04/30/2021 Author: VT-METALL

Issues discussed in the material:

- How was aluminum discovered and what are its main properties?

- Basic physical properties of aluminum

- Basic chemical properties of aluminum

- How to use the basic properties of aluminum

- How to use the basic properties of aluminum in construction

The basic properties of aluminum make this material truly versatile and valuable. It is used in all types of industrial production, in agriculture, in everyday life, in commerce. It has a huge number of advantages over steel and other types of metal.

The most popular applications of aluminum are the manufacture of metal structures and metalworking. Read on to learn about the properties of the metal and where exactly they found their application.

Consumption in industry and life

The figure below shows eight industrial and construction sectors in which aluminum is being used particularly strongly. The percentage shares of various industrial sectors in total consumption are presented according to statistics from the International Aluminum Institute for 2007. Since then, I think the picture as a whole has not changed, and these data are quite relevant.

Application of aluminum in finished industrial products [1]

The main industries that actively use aluminum are:

- Construction

- Product packaging

- Electrical industry

- Transport engineering

- Manufacturing of machinery and equipment

- Production of goods for everyday life

- Powder metallurgy

- Deoxidation of steel in ferrous metallurgy

Recycling: where does aluminum scrap end up after the collection point?

Recycling aluminum scrap is a necessary process for humanity, both environmentally and economically. It takes 500 years for an aluminum can to decompose, whereas a conventional recycling plant can turn it into a new aluminum product in just 60 days.

The recycling process includes several main stages.

Sorting

Aluminum waste is sorted at the plant. Recyclable materials are separated by color, weight, hardness, marking, and chemical composition.

Grinding

Sorted for further processing, the metal is disassembled into parts, debris is removed, and then crushed and shredded.

Drying

Recycled materials are dried to achieve the required moisture content. This is necessary in order to obtain good quality metal after processing. To remelt the charge, the moisture value should not exceed 4%. For slags and flux - no more than 1%. The following drying methods are used:

• Drum drying;

• Chamber drying (for lump scrap and waste);

• Induction drying (for crushed flux).

Melting

Aluminum waste is melted in special furnaces. There are two types of ovens:

- Heated by fuel (fuel oil or gas);

- Heated by electricity.

Afterwards, the molten aluminum is poured into molds, so-called ingots. When the metal has cooled, it is transported to enterprises that produce various aluminum products.

Metal can be recycled an infinite number of times.

Visual diagram of aluminum processing

Construction

Aluminum windows and facades

The main aluminum alloys that are used in the construction industry are alloys 6063 and 6060, as well as alloy 6082 (in Europe) and alloy 6061 (in North America). They have fairly high strength (6082 and 6061 - up to 400 MPa) and good corrosion resistance.

Window aluminum profiles with thermal decoupling (alloys 6060/6063)

The most important structural characteristics of aluminum, which determine the use of aluminum as a material for window and door frames:

- strength for rigidity and safety;

- the ability to take complex shapes (provided by extrusion);

- attractive appearance;

- corrosion resistance;

- minimal need for maintenance.

Curtain facade with aluminum frame (alloys 6060/6063)

Post-transom facade

Aluminum roofing and aluminum cladding of buildings

Decorative and protective profiled cladding materials are often made from rolled aluminum sheets. Various types of decorative and protective coatings make them ideal materials for use as roofing materials.

Application for roofing and cladding of buildings provides the following properties of aluminum:

- low weight due to low density;

- resistance to water;

- corrosion resistance;

- decorative look.

Aluminum roofing

What products can you find aluminum in?

What is made from aluminum

Aluminum is a silver (gray) metal that is light in weight, has a high level of strength and ductility, and is a good conductor of heat and electricity. The metal is resistant to environmental influences, namely, it does not oxidize due to the presence of moisture and any chemicals.

Aluminum and its alloys are used in various fields: mechanical engineering, food industry, construction, in the manufacture of ships, aircraft, furniture and sports goods.

The most common aluminum products are:

• Dishes (containers and food containers, jars, cling films);

• Wires, window elements, as well as sheets, trimmings and shavings of metal structures;

• Spare parts for cars and electrical appliances, radiators.

All these products can be handed over to a special collection point and receive an appropriate reward.

Aluminum pans are one of the most common types of scrap

Types of aluminum scrap

Aluminum scrap metal, as one of the types of recyclable non-ferrous metals, comes in the following types:

• Electrical engineering. Cable and various electrical equipment made of pure aluminum;

• Food. The most common type of scrap, including pots, cans, spoons and other utensils;

• Profile. Various window and door aluminum profiles;

• Profile (thermal insert). Profile with thermal insert;

• Motor. Aluminum from engine housings;

• Household. Door handles, aluminum with various household appliances;

• Scrap aluminum cans;

• Foil;

• Chips;

• Aluminum cable (insulated);

• Slag.

Transport

Aluminum in passenger cars

The average weight of aluminum in passenger cars in Europe in 2006 was about 118 kg and continued to increase. Its share in various components and parts of cars is (in kilograms per car):

- engine cylinder blocks: 40.3

- transmission: 16.3

- Chassis, suspension and handling: 12.5

- wheels: 17.7

- heat exchanger: 12.3

- brakes: 3.7

- body: 6.8

- heat shields: 1.4

- bumpers: 2.8

- other components: 3.9.

Aluminum car engine block

Aluminum car wheel rim

The use of aluminum for the manufacture of automotive parts is due to its following properties:

- low density;

- strength;

- rigidity;

- viscosity;

- price;

- corrosion resistance.

Aluminum car frame

Aluminum alloys for trucks

Aluminum alloys for automobile tanks [5]

Production of aluminum automobile tanks [5]

Aluminum alloys for dump truck bodies [5]

Production of aluminum dump truck bodies [5]

Aluminum alloys for car vans [5]

Aluminum alloys for truck chassis [5]

Aluminum in carriage building

Construction of the Intercity Express high-speed train from extruded aluminum profiles - Germany, 1992

Aluminum urban rail car [7]

Aluminum freight car for coal transportation [7]

Aluminum in shipbuilding

Aluminum patrol boat

Cruise ship with aluminum superstructure [5]

Aluminum catamaran yacht [5]

Aluminum alloys for aircraft

The Wright brothers' first airplane in 1903 was primarily made of wood with an aluminum engine.

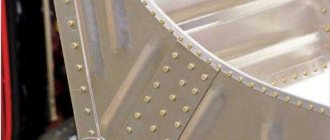

Among the aluminum alloys used in aircraft construction, high-strength wrought alloys dominate, such as alloy 2024 (containing copper and magnesium) and alloy 7075 (containing magnesium, zinc and some copper). Most aluminum alloys used in aircraft construction are non-weldable and are joined mainly with rivets.

The figures below show the use of 2xxx series alloys for the manufacture of aircraft fuselage and 7xxx series alloys for wings.

(a)

(b)

The use of aluminum alloys in aircraft construction: a – alloys of the 7xxx series for the fuselage and b – alloys of the 2xxx series for the wings [2].

Airbus A380

Basic requirements for aluminum alloys in the aerospace industry:

- low density;

- high strength;

- precision machining;

- corrosion resistance;

- price.

Alloying

Aluminum is used for the production of products and alloys based on it.

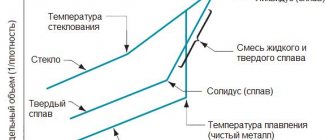

Alloying is the process of introducing additional elements into the melt that improve the mechanical, physical and chemical properties of the base material. Alloying is a general concept of a number of technological procedures carried out at various stages of obtaining metal material with the aim of improving the quality of metallurgical products.

The introduction of various alloying elements into aluminum significantly changes its properties, and sometimes gives it new specific properties.

The strength of pure aluminum does not satisfy modern industrial needs, therefore, for the manufacture of any products intended for industry, not pure aluminum, but its alloys are used.

With various alloying, strength, hardness increase, heat resistance and other properties are acquired. At the same time, undesirable changes also occur: electrical conductivity inevitably decreases, in many cases corrosion resistance deteriorates, and relative density almost always increases. The exception is alloying with manganese, which not only does not reduce corrosion resistance, but even slightly increases it, and magnesium, which also increases corrosion resistance (if it is not more than 3%) and reduces the relative density, since it is lighter than aluminum.

Space technology

The first person to understand the enormous potential of aluminum for space was the great novelist Jules Verne. In his novel “A Trip to the Moon,” he described in detail an aluminum rocket back in 1865.

Aluminum alloys for spacecraft

The body of the first Soviet satellite, which was launched in October 1957, was made of aluminum-magnesium alloy AMg6 with a magnesium content of 6%. Aluminum-magnesium alloys remain the main material for the manufacture of rocket bodies. Duralumin aluminum alloys are also used in the internal compartments of missiles.

The first artificial space object - Soviet Sputnik 1

In the last decades of the 20th century, aluminum-lithium alloys began to be used in spacecraft. The density of lithium is only 0.533 g/cm3 - it is lighter than water. Additions of lithium to aluminum in amounts up to 2.5% reduce the density of the aluminum alloy and also increase its elastic modulus. Thus, alloy 8090 has a density 10% lower and a modulus of elasticity 11% higher than that of alloys 2024 and 2014, popular in aircraft construction. The figure below shows the Curiosity rover wheel made of aluminum alloy 7075.

Curiosity rover wheel made of aluminum alloy 7075-T7351

Aluminum is also used as a binder material in boron-aluminum composites, which are currently also used in space technology.

Boron-aluminum composite (40% boron fibers)

Powdered aluminum - a component of rocket fuel

The high chemical activity of aluminum makes it possible to use it as a component of rocket fuel for solid rocket boosters in the space launch system (SLS) being developed by NASA.

In rocket boosters, aluminum powder and ammonia perchlorate are bonded together using a special binder. This mixture, similar to eraser material, is then placed in a steel casing [3].

When this mixture ignites, the oxygen from the ammonia perchlorate combines with the aluminum to form aluminum oxide, aluminum chloride, water vapor and nitrogen gas, and release enormous amounts of energy.

Aluminum is a component of solid fuel for NASA rocket boosters [3]

Aluminum alloys with manganese and magnesium

Among non-hardening aluminum alloys, alloys based on Al-Mn and Al-Mg have acquired the greatest importance.

Manganese and magnesium, like copper, have limited solubility in aluminum, which decreases with decreasing temperature. However, the hardening effect during their heat treatment is small. This is explained as follows. During the crystallization process in the manufacture of alloys containing up to 1.9% Mn, excess manganese released from the solid solution would have to form with aluminum a chemical compound Al (MnFe) soluble in it, which is insoluble in aluminum. Consequently, subsequent heating above the limiting solubility line does not ensure the formation of a homogeneous solid solution; the alloy remains heterogeneous, consisting of a solid solution and Al (MnFe) particles, and this leads to the impossibility of quenching and subsequent aging.

In the case of the Al-Mg system, the reason for the lack of hardening during heat treatment is different. With a magnesium content of up to 1.4%, hardening cannot occur, since within these limits it dissolves in aluminum at room temperature and no precipitation of excess phases occurs. With a higher magnesium content, hardening followed by chemical aging leads to the release of an excess phase - the chemical compound MgAl.

However, the properties of this compound are such that the processes preceding its isolation, and then the resulting inclusions, do not cause a noticeable strengthening effect. Despite this, introducing both manganese and magnesium into aluminum is beneficial. They increase its strength and corrosion resistance (with a magnesium content of no more than 3%). In addition, magnesium alloys are lighter than pure aluminum.

Product packaging

Rolled aluminum – strips and foil – are used in the packaging of bulk and liquid products. Aluminum packaging accompanies us everywhere in our lives - for example, aluminum cans and bottles, foil in food and medicine packaging. Aluminum has low density, food and beverage compatibility, and an attractive appearance. This makes it an ideal material for various types of packaging: hard (cans) and soft (foil).

Aluminum cans for food packaging [6]

Aluminum cans

Aluminum is used to make 75% of beverage cans and 15% of aerosol containers. Aluminum cans provide a significant reduction in packaging weight compared to similar steel cans.

The can body is made of 3000 series alloy (aluminum-manganese alloys), which, after deep upsetting, is rolled out to a wall thickness of 0.27 mm.

The lid of the jar makes up 25% of its weight. It is made from a more durable aluminum-magnesium alloy. The “opener” lever built into the can, which is attached to the can with an integral rivet, consists of a different aluminum-magnesium alloy. This rivet is rolled from the body of the cap during its manufacture.

Aluminum can for packaging beer and soft drinks

Requirements for aluminum alloys for the packaging industry:

- low density;

- strength;

- good formability;

- compatibility with food and drinks;

- decorativeness (the ability to apply drawings and inscriptions);

- price.

Packaging foil

Aluminum foil is usually made from 1000 series grades of commercial aluminum. The properties of aluminum that make it suitable for use as a foil material are as follows:

- strength and impermeability to liquids and gases with small thickness;

- low density;

- thermal conductivity;

- heat resistance;

- resistance to penetration of gases and liquids;

- compatibility with food and drinks;

- aesthetic and decorative potential.

Aluminum Packaging Foil

What is aluminum and why recycle it?

Aluminum surrounds us everywhere. It is lightweight, melts well, is not afraid of corrosion, and because of this it is in great demand. Aluminum products can not only be produced, but also successfully processed , obtaining new raw materials.

Aluminum scrap is popular and remains one of the most affordable types of non-ferrous scrap metal.

Aluminum waste awaits recycling

After processing, scrap aluminum produces a high-quality material that will be used in industry. As has long been known, it is much more profitable to process metal than to mine it. This not only saves natural resources and protects the environment from pollution, but also brings excellent additional income.

Recycling aluminum has the following advantages:

• Consumes 95% less energy than virgin production.

• Emits less greenhouse gases that have a negative impact on the environment;

• Reduces the use of natural resources and chemicals, stops changing the landscape.

Wires and cables

The high electrical conductivity of the 1000 series aluminum grades, as well as the 8000 series aluminum alloys, makes them very suitable for the manufacture of electrical conductors. Aluminum conductors are used in the following cases:

- electrical distribution substations;

- power systems of high-rise buildings;

- high-voltage power lines;

- most underground power lines;

- power cables for industrial applications.

Most aluminum in the electrical industry is used in the form of cables (8 out of 13%). However, it is also used in the form of electrical busbars for equipment with high current strength, as well as for powering large buildings. In addition, cables for industrial, commercial and residential buildings may contain many insulated conductors, which are placed in a common protective aluminum sleeve.

Requirements for aluminum used for electrical applications:

- reasonable cost;

- sufficiently high electrical conductivity;

- corrosion resistance;

- strength.

Types of aluminum alloys accepted as scrap

Types of aluminum alloys

Along with products made from pure aluminum, non-ferrous metal stations also accept alloys with a high content of other elements: copper, silicon, nickel, etc. All alloys obtained from aluminum are usually divided into two types:

• Deformable. Used for the manufacture of sheets, rods, wire and other profiles;

• Foundries. Used for shaped casting.

According to GOST, the following types of aluminum waste, which contain other metals, are distinguished:

• Unalloyed secondary metal; • Copper. There are scraps with a low content of this element (up to 0.5%) and high (no more than 5%);

• Zinc. Includes two subgroups. The first contains products made from alloys characterized by a low level of zinc (less than 0.5%). The subgroup with high (up to 6.5%) zinc inclusion includes rolled aluminum and parts of aircraft;

• Magnesium. This group includes secondary rolled aluminum and castings, the magnesium content of which does not exceed 13%. This category also includes used pipelines and welded tanks.

It should be noted that mixed aluminum production waste such as castings of components intended for mechanical engineering, alloys with silicon and alloys with nickel are accepted separately

Low grade recyclables

This category refers to crushed scrap, namely chips of various origins: turning, drilling or milling. The only requirement for this type of waste is sorting by type of alloy. It is necessary to separate casting, wrought, and silicon-containing alloys among themselves. Shavings from different types of alloys, as well as vine-shaped shavings, are accepted separately.

Usually you can get a little money for aluminum shavings

In addition, the category of low grade aluminum scrap includes:

• slags, foam, refining residues of metal alloys;

• pre-melted alloys;

• cans, necessarily briquetted;

• foil.

cars and equipment

Heating and ventilation systems

Aluminum alloys of the 3000, 5000 and 6000 series have good thermal conductivity. Combined with high strength, these alloys are a good choice for heating and ventilation applications. These systems include the following components using aluminum alloys:

- compressors;

- condensers/evaporators;

- expansion valves;

- fans;

- pipes.

Properties of aluminum that are important for heating and ventilation systems:

- high thermal conductivity;

- high contact coefficient;

- low density;

- high corrosion resistance.

Division of aluminum into classes and groups

Recyclable materials made from aluminum and its alloys have a multi-level classification. Aluminum scrap can be divided into:

• Classes. A – lump scrap, B – shavings, C – powdered waste, D – other recyclables;

• Groups. There are 10 groups, differing in chemical composition and type of alloy;

• Variety. Differences are made in the type and shape of the products.

Aluminum scrap metal groups

Aluminum waste is divided into the following groups:

• Group I. Pure aluminum (unalloyed), containing this metal in an amount of at least 99%.

Electrical aluminum is considered the purest type of scrap

• Group II. Wrought aluminum alloys with low magnesium content.

• Group III. Wrought aluminum alloys with high magnesium content.

• Group IV. Aluminum casting alloys with low copper content.

• Group V. Aluminum casting alloys with high copper content.

• Group VI. Wrought aluminum alloys with high magnesium content.

• Group VII. Aluminum casting alloys with high magnesium content.

• Group VIII. Wrought aluminum alloys with high zinc content.

• Group IX. Aluminum casting alloys with high zinc content.

• Group X. Low-quality scrap and lump waste of aluminum and aluminum alloys that do not meet the requirements of all groups.

The quality of the scrap determines the possibility of its further use. It is most effective to use aluminum scrap metal to produce those alloys during the processing of which they were formed, since in this case the raw materials already contain the necessary components.

Consumer goods

Aluminum is used in large quantities in the manufacture of various components, parts and housings of many consumer products that surround our lives - household products, for example, refrigerators, freezers, dishwashers. Refrigerators and freezers contain refrigeration units, which, as mentioned above, also contain significant amounts of aluminum. Important properties of aluminum for consumer products are:

- aesthetic properties;

- corrosion resistance;

- strength;

- high thermal conductivity (for refrigeration units).

Metal in nature

7.4-8.1% of the earth's crust is aluminum. In nature, it is represented by rocks and minerals that form the earth's crust.

Almost always these are aluminum compounds:

- Bauxite (oxides with an admixture of silicon, calcium, iron).

- Alumina (kaolin-sand or lime, magnesium mixture).

- Nephelines (with potassium).

- Kaolinites.

- Corundums.

In the corundum segment, “harsh” emery and jewelry minerals coexist: sapphire, ruby. The structure of their lattices is identical.

“Aluminum” gems: sapphire, ruby, emerald, aquamarine, alexandrite.

Aluminum compounds are found in the water of rivers, seas, and oceans. In its pure form - only in the craters of volcanoes.

Medicine

Equipment and tools

Anodized aluminum is widely used for products and parts in medical and dental equipment, including:

- Interior decoration of hospital wards and medical offices

- Instruments that can withstand regular autoclave sterilization

- Hospital beds, stretchers, strollers and other means for moving patients

- Medical Oxygen Equipment

- Dental equipment and instruments

- X-ray machines

- Dialysis equipment.

Medicine packaging

Aluminum foil is an unrivaled barrier that reliably protects medications from microorganisms, sunlight, oxygen and other gases. Therefore, this foil is the main material for protective packaging of medicines and pharmaceutical materials.

Medicinal tablets in aluminum packaging

Production of household items

There are countless things in everyday life that are made from this metal. In particular, aluminum stairs are popular - they are found in almost every home and garage. Kitchen utensils, TV brackets - all these elements can be made of aluminum, not to mention smaller items.

Aluminum ladders, by the way, have confidently replaced iron ones, since the latter are very difficult to move from place to place. This once again demonstrates the advantage of this metal. The list of household items made from it could take a very long time.