Advantages of PVC panels

There are quite a lot of them, these are objective data that you can trust.

- Light weight. The additional load is so insignificant that it is not taken into account during the design of the building. Finishing can be done on fragile surfaces; the coating is not afraid of minor temperature fluctuations in the linear dimensions of the room.

- Manufacturability. Plastic panels are very quickly mounted on metal or wooden frames. The former are more expensive, the latter are much cheaper. When it comes to quality and durability, there is no practical difference. An important advantage is that the panels can be installed on uneven and unplastered walls. Finishing masonry materials to level them requires a lot of time and money. Another quality related to manufacturability is that when decorating walls with PVC panels, there is no need to use special expensive devices and tools. The complexity of the installation is accessible to beginners.

Fastening the panels does not require much effort

PVC panels are often used in bathroom decoration

Video. Finishing the walls and ceiling of the bathroom with PVC panels

Among all the numerous types of wall decoration, PVC panels are one of the most budget-friendly. But in terms of performance characteristics, these materials meet most of the rather stringent requirements of modern consumers. Let's look at how to attach plastic panels to the wall, as well as the features of choosing and using such a finish.

How to attach plastic panels to the wall

Features of installing plastic panels on walls

If the room is dry and the walls are smooth, then the panels can be mounted directly on the wall without using lathing.

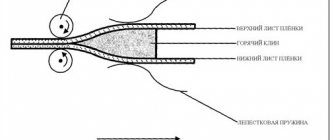

Fastening panels with glue directly to the walls without using lathing.

In rooms with high humidity, a plastic or metal mounting profile should be used as lathing. In this case, the panels are attached to the slats with special clips, which greatly facilitates the installation and dismantling of the structure.

Fastening panels using a plastic profile using special clips.

You should take into account the expansion of the material when the temperature changes, so when adjusting the panels in height, leave a small gap. If you use a wide beam for the sheathing, then insulation or soundproofing material can be placed in the resulting space between the wall and the panels.

Panel fastening methods

The technology of finishing walls with panels provides three methods of fastening, each of which has its own strengths and weaknesses.

- On glue. Special compounds with high adhesion to plastic surfaces are used. The advantages of the method are that there is no need to prepare a special sheathing. Disadvantage - the wall surface must be flat; differences of no more than five millimeters can be eliminated with glue.

Gluing PVC panels to the wall

Mounting on clamps

Fastening panels to slats is the most convenient way

In this article we will give detailed instructions for attaching panels to the wall using wooden slats.

What glue to use to glue plastic to: plastic, metal, chipboard, tile, concrete

The modern world is unthinkable without plastic products; the lightweight material is used everywhere: construction, decorations, furniture, dishes, decorative elements, household appliances. Polymer products do not rust, are beautiful, but not always durable. Therefore, breakage of plastic items occurs frequently; every time something is dropped, the problem arises of how to restore the broken product.

Universal glue

Don’t be upset - there are no eternal objects, and you shouldn’t throw away a broken thing. Today there are no problems in repairing any material, even polymer. You just need to think about how to glue your favorite thing together.

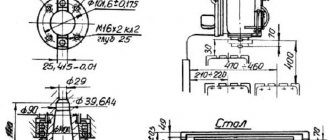

Features of installing plastic panels on the ceiling

Now let's look at ways to attach plastic panels to the ceiling. Before installation, you need to determine the distance between the panels and the ceiling. This gap will depend on the type of lighting. If you plan to install built-in lamps, then the distance should be at least 10-15 cm, so you can completely hide the wiring. Mark the locations of the lamps in advance with a pencil, cut out the holes and install the lamp bases.

Metal lathing for mounting plastic panels on the ceiling in the bathroom.

Next, you perform the same steps as when installing the panels on the walls. In a room with a flat ceiling, you can do without lathing. Install the ceiling plinth on three walls before starting work. Use a building level to position the panels evenly.

When installing plastic panels in a room with high humidity, fill the ceiling gaps with silicone sealant to achieve complete waterproofness.

Gluing plastic surfaces

All plastic surfaces, regardless of processing method, can be cured with epoxy adhesives at normal temperatures. All connections made using the cold method will not always be properly glued. Another thing is to glue using heating temperature; the choice of suitable glue here is very diverse. Samples BF, VS 0T will be ideal for gluing the surface of plastic to any material.

One of the options for choosing an adhesive composition is to create glue at home. Sometimes it is easier and more profitable to make such a composition yourself, especially since for this you will need to dissolve a piece of plastic in a solvent, waiting for it to melt.

The glue for gluing two plastic surfaces together differs from the glue for various materials. For example, when you glue paper and wood, you will have two different surfaces. Polymer is another matter - when gluing, two surfaces, dissolving, turn into one.

Again, you need to look at the brand of polymer, for example, polystyrene polymer is treated with acetone and joined, resulting in welding.

An effective option is glue with dichloroethane, which dissolves the plastic surface and the seam is “tight”.

For joining plastics, you can choose the following modern means:

- Tensol Cement gives an excellent bond if the surfaces are clamped for 24 hours.

- Contact adhesive is applied to both surfaces and will perfectly bond any type of plastic.

- Super glue based on cyanoacrylate will glue any surface, even your fingers. If you're not careful.

- Epoxy resin can hold most materials together, you just need to quickly mix the catalyst with the resin. Suitable adhesives are adhesives BF-2, BF-4, 88.

- A glue gun is used to join plastic surfaces; its action is based on the work of thermal adhesive.

Any surface can be glued using the following technology:

- We prepare the plastic by sanding its surface with sandpaper.

- The adhesive is squeezed onto the surface of the first piece of plastic. Also processed like the first one.

- Distribute the solution with a brush over the entire surface of the part.

- Two plastic panels are pressed against each other.

- In order for air bubbles to disappear, you need to move the surface a little.

- Place the glued surfaces under a press or simply clamp them in a vice.

Deciding on the material

It turns out that there are different types of polymer, so sometimes all our attempts to glue a polymer product together do not lead to the desired result.

Read also: Miter saw with circular table

It is impossible to determine the type of polymer by eye or touch, so let’s inspect our product for markings that resemble a Mobius Loop with different meanings. Types of polymer can be seen in the photo. Depending on the marking, you can choose glue today for any product. But even in the case when an advertisement invites you to purchase a universal miracle glue, you should not count on effective gluing; perhaps this is just a PR trick.

Having “recognized” the polymer material more closely, you need to select your own solvent for its type:

- Brand PA66 is glued using a solvent containing formic acid.

- The PMMA grade requires dichloroethane.

- ABS - acetone glue is suitable.

Messages [ 1 to 25 of 28 ] 882

1 Topic by VladiZ 01/08/2017 13:02:00 (2 years 6 months ago)

- VladiZ

- Local

- Topic author

- Inactive

- From: Barnaul

- Experience: 7 years 10 months

- Messages: 5 324

- Reputation: [ 92 | 3]

Read also: How to cut ceramic tiles at home

Topic: What kind of glue is used to “tightly” glue metal to plastic?

Subject There will be frequent loading (moving here and there), the contact area is not very large. so all sorts of moments will not work. Tell me, what can I buy in a store that is more serious?

2 Reply from sanya22-96 01/08/2017 13:20:28 (2 years 6 months ago)

- sanya22-96

- Participant

- Inactive

- Experience: 4 years

- Messages: 575

- Reputation: [ 23 | 0 ]

Re: What kind of glue is used to “tightly” glue metal to plastic?

3 Reply from barbarian 01/08/2017 13:23:53 (2 years 6 months ago)

- barbarian

- Participant

- Inactive

- From: Barnaul

- Experience: 9 years 1 month

- Messages: 3 552

Re: What kind of glue is used to “tightly” glue metal to plastic?

what kind of plastic? what metal? thickness? Under what conditions will it be used? no answers - buy a “second” and don’t worry, it will fall off anyway.

4 Reply from VladiZ 01/08/2017 13:26:05 (2 years 6 months ago)

- VladiZ

- Local

- Topic author

- Inactive

- From: Barnaul

- Experience: 7 years 10 months

- Messages: 5 324

- Reputation: [ 92 | 3]

Re: What kind of glue is used to “tightly” glue metal to plastic?

barbarian , xs metal, brass most likely, because it’s yellow, which is what small nuts are made from. Room temperature conditions without heating or cooling.

5 Reply from Dim76 01/08/2017 13:32:23 (2 years 6 months ago)

- Dim76

- Participant.

- Inactive

- From: pick up goods - Yurina 202B

- Experience: 8 years 5 months

- Messages: 21 360

Re: What kind of glue is used to “tightly” glue metal to plastic?

With such data it is difficult to say. if it’s for a dildo, a second of glue will be enough, but if it’s a barbell stop, it won’t hold anything.

6 Reply from Kompozit 01/08/2017 13:35:08 (2 years 6 months ago)

- Composite

- Engineer, Ph.D.

- Inactive

- From: Krasnoarmeysky 57

- Experience: 9 years 3 months

- Messages: 4 137

- Reputation: [241 | 1 ]

Re: What kind of glue is used to “tightly” glue metal to plastic?

Cyanoacrylate glue - “Moment Second” type.

cell 8-9OЗ-957-7ЗЗ8 (Beeline) 8-91З-266-57З7 (MTC) skype kompozitenen Yegor2003 @mail.ru (without space)

Before you start something, know how to finish it.

7 Reply from gore 01/08/2017 01:36:45 PM (2 years 6 months ago)

- gore

- Participant

- Inactive

- Experience: 5 years

- Messages: 368

Re: What kind of glue is used to “tightly” glue metal to plastic?

Coat the perimeter with a thick layer of Secunda + salt + soda.

8 Reply from markovnik 01/08/2017 13:41:55 (2 years 6 months ago)

- markovnik

- Participant

- Inactive

- Experience: 9 years 2 months

- Messages: 1 262

- Reputation: [ 16 | 1 ]

Re: What kind of glue is used to “tightly” glue metal to plastic?

Cosmofen glues everything tightly, just work with it carefully, be sure to wear gloves! I don’t know about metal to plastic, but you can’t separate plastic from plastic! Yes, and I glued a lot of things to them. I repeat, work extremely carefully!

9 Reply from Yus 01/08/2017 13:49:20 (2 years 6 months ago)

- Yus

- Elder Price

- Inactive

- From: something about latitude and longitude

- Experience: 11 years 8 months

- Messages: 7 040

- Reputation: [ 141 | 0 ]

Re: What kind of glue is used to “tightly” glue metal to plastic?

Edited by Yus (01/08/2017 01:49:52 PM, 2 years 6 months ago)

10 Reply from Eddy 01/08/2017 13:55:56 (2 years 6 months ago)

- Eddy

- advertiser

- Inactive

- From: Chkalova

- Experience: 5 years 1 month

- Messages: 3 130

- Reputation: [ 65 | 0 ]

Re: What kind of glue is used to “tightly” glue metal to plastic?

Coat the perimeter with a thick layer of Secunda + salt + soda.

Cosmofen glues everything tightly, just work with it carefully, be sure to wear gloves! I don’t know about metal to plastic, but you can’t separate plastic from plastic! Yes, and I glued a lot of things to them. I repeat, work extremely carefully!

cosmofen, like this, you can buy in Acrylic: https://akril22.ru/, Zenon: https://www.zenonline.ru/brn/ + baking soda - use it to spill areas where the glue sticks out a little - acts instantly, holds like epoxy

outdoor advertising 8-9I3-363-7I37

The modern world is unthinkable without plastic products; the lightweight material is used everywhere: construction, decorations, furniture, dishes, decorative elements, household appliances. Polymer products do not rust, are beautiful, but not always durable. Therefore, breakage of plastic items occurs frequently; every time something is dropped, the problem arises of how to restore the broken product.

Don’t be upset - there are no eternal objects, and you shouldn’t throw away a broken thing. Today there are no problems in repairing any material, even polymer. You just need to think about how to glue your favorite thing together.

Stamps

Poxipol

The glue is heat-resistant, water-resistant, and quick-hardening. Withstands low temperatures, resistant to moisture, waterproof. Adheses well to many surfaces. It has a gray color, which makes it invisible on metal.

The Poxipol package contains two tubes - the main component and the hardener. Mix in a 1 to 1 ratio and immediately apply to the metal base.

After 10 minutes the layer becomes durable. After an hour, the part can be machined - drilled, cut, sawed. But, complete polymerization requires 24 hours.

Poxipol is inexpensive, but has disadvantages:

- does not connect thin bases end to end;

- Due to its thick form, it is applied only in a thick layer.

Weicon VA 110

- The glue is moisture resistant;

- operating temperature -30 - +80 °C;

- because of the cyanoacrylate it contains, it is called superglue - polymerization from 20 to 50 s;

- maximum strength after 24 hours;

- shear strength – up to 20 N per mm2 after sandblasting;

- no color, completely transparent;

- in addition to metal, glues plastic, rubber, caoutchouc and others;

- Can be used for metal utensils that come into contact with food.

The composition is expensive: for a 12-gram tube you will have to pay a little more than 1 thousand rubles, while 60 g of the product costs more than 3 thousand.

Strong steel stick renewal composite 114 g

Has high adhesion and rapid polymerization (20 minutes). The basis is epoxy resins. The structure is plastic, easy to apply. The shape is a plasticine rod. Before application, knead with hands.

After polymerization, it is resistant to stress, chemicals, salts, alkalis, acids, and solvents.

Great for patching pipes. Difficult to access on the Russian market, not so cheap. It has disadvantages similar to Poxipol.

Weicon RK-1500

Two-component adhesive composition for metal. Connects iron, steel, aluminum, and other alloys. Strongly holds thin sheets of metal end to end.

- Also suitable for plastics and ceramics.

- The glue can be called high-temperature: it can be used from -50 to +130 °C, and overheating is allowed up to 180 °C for a short time.

- Tensile strength after drying up to 26 N per square meter. mm.

- 5 minutes after treatment, the adhesive joint reaches its initial strength.

- The activator can be added to one or both sides of the main component. This depends on the thickness of the applied layer - from 0.4 mm to 0.8 mm.

- The activator must be applied carefully. Due to the too liquid consistency, it may spread.

- It even glues substrates of different structures, the adhesion between which is minimal, for example, metal with glass, other smooth substrates.

EpoximaxX

It is an improved version of the classic epoxy EAF. The hardening time (3 hours), thermal resistance (120 °C) have changed, and operation in heated conditions has become possible. EpoximaxX does not change properties when moistened. Tensile strength is 60-80 MPa.

The consistency is liquid, so application with a brush is possible. Recommended for gluing large areas overlapping rather than end-to-end. It's inexpensive.

Bison Super Glue Gel

This is superglue for minor household repairs. It is universal and adheres to different materials. The consistency is similar to a gel, which makes it easier to use and prevents spreading.

- It hardens in one to two minutes, which allows you to adjust the position of parts after fastening and reduce the risk of finger gluing, as in the case of conventional superglue.

- By spreading it on the metal, small cracks are filled with glue. pores, which increases the reliability of the coupling.

- The tube contains only 3 g of substance, enough only for small jobs.

How to glue plastic to metal?

The modern world is unthinkable without plastic products; the lightweight material is used everywhere: construction, decorations, furniture, dishes, decorative elements, household appliances. Polymer products do not rust, are beautiful, but not always durable. Therefore, breakage of plastic items occurs frequently; every time something is dropped, the problem arises of how to restore the broken product.

Universal glue

Don’t be upset - there are no eternal objects, and you shouldn’t throw away a broken thing. Today there are no problems in repairing any material, even polymer. You just need to think about how to glue your favorite thing together.

How to glue plastic tightly at home

Often we need to glue a broken or cracked plastic product - from the temple of glasses to the bumper of a car. It may also be necessary to glue a hook in the bathroom or a holder for a garden sprayer.

The essence of the gluing process is to dissolve the surface layer of two workpieces and form from this solution a layer of plastic common to both parts.

After hardening, the parts form a single whole, or, as they say, “glue tightly together.”

How to glue plastic tightly at home

Determining the type of plastic

In order to reliably glue plastic, you first need to find out what kind of plastic the object is made of. Knowing the plastic, you can choose the most suitable adhesive for it.

All manufacturers put recycling symbols on their plastic products - this is the well-known Recycling Triangle - a triangle with arrows on the sides, symbolizing the reuse of materials.

The triangle contains numbers from one to seven. Often the numbers are supplemented by an abbreviation. These designations are used to determine the type of plastic.