Villagers, who lack city-dwelling amenities and central heating, must heat their homes with traditional wood-burning stoves. And firewood is things made of wood, that’s why they are called firewood. To load the stove with them, you need to cut a long log into logs, and they, in turn, split them into logs. You can chop wood with an axe, but it is much more convenient to use a homemade mechanical wood splitter for chopping.

DIY mechanical wood splitter

History of the woodcutter. A few words about the evolution of the instrument

The most labor-intensive stage of the entire firewood preparation process is splitting the logs. And for this purpose a tool such as a wood splitter is used. In Rus', a woodcutter was a person who chops wood for a stove with a cleaver or an ax. Of course, at the age of 20, 30 or 40, a man can easily cope with this. Take a good swing, hit hard - and that's it! But by the age of 50, even for a person accustomed to physical labor since childhood, it is no longer easy to swing a cleaver, and therefore the need arose for a device for chopping wood that could make the work easier.

Ax device

Today it is easy to acquire a wood splitter. It can be bought in a store (similar tools are produced by many companies), but the average rural resident does not always have the means to purchase it.

In this case, there is only one way out - to make this most useful device with your own hands ; fortunately, you can find a great many photographs of a homemade wood splitter on the Internet.

DIY mechanical spring wood splitter

Note! Mechanical wood splitters come in various types - manual, spring, cone. However, they all make work much easier (to a greater or lesser extent).

The wood splitter has evolved to this form

Features of application

A device such as a hydraulic wood splitter is widely used in production workshops and private households. The machines are responsible for bucking and splitting logs. Those who have had to collect firewood by hand know how much free time this work takes. Non-hydraulic installations are significantly inferior in terms of reliability and durability. Uneven loads often lead to premature equipment failures.

Another thing is a hydraulic wood splitter, made by yourself or assembled at a factory. Such designs are gaining popularity among consumers. Even if the load reaches ten tons, it is applied gradually. Therefore, the oil pump and engine can withstand it without breaking. If there is not enough force, the cylinder will simply stop rotating. And the oil pump will not break down.

DIY hydraulic wood splitter

The nuances of splitting wood

So, we found out that firewood can be split in various ways. As a rule, for this purpose, blows are made with an ax in order to split a sawn piece of log, and the blows are applied to the end.

A massive wedge (and the ax is shaped like a wedge) is driven into the log. If it is soft and without knots, then the wedge will go inside even with relatively little physical effort. The wood fibers will move apart under the influence of tangential forces, and the body of the log will split into two parts.

Chopping wood with an ax

In the case of a small angle at the apex, the tangential forces will be smaller, but the wedge will penetrate deeper inside. However, the destructive force will not be enough, and the ax will jam in the crack that appears. And if the angle is less acute, the tangential forces will increase and the wood, as a result, will split.

On a note! The viscosity of wood will depend on a number of factors. It has been laboratory proven that the wedge angle at the apex for most wood species should be 25-30°. In this case, the chopping properties of the wedge-shaped tool will be the best.

Impact strength of wood

If the wedge penetrates slowly, then the energy accumulated during the swing and subsequent impact is no longer a determining factor. In this case, the connections between the fibers are broken after certain values are reached during implementation. According to research, the optimal tip angle for manual wood splitters is 30-38°. Then the connections will be broken with less effort. Although some types of wood can “resist” - for example, cherry, elm, apple tree.

What should the logs be like?

Pine, ash, oak and some other species split with a slight penetration of the wedge.

Important! The magnitude of the forces also depends on the length of the block. The shorter the log, the less resistance the wood will provide when splitting. As a rule, this length is determined by the depth of the firebox, because the firewood in the stove must be positioned in such a way that the door closes smoothly.

Hydraulic wood splitter

GOST 3243-88. Firewood. Specifications . Downloadable file (click the link to open the PDF in a new window).

GOST 3243-88

Types of manual wood splitters

The most popular are manual wood splitters (also called kinetic), which operate using simple physical principles and do not require special physical capabilities. Here are the main types of devices:

- crowbar cleaver (the log on which the cleaver is installed is split with a sharp forward movement using a special crowbar rod);

Wood splitter

- spring (there is a lever of force, the method of a weighted working element is used);

Do-it-yourself spring-loaded manual wood splitter

- with a manual drive (there is a special cabinet with a blade oriented upward on it. The log is placed on the blade and is easily split in two using, for example, a sledgehammer);

- rack and pinion (there is a special rack with notches, which is a pushing element).

Homemade rack wood splitter

A tool for splitting firewood with a foot pedal

If you often burn wood, you have already repeatedly encountered the problem of cutting wood. To simplify the process as much as possible, you can use manual mini-wood splitters - such as Greenween, Strela, Kolundrov. Such devices will help you quickly and efficiently split the most “complicated” logs, and even women (including the elderly) can operate them.

It’s convenient to use these mini wood splitters

Even women can use this wood splitter

Important! When choosing a wood splitter, be guided by the volume of wood being harvested. Also give preference to proven and non-hazardous tools. Let's take a look at the mini wood splitters mentioned earlier.

Greenween

The device has basic and multifunctional modifications. But the device in both cases is identical: a wide blade made of high-strength steel is fixed to the frame. Ribs are melted onto the edges of the blade - special hard plates that separate the cracked log into parts.

Photo of Greenween wood splitter

Wood splitter GreenWeen

The basic model differs from the multifunctional one in the diameter of the lumps that can be split. With the help of the second version of the device, you can cope with even the thickest blocks. It has a special semicircular plate into which the free end of the log rests.

The main advantage of the Greenween log splitter is its safety

The basic modification is equipped with a solid metal ring that acts as a side support. The inner diameter of the ring indicates the maximum thickness of the chocks. The Greenween wood splitter is carefully designed and ergonomic, and therefore working with it is easy and not tiring. It weighs 5.7 kg, its height is only 35 cm. The multifunctional version of the tool weighs even less - 4.8 kg.

The basic modification of the wood splitter has a solid metal ring

You will probably be interested in: DIY isolon lamp

"Arrow"

This is a hand tool, something between a construction crowbar and a splitting axe. As a result, it can be used for many purposes, not just for chopping wood. For example, for knocking down ice or frost, for loosening frozen or dense soil during construction.

Manual wood splitter "Strela"

The design of the tool is telescopic, there is a working element (a long rod with a handle) and a striking element (a pointed cone at the bottom). The handles are rubber, so the tool does not slip during use. The principle of the work itself is simple: the rod rises and falls onto the log, as a result of which it splits.

This tool is multifunctional

Using the "Arrow" you can split very heavy and thick logs. The tool is easy to use and works great on soft wood. As for other advantages, these include:

- small sizes;

- reduction of applied physical force during work;

- versatility (we talked about this above).

"Strela" can split the heaviest and thickest logs

The wood splitter is small in size,

but there are disadvantages, including:

- unattractive appearance;

- load on the lower back (this is not going away);

- high risk of injury (the wedge can slip off the log - usually of small diameter, and chips or the log itself can bounce off);

- the appearance of calluses (even despite the fact that the handles are rubber).

There is a risk of injury when working with a wood splitter.

Kolundrov

This is an alternative to Strela, but safer to use. Kolundrov has high performance, looks quite nice and is safe to use. The lower part is stable, it has holes for fastening, thanks to the metal ring on top, chips and split logs do not fly off to the sides, which means they cannot injure a person.

Manual wood splitter Kolundrov

With the help of sharpened knives, even knotty and wet logs can be easily broken.

Table. Average market prices for popular manual wood splitters in 2019-2020.

| Name of the wood splitter | Average cost, rub. |

| Greenween | 5 650 |

| "Arrow" | 1 690 |

| Kolundrov | 5 800 |

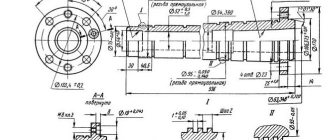

Design and principle of operation of a wood splitter

The unit has a durable frame on which the knife is attached. He plays the role of a powerful cleaver. The knife will cut any log into logs of the required size. It is driven by a hydraulic piston and actuator. All that remains for a person is to put the hemp under the knife. The necessary load is created by hydraulics, which is driven by the power unit. A special piston pushes the wooden log onto the tip of the knife.

This principle of operation is incorporated into devices by a large number of manufacturers. In stores you can find cone-type screw splitters, etc. Such devices are in demand due to their reliable design and ease of operation.

Features of spring log splitters

A spring-type wood splitter is considered to be a simple-to-use, economical, reliable, and inexpensive tool. It is the result of the modernization of traditional cleavers. When operating a spring log splitter, muscle force is also applied, but to a lesser extent, thanks to the additional load, large lever and the spring mechanism itself.

Spring log splitter is simple and reliable

Mechanics of a spring log splitter

On a note! You can make this wood splitter yourself. The structure in this case will consist of a profile or metal pipe (this will be a lever with a knife at the end), an iron stand and a hinge-type connection. You can use an old shock absorber as a return mechanism.

Kinematic diagram of a spring splitter

Let's look at an example of how to make a simple spring splitter yourself.

Wood splitter - what is it?

This device is designed for splitting logs of various lengths and diameters. All wood splitters consist of the following parts:

- beds;

- control unit;

- gutters for laying logs;

- a knife or cone with threads that splits wood;

- devices that throw split logs to the side (installed on an industrial group of wood splitters);

- electric or internal combustion engine (muscle traction of the operator can also be used as a source of force);

- a device for transmitting force that pushes a log onto a stationary knife, or a knife onto a fixed log, or screws a threaded cone into a piece of wood.

As a result, the log splits in half, and in some models into more parts. Powerful industrial devices are capable of splitting large lengths of workpieces and loading the finished product onto conveyors that transport the resulting firewood to the place of packaging, transportation or burning. In addition, they can cut logs into specific lengths. The cost of the cheapest household wood splitter differs tenfold from the cheapest industrial one.

Spring wood splitter. Step-by-step manufacturing instructions

First, prepare all the necessary tools - in our case these are:

- grinder (as well as cleaning and cutting discs for it);

- tools for marking and measuring;

- welding machine (fortunately, current inverter machines weigh little, are easy to use and allow you to obtain neat welds).

Also prepare the following supplies:

- shock absorber from a passenger car;

- channels;

- steel pipes (diameter from 4 cm to 7 cm);

- profile pipe 3x6 cm (4x6 cm);

- bushing from a car suspension (worn is allowed);

- rail (30-40 cm);

- corner;

- I-beam (No. 12-16).

Step 1. First, prepare a sketch of the future structure. If possible, you can use a special engineering design program that allows you to work out all the details. Here is a rough diagram of the future wood splitter.

Approximate diagram of a do-it-yourself spring log splitter

Step 2. Make a support from a channel, weld a stand to it (the latter is best made from an I-beam, which is highly rigid; such a stand will be difficult to bend even under prolonged loads). For greater stability, weld the jibs to the base. Also, additionally make stops from the pipes to prevent a possible fall of the wood splitter.

Support for the future wood splitter

Step 3. Take the channel and cut out the support for the spring. Cut a square hole in the support, thanks to which the element will be securely fixed to the stand.

Spring support

Step 4. As for the installation height of the support, it depends on the length of the spring used. Also focus on the height of the entire structure and how convenient it will be to use. Thus, it is most convenient to lift the load when it is at waist height (it will rise slightly above the chest).

The installation height of the support is determined

Step 5. Make the jibs necessary to hold the support from the corners. Thanks to this, the supporting surface will not move when the device is dynamically loaded.

Corner jibs

Step 6. Make a cylindrical clamp to secure the bottom of the spring, which will require a small piece of pipe. When choosing the diameter of the pipe, be guided by the internal diameter of the spring so that it does not move during operation.

Cylindrical spring retainer

Step 7. Make a slot in the top of the post, install the bushing there, and then weld the latter. It is important to maintain perpendicularity to the stand. Also make sure that the hub axis is parallel to the ground.

The hub axis must be parallel to the ground

Step 8. Install the shaft into the sleeve. Weld a rocker arm from a channel to it, at the bottom of which install a small piece of pipe. This pipe is necessary to fix the upper part of the spring.

Channel rocker

Step 9. Cut a “window” in the rocker, the dimensions of which depend on the size of the rack itself. Thanks to this, the rocker will move freely.

"Window" in the rocker

Step 10. Weld the profile pipe to the rocker arm, install a chisel on one end. By the way, the chisels are made of hard carbon steel U9 or U10, and therefore the element will last a long time. Then, during operation, the chisel can be easily sharpened using a grinder and a sharpening wheel.

Chisel at the end of a profile pipe

Step 11. Our wood splitter is almost ready. Weld a piece of rail above the chisel, which will act as a weight. Also weld the handle to make it more convenient to use the wood splitter. It is advisable to put rubber elements on them - they will dampen vibrations.

For convenience, a handle is installed on the wood splitter

Note! Lay a piece of large diameter log - it is necessary for the work. Logs for splitting will be installed on it.

Step 12. Check the functionality of the wood splitter. Place the block of wood and, holding it with one hand, lift the cleaver and strike.

The cleaver strikes

Mechanics of splitting wood when a cleaver is inserted into it

Step 13. The cleaver will go down, causing the log to split. If it splits completely, the chisel will go further, but will hit the wooden support, and therefore will not become dull.

Splitting firewood with a spring log splitter

Recommendations for choosing a wood splitter

Type of design

In the most common units, wood is split due to the movement of a hydraulic piston, which crushes the workpiece against a metal knife. After which, it falls into pieces. The necessary force is created by the engine.

The screw cleaver also has many fans. You can build such a unit with your own hands. In this case, the working element has the shape of a screw cone. The motor sets it in motion. When feeding the workpiece, the cone is drilled into dense layers of wood and breaks it into several parts.

The design of the rack wood splitter is quite simple. However, this type of wood splitting is considered dangerous. In this case, the workpiece moves due to the rotation of the gear.

The operating principle of an inertial or spring wood splitter is somewhat different. All drive options are missing here. Chopping wood is carried out due to a large arm and a spring, which returns the working bar to its original position.

Drive unit

Units with electric motors and gasoline engines are available for sale. The buyer needs to determine in what conditions the wood splitter will be used.

Maximum pressure on workpiece

The force with which the piston acts on the workpiece depends on this value. This characteristic is inherent in rack and hydraulic wood splitters. At home, a force of 4 to 6 tons is sufficient. More powerful units are used in industrial enterprises. They can handle large logs.

Working position

This parameter is responsible for the location of the workpiece axis during operation. There are units with vertical, horizontal and combined orientation. The second option can be considered the most common type. Buyers purchase it for its simplicity of design and ease of use. Such hydraulic and rack and pinion devices are highly safe.

Stump size

The length of the workpieces is determined by the free stroke of the piston and the maximum splitting force. The thickness of the hemp ranges from 0.25 to 0.5 m. Its length is limited to 0.52 m. It all depends on the model and type of installation. In rack and pinion machines, the length of the workpiece is determined by the size of the rack in combination with the greatest force generated. Screw splitters are not used very often. However, with their help you can break stumps with a diameter of up to 0.7 m.

Availability of options

On some units the height is adjustable. This is done for convenience during work. A person can set the height to the size of the workpiece. However, the cost of the product increases. If necessary, you can come up with homemade stands.

It wouldn't hurt if the unit had wheels. This option will allow you to easily move the device around the territory. You need to keep in mind that large diameter wheels are much more convenient than small ones.

The machine must have a safety system (most often it has two levers). All manufacturers equip their units with this option. It is a mandatory component for factory devices.

For many users, speed is of great importance. However, experts believe that the minimum values of this parameter are sufficient for working at home.

A simple manual wood splitter. Step-by-step manufacturing instructions

Do-it-yourself manual wood splitter

A simpler design, for the creation of which you need to prepare:

- spring from a car;

- metal corner (40 or 50);

- a couple of corner pieces 55 cm long;

- another couple - 15 cm long.

car spring

Metal corner

Two corners of 5 cm each and two more of 15 cm

each Step 1. Take a long corner, mark it on it, stepping back 10 cm from the edges.

You need to retreat 10 cm from the edges

A long corner is marked

Step 2. Step back 1.5 cm from the very corner.

You need to retreat 1.5 cm from the corner

Step 3. Mark the middle 5 cm, as in the photo below.

The middle of the corner is marked at 5 cm

Step 4. After this, take a grinder and trim according to the markings.

Trimming a corner according to the markings

Step 5. Next, take the second long corner, attach it to the already cut one, using the latter as a template.

The cut out corner is used as a template

Step 6. Cut the second long corner in the same way.

The second corner is cut off

Step 7. You should end up with something like this.

The result of the work done

Step 8. Now it's time to start working on the short corners. Take them.

Short corners are taken

Step 9. Weld the long corners to the short ones.

Long corners are welded to short corners

Step 10. Cut a 35 cm long piece from the spring.

A piece of spring is cut off

Step 11: Make the bushing. Take a round piece of wood for this purpose and drill a hole in it for the mounting bolt.

A hole is drilled in the round timber

Step 12. Cut the round timber to the required length - it should be the same as the width between the corners.

The length of the sleeve must correspond to the width between the corners

Step 13. Make a small opening in the spring.

A small opening is machined in the spring

Step 14. Weld the bushing made earlier to it.

The bushing must be welded to the spring

Bushing is welded

Step 15. To connect the spring to the corners, make holes in the latter.

Holes are drilled in the corners

Step 16. Next, take a piece of pipe.

Take a piece of pipe

Step 17. Weld this piece to the spring on the other side.

The pipe is welded to the spring

Step 18. After this, sharpen the spring.

Sharpened spring

Step 19. Assemble all the parts into a single structure.

Assembly of all parts

Build process

Step 20. That's it, the manual wood splitter is ready, you can start testing it.

Testing a homemade wood splitter

Step 21. To make it more convenient to use the wood splitter, in our example it is welded to a pipe that is concreted into the ground.

The wood splitter is welded to a pipe concreted into the ground

This makes the tool easier to use

Video - Simple but effective wood splitter

How to organize the workflow?

Having built a homemade wood splitter, you can safely start chopping firewood. But to make the work easier, it is important to properly organize the entire process. So, the cut fragments should be located on one side at a distance of two or three steps (so as not to get too tired). It is recommended to put chopped firewood in a cart. It has a small volume; a maximum of 30-40 kg of firewood will fit into it.

Firewood chopped with a homemade wood splitter

After each cart is filled, transport the wood and place it on the woodpile. During transportation, by the way, there will be time to take a break from your main work, because a change of occupation is also a rest!

5/5 (7)