How to replace solder

Solder at home can be replaced with:

| Solder option | Description |

| Aspirin | Probably the most affordable option, since it can be found in every first aid kit. To carry out high-quality soldering, be sure to use only a highly concentrated solution. It is also important to consider that soldering with acetylsalicylic acid is accompanied by an unpleasant odor. Therefore, it is important to ensure good ventilation; the room should be well ventilated. |

| Fat | An affordable product with low cost. The main disadvantages of fat are its consistency and unpleasant odor. However, it melts easily and spreads across solder joints. When considering options for replacing solder for soldering, fat cannot be ignored. |

| Resin | It is better to use tree resin, especially coniferous ones. It is a non-aggressive substance that is easy to melt and spread over the surface. Can be used for various soldering and tinning applications. |

| Amber | Exotic and expensive option. However, due to its similar characteristics to rosin, it is the best option for soldering at home. The main disadvantage is low availability. Finding amber is not so easy. |

| Rosin for instruments | Used for rubbing the bows of musical instruments. However, it can be used for soldering, since it has characteristics similar to ordinary rosin. |

Sometimes it happens that you need to find a way to replace solder for soldering, since you don’t have regular rosin at home. At home, you can use many fairly relevant options, some are more affordable, others, on the contrary, will be more difficult to find.

Even acetic and citric acids provide a weak effect, so they can also be used for soldering.

Lead-free solders

Solders that are used when mounting motherboards and other computer components are soft.

It should be said that in recent years they have switched to lead-free solders.

Environmentalists believe that lead is harmful to the environment. Therefore, the RoHS directive was adopted, regulating, in particular, the use of lead-free solders.

Devices installed in accordance with this directive can be identified by lighter and shinier soldering areas. Such solders are often more refractory, so when repairing them, not every soldering iron can be used. Such solders may contain zinc, copper, silver and other metals along with tin.

Electronic components are quite sensitive to overheating. Therefore, when repairing devices made using RoHS technology, it is necessary to monitor the temperature of the soldering iron tip to prevent overheating.

There is a version that the introduction of lead-free solders was caused not only (and not so much) by concern for the environment. There was also a desire to make a profit from the sale of new soldering equipment, which more accurately controls the temperature at the soldering site.

Using Alternative Soldering Media

Soldering work is standard for any chosen product; differences can only be observed at the preparatory stage:

- the fat must be melted or heated;

- prepare a solution from aspirin;

- No preparation is required for resin, amber, and bow rosin.

The use of analogues cannot be a complete replacement for soldering rosin, however, when you don’t have it at hand, they will be an ideal way to achieve the desired result.

You also need to take into account that home methods are not suitable for production purposes. The quality of soldering will be significantly worse than when using standard soldering.

How to make solder at home

Many radio amateurs know how to make solder for soldering. To do this, you need to know the characteristics of solders and the ratio of elements. Scrap metal or waste parts from devices, batteries, coins, etc. can be used as raw materials. What can be used as solder, and where to find the substances:

- Tin can be removed from light bulbs or circuit boards of old unnecessary equipment. The walls of food cans and lids are covered with a thin layer.

- Lead is found in a pure state in batteries, cables, and car wheels.

Low-melting metals are used as solders (relative to the melting point of the parts being connected). These are mainly two-component alloys, less often 3-component. The ratio of these elements is of primary importance: with an increase in the content of a more fusible metal in the composition, the melting point decreases, and vice versa. We'll tell you in this article how to make silver solder at home, the most refractory of all existing ones.

Technology for creating silver solder

First you need to decide on the composition of the material, and then prepare the necessary elements in the required proportions. Pour the silver into a spoon and melt it using a burner. After this, you can start adding other elements, the main thing is not to rush and do everything carefully so that the resulting mixture is homogeneous. Therefore, you will have to spend some time on this, but the result is definitely worth it. However, it is worth remembering that the components gradually burn out and evaporation occurs if the process is too long. Then you can pour the resulting mixture into the ingus, and then roll it out without annealing. To make hard solder, you need to use the material in certain proportions:

- 80% silver;

- 16% copper;

- 4% zinc.

Medium hardness:

- 75% silver;

- 22% copper;

- 3% zinc.

To create soft solder:

- 65% silver;

- 20% copper;

- 15% zinc.

Making your own solder

Soldering with silver solder is a very responsible and important task, therefore it is necessary to prepare it with the utmost care and precision. It is necessary to properly ensure its transformation from liquid to solid state. It is necessary to add all the necessary ingredients and make the composition homogeneous, and after all these actions it becomes possible to pour the material into the ingus. In this case, there are three main stages:

- First you need to prepare for melting in a spoon.

- Add remaining ingredients.

- After this, you should mix the finished composition and pour it into the Ingus.

It is necessary to put a little cardboard on the bottom of the spoon, and then a plate of a larger diameter so that it covers the spoon completely. Then you need to press the plate into a spoon to obtain a concave shape. This is very important, because with greater depth the process will take longer.

Types and features of solders

Important! Low-melting solders up to 450° C are applied using a soldering iron, refractory solders (up to 1100° C) are fused with a gas torch.

To avoid damage to the product, you can learn how to make solder at home. There are 3 main types.

A large proportion of solders used for soldering electronics are tin-based. The second and essential component is lead. Depending on the proportions, the properties of the solder differ: the higher the lead content, the higher the melting point. To increase the strength and melting temperature, a third element can be added to the solder: cadmium, antimony.

Lead-free solders are a new development by chemists. Such solders are made on the basis of tin, but with the addition of silver, cadmium, zinc, copper, and aluminum. All tin-based solders have high adhesion to metal surfaces. They wash off well with acids and also allow you to work with a large number of metals. They are classified as low-melting and are marked with PIC indices.

Accurate all ingredients and their sorting

One recipe requires the exact content of the following ingredients:

- 20 g 916 silver;

- 875 silver scrap;

- 12 g pure silver;

- metals;

- borax;

- gas-burner.

It is recommended to distribute the metal to create solder in small separate piles. Then everything is done according to the recipe used and mixed thoroughly. Then you should add borax 1/10 of the total amount. And only after that you can start heating it in a spoon.

It is necessary to place the ingus close to the process. To begin with, it should be lubricated with wax and then heated, because the material cannot be placed from a hot to a cold container. When heated, the composition must be at the same temperature, so as soon as the required consistency is achieved. It immediately pours into ingus. Once the solder is in the desired shape. You need to put it in cold water. When completely cooled, the block is pulled out. It should be remembered that the cardboard in the spoon can withstand no more than five processes of this kind, then it needs to be changed.

Manufacturing instructions

We prepare solder for soldering silver with our own hands. Since a burner is used to melt refractory elements, we do this in a garage or workshop. Silver solder consists of 2 elements:

- silver in the amount of 3 grams;

- brass (copper + zinc) 1 gr.

Silver must be as pure as possible - 925. As brass, you can use broken brass products and coins. Or take a ratio of 70% copper and 30% zinc. The two-component alloy should be in exactly this ratio, since when the zinc content increases to 40%, brittleness increases.

It is necessary to melt the elements first of all that have a high melting point and add the rest as they decrease. The melting point of copper is 1080° C, silver – 930° C, zinc – 420° C.

To produce homemade solder, we will need a small mold and a bowl in which we will melt. It's best if it's cast iron. Warm up the mold and add a little wax to it, heat the bowl. If we use ready-made brass, then melting begins with silver. If these are 3 separate elements, then we start melting with copper. If the melting is not complete, add silver; when mixing, the process begins to happen faster. Finally add zinc. Without ceasing to heat the bowl of metal, we pour the resulting melt into the mold. Cooling of the melt occurs very quickly, in a matter of seconds. After crystallization, the resulting workpiece can be cooled.

How can I replace tin solder for soldering? This category is characterized by high ductility and adhesion to metal surfaces. Low refractoriness allows the use of solder for non-ferrous metals and thin parts. A mixture is obtained by mixing tin and lead in their pure form. The elements themselves can be obtained chemically by extracting tin from cans and lids. We do it step by step:

- Pour water into a jar, put it on fire and boil. Mine.

- We connect 3 batteries and a 9-2 volt battery. We connect the positive pole to the jar, the negative pole to metal of any shape (let it be an electrode).

- Fill the jar with sodium hydroxide or soda solution.

- We lower the electrode into the jar, but so that it does not touch its walls.

- Over time, a deposit of pure tin will appear on the anode (electrode).

The method for extracting tin from old circuit boards requires the use of hydrochloric acid followed by leaching.

It is much easier to obtain lead at home; all you need to do is:

- disassemble the old battery;

- find fishing weights or shot;

- disassemble and clean the lead cable;

- finding unnecessary seals from the water meter.

Recommendations for use

Important! Initially, the most refractory metal is melted, after which the remaining components are added in descending order.

Solder is used in 3 types: wire, powder or chips and plate. The choice of shape is determined either by personal preference or by design features.

If you are looking for where to get solder at home, if you don’t have a store-bought one at hand, determine the degree of importance of the product. It is possible that the resulting solder will not match the desired chemical composition and will not provide mechanical parameters.

Conclusion

There are several alternatives to replacing solder. Let us highlight the goals that are achieved by soldering: rigid fastening of parts (for electronics - preserving the conductive ability of the element). This result can be achieved by using the following types of glue:

- epoxy resin;

- glue gun.

The disadvantage of this connection can be considered the high fragility of the resin and the low strength of hot glue. If these shortcomings are unacceptable and there is no solder, then you can make even the most refractory copper solder with your own hands.

How to use solder for soldering?

The best solder for soldering metals is pure tin. But in practice, an alloy is used in which tin is the base and lead is added. Similar solders can be found on sale, and there are many brands. If desired, you can make it yourself if all the necessary ingredients are available. Tin and lead solder is designated by three letters - POS, followed by a number. The most popular brands are POS-60 and POS-40. The numbers are the percentage of lead in the mixture. Such solders are used for soldering both brass and radioelements and copper wires.

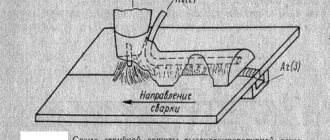

Hard soldering diagram.

Making solder yourself

To make solder for soldering at home, you will need the following ingredients:

- Lead.

- Tin.

You also need the following tools:

Materials and tools for brass soldering.

- Ceramic forms (can be made of plaster or tin).

- Steel spoon.

- Steel stick.

- Container (preferably steel).

Don't forget that you are working with lead, one of the dangerous metals. Wear goggles and a respirator, ventilate the room. For convenience, wear gloves to avoid getting burned. Melt lead and tin over a gas burner in a container, weighing them on scales in advance and achieving the desired proportion. Using a steel spoon, remove the “fat” - the slag on the surface. And, stirring with a steel rod so that the metals combine evenly, pour the melt into the molds. That's it, the solder for soldering copper wires and radio elements is ready, you can begin installation work. Don't forget to ventilate the room.

Characteristics and properties of silver solder

Making your own silver solder is often done for use at home. In most cases, silver solder is needed in order to solder together several layers of various metals at once, because the result should be a large layer of thickness that needs to be created several times. That is why the material must have a high melting point for stepwise soldering, so that when soldering the next metal the previous layer does not deteriorate. Solder must melt at a temperature of at least 600 degrees Celsius.

When creating this type of material, it is necessary to ensure that the composition includes 30% silver. Copper should be about 20%, zinc 16%, and cadmium 33%. This material is quite fragile, so you should avoid mechanical and physical impact on it so that it does not collapse over time. To increase the fluidity of the alloy during single-layer soldering, you can add about 50% of silver from the total amount of the composition. At the same time, resistance to external influences significantly increases. Multi-stage soldering is also possible in this case, it just requires great care in the work.

Materials and tools for creating solder

There are several options for creating silver solder yourself. However, even the simplest of them require careful work, and it is not a guarantee that the material will be of high quality. First you need to find all the tools and necessary materials. For this you will need:

- silver crowbar;

- other metals included in the composition, for example, soldering borax, brass, copper;

- scales;

- spoon;

- wire cutters;

- scissors;

- sandpaper;

- gas stove;

- spatula;

- folds;

- Ingus.

How to solder brass correctly?

With amateur radio solders everything is very clear, but sometimes it is necessary to solder more massive parts. It is especially difficult to work with brass elements, since during soldering an oxide film forms on the metal. Zinc also evaporates during heating, since brass contains a large amount of this metal. There is only one way out - you need to solder at a low temperature, using tin and lead solder. But it is necessary to use a flux; the most common one is made from rosin and alcohol.

To solder L-63 brass, you need to use a flux that contains sweat acid and zinc chloride. Very high mechanical strength cannot be achieved. Compared to soldering copper, the strength of brass will be half as strong. This is largely due to the fact that the seams have a porous structure. Moreover, pores are formed with any soldering method, both at high and low temperatures. Soldering brass in a gas environment is often used (provided that fluxing was carried out before starting work). It is permissible not to use flux if there is a layer of nickel or copper on the surface of the brass.

In a salt bath at a temperature of 850 degrees, you can solder brass elements. The main thing is to add a little flux to the saline solution, which contains potassium fluorobate. Flux should be approximately 4-5% of the total mass of the brine solution. Flux is needed to ensure that the solder penetrates as best as possible into the gap between the parts being joined.

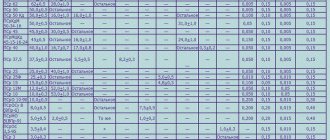

Copper-rich brass can be soldered with the following solders:

Brass, which has a low melting point, requires the following soldering alloys:

For soldering brass, which has a high percentage of zinc, use PSR-40 solder grade.

It is impossible to use copper-phosphorus solder, since the connection turns out to be low-plasticity due to the formation of zinc phosphides on the surface of the seam during soldering.

If during operation of elements that are subject to soldering, dynamic and vibration loads do not occur, then it is allowed to use PMC-48 and PMC-36 solder.

What does a car enthusiast need to perform soldering work?

To solder the necessary parts, the motorist will need a soldering iron and materials to perform the soldering process itself (fluxes, rosin, solder, and other auxiliary consumables). You can purchase these things separately, or you can immediately order special soldering kits, which include all the necessary materials and devices that allow you to solder various materials, even such as steel, copper, aluminum and many others. So that the motorist can carry out soldering work both in the garage and, if necessary, on the road, there are kits that include a soldering iron that operates from the car’s 12 V electrical network.

Composition of the soldering kit 220 V/12 V

This set will be the optimal solution for performing tinning and soldering procedures using low-temperature solders. It includes:

- soldering iron operating on 220 V or 12 V;

- rosin;

- soldering acid;

- alcohol-rosin flux;

- flux for aluminum;

- solder;

- installation wire;

- heat-shrink tubing.

Contents of soldering kit 2

This set will be the optimal solution for those car enthusiasts who already have a soldering iron and only need consumables. It included:

- rosin;

- solder POS-61;

- soldering acid;

- alcohol-rosin flux.

If you are a beginner radio amateur and have already decided on the choice of your soldering tools, the following 2 questions arise: what kind of consumable materials should you buy for soldering? How are the different formulations different?

We will answer these questions.

So, in order to solder one electronic circuit component to another with a soldering iron, you definitely need solder . Previously, the choice was small, exaggerating, we can say that “Grandfathers soldered” with tin and pine resin. Now the choice is much wider. This is due both to the development of the chemical industry and to the miniaturization of radio components, the emergence of highly integrated microcircuits and new types of soldering equipment.

For example, on the page of the Electronoff online store of measuring instruments and multimeters there are 45 positions.

Solders

There are soft ones, with a melting point of 400˚C (PMC-35). Radio amateurs use soft, low-temperature ones, which differ in composition, type (wire, tube), and thickness. The most common is POS-61 or POS-60 .

In most cases, information about the composition of the solder is already in the name. For example, “Cynel Sn60Pb40 3mm 1kg (POS-60F)” means that the composition is 60% tin (Sn) and 40% lead (Pb); thickness 3mm, weight 1kg, the POS-60 solder itself has the shape of a tube with flux , which is very convenient to use. Below is some useful background information on some solders.

- POSV-50 (Rose Alloy) Sn25 / Pb25 / Bi50 - for radio components sensitive to overheating, operating temperature 94˚C.

- POSV-33 Sn33.4 / Pb33.3 / Bi33.3 - copper, brass, constantan alloy with a sealed seam, 130˚C.

- POS-61 Sn61 / Pb39 - current-carrying copper, brass, bronze elements with a sealed seam, 190˚C.

- POS-61M Sn61 / Pb37 / Cu2 - thin copper cores, board tracks, 192˚C.

- POS-40 Sn40 / Pb60 - contact surfaces in radio equipment and galvanization, 238˚C.

Where can I get tin?

I need a certain amount of tin - I wanted to cast it here in my spare time. anything.

I just can’t even imagine where they get it.

- pro

- Group: Users

- Posts: 7,654

at non-ferrous metal collection points! outbid, or wait for those who bring))

P.S. steelworker?? are you doing HARD? )) P.P.S. fuck with me?))))

- V-Twin Drag Machine

- Group: Users

- Messages: 2,990

- male chauvinist pig

- Group: Users

- Posts: 8,156

- coffee for me!

- Group: Users

- Posts: 2,283