General information about the Ergobox septic tank

The manufacturer of the Ergobox septic tank is. The septic tank can be available in modifications of different capacities and for different numbers of residents.

Advantages

The product made in this way is highly resistant to chemicals and impact resistance. Also, the product does not have seams, scratches or any damage inherent in products made by other methods.

All models of Ergobox stations have an average electricity consumption of one and a half kilowatts per day. The length and height of the body are from two to two point two meters, and the width is 0.785-1.2 m. There are no specific standards; the dimensions of this design are selected by the manufacturer independently.

Modifications

The Ergobox septic tank model range is presented with the following capacities - 1000, 1300, 1600 and 1900 l/day.

All powers are available in 2 modifications:

- gravity septic tank with the designation S, used for normal soils;

- forced release - PR, suitable for areas with high levels of groundwater flow.

The Ergobox 4S septic tank is presented in the smallest dimensions, designed to process wastewater up to a thousand liters per day for a family of four members. The most powerful stations are Ergobox 10S and 10 PR, up to one thousand nine hundred liters per day and ten residents.

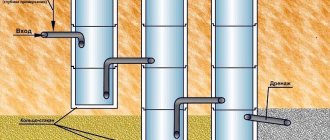

Drainage schemes

Ergobox septic tanks are produced in two modifications:

“Ergobox” S is a gravity-flow unit that provides natural gravity for wastewater throughout the full cycle: from inlet to liquid discharge. The models are non-volatile and do not require connection to the electrical network.

"Ergobox" PR - septic tanks with forced pumping. The internal part of the structure facilitates the gravity flow of wastewater through overflows and collection in a post-treatment chamber for further pumping.

The PR septic tank is powered from a 220 V power supply with a frequency of 50 Hz using a 3-wire circuit with grounding. The manufacturer has provided for the mandatory passage of the power cable through the RCD. A prerequisite is the use of a plug socket (16 A/30 mA), protection of the electrical wire with metal pipes or PVC corrugation. In a septic tank, the cable is protected by a pipe. After connection, the free space is filled with silicone sealant.

Electrical installation work should be entrusted to a qualified specialist in compliance with the requirements of PUE, PTEEP. Water must not penetrate into the housing containing the electronic unit. If an emergency occurs, you should immediately disconnect the device from the network, preventing the risk of electric shock, eliminate the water, dry the case, and check the operation of the electrical equipment.

General characteristics

According to reviews from owners who installed the Ergobox septic tank, it is unpretentious in operation and highly productive. This modern device for deep aerobic cleansing is suitable for both a country house and a large cottage. There are no difficulties during installation, and the total weight of the structure is no more than one hundred and fifty kilograms. Installation can be done even by one person.

The manufacturer offers video instructions on installing a cleaning station, as well as a detailed description of all the advantages of the unit.

Another important parameter of the Ergobox septic tank is peak discharge. These local purification systems can have from one hundred eighty to five hundred and fifty liters per hour. The value of this parameter corresponds to the volume of wastewater that the septic tank is capable of processing at a time.

Please note: The value of this parameter will be higher the longer the period of residence in the house. Before you purchase an appropriate septic tank, you will need to accurately calculate your water consumption.

Advantages of the Ergobox cleaning station

- Models available for any type of soil,

- Does not harm the environment,

- Wastewater purification up to ninety-eight percent,

- Long service life up to fifty years,

- Affordable price,

- Energy-dependent operating mode. This mode is convenient if the number of residents decreases,

- The body is ergonomic and the design is thought out to the smallest detail,

- Immediately after installation it is ready for use. Can be installed even in areas with high groundwater levels, the structure does not move in the ground,

- Uniform distribution of wastewater over the inner surface of the tank,

- Easy installation. No need to dig a huge pit or use machinery,

- The station is very easy to use. To clean the device from sludge, use a suction pump, placing it inside,

- Since the design is seamless, there are no leaks or blockages,

- Does not require additional irrigation field.

Flaws

The Ergobox septic tank has a disadvantage, which is the necessary careful adherence to all technologies when filling up the local treatment system.

If an error is made at this level, the housing may be damaged. Plastic walls may become deformed or crack if installed incorrectly. Also, the processes of filtration and wastewater purification are somewhat slower due to the multi-chamber design.

Maintenance Ergobox is quite easy to maintain. To clean this device, it will be enough just to use a suction pump or the services of a sewage disposal machine once every few years. But if this is not done in a timely manner, then work efficiency may be impaired.

Selecting a biological treatment station

The main criterion when choosing a septic tank of appropriate capacity is the number of permanent residents. To make selection easier, the manufacturer has created a table that shows models of each power and recommendations for the number of residents.

Principle of operation

Essentially, Ergobox is a local anaerobic treatment station, although it is often called a septic tank. A distinctive feature of the station from a septic tank is its energy dependence, as well as the highest quality water purification and the absence of the need for frequent pumping. The septic tank is made in the form of an elongated tank with a neck. The polyethylene body is sealed without seams and is also equipped with stiffening ribs. It is very durable and not subject to deformation.

Consists of five chambers

- Receiving container with the function of filtering large sediments;

- Sludge reservoir;

- Clean water settling tank;

- A control unit with a compressor located at the neck.

In another tank, microorganisms come into contact with wastewater. The aeration tank is the site of the main process of processing organic substances by microorganisms. In the third chamber, activated sludge settles to the bottom, which is then sent back to the first container by the action of a circulation pump.

The principle of operation of a septic tank is as follows: Wastewater enters the first tank. Here biological purification occurs under the influence of bacteria that are in the sludge. Then the wastewater, passing through filtration, passes into a second container called an aeration tank.

In this chamber, the waste liquid is saturated with air, which the bacteria need to carry out their activities, i.e. aeration occurs. The third reservoir is where the sediment is separated by gravity. Wastewater is divided into liquid and sediment in the form of active sludge deposits.

Then the light water goes into the 4th tank, and under the influence of a special sediment, activated sludge is pumped into the first tank. In the fourth chamber, the liquid finally settles. 5 the container is placed at the top in the neck. It is storage, from where purified water is pumped out.

Selection principle

The main criterion for choosing power is the number of permanent residents.

The manufacturer made sure that when purchasing the installation the consumer did not bother himself with complex calculations. The table for each model shows the recommended number of family members, taking into account plumbing.

| Model | Number of people | Number of san. nodes | Number of shells | Bathroom | Washing machine |

| Ergobox 4 | 4 | 1 | 2 | 1 | 1 |

| Ergobox 6 | 6 | 3 | 2 | 1 | 1 |

| Ergobox 8 | 8 | 3 | 4 | 1 | 1 |

| Ergobox 10 | 10 | 4 | 5 | 1 | 1 |

It is recommended to install the Ergobox 4 septic tank in dachas or small houses, since its capacity is not designed for a large amount of wastewater.

Most often, for private households, a septic tank Ergobox 8 or Ergobox 6 is purchased. They are designed for a number of people from 6 to 8. If you make a choice between these two models, then it is better to give preference to the Ergobox 8 septic tank, since it can easily cope with the additional load in case of arrival of guests.

Appearance of the Ergobox septic tank

Installation of Ergobox septic tank device

It is quite possible to do it yourself. The finished factory design is simply installed in a prepared place and the pipes are connected.

You just need to follow these simple instructions:

- First you need to inspect everything, make sure there are no faults.

- A pit is being dug. You need to leave a distance of about 25 cm from the outer wall of the device. The depth of the pit is about two and a half meters.

- The bottom needs to be leveled. The permissible horizontal deviation should be no more than one centimeter.

- Dig a trench under the pipeline. The supply trench must be at a slope of at least two centimeters for gravity drainage.

- A layer of sand from twenty to thirty centimeters is poured onto the bottom of the trench.

- Immerse the device directly into the pit.

- Next, backfill is carried out using a mixture of cement and sand in a ratio of one to five. Falling asleep must be done in stages with compaction every twenty centimeters.

- Simultaneously with the backfilling process, it is necessary to gradually fill the tanks with water; the water level should be higher than the backfill. All containers must be filled at once in order to create equal pressure on the walls of the tank from the outside and from the inside. If there is a need for insulation on top of the local station, you can use polystyrene foam, and they will finally bury it, leaving one hatch.

For your information: The manufacturer offers these or “Chief installation” - installation of a septic tank with your own hands under the supervision of a specialist.

Ergobox installation

There should not be any particular difficulties with self-installation of a septic tank of the brand in question. This is not a DIY strip or column foundation. With the Ergobox station everything is much simpler. The factory-ready structure just needs to be put in place and the pipes connected to it.

First, a pit is dug to a depth of 2.5 m. Two meters is the height of the station with a neck. Plus 50 cm on the compacted sand cushion below. On the sides, the pit should exceed the dimensions of the body by 25 cm.

The bottom of the pit is leveled and a treatment facility is installed there. A sewer pipe from the house is connected to it and a pipe is brought out for the treated wastewater.

Backfilling is carried out layer by layer with a cement-sand mixture (1:5) of 20–30 cm, compacting the layers and gradually pouring clean water into the station chambers. If necessary, the VOC is insulated from above with foam plastic and finally buried so that only the hatch remains above the ground.

Description and principle of operation of a septic tank

Externally, the Ergobox septic tank is made in the form of an elongated container with a neck on top. The station's seamless sealed body is made of polyethylene and has stiffening ribs. It has high strength, which eliminates deformation even with severe heaving and high groundwater level.

Ergobox view

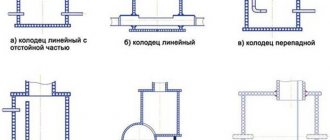

Inside, the Ergobox septic tank is divided into five sections:

- Receiving chamber with a filter for large fractions.

- Aerotank with forced aeration.

- Sludge gravitational settling chamber.

- Block calmer for settling purified water.

- A control unit with a compressor located in the neck.

Scheme and principle of operation of the Ergobox station

The contact of aerobic bacteria with sewage water occurs in the Ergobox septic tank in the first chamber. The main process of them eating organic matter takes place in the aeration tank. And the third chamber serves to deposit activated sludge to the bottom, from where it is sent back to the first section by a circulation pump.

Use and maintenance of the Ergobox septic tank

At least once a year it is necessary to call a vacuum cleaner and remove accumulated sludge from the station. It is recommended to remove and wash the compressor air filter. Once every 3-4 months, disconnect and clean the hair trap.

The station is mothballed for the winter. To do this, the compressor and pump are disconnected from the power supply, the contents are pumped out from the first and third chambers, the receiving chamber, airlift and aerator are washed. After this, the station is filled 2/3 with water. In the technical data sheet, the manufacturer also recommends insulating the lid of the unit so that the water in the container does not freeze.

Isobox product range

Due to the technical characteristics of mineral wool, Isobox is widely used in the construction of civil and industrial facilities, and is also used in the manufacture of equipment and mechanical engineering. Due to the wide scope of use, for convenience and for full technical compliance, Isobox mineral wool is produced in an assortment in the form of rolls, slabs and mats. The Isobox model range consists of the following modifications:

- General construction lines Isobox LIGHT and Isobox EXTRALIGHT Mineral wool of this type is used for insulation of apartments, country houses, country houses and outbuildings. Thermal conductivity of the type modification is 0.039-0.042 W/(m K)λ25, density 30-38 kg/m3. and vapor permeability within 0.3 mg/(m·h·Pa) provide the opportunity for mineral wool of this level to be used in insulation of construction sites throughout the Russian Federation. The material belongs to the fire safety class NG. At the construction site, thermal insulation products are delivered in vacuum packages; during packaging, the mineral wool is straightened, taking on natural dimensions and a certain thickness (5-10cm).

- Facade line Isobox INSIDE, Isobox FACADE and Isobox VENT For heat and sound insulation of ventilated facades, Isobox INSIDE, FACADE and VENT are suitable for all technical parameters of construction projects. Cotton wool has a high density (45-80-150 kg/m3) and low thermal conductivity (0.036-0.045 λ25 W/(m K)) providing an excellent barrier to cold from the outside and creating a comfortable microclimate indoors. The lightness of the material does not burden the load-bearing structures, and the dimensional parameters of 100x50cm and 120x60cm make the installation process quick and convenient. Cotton wool from fibers of basalt mountain stones is cut with a knife, taking on any shape.

- Roofing line Isobox RUF, Isobox RUF Hi B These products are widely used in industrial and civil construction in the installation of flat roofs. High density of 100-150 kg/m3. makes the material invulnerable to moisture and external sound background. Endurance to temporary or constant vertical loads and resistance to sudden temperature changes and fire safety class NG are ideal characteristics for roofing heat and sound insulation, suitable for any region of the Russian Federation.

Installation of Ergobox septic tank device

It is quite possible to do it yourself. The finished factory design is simply installed in a prepared place and the pipes are connected.

You just need to follow these simple instructions:

- First you need to inspect everything, make sure there are no faults.

- A pit is being dug. You need to leave a distance of about 25 cm from the outer wall of the device. The depth of the pit is about two and a half meters.

- The bottom needs to be leveled. The permissible horizontal deviation should be no more than one centimeter.

- Dig a trench under the pipeline. The supply trench must be at a slope of at least two centimeters for gravity drainage.

- A layer of sand from twenty to thirty centimeters is poured onto the bottom of the trench.

- Immerse the device directly into the pit.

- Next, backfill is carried out using a mixture of cement and sand in a ratio of one to five. Falling asleep must be done in stages with compaction every twenty centimeters.

- Simultaneously with the backfilling process, it is necessary to gradually fill the tanks with water; the water level should be higher than the backfill. All containers must be filled at once in order to create equal pressure on the walls of the tank from the outside and from the inside. If there is a need for insulation on top of the local station, you can use polystyrene foam, and they will finally bury it, leaving one hatch.

For your information: The manufacturer offers these or “Installation Supervisor” – installation of a septic tank with your own hands under the supervision of a specialist.

Modifications of Ergobox stations

The line of septic tanks with aerobes "ERGOBOX" according to performance is divided into five main models:

- “ERGOBOX 3” – up to three people, 500 l/day.

- “ERGOBOX 4” – up to four people, 800 l/day.

- “ERGOBOX 6” – up to six people, 1300 l/day.

- “ERGOBOX 8” – up to eight people, 1600 l/day.

- “ERGOBOX 10” – up to ten people, 1900 l/day.

Model range of Ergobox stations

All these septic tanks consume about 1.5 kW/day of electricity. Their body dimensions in height and length are in the region of 2–2.2 meters. And the width, depending on the model, ranges from 0.785 to 1.2 m.

There is no standard here, such as for the sizes of aerated concrete blocks or bricks. The manufacturer selects the overall parameters of the treatment structure based on its own preferences. Moreover, depending on the air temperature, these values for the polymer case may deviate within 3%.

Each of these modifications is further divided into two varieties:

- “S” – version with gravity flow for ordinary soils;

- “PR” is a subspecies with forced release of treated wastewater, used for high groundwater.

In the first case, the VOC has a pair of identical pipes - one each at the inlet and outlet with a diameter of 110 mm. In the second variation, the outlet pipe has a cross-section of 32 mm, and the septic tank kit includes a coupling for connecting the water drainage hose.

Models of Ergobox treatment stations

| Station | Human | LxWxH | Energy | Produces. | Price from* |

| Ergobox 3 | 1-3 | 1555x785x2000 mm | 1.5 kW/day | 500 l/day | 55000 rub. |

| Ergobox 4 | 4 | 2000x800x2000 mm | 1.5 kW/day | 800 l/day | 59000 rub. |

| Ergobox 6 | 6 | 2000x1000x2100 mm | 1.5 kW/day | 1300 l/day | RUB 69,000 |

| Ergobox 8 | 8 | 2050x1050x2110 mm | 1.5 kW/day | 1600 l/day | RUR 82,400 |

| Ergobox 10 | 10 | 2190x1200x2070 mm | 1.5 kW/day | 1900 l/day | 99900 rub. |

*Prices are indicative for 2021 excluding installation

Another important parameter of the Ergobox deep cleaning station is peak discharge. Depending on the size and performance of the modification for the VOCs under consideration, it ranges from 180 to 550 liters/hour. This septic tank parameter characterizes the volume of wastewater that the treatment plant can without any problems simultaneously accept and process.

The more people live in the cottage, the higher this value must be selected. But at the same time, if the water supply of a private house is designed for a large number of plumbing fixtures, even with one resident, the sewerage system will produce a lot of waste

Therefore, before choosing a septic tank, it is so important to correctly and accurately calculate water consumption. Otherwise, VOCs may not cope with wastewater treatment

Special offers

drainage pump station from us ! 2. We provide all our clients with a discount of 5,000 rubles on any additional service, including installation of: water supply, drainage, heating, cellar. 3. Free delivery within the Moscow region within the Moscow Bank. 4. Discounts for pensioners on installation work - 10% . 5. Installment plan without overpayments - 0%. 6. Possibility of payment by cards . 7. We work under special conditions with the Halva .

General characteristics

According to reviews from owners who installed the Ergobox septic tank, it is unpretentious in operation and highly productive. This modern device for deep aerobic cleansing is suitable for both a country house and a large cottage. There are no difficulties during installation, and the total weight of the structure is no more than one hundred and fifty kilograms. Installation can be done even by one person.

The manufacturer offers video instructions on installing a cleaning station, as well as a detailed description of all the advantages of the unit.

Another important parameter of the Ergobox septic tank is peak discharge. These local purification systems can have from one hundred eighty to five hundred and fifty liters per hour. The value of this parameter corresponds to the volume of wastewater that the septic tank is capable of processing at a time.

Please note: The value of this parameter will be higher the longer the period of residence in the house. Before you purchase an appropriate septic tank, you will need to accurately calculate your water consumption.

Advantages of the Ergobox cleaning station

- There are models for any type of soil;

- Does not harm the environment;

- Wastewater treatment up to ninety-eight percent;

- Long service life up to fifty years;

- Affordable price;

- Energy-dependent operating mode. This mode is convenient if the number of residents decreases;

- The body is ergonomic and the design is thought out to the smallest detail;

- Immediately after installation it is ready for use. It can be installed even in areas with high groundwater levels; the structure does not move in the ground;

- Uniform distribution of wastewater over the inner surface of the tank;

- Easy installation. There is no need to dig a huge pit or use machinery;

- The station is very easy to use. To clean the device from sludge, use a suction pump by placing it inside;

- Since the design is seamless, there are no leaks or blockages;

- Does not require additional irrigation field.

Flaws

The Ergobox septic tank has a disadvantage, which is the necessary careful adherence to all technologies when filling up the local treatment system.

If an error is made at this level, the housing may be damaged. Plastic walls may become deformed or crack if installed incorrectly. Also, the processes of filtration and wastewater purification are somewhat slower due to the multi-chamber design.

Maintenance Ergobox is quite easy to maintain. To clean this device, it will be enough just to use a suction pump or the services of a sewage disposal machine once every few years. But if this is not done in a timely manner, then work efficiency may be impaired.

General information about the Ergobox septic tank

The manufacturer of the Ergobox septic tank is. The septic tank can be available in modifications of different capacities and for different numbers of residents.

Advantages

The product made in this way is highly resistant to chemicals and impact resistance. Also, the product does not have seams, scratches or any damage inherent in products made by other methods.

All models of Ergobox stations have an average electricity consumption of one and a half kilowatts per day. The length and height of the body are from two to two point two meters, and the width is 0.785-1.2 m. There are no specific standards; the dimensions of this design are selected by the manufacturer independently.

Modifications

The Ergobox septic tank model range is presented with the following capacities: 1000, 1300, 1600 and 1900 l/day.

All powers are available in 2 modifications:

- gravity septic tank with the designation S, used for normal soils,

- forced release - PR, suitable for areas with high levels of groundwater flow.

The Ergobox 4S septic tank is presented in the smallest dimensions, designed to process wastewater up to a thousand liters per day for a family of four members. The most powerful stations are Ergobox 10S and 10 PR, up to one thousand nine hundred liters per day and ten residents.

Turnkey installation of Ergobox septic tank

| Name | Installation in loam | Installation in clay | Installation in quicksand |

| Installation of ERGOBOX 3 | 24 000 | 25 000 | 26 000 |

| Installation of ERGOBOX 4 | 26 000 | 27 000 | 28 000 |

| Installation of ERGOBOX 6 | 28 000 | 29 000 | 30 000 |

| Installation of ERGOBOX 8 | 33 000 | 34 000 | 35 000 |

| Installation of ERGOBOX 10 | 42 000 | 43 000 | 45 000 |

The standard installation of an Ergobox septic tank includes: insulation, cement, 110 mm pipes, angle, tee, fitting, 4 meters of pipes.

Pros and cons of Ergobox stations

There is no need to preserve this septic tank for the winter. The incoming sewer water will prevent it from freezing. The bottom of the VOC is always below the freezing level of the soil; the wastewater inside can turn into ice only as a last resort. If the installation is carried out according to the rules, then it is more likely that the facade panels for the exterior of the house nearby will be covered with frost than this cleaning station will freeze.

Ergobox has only one drawback - the need to carefully follow the technology for filling VOCs in the pit. If you make a mistake here, it won’t take long to damage the plastic case. Metal tiles or bricks have high strength. And the plastic walls of the station may well bend and crack if installed incorrectly.

After 9 months

Ergobox or Topas. Main differences from analogues

- Japanese compressors and German pumps in stations

- Complete energy independence of the gravity-type station. The ergobox continues to operate for 2 days after a power outage, and then switches to septic tank operating mode.

- The station body is made using rotational molding technology, due to which the station body has 100% tightness and increased strength. Stiffening ribs and a high neck make it suitable for any type of soil, especially in areas with groundwater.

- Ergobox is an autonomous sewer system that does not require frequent calls to a sewer truck

- Gravity movement of wastewater inside the station and the absence of narrow overflow pipes that are prone to blockages.

Selecting a biological treatment station

The main criterion when choosing a septic tank of appropriate capacity is the number of permanent residents. To make selection easier, the manufacturer has created a table that shows models of each power and recommendations for the number of residents.

Principle of operation

Essentially, Ergobox is a local anaerobic treatment station, although it is often called a septic tank. A distinctive feature of the station from a septic tank is its energy dependence, as well as the highest quality water purification and the absence of the need for frequent pumping. The septic tank is made in the form of an elongated tank with a neck. The polyethylene body is sealed without seams and is also equipped with stiffening ribs. It is very durable and not subject to deformation.

Consists of five chambers

- Receiving container with the function of filtering coarse sediment,

- Sludge tank,

- Clean water sump,

- A control unit with a compressor located at the neck.

In another tank, microorganisms come into contact with wastewater. The aeration tank is the site of the main process of processing organic substances by microorganisms. In the third chamber, activated sludge settles to the bottom, which is then sent back to the first container by the action of a circulation pump.

The principle of operation of a septic tank is as follows: Wastewater enters the first tank. Here biological purification occurs under the influence of bacteria that are in the sludge. Then the wastewater, passing through filtration, passes into a second container called an aeration tank.

In this chamber, the waste liquid is saturated with air, which the bacteria need to carry out their activities, i.e. aeration occurs. The third reservoir is where the sediment is separated by gravity. Wastewater is divided into liquid and sediment in the form of active sludge deposits.

Then the light water goes into the 4th tank, and under the influence of a special sediment, activated sludge is pumped into the first tank. In the fourth chamber, the liquid finally settles. 5 the container is placed at the top in the neck. It is storage, from where purified water is pumped out.

Operation of the Ergobox station

The runoff enters the first chamber, where simple settling occurs. Heavy impurities settle, and light impurities float. Next, the clarified waste seeps through the perforated wall into the second chamber, where the bioload is located and an aerator is installed, enriching the water with oxygen. In the second chamber, wastewater is purified from organic contaminants - they are decomposed by bacterial enzymes into simple organic substances.

The hair trap traps hair and other debris falling into the drain. From the aeration tank, the runoff flows through the second perforated wall into the third chamber, settles and is further purified by bacteria attached to the tow threads. Then the drainage is drained from the station by gravity or poured into a container with a pump and pumped out forcibly. A recirculation airlift is installed in the third chamber, which returns the activated sludge runoff to the receiving chamber.