05.02

2020

High-quality welding is impossible without accurate and correct calculation of current strength - the most important parameter in welding technology. If this indicator is too low, the rod will stick and the arc will not ignite. On the contrary, if too high currents are selected, the electric arc will ignite well, but it is possible to burn through the metal of the part. In addition, the rod itself will burn faster than expected, especially if it is of small diameter.

How to calculate the required power? What current should be used to cook with an electrode of a particular diameter? Let's take a closer look.

Key parameters for calculating the welding mode

Correctly selected operating mode of welding equipment ensures good and fast ignition and a stable electric arc. In addition to the current strength, the parameters that affect the mode setting are:

- type of current (direct, alternating) and polarity of direct;

- diameter of the electrode rod;

- brand of electrode conductor;

- spatial position of the seam when performing work.

The more of the listed indicators are taken into account in the calculations, the better the result will be. Let's consider what current is supplied to which electrode depending on the thickness of the latter.

Practical guide to selecting welding current

Let's look at a specific example of how to select the correct current values for welding for novice welders. So, first we set the recommended welding current value from the table above. In this case, we take into account the thickness of the metal being welded and the diameter of the electrodes used.

We light the welding arc and try to cook, controlling the thickness of the seam. If the thickness of the welding seam turns out to be much greater than the thickness of the electrode, then we reduce the current on the inverter, since there is too much of it. Let's try cooking further.

Ideally, with correctly selected welding current, the width of the seam should be larger, but not more than twice. However, you should know that a lot here depends on the welding position. The most current is needed for welding corner joints.

Source

Electrode diameter and current

The thickness of the electrode directly depends on the thickness of the parts being welded and the size of the weld. If the width of the latter does not exceed 3–5 mm, then an experienced welder, as a rule, will choose a consumable with a diameter of 3 to 4 mm. For large weld pool sizes (5–8 mm), the thickness of the rod is usually no more than 5 mm.

As for the current value, the following indicators work.

- At d 3 mm - from 65 to 100 Amperes. The range of values is wide; they depend on the spatial position of the weld and the chemical composition of the metal being welded (and, accordingly, the core metal). Beginner and amateur welders will not go wrong if they choose the average value - 80–85 Amps.

- At d 4 mm - from 120 to 200 A. The dependence is the same - the composition of the metal, the location of the seam in space. This is the most common rod diameter typical for industrial work. Allows you to weld both thin and wide seams.

- At d 5 mm, the value varies in the range of 169–250 A. This is already a fairly large diameter. A role is played not only by the composition of the alloy and the position of the seam, but also by the depth of welding: the greater it is, the greater the current strength should be. If the depth of the weld pool is at least 5 mm, the maximum value should be set in the mode - 250 A.

- With d 6–8 mm, the minimum power rating is the same 250 Amperes. In conditions of heavy work using transformers, it increases to 300–350 A.

The table below shows recommended values that are known to any professional welder, but which may be useful for amateurs and beginners.

| Electrode diameter, mm | Metal thickness, mm | Current strength, A |

| 1,6 | 1… 2 | 25… 50 |

| 2 | 2… 3 | 40… 80 |

| 2,5 | 2… 3 | 60… 100 |

| 3 | 3… 4 | 80… 160 |

| 4 | 4… 6 | 120… 200 |

| 5 | 6… 8 | 180… 250 |

| 5… 6 | 10… 24 | 220… 320 |

| 6… 8 | 30… 60 | 300… 400 |

How to set the welding current for a novice welder to weld metal from 1 to 5 mm

Correct settings of the welding current will not only improve the quality of welding, but also significantly facilitate the work of welding metal. However, it is difficult for novice welders to achieve the correct current values because they do not have the appropriate experience.

For these purposes, you can use a ready-made table with welding current values or listen to the advice below.

The welding current must be selected taking into account the thickness of the metal being welded and the diameter of the electrodes used. If the inverter still refuses to weld, then there is a problem with the voltage in the network, it is low, and the welding current needs to be adjusted.

When choosing the optimal current for welding, it is recommended to focus on the following indicators:

- A 2 mm electrode can weld metal with a thickness of 1 to 2 mm. The welding current should be from 20 to 50 amperes;

- A 2.5 mm electrode welds metal with a thickness of 2-3 mm. The current values on the inverter are set in the range from 40 to 80 amperes;

- It is recommended to weld metal with a thickness of 3-5 mm using a 3 mm electrode. The current value should be about 100-120 amperes.

It is important to know that thin metal, up to 3 mm thick, must be welded with reverse polarity, when the electrode holder is connected to the positive of the inverter, and the ground clamp to the negative. In this case, the welding seam is shallow and wide, and metal burns are eliminated.

Seam position

The spatial position of the seam also plays a big role when calculating power. What current should I choose for electrode welding taking into account this criterion? It is important to know here that the highest values are selected when welding seams in a horizontal (lower) position. If the seam is applied vertically, the current strength will be on average 10–15% less.

The lowest indicator is when applying ceiling seams: the current should be on average 20% lower than when working on horizontal surfaces. For clarity, we indicate the values in the table (using the example of electrodes with a basic type of coating).

| d electrode, mm | Spatial position | ||

| Lower | Vertical | Ceiling and semi-ceiling | |

| 3 | 100… 130 A | 100… 130 A | 90…110 A |

| 4 | 170… 220 A | 160… 180 A | 150… 180 A |

| 5 | 210… 250 A | 180… 200 A | Welding fails |

Polarity

Welding with modern machines is carried out only with direct current of direct or reverse polarity. DC electrodes provide a much greater (15-20%) penetration depth than when using alternating current from a transformer.

- Cast iron, low-alloy, low- and medium-carbon steels are cooked using direct polarity and deep penetration of the metal parts is achieved.

- A wider range of steels are welded using the reverse method (low-alloy, low-carbon, medium- and high-alloy), thin-walled structures are welded, and it is also used at a high melting rate of electrodes.

Both deep penetration and high welding speed require large amounts of current. Thus, with both reverse and direct polarity, the current strength can be increased in both of these cases.

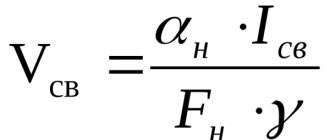

Calculation formula

Experienced welders usually set up the electric arc experimentally, without making complex preliminary calculations. And for beginners, not only the tables posted in the article will be useful, but also the formula that calculates which electrodes need what current. It applies to electrodes of the most popular diameters (3–6 mm).

- I = (20+6d)d, where

- I – current strength, d – electrode diameter.

If the thickness of the rod is less than 3 mm, the calculation is carried out according to the formula: I = 30d.

However, these formulas should also be used taking into account the spatial position of the welding: for ceiling welding, we subtract 10–15% from the result obtained from the formula.

The manufacturer, as a rule, provides all the most important parameters of the welding mode on the packaging. The products of the Magnitogorsk Electrode Plant are no exception. With the correct setting of the necessary parameters of the welding operation mode, the MEZ electrodes will ensure excellent ignition of the electric arc, its stable combustion and an exemplary result - an even weld with the necessary characteristics.

You might be interested

Ø 2 (1 kg) Ø 2.5 (1 kg) Ø 2.5 (2.5 kg) Ø 3 (1 kg) Ø 3 (2.5 kg) Ø 4 (1 kg) Ø 4 (2.5 kg)

Electrodes for welding ANO-21 STANDARD Current - alternating or direct of any polarity

RUR 199.44 ?

Price including VAT per 1 kg.

Ø 2 (1 kg) Ø 2.5 (1 kg) Ø 2.5 (5 kg) Ø 3 (1 kg) Ø 3 (5 kg) Ø 4 (1 kg) Ø 4 (6.5 kg) Ø 5 (1 kg) Ø 5 (6.5 kg)

Electrodes for welding MP-3 LUX (NAKS) Current - constant reverse polarity, alternating

RUB 176.88 ?

Price including VAT per 1 kg.

Ø 2 (1 kg) Ø 2.5 (1 kg) Ø 2.5 (5 kg) Ø 3 (1 kg) Ø 3 (5 kg) Ø 4 (1 kg) Ø 4 (6.5 kg) Ø 5 (1 kg) Ø 5 (6.5 kg)

Electrodes for welding MP-3 (NAKS, RRR) Current - alternating or direct, reverse polarity

168.60 rub. ?

Price including VAT per 1 kg.

Ø 2.5 (1 kg) Ø 2.5 (5 kg) Ø 3 (1 kg) Ø 3 (5 kg) Ø 4 (1 kg) Ø 4 (6.5 kg) Ø 5 (1 kg) Ø 5 (6.5 kg)

Electrodes for welding OZS-4 (NAKS) Current - alternating or direct polarity (plus on the electrode)

170.88 rub. ?

Price including VAT per 1 kg.

Ø 2.5 (1 kg) Ø 2.5 (5 kg) Ø 3 (1 kg) Ø 3 (5 kg) Ø 4 (1 kg) Ø 4 (6.5 kg) Ø 5 (1 kg) Ø 5 (6.5 kg)

Electrodes for welding ANO-4 (NAKS) Current - alternating or constant of any polarity

170.64 rub. ?

Price including VAT per 1 kg.

Ø 2 (1 kg) Ø 2.5 (1 kg) Ø 2.5 (5 kg) Ø 3 (1 kg) Ø 3 (5 kg) Ø 4 (1 kg) Ø 5 (6.5 kg) Ø 4 (6.5 kg) Ø 5 (1 kg)

Electrodes for welding ANO-21 (NAKS) Current - alternating or constant of any polarity

180.36 rub. ?

Price including VAT per 1 kg.

Ø 2 (1 kg) Ø 2.5 (1 kg) Ø 2.5 (5 kg) Ø 3 (1 kg) Ø 3 (5 kg) Ø 4 (1 kg) Ø 4 (6.5 kg) Ø 5 (1 kg) Ø 5 (6.5 kg)

Electrodes for welding MK-46.00 (NAKS) Current - constant reverse polarity, alternating

RUB 230.88 ?

Price including VAT per 1 kg.

Ø 2 (1 kg) Ø 2.5 (1 kg) Ø 2.5 (5 kg) Ø 3 (1 kg) Ø 3 (5 kg) Ø 4 (1 kg) Ø 4 (6 kg) Ø 5 (1 kg) Ø 5 (6 kg)

Electrodes for welding OZS-12 (NAKS, RRR) Current - alternating or direct polarity

RUB 183.84 ?

Price including VAT per 1 kg.

Ø 2 (1 kg) Ø 2.5 (1 kg) Ø 2.5 (4.5 kg) Ø 3 (1 kg) Ø 3 (4.5 kg) Ø 4 (1 kg) Ø 4 (6 kg) Ø 5 (6 kg) Ø 5 (1 kg)

Electrodes for welding UONI-13/55 (NAKS, RRR, RS) Current - constant, reverse polarity

RUB 170.16 ?

Price including VAT per 1 kg.

Ø 2 (1 kg) Ø 2.5 (1 kg) Ø 2.5 (4.5 kg) Ø 3 (1 kg) Ø 3 (4.5 kg) Ø 4 (1 kg) Ø 5 (6 kg) Ø 4 (6 kg) Ø 5 (1 kg)

Electrodes for welding UONII-13/55 (NAKS, KSM, RS) Current - constant, reverse polarity

RUB 179.16 ?

Price including VAT per 1 kg.

Ø 2 (1 kg) Ø 2.5 (1 kg) Ø 2.5 (4.5 kg) Ø 3 (1 kg) Ø 3 (4.5 kg) Ø 4 (1 kg) Ø 4 (6 kg) Ø 5 (1 kg) Ø 5 (6 kg)

Electrodes for welding UONI-13/45 (NAKS, RRR, RS) Current - constant, reverse polarity

170.28 rub. ?

Price including VAT per 1 kg.

Ø 3 (1 kg) Ø 3 (4.5 kg) Ø 4 (1 kg) Ø 4 (6 kg) Ø 5 (1 kg) Ø 5 (6 kg)

Electrodes for welding UONI-13/45 A (NAKS) Current - constant, reverse polarity

RUB 182.16 ?

Price including VAT per 1 kg.

Ø 3 (1 kg) Ø 3 (4.5 kg) Ø 4 (1 kg) Ø 4 (6 kg) Ø 5 (1 kg) Ø 5 (6 kg)

Electrodes for welding UONI-13/65 Current - constant reverse polarity (plus on the electrode)

183.12 rub. ?

Price including VAT per 1 kg.

Ø 3 (1 kg) Ø 3 (4.5 kg) Ø 4 (1 kg) Ø 4 (6 kg) Ø 5 (1 kg) Ø 5 (6 kg)

Electrodes for welding TMU-21U (NAKS) Current - constant, reverse polarity

RUB 157.44 ?

Price including VAT per 1 kg.

Ø 2.6 (1 kg) Ø 2.6 (4.5 kg) Ø 3.2 (1 kg) Ø 3.2 (4.5 kg) Ø 4 (1 kg) Ø 4 (6 kg)

Electrodes for welding MEZLB-52U (NAKS) Current - constant, reverse polarity; constant straight polarity for root welds

RUR 231.96 ?

Price including VAT per 1 kg.

Ø 3 (1 kg) Ø 3 (4.5 kg) Ø 4 (1 kg) Ø 4 (6 kg) Ø 5 (1 kg) Ø 5 (6 kg)

Electrodes for welding UONI-13/55 A Current - constant reverse polarity (plus on the electrode)

RUB 171.60 ?

Price including VAT per 1 kg.

Ø 3 (1 kg) Ø 3 (4.5 kg) Ø 4 (1 kg) Ø 4 (6 kg) Ø 5 (1 kg) Ø 5 (6 kg)

Electrodes for welding UONI-13/55 U Current - constant reverse polarity (plus on the electrode)

RUB 179.28 ?

Price including VAT per 1 kg.

Ø 2.5 (1 kg) Ø 2.5 (4.5 kg)

Electrodes for welding TsU-5 Current - constant reverse polarity (plus on the electrode)

RUB 188.76 ?

Price including VAT per 1 kg.

Show 10 more products

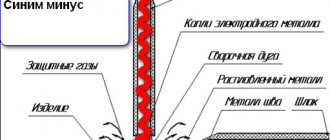

DC welding

DC welding, like AC welding, has its advantages, and is used in cases where AC welding cannot provide the desired result, for example, vertical welding, single solder soldering or TIG welding of stainless steel.

DC welding has a higher deposition rate and is best suited for welders who require larger deposit sizes. Although AC welding provides better penetration, it has a lower deposition rate which may not be suitable.

DC welding also produces less spatter than AC welding, resulting in a more uniform and smooth weld. Direct current is also more reliable and therefore easier to work with as the arc remains stable.

DC welding is often used to weld thin metals. Equipment that operates with this type of current is also cheaper, which helps reduce costs.

However, while the hardware itself is lower in cost, the process of actually using DC is a bit more expensive.

This is because special equipment is needed to convert AC to DC because this is not provided by the electrical network. However, since direct current is better suited for most types of welding processes, this expense is considered necessary.

Although DC welding is better for many metals, it is not recommended when working with aluminum as it requires high intensity heat, which is not possible with DC. In addition, if a magnetic field is created when operating with direct current, the risk of arcing will increase, which can be dangerous.

- Electrodes for AC welding are inferior in connection quality;

- They exhibit high metal spattering and uneven seam formation;

- They have relatively low impact strength.

Physico-chemical composition

DC and AC electrodes may have significant differences in their composition if they are intended for different types of metal, but for the same ones they can be very similar. There are often small differences of tenths of a percent.

Content in composition, %

Specifications

These characteristics are the main ones that guide specialists when choosing. They are determined by the composition, coating and other parameters of the surfacing material. After all, to make the right choice, you need to know what the temporary tensile strength of the electrodes is, and so on. Using the example of the technical characteristics of the OK-46 electrode, you can find out the basic data that this type has.

Impact strength, Jcm squared

Test temperature, degrees Celsius

Tensile strength, Nmm squared

Maximum bend angle of the weld, degrees

Relative yield of deposited metal, %

Weight of electrodes for 1 kg of seam, kg

Stamps

Many of the brands that are designed for alternating current are also well suited for working with direct current, both with direct and reverse polarity. It is for this reason that their choice may seem wider, and some repetitions with materials for other types of current will also be noticeable. The following brands are very common:

- ANO-4;

- ANO-6;

- ANO-21;

- MP-3;

- OZS-4;

- OZS-6;

- OZS-12.

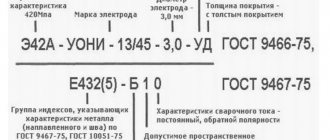

Designation and marking

In the marking, the type of electricity is indicated by the last digit. But taking into account the fact that there is a selection here not only in variants with alternating or direct current, but many brands of electrodes for welding with alternating current can also be used with direct current, there may be several numbers:

- 1 – for any polarity of direct current and at alternating current with a frequency of 50 V;

- 2 – direct polarity of direct and alternating at 50 V;

- 3 – reverse polarity of DC and AC at 50 V;

- 4 – for any polarity of direct current and at alternating current with a frequency of 70 V;

- 5 – direct polarity of direct and alternating at 70 V;

- 6 – reverse polarity of DC and AC at 70 V;

- 7 – for any polarity of direct current and at alternating current with a frequency of 90 V;

- 8 – direct polarity of direct and alternating at 90 V;

- 9 – reverse polarity of DC and AC at 90 V;

Choice

The first thing to do when choosing is to pay attention to the metal with which you will be working. The base metal and the one that goes into the electrode rod should be as similar as possible. More detailed details can already be found in the specific brand, what it is intended for. The next important point is the diameter. It is also important here that the thickness of the workpiece matches the consumable material being used. It is also worth paying attention to what frequency the device should have. The materials are suitable for three standards: 50, 70 and 90 V. If your machine cannot support what it is designed for, then it is better to choose a different brand of electrodes, as there will be too many technical problems that will degrade the quality of the seam.

“Important! You should not take materials with “0” in the marking, since it is only used for permanent use.”

Basic modes and nuances of application

Choosing the right frequency. It is necessary to determine which mode is best suited for the selected spatial position and material thickness.

You might be interested

Ø 2.5 (1 kg) Ø 2.5 (5 kg) Ø 3 (1 kg) Ø 3 (5 kg) Ø 4 (1 kg) Ø 4 (6.5 kg) Ø 5 (1 kg) Ø 5 (6.5 kg)

Welding electrodes OZS-4 (NAKS) Current - alternating or direct polarity (plus on the electrode)

170.88 rub. ?

Price including VAT per 1 kg.

Ø 2 (1 kg) Ø 2.5 (1 kg) Ø 2.5 (5 kg) Ø 3 (1 kg) Ø 3 (5 kg) Ø 4 (1 kg) Ø 4 (6.5 kg) Ø 5 (1 kg) Ø 5 (6.5 kg)

Welding electrodes MK-46.00 (NAKS) Current - constant reverse polarity, alternating

RUB 230.88 ?

Price including VAT per 1 kg.

Ø 3 (1 kg) Ø 3 (4.5 kg) Ø 4 (1 kg) Ø 4 (6 kg) Ø 5 (1 kg) Ø 5 (6 kg)

Welding electrodes TMU-21U (NAKS) Current - constant, reverse polarity

RUB 157.44 ?

Price including VAT per 1 kg.

Ø 2 (1 kg) Ø 2.5 (1 kg) Ø 2.5 (4.5 kg) Ø 3 (1 kg) Ø 3 (4.5 kg) Ø 4 (1 kg) Ø 4 (6 kg) Ø 5 (1 kg) Ø 5 (6 kg)

Welding electrodes UONI-13/45 (NAKS, RRR, RS) Current - constant, reverse polarity

170.28 rub. ?

Price including VAT per 1 kg.

Ø 3 (1 kg) Ø 3 (4.5 kg) Ø 4 (1 kg) Ø 4 (6 kg) Ø 5 (1 kg) Ø 5 (6 kg)

Welding electrodes UONI-13/45 A (NAKS) Current - constant, reverse polarity

RUB 182.16 ?

Price including VAT per 1 kg.

Ø 3 (1 kg) Ø 3 (4.5 kg) Ø 4 (1 kg) Ø 4 (6 kg) Ø 5 (1 kg) Ø 5 (6 kg)

Welding electrodes UONI-13/65 Current - constant reverse polarity (plus on the electrode)

183.12 rub. ?

Price including VAT per 1 kg.

Ø 2 (1 kg) Ø 2.5 (1 kg) Ø 2.5 (5 kg) Ø 3 (1 kg) Ø 3 (5 kg) Ø 4 (1 kg) Ø 4 (6 kg) Ø 5 (1 kg) Ø 5 (6 kg)

Welding electrodes OZS-12 (NAKS, RRR) Current - alternating or direct polarity

RUB 183.84 ?

Price including VAT per 1 kg.

Ø 2 (1 kg) Ø 2.5 (1 kg) Ø 2.5 (4.5 kg) Ø 3 (1 kg) Ø 3 (4.5 kg) Ø 4 (1 kg) Ø 5 (6 kg) Ø 4 (6 kg) Ø 5 (1 kg)

Welding electrodes UONII-13/55 (NAKS, KSM, RS) Current - constant, reverse polarity

RUB 179.16 ?

Price including VAT per 1 kg.

Ø 2 (1 kg) Ø 2.5 (1 kg) Ø 2.5 (4.5 kg) Ø 3 (1 kg) Ø 3 (4.5 kg) Ø 4 (1 kg) Ø 4 (6 kg) Ø 5 (6 kg) Ø 5 (1 kg)

Welding electrodes UONI-13/55 (NAKS, RRR, RS) Current - constant, reverse polarity

RUB 170.16 ?

Price including VAT per 1 kg.

Ø 2 (1 kg) Ø 2.5 (1 kg) Ø 2.5 (5 kg) Ø 3 (1 kg) Ø 3 (5 kg) Ø 4 (1 kg) Ø 4 (6.5 kg) Ø 5 (1 kg) Ø 5 (6.5 kg)

Welding electrodes MP-3 (NAKS, RRR) Current - alternating or direct, reverse polarity

168.60 rub. ?

Price including VAT per 1 kg.

Ø 2.6 (1 kg) Ø 2.6 (4.5 kg) Ø 3.2 (1 kg) Ø 3.2 (4.5 kg) Ø 4 (1 kg) Ø 4 (6 kg)

Welding electrodes MEZLB-52U (NAKS) Current - constant, reverse polarity; constant straight polarity for root welds

RUR 231.96 ?

Price including VAT per 1 kg.

Ø 2 (1 kg) Ø 2.5 (1 kg) Ø 2.5 (5 kg) Ø 3 (1 kg) Ø 3 (5 kg) Ø 4 (1 kg) Ø 4 (6.5 kg) Ø 5 (1 kg) Ø 5 (6.5 kg)

Welding electrodes MP-3 LUX (NAKS) Current - constant reverse polarity, alternating

RUB 176.88 ?

Price including VAT per 1 kg.

Ø 2.5 (1 kg) Ø 2.5 (5 kg) Ø 3 (1 kg) Ø 3 (5 kg) Ø 4 (1 kg) Ø 4 (6.5 kg) Ø 5 (1 kg) Ø 5 (6.5 kg)

Welding electrodes ANO-4 (NAKS) Current - alternating or direct of any polarity

170.64 rub. ?

Price including VAT per 1 kg.

Ø 3 (1 kg) Ø 3 (4.5 kg) Ø 4 (1 kg) Ø 4 (6 kg) Ø 5 (1 kg) Ø 5 (6 kg)

Welding electrodes UONI-13/55 U Current - constant reverse polarity (plus on the electrode)

RUB 179.28 ?

Price including VAT per 1 kg.

Ø 2 (1 kg) Ø 2.5 (1 kg) Ø 2.5 (5 kg) Ø 3 (1 kg) Ø 3 (5 kg) Ø 4 (1 kg) Ø 5 (6.5 kg) Ø 4 (6.5 kg) Ø 5 (1 kg)

Welding electrodes ANO-21 (NAKS) Current - alternating or direct of any polarity

180.36 rub. ?

Price including VAT per 1 kg.

Ø 2.5 (1 kg) Ø 2.5 (4.5 kg)

Welding electrodes TsU-5 Current - constant reverse polarity (plus on the electrode)

RUB 188.76 ?

Price including VAT per 1 kg.

Ø 3 (1 kg) Ø 3 (4.5 kg) Ø 4 (1 kg) Ø 4 (6 kg) Ø 5 (1 kg) Ø 5 (6 kg)

Welding electrodes UONI-13/55 A Current - constant reverse polarity (plus on the electrode)

RUB 171.60 ?

Price including VAT per 1 kg.

Ø 3 (1 kg) Ø 3 (5 kg) Ø 4 (1 kg) Ø 4 (6 kg) Ø 5 (1 kg) Ø 5 (6 kg)

Welding electrodes TML-3U (NAKS) Current - constant reverse polarity (plus on the electrode)

RUR 220.44 ?

Price including VAT per 1 kg.

Show 10 more products

How to choose a welding electrode?

Dear novice welders, in this article we will briefly talk about electrodes and give practical recommendations on their use.

- Metal thickness - (the thicker the metal, the larger the diameter of the electrode).

- Steel grade - (ferrous metal, stainless steel, heat-resistant, etc.).

- We determine the current by the electrode!

- Welding position - (bottom, horizontal, bottom T, vertical - welding from bottom to top, ceiling, ceiling T).

Which welding electrode to choose?

MP-3 and ANO - these electrodes are best used on alternating current. They are not picky about dampness. These electrodes are not for critical structures; they are never used to weld bridges and load-bearing roof beams; they are used to weld fences, gates and greenhouses in the country, fences, and small metal structures for domestic use. If there is no overload, these are the electrodes for you. The most popular brands among amateur welders and summer residents.

UONII 13/55 are excellent electrodes, but very “specific”. UONII 13/55 is brewed by professionals. You have to cook on a short arc! These are electrodes for critical structures. They burn only on direct current, they like a stable arc and do not like voltage surges. Start working with UONII 13/55 only when you learn how to cook MP-3 and ANO.

LB-52U - we recommend buying these electrodes from the Japanese company KOBELCO. These electrodes are used for welding pipes under high pressure. Very high quality seam. LB-52U electrodes are one of the most expensive; as a rule, they are purchased by enterprises and structures involved in the repair of urban heating/water networks.

We introduced you to the most popular electrodes. Below we will briefly describe the electrodes of the ESAB Concern (Sweden), perhaps you will find exactly what you need. All ESAB electrodes begin with the letters OK - in honor of the founder of the Concern, Oskar Kelberg.

OK 46.00 ESAB (Russia) – metals can be welded with these electrodes using direct and alternating currents. Often these electrodes are called UNIVERSAL or ELECTRODE FOR STEEL. If you don’t know what to choose, take these electrodes – you won’t go wrong. Electrodes are good because they have a wide range of diameters. You can always choose the one you need.

OK 48.00 ESAB (Sweden) - DC only. Ideal for critical structures.

OK 61.30 ESAB – stainless steel/stainless steel welding (steel grades 304, 308L, 03Х18Н11, 06Х18Н11, 08Х18Н10, 08Х18Н10Т, 12Х18Н10).

OK 67.60, OK 67.62 ESAB - stainless steel/steel welding.

OK 63.30 ESAB (Russian analogs of ANV-26) - (steel grades 316 , 03Х17Н14М2, 10Х17Н13М3Т, 06Х19Н11Г2М2) are ideal for welding thin-walled pipes and thin-sheet products.

If you don’t understand what kind of steel is in front of you, you don’t know its composition - your choice is OK 68.81, OK 68.82 - these electrodes can be used to weld dissimilar steel products and steels of unknown composition.

There are many nuances when welding cast iron!

Welding cast iron steel ESAB OK 92.18 (new name OK Ni-Cl) - designed for welding thin cast iron (no more than 3 layers).

Welding cast iron; cast iron steel ESAB OK 92.60. (new name OK NiFe-Cl) - they can just cook cast iron of any thickness and cast iron with steel

Aluminum welding. Aluminum is a very complex metal, it requires heating before welding, it melts quickly and hardens quickly. Aluminum is usually welded using TIG or MIG welding. It is very difficult to weld aluminum with an electrode, but if you succeed, you can consider yourself a master!

OK 96.20 ESAB - it can be used to weld a very limited number of grades of aluminum. Study the composition carefully.

The most universal electrode for aluminum is OK 96.40 . IMPORTANT that the aluminum electrode must be used in one ignition. An unfinished electrode must be replaced with a new one. Plus, unlike steels, you need to make circular movements with the end of the electrode.

Why do you need to calcinate the electrodes?

The electrodes are calcined in order to remove moisture from them. If the electrode is damp, during welding, defects may occur in the weld seam or the electrode will constantly stick to the product.

Please note that in our online store all the electrodes are “fresh”, we purchase them from suppliers who have special heated warehouses, the electrodes are not stored in warehouses for more than a month, all packs are sealed.

Construction companies have special equipment for calcining electrodes; amateur welders, as a rule, do not have such equipment. If you have opened a new pack, we recommend that you either use it completely or remove the remaining unused electrodes from the pack in a dry, warm place. Do not store electrodes in open spaces, attics or basements.

Helpful information.

| Metal thickness, mm. | 1.1-2.0 | 3.0 | 4.0-5.0 | 6.0-8.0 | 9.0-12.0 | 13.0-15.0 |

| Electrode diameter, mm. | 1.5-2.0 | 3.2 | 3.2-4.0 | 4.0 | 4.0-5.0 | 5.0 |

Forward polarity and reverse polarity.

If the electrode is on “+” and the terminal is on “-“, then the electrode melts more. - this is called reverse polarity.

If the electrode is on “-” and the terminal is on “+”, then the metal being welded melts more. - this is called direct polarity.

Direct current is DC, alternating current is AC. As a rule, all manual arc welding machines are welded on DC (direct current).

When welding with direct polarity, penetration is less (welding of thin-sheet products), and, accordingly, with reverse polarity it is greater (thick-walled products).

Buy reliable equipment from reputable companies, as well as high-quality electrodes, then welding will be a joy!

- Welding equipment Welding machines MMA welding machines

- TIG welding machines

- MIG welding machines

- SAW welding tractors

- Plasma cutting CUT

- Spot welding STUD

- Cooling units

- Feeding mechanisms

- TIG welding torches

- Gas cutters

- Gearboxes

- Generators

- Welding wire

- Welding masks

- Search

- Site Map

- Articles

- Contract offer

- Return and refusal

- legal information

- Privacy Policy

© 2012–2020 Welding equipment and materials “SvarkaMall”.

All rights reserved.

Opening hours : Mon–Fri 09:00–18:00; Sat–Sun 09:00–18:00.

Moscow, 117461, st. Kakhovka, 30

St. Petersburg, 198095, st. Kalinina, house 57, of. 202