to the fact that the free surface of the metal poured into the mold moves downward from the axis of rotation (Fig. 3.10).

Figure 3.10

– Hydrostatic forces acting on the metal when the mold rotates relative to the horizontal axis: 1-melt; 2-form; Fр – resultant of centrifugal (Fc) and gravity (Fg) forces

In long molds, the kinetic energy of the jet of metal being poured is not enough to spread it evenly along the mold, so the rotation axis of such molds is made inclined, or the pouring chute is moved along the mold while pouring the melt, or the mold is moved along a stationary chute. The rotational speed of the mold during centrifugal casting is one of the main technological parameters that determine the quality of the casting. The density of the casting, its mechanical strength, the uniformity of the composition along the radial section, the degree of removal of slag inclusions from the outer surface of the casting to the inner one, and the correct shape of the free surface of the casting depend on the frequency of rotation of the mold.

Determining the mold rotation speed is one of the main issues in the development of casting technology and the design of centrifugal machines. An excessive increase in rotation speed is undesirable due to the possibility of the formation of longitudinal cracks in the castings on the outer surface and increased segregation of alloy elements.

In addition, machines with high rotation speeds are structurally more complex, less convenient and less safe to operate. Therefore, during the technological development of the process and the design of machines, they choose not the highest, but the lowest rotation frequency, which would ensure the proper quality of castings. The lower limit of the rotation speed when casting hollow workpieces with a horizontal axis of rotation is determined by the following condition: the metal being poured during the first revolution around the axis must receive an acceleration exceeding g. Failure to comply with this condition results in “sprinkling” of the metal when pouring into the mold. The most well-known way to calculate the rotation speed of a mold is to calculate it using the gravity coefficient.

The gravity coefficient of centrifugal casting is a number that shows how many times the centrifugal force acting on the metal being poured is greater than the force of gravity. When making calculations, it is necessary to distinguish between pouring into a mold with horizontal and vertical axes of rotation.

When calculating the rotation speed of a mold with a horizontal axis of rotation using the gravity coefficient, it is taken into account that the melt particles are affected by centrifugal force and gravity.

The gravity coefficient K depends on the type of mold and the alloy being poured. For a sand mold with a horizontal axis of rotation, K=75 is taken, for a metal mold K=80, for alloys with a narrow solidification range K=90...100.

With a vertical axis of rotation, the metal freely poured into the mold is gradually entrained by it into a rotational movement. After some time, the angular velocities of rotation of the individual layers of metal and the form itself are leveled off, and the liquid comes to a state of relative rest. In this case, there is no pulsation of the resulting force during the period of rotation of the mold, since the direction of the centrifugal force does not change during rotation relative to the vertical axis.

The heating temperature of the mold before pouring metal, the lining of the mold and the method of pouring metal into the mold affect the formation of centrifugal castings and their quality. Preheating the mold reduces thermal shock when pouring metal, promotes better distribution of metal over diameter and length, improves the quality of the outer surface of castings and reduces chipping defects when casting cast iron.

The refractory coating reduces the speed and degree of heating of the molds when pouring them with metal, and also reduces the cooling rate of the castings, which prevents the formation of cracks when casting steel and chilling when casting cast iron.

For molds, the most common fire-resistant coatings are made from bulk materials (usually dry quartz sand). Due to the high frequency of rotation of the mold, such a coating is applied in an even layer to its wall, is retained on it and is not washed away by a jet of hot metal. But significant sand burning and the formation of poor-quality outer surfaces of castings necessitate the development of more technologically advanced fire-resistant coatings.

It is promising to use liquid fire-resistant coatings based on diatomite for these purposes, for example, fire-resistant paint containing, % (wt. fraction): heat-treated diatomite 55-70; bentonite 1.0-2.5; colloidal solution of silicic acid sol containing 20% Si02 3.0-9.0; water (up to a paint density of 1200-1400 kg/m3) - the rest, as this ensures the production of high-quality single-layer and bimetallic castings from cast iron and steel.

The speed of metal pouring affects the quality of the outer surface of the casting and filling the mold and depends on the critical rotation speed of the mold. It is recommended to speed up the supply of metal at the beginning of pouring so that the metal is quickly distributed over the entire surface of the mold. In this case, non-slates and joints are not formed on the surface of the casting. Subsequently, the rate of increase in layer thickness is reduced in order to create favorable conditions for directional solidification, reduce the hydraulic pressure on the hardened shell and the likelihood of the development of segregation, etc. It is more convenient to regulate the pouring speed when pouring metal through the toe of the ladle and much more difficult - through a stopper or a bowl with a hole.

When developing a technological process for centrifugal casting, it is necessary to take into account the densities of the primary precipitating phases in the crystallization range and the remaining mother liquor. In cases where the density of the primary precipitating phase is less than the density of the liquid, it is necessary to ensure minimum casting speed, metal temperature and mold temperature to ensure directional crystallization.

Water supply and sewer pipes made of gray cast iron are one of the most popular types of products manufactured by centrifugal casting. Pipes are characterized by a long length and relatively small wall thickness. Sewage pipes are made 2 m long and 50-150 mm in diameter with a wall thickness of 4-5 m; water pipes - 2 - 5 m long, 50-1000 mm in diameter and 7.5 - 30 mm in wall thickness. Cast pipes are not processed by cutting. The technical conditions for their acceptance regulate the weight of the pipes and their wall thickness (longitudinal and radial). For water pipes, a leak test is also mandatory. From the mechanical properties, hardness (according to Brunelle) and the so-called ring strength modulus R are determined.

Centrifugal casting of pressure pipes ensures their dense structure and the absence of variations in thickness. This casting method is as economical as possible, since cores are not used to form the inner surface, and mass production of products justifies the use of expensive machines and installations. As a rule, water and sewer pipes are produced in metal, intensively cooled movable forms.

The disadvantages of the process are the significant cost of metal molds with their low durability, the formation of surface chill in castings and large internal stresses, which forces the pipes to be subjected to high-temperature annealing, which increases the cost of the product.

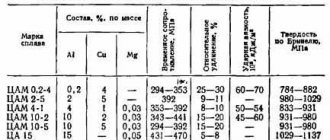

In table 3.2 shows the compositions of cast irons for centrifugal casting of pipes; and in the table 3.3 - characteristics of pressure pipes for various production methods (GOST 9583-75), indicating the advantages of centrifugal casting compared to other methods.

The use of spheroidal graphite cast iron (high-strength) for pressure pipes is promising. The increased strength and ductility of this cast iron and good weldability open up the opportunity to save metal by reducing the thickness of the pipe walls and maintaining high corrosion resistance compared to steel pipelines.

Table H.2

– Cast iron compositions for centrifugally cast pipes

Table 3.3

– Characteristics of cast iron pressure pipes

| 3.4 Centrifugal casting |

Centrifugal casting with vertical axis of rotation

In order to obtain a casting on machines that rotate the mold around a vertical axis, molten metal or alloy is poured from above into a rotating mold through a hole located along the axis of rotation of the spindle.

During rotation, the metal or alloy, under the influence of centrifugal forces, tends to the side walls of the mold (mold). Rotation is carried out until the mold hardens completely. As soon as this happens, the mold stops and the casting is removed from it.

One of the characteristic features of those castings that are produced on machines with vertical axes of rotation is that the thickness of their walls is uneven in height: in the lower part they are thicker. This is largely why castings with a small overall height are usually made in this way: rings, flanges, short bushings.

The plant works with the following metals and alloys:

- bronze,

- cast iron,

- brass,

- and, among other things, provides services for machining of the resulting castings.

compares favorably with its competitors due to its high-tech level of production and centrifugal casting of cast iron . specializes not only as a manufacturer of serial production of spare parts and components, but also as a manufacturer of piece batches and has established itself as a quality supplier.

Delivery of products manufactured at the customer’s request can occur anywhere in Russia and the CIS. In this regard, the castings of our company have become widely known among post-Soviet countries and continue to win new customers.

Advantages and disadvantages of centrifugal casting

Using centrifugal casting, it is possible to obtain a casting with a geometrically correct free surface only if the rotation speed is strictly defined (it is determined by such an indicator as the gravitational coefficient). If the rotational speed of the casting is insufficient, then due to shrinkage, both in the vertical and horizontal position of the axis, distortions inevitably occur.

Thus, it can be stated that one of the advantages of centrifugal casting is that it can significantly improve the fillability of the mold with the melt, since it is subject to increased pressure arising under the influence of centrifugal forces. In addition, fewer shells, pores, and various inclusions are formed in castings, and their density increases significantly.

It should also be noted that the advantage of this casting method is also a reduction in metal consumption and an increase in such an indicator as the yield, due to the absence of a gating system. In addition, when centrifugally casting parts and workpieces in the form of pipes and bushings, there is no need to incur costs for technological rods.

As for the disadvantages, centrifugal casting also has them. These include the difficulty of making castings from those alloys that are prone to segregation; inaccuracy in the dimensions of the cavity of castings having free surfaces; increased contamination of casting surfaces with liquids and non-metallic inclusions (because of this, it is necessary to significantly increase the allowances for their mechanical processing).

Molds for casting silicone baits

Before you start melting baits, you should acquire the most necessary things, without which this process is impossible - a mold for their manufacture. You can either buy it or make it yourself.

On sale, mainly in online stores, there are a variety of forms for casting baits. Of course, buying molds for casting silicone baits will not be difficult, but it is much more interesting and cheaper to make them yourself. In addition, you can make such forms based on your own preferences.

Any form consists of two surfaces that, when in contact, form a sealed area. The surfaces of high-quality forms should be closely adjacent to each other. Up to a dozen contours can be placed on the mold, which greatly speeds up the casting process. High-quality matrices are characterized by the presence of air ducts designed to remove air.

CENTRIFUGAL CASTING MACHINES

CENTRIFUGAL

CASTING MACHINE

Centrifugal casting machine

is a machine for forming a casting that rotates the casting mold in order to influence the metal by centrifugal forces during the process of its crystallization.

Centrifugal machines are used to produce bushings, rings, and pipe blanks from cast iron, steel, bronze, aluminum and their alloys.

The design of a centrifugal casting machine involves the presence of a water cooling system, as well as a frequency converter, which allows you to change and regulate the rotation speed of the mold, which is measured by the number of revolutions per minute. In addition, injection molding machines have a control system consisting of several elements. Thanks to this, the technological process is simplified as much as possible, and losses from defects are reduced.

The advantage of the centrifugal casting method is:

The operating principle of the machine is as follows:

The process of casting into a centrifugal machine is quite simple; liquid metal is poured into a rotating mold (mold, chill mold). Before pouring, the mold is preheated to 250 degrees and painted with paint to avoid burning of the casting to the mold. After it spreads along the inner walls of the mold, cooling with water (dusting) is applied to the outside of the mold to crystallize the casting; the metal crystallizes and remains until the end of crystallization. Centrifugal forces arising during rotation of the mold press the molten metal to the surface of the mold, resulting in its compaction and removal of gas and slag inclusions from it. This results in a strong casting with good density, which always has the shape of a body of revolution.

Operation of centrifugal casting machines

The use of centrifugal casting machines has a number of serious advantages over other casting methods. Thanks to special technology, finished castings are dense, high-quality and wear-resistant, without the inclusion of slag and non-metallic elements. Because of this, the output of quality products is maximized.

In addition, the use of this particular casting technology allows you to significantly save metal and energy, optimally adjust the duration of the production cycle, and increase labor productivity several times. Centrifugal casting eliminates the need for molding space and drying equipment for molds and cores.

Chill casting

Casting metals in a chill mold is a higher quality method. A mold is made - a collapsible mold (usually metal) into which casting is carried out. After solidification and cooling, the chill mold opens and the product is removed from it. The die can then be reused to cast the same part.

Chill casting , chill casting, a method of producing shaped castings in metal molds - chill molds. Unlike other methods of casting into metal molds (pressure casting, centrifugal casting, etc.), when casting in a chill mold, the mold is filled with a liquid alloy and its solidification occurs without any external influence on the liquid metal, but only under the influence of gravity. Basic operations and processes: cleaning the mold from the old lining, heating it to 200-300°C, covering the working cavity with a new layer of lining, inserting rods, closing parts of the mold, pouring metal, cooling and removing the resulting casting. The process of crystallization of the alloy when casting in a chill mold is accelerated, which contributes to the production of castings with a dense and fine-grained structure, and, consequently, with good tightness and high physical and mechanical properties. However, cast iron castings require subsequent annealing due to the carbides formed on the surface. With repeated use, the mold warps and the dimensions of the castings in directions perpendicular to the parting plane increase.

Castings from cast iron, steel, aluminum, magnesium and other alloys are produced in chill molds. The use of die casting is especially effective in the production of castings from aluminum and magnesium alloys. These alloys have a relatively low melting point, so one die can be used up to 10,000 times (with the insertion of metal rods). Up to 45% of all castings from these alloys are produced in molds. When casting in a chill mold, the range of cooling rates of alloys and the formation of various structures expands. Steel has a relatively high melting point, the resistance of chill molds when producing steel castings is sharply reduced, most surfaces form rods, therefore the chill casting method for steel is less used than for non-ferrous alloys. This method is widely used in serial and large-scale production.

Shell casting

Shell casting is a method of producing shaped castings of metal alloys in molds consisting of a mixture of sand grains (usually quartz) and synthetic powder (usually phenol-formaldehyde resin and pulverized bakelite). Preferably, clad sand grains (coated with a layer of synthetic resin) are used.

The shell form is obtained by one of two methods. The mixture is poured onto a metal model heated to 300°C, held for several tens of seconds until a thin hardened layer is formed, and the excess mixture is removed. When using a clad mixture, it is blown into the gap between the heated model and the outer contour plate. In both cases, it is necessary to further strengthen the shell in an oven (at temperatures up to 400°C) on the model. The resulting shell halves are held together and liquid alloy is poured into them. To avoid deformation of the molds under the influence of the poured alloy, before pouring they are placed in a metal casing, and the space between its walls and the mold is filled with metal shot, the presence of which also affects the temperature regime of the cooling casting.

This method produces various castings weighing up to 25 kg. The advantages of the method are a significant increase in productivity compared to the production of castings by sand casting, control of the thermal cooling mode of the casting and the ability to mechanize the process.

Lost wax casting

Another method of casting metals - using a lost wax model - is used in cases of manufacturing high-precision parts (for example, turbine blades, etc.) An exact model of the product is made from low-melting material: paraffin, stearin, etc. (in the simplest case - from wax) and gating system. The most widely used model composition is P50S50, consisting of 50% stearin and 50% paraffin; for large-sized products, salt compositions are used that are less prone to warping. The model is then dipped into a liquid suspension based on a binder and refractory filler. Hydrolyzed ethyl silicate of the ETS 32 and ETS 40 brands is used as a binder; hydrolysis is carried out in a solution of acid, water and a solvent (alcohol, acetone). Currently, silica sols have been used in LVM, which do not require hydrolysis in workshop conditions and are environmentally friendly. The following are used as refractory fillers: electrocorundum, distensilimanite, quartz, etc. A suspension is applied to the model block (model and LPS) and sprinkled, so 6 to 10 layers are applied. With each subsequent layer, the grain fraction of the coating changes to form a dense surface of the shell shape. Drying each layer takes at least half an hour; to speed up the process, special drying cabinets are used, into which ammonia gas is pumped. A model composition is melted from the formed shell: in water, in a model composition, by burning, or with high-pressure steam. After drying and heating, the block is calcined at a temperature of approximately 1000 to remove substances capable of gas formation from the shell form. After which the shells are sent for filling. Before pouring, the blocks are heated in furnaces to 1000. The heated block is placed in the furnace and the heated metal is poured into the shell. The poured block is cooled in a thermostat or in air. When the block has cooled completely, it is sent for knocking out. By striking the sprue bowl with a hammer, the ceramic is beaten, then a piece of LPS is produced. Thus, we obtain a casting.

Due to the high consumption of metal and the high cost of the process, LVM is used only for critical parts.

investment casting process is based on the following basic principle:

• A copy or model of the final product is made from a low-melting material.

• This model is surrounded by a ceramic mass that hardens and forms the shape.

• Upon subsequent heating (calcination) of the mold, the casting model is melted and removed.

• Then metal is poured into the cavity remaining in place of the removed wax, which accurately reproduces the original casting model.

Only this casting method

The accuracy of copper casting is generally characterized by the dimensional accuracy class, its degree of warping, as well as the degree of surface accuracy and weight accuracy class.

The dimensional accuracy class and weight accuracy of the casting must be used. The use of other properties of casting precision, if necessary and special conditions for the precision of cast parts, depending on their application and features of use, is regulated by the scope of regulatory and technical documentation.

On sketches of copper casting (or sketches of an element with specified casting dimensions), it is necessary to indicate the measurement base (marking base) and the initial surface finishing base. Copper casting is used for the production of spare parts for the repair of electrical equipment and the manufacture of various products with an electrical resistance of 0.01724-0.018 Ohm*mm/m. We have all types of castings from ferrous and non-ferrous metals available from 1 kg .