One of the most common methods of installing a sewer system in a private home is the construction of a concrete septic tank. At the same time, not everyone wonders about its tightness.

But in vain, because properly waterproofing sewer wells will not only extend their service life, but also protect the soil from contamination. Let's figure out why you need to waterproof sewer drains and how to do it correctly.

Content

Plastic containers are initially sealed and do not have to be protected from water, but concrete structures often leak at the joints. When designing waterproofing of sewer wells, it is necessary to take into account the characteristics of the materials from which they are made, the level of occurrence of aquifers, and the type of soil. Depending on this, suitable waterproofing agents are selected.

Concrete sewer well

When is waterproofing of sewer wells needed ↑

There are several reasons why a sewer well leaks in different areas:

- Bottom. Leaks in the bottom part occur if the waterproofing materials were initially incorrectly selected or worn out over time. If a leak occurs in the bottom, then water can flow in both directions: drains flow out, and surface water can flow in. The bottom of the septic tank must be well insulated at the stage of installation of the structure.

- Pipe entry points. This zone also needs high-quality protection during construction. To enter pipes, holes are made larger than the diameter of the products themselves. The remaining gaps are sealed with cement-sand mortar. The ideal option is if the owner of the treatment plant immediately buys cement with hydrophobic additives. If not, then you will have to take care of insulation with special materials.

- Joints and seams. It is especially important to properly waterproof concrete structures at joints and seams. Even high-quality installation does not guarantee that the septic tank will not leak. There are special materials that can reliably protect seams from moisture. They expand from water and tightly close the gaps.

- Cracks in the walls. Even very durable materials deteriorate over time, especially if structures are located underground. The reasons for the wear and tear of the walls of septic tanks are time, soil movement, and exposure to aggressive substances. Cracks and leaks occur. If this happens, then it is worth using polymer-based repair materials. If everything is done correctly, the cracks will be closed for many years. Surfaces can be treated with penetrating compounds.

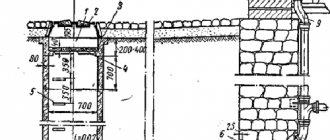

Scheme of the design of a concrete well for sewerage

Polymer membranes

Insulation of a well made of concrete rings can be done using composite materials, which are easy to install and highly effective. The films completely prevent the penetration of moisture into the structure, protect the seams well, but without additional protective layers they are not used for processing joints and joints (usually used with polymer-based mastics).

Types of polymer membranes:

- Profiled - durable polyethylene made of several layers with many stiffeners. The material is used where there is a rise in the groundwater level to the structure.

- Film – reliable reinforced polymer film about 2 millimeters thick. Suitable for protecting structures when the groundwater level is lower.

Underground structures are protected with membranes at least 0.4 millimeters thick. They are resistant to moisture, very durable, environmentally friendly, can be combined with bitumen-based materials, and last up to 40 years. The disadvantages of this method include the high cost of the material and the need to attract craftsmen with the appropriate qualifications to perform the work.

Two main types of moisture protection - internal and external ↑

In order to invest as little effort and money as possible, but still get a sealed structure, you should focus on building codes and regulations, technical conditions. Waterproofing of sewer wells is regulated by SNiP 2.04.03-85 “Sewerage. External networks and structures.” Review this document when designing your system.

There are only two types of waterproofing of sewer wells - from the inside and from the outside. In order for the sewer system to be airtight, this should be taken care of when purchasing materials. If you plan to build a concrete structure, you need to order high-quality rings. Saving on them will lead to problems during operation.

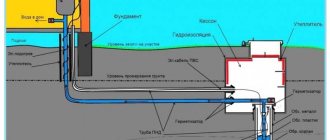

Waterproofing scheme with “Penetron” and “Penecrite”

Moisture-resistant concrete rings ↑

When purchasing concrete rings, carefully read the technical and operational characteristics of the material. Don't hesitate to ask questions to sales consultants. You need to find concrete with special additives that ensure minimal moisture absorption. This halves the likelihood of wastewater seeping into the ground.

Important! In regions with harsh climates, increased demands are placed on sewerage installations. Conventional rings made of moisture-resistant concrete cannot always be used, so when choosing materials it is worth consulting with a specialist.

Rings made of moisture-resistant concrete

How to do external waterproofing ↑

For external waterproofing, clay castle technology is used. They are structures made of tightly compacted layers of clay. The depth of such a lock depends on the level of the perched water.

If rings made of water-repellent concrete were chosen during construction, then interlocking external waterproofing will be sufficient. For more reliable protection, you can use rolled materials.

Often they choose the good old roofing felt. This is the cheapest way to achieve sealing of sewer wells. If funds allow, it is better to purchase more modern roll materials. They are reliable and last much longer.

Preparation for waterproofing work

How can you protect a well from the inside ↑

Internal waterproofing is carried out using plaster and painting materials. An excellent option is the use of penetrating compounds. They can be used both outside and inside the structure. Domestic compositions of the Penetron system have proven themselves well.

When choosing materials, there is only one requirement - reliable protection from moisture for a long time. Since we are not talking about a drinking well, environmental safety is a secondary issue, but it is also worth paying attention to, because when there is a leak, water seeps into the ground.

Scheme of application of waterproofing materials

External waterproofing

Reliable external waterproofing of the well prevents the negative influence of groundwater on the walls of the structure. It is more convenient to carry out such work during the construction of the well.

If an existing water source is being repaired, then soil is dug out around it to a depth of 3-4 m. Next, the following work is performed:

- loose concrete is removed;

- the surface of the walls is cleaned of all unnecessary things (dirt, salt deposits, mold, moss, etc.);

- Rust is removed from the exposed reinforcement, and the metal is coated with an anti-corrosion agent.

External waterproofing of a well can be done using the following materials:

- rolls (roofing felt) are applied to special mastics;

- cement mortar, which is used to repair damage and construct a blind area;

- penetrating compounds;

- waterproof expanding (or non-shrinking) cement used for shotcreting.

When performing sealing with roll materials, the following actions are performed:

- to ensure the necessary adhesion, a primer is applied; 3 layers of a bitumen-gasoline mixture can be applied (a cement gun or sprayer is used for this);

- after drying, the walls are repaired (damages are repaired), cement mortar can be used for this, but it is better to mix it with PVA;

- patches dry out;

- the surface is primed again;

- the walls are covered with a coating material (tar or bitumen mastic), 3-4 layers of waterproofing are applied on top;

- the seams are coated with mastic.

If impregnation is used, a number of operations are performed:

- the moistened surface of the walls is lubricated with a mixture of deep penetration;

- later the impregnation is applied a second time;

- After 72 hours, the layer dries; to prevent the surface from cracking, it should be moistened.

Sealing of sewer wells is carried out in the same way.

When shotcreting the walls of a well, the following sequence of actions is performed:

- a layer of cement (thickness 5-7 mm) is applied using a gun;

- after 10-12 days the solution will set;

- the coating must be moistened in order for it to crack;

- the 2nd layer is applied.

External waterproofing of the well is carried out to the very top. The space around the container is filled with sand mixed with gravel and compacted. A cement blind area is made on top. It is recommended to install a clay “castle” around the structure to drain away precipitation.

When arranging a container around the rings, you should leave a trench (about 50 cm wide), which must later be filled with clay. It is necessary to form a slope above the ground so that precipitation flows away from the structure. The upper rings retain high-passing groundwater. The above-ground layer protects the container from precipitation.

Preparation before starting waterproofing work ↑

If work is being done to waterproof an existing sewer well made of concrete rings, then the liquid should be pumped out of the reservoir and wait until the surfaces are completely dry. After this, the concrete is thoroughly cleaned of exfoliated pieces, removed from dust using primers, and dirt and deposits are removed.

If during work pieces of reinforcement become visible, they are also cleaned and coated with anti-corrosion compounds. Joints, seams, cracks that appear during the operation of the structure are expanded and deepened. This is necessary for treatment with sealing compounds. The larger the area, the better the materials adhere. The optimal crack depth is 25 mm.

As primers, you can use compositions offered by hardware stores, or you can make your own primer. To do this, mix gasoline and bitumen in proportions of 3:1, stir until a homogeneous composition is obtained. Surfaces are primed in two layers using a wide brush or roller. The second layer is applied after the first has dried. The seams are isolated with penetrating cementitious compounds.

Homemade primer made from bitumen and gasoline

Sealing joints between concrete rings

No matter how the septic tank is waterproofed from concrete rings, it will not be able to ensure complete tightness without mandatory treatment of the joints between the rings. Even at the stage of installation work, a waterproofing and shock-absorbing gasket should be laid between the rings.

It is best to use a bentonite-rubber gasket. The bentonite clay granules present in its composition can increase their volume by 3-4 times upon contact with water. This reaction of the clay makes it possible to maximally fill the cracks and voids present between the concrete rings of the sewer well.

The concrete-rubber gasket increases in size up to 400% under the influence of moisture, filling all the voids and ensuring maximum sealing of the inter-ring seam

The concrete-rubber gasket has a high level of ductility. This quality allows you to maintain the tightness of the septic tank even if the concrete rings are slightly displaced. Seams should be sealed not only between the rings, but also when installing the first ring on a concrete base.

You can do it easier and instead of an expensive concrete-rubber gasket, use ordinary hemp, jute or linen ropes. The ropes themselves will not ensure the tightness of the seam, so they must be impregnated with fiber rubber. The ropes should be laid on a polymer-cement mixture, which can be replaced with a mixture of cement and PVA glue.

How to waterproof a sewer well from the outside yourself ↑

The simplest and cheapest methods of waterproofing sewer wells are a clay castle, insulation with roll materials, penetrating compounds. You can use combined options: clay castle and penetrating materials, clay castle and roofing felt.

By using two insulation options, the owner will receive a completely sealed sewer well that will last for many years without the slightest leak. Let's consider the most popular method of do-it-yourself moisture protection.

Clay castle

Combined moisture protection: roofing material + clay ↑

- The walls of the structure are excavated to their full depth.

- The concrete surface is cleaned. If necessary, use a jackhammer to remove loose pieces.

- The concrete is washed, salt deposits are removed using spatulas, metal brushes and other suitable tools, and primed.

- After the concrete has dried, it is leveled by sealing the cracks with cement-sand mortar. PVA glue can be added to the mixture to improve the characteristics of the material.

- The walls of the structure are coated with mastic - bitumen or bitumen-polymer. It is better to choose the second option, because... bitumen mastic is considered less reliable.

- Roofing material is overlapped onto the mastic, carefully covering the seams. The insulation is applied in 3-4 layers. When the materials are dry, you can fill the structure and build a clay castle.

- You will need clay with a percentage of sand of 5-15%. It is prepared in advance so that it can rest and freeze for at least one winter. The solution is prepared by adding lime (20% of the clay volume) and a little water to obtain a plastic mass after mixing.

- The clay is placed in layers dug around the well, each layer is carefully compacted, and a clay blind area is constructed so that atmospheric waters do not flow under the castle.

- It is possible to backfill the lower part of the pit with a sand-gravel mixture. Then layers of clay are laid on top of bulk materials.

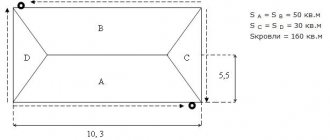

Diagram: correct construction of a clay castle

Waterproofing a sewer well from the inside

First, the surface is prepared: weak spots and dirt deposits are removed, and a primer is applied. Crevices and potholes should be filled with cement mixture to create a smooth surface. When the cement has set, waterproof the sewer well with Penetron with your own hands. To do this, the base is wetted and a penetrating mixture is applied with a brush in several layers.

Mastic Slavyanka is a bitumen-polymer composition with a pasty consistency of black color. After drying, the waterproofing creates a thin layer of rubber-like membrane on the surface.

Sealing the bottom of the well

To properly insulate the bottom, before installing the first ring of the well, you should lay a waterproofing cord around the perimeter of the bottom to seal the joint between the bottom and the first ring. The surface of the concrete bottom itself must be cleaned of dust, covered with Slavyanka bitumen mastic and roofing felt pasted. If you follow the technology, you can waterproof the cesspool yourself.

We make internal waterproofing with our own hands ↑

To waterproof sewer wells in wet soils, plastic is used: a pipe made of polyethylene or an old unnecessary barrel is put on a concrete or metal tank. Sometimes a container is placed inside a concrete septic tank and a sewer pipe is led into it.

This method of moisture protection is quite effective, because... polymer products are absolutely sealed and are not afraid of the effects of aggressive environments. However, it is much safer to immediately install a plastic container as a septic tank. In areas where groundwater is high, it is better to do this.

The most popular waterproofing materials for concrete treatment facilities are penetrating, polymer-cement and bitumen compounds. They protect structures well from water and are easy to apply. Let's look at how to make internal waterproofing of sewer wells using these materials.

Materials of the Penetron system

Method #1: penetrating compounds ↑

Penetrating materials are universal. Concrete impregnated with such compounds becomes stronger and more durable, because its structure changes. The materials bond at the molecular level: the waterproofing agent penetrates the concrete and crystallizes under the influence of water, clogging pores and microcracks. The surface acquires hydrophobic properties.

The Penetron system materials are excellent for waterproofing concrete sewer wells. These are several compositions intended for impregnation of surfaces, sealing seams and joints, cracks. The method of using each material is described in detail by the manufacturer on the packaging. Waterproofing does not require complex equipment or expensive tools; brushes, rollers, and trowels are sufficient.

Scheme: scope of application of “Penetron” and “Penecritus”

Work order:

- After preparing the surfaces, the seams and joints are treated. Ideally, this should be done at the stage of installation of concrete rings, installing seals.

- Penetrating materials are applied to the concrete surface with a brush or roller in two layers. If the mixture is dry, it is prepared in accordance with the manufacturer's recommendations.

- Time for complete drying is 3 days. During this period, the coating should be moistened regularly.

Waterproofing joints with Penecrit

Method #2: bituminous materials ↑

The inner surface of concrete tanks is often coated with hot bitumen. After drying, it forms a dense water-repellent layer on the surface. However, the finished coating is not elastic enough, so it cracks after a few years. Leaks may occur.

A more practical option is to use bitumen mastic, which initially contains additives to improve the performance characteristics of the compositions. Mastics adhere well to substrates, withstand frost better, and last longer. An additional plus is that they do not require heating, which simplifies the work.

Bitumen preparation

Method of applying bitumen mastic:

- Surfaces are cleaned, prepared, seams and cracks are sealed.

- The concrete is treated with a primer and left to dry for 24 hours.

- The mastic is applied using a convenient brush or trowel. If the composition is too thick, it is diluted with gasoline or solvent.

- For high-quality waterproofing, 2-3 layers will be required. The drying time for each layer is one day.

Bitumen mastic for waterproofing

Method #3: polymer cement insulation ↑

Cement and polymer-cement materials are a worthy alternative to bitumen. They do not emit harmful substances, resist aggressive chemicals well, and have a long service life.

Protective coatings made using such materials last as long as the building structure itself. The compositions are suitable for waterproofing sewer wells in wet soils.

Cement insulation

Method of applying cement and polymer-cement materials:

- The surface is prepared: cleaned, dusted, slightly moistened.

- The material is applied in two layers, without gaps. The second layer is applied when the previous one is just beginning to set, and in the opposite direction to it.

- The total thickness of the coating should be 20-25 mm.

- Where pipes enter, the material is protected with reinforcing mesh.

- The complete drying time for each specific product is indicated on the packaging.

Waterproofing concrete

What are reinforced concrete rings

A reinforced concrete well is an element of the sewer system. Regardless of whether a septic tank or a cesspool is being installed, the joints of the rings should be well sealed, otherwise dirty wastewater will enter the soil and change its quality.

Important! Reinforced concrete rings are the most inexpensive solution when organizing a sewer system. But even with good waterproofing, they cannot be used if the GWL (groundwater level) is too high. This design is potentially dangerous for the soil, and seal failure occurs frequently.

Among the advantages of using rings:

- Due to the increased strength of the walls, they are able to withstand various influences of the soil, including its heaving.

- It is possible to build such a well quickly.

- The price of the arrangement is affordable, especially when compared with an alternative option such as brick.

- Any waterproofing can be used.

- The inner surface is smooth, which makes it possible to clean the well from wastewater during pumping without much difficulty.

- Concrete is resistant to aggressive substances and environments.

- Reinforced concrete sewer wells can be used for a long time without major repairs; their service life reaches 50 years.

- A variety of ring sizes allows you to equip a pit of any size and depth.

- Maintainability – rings can be sealed with cement if cracks appear.

They are not without their drawbacks, including the weight of the rings. If they have a large diameter, then it is impossible to move them from place to place, much less immerse them in a pit, without the use of special equipment. They also have to be transported using special equipment. Another drawback is a low-quality product that does not comply with GOST. If you buy this, you simply won’t be able to feel any benefits.

Video: waterproofing sewer wells ↑

It is necessary to take care of high-quality sealing of sewer pipes in the well. For this purpose, self-adhesive anti-corrosion tapes and films are used. They reliably protect metal and plastic pipelines from freezing and the negative effects of other environmental factors.

If the materials for sewer waterproofing are chosen correctly, their service life can be counted in decades, so it makes sense to choose the best of what the market offers. In the end, the total cost of waterproofing does not exceed 2-5% of the cost of constructing the system as a whole. Saving is not rational.

If you have doubts about materials or technologies, there is no need to experiment. This will require specialist advice.