There is no technology more widespread and in demand in industry than welding. Without it, it is impossible to build a bridge or a skyscraper, or make a car or a washing machine. A master needs to spend a lot of time and burn thousands of electrodes in order to learn how to apply beautiful and durable seams on parts made of any metals and alloys, and therefore few owners of other professions are paid as much as a welder in Russia earns per month. We should not forget that the price for such a privilege is enormous responsibility and extremely difficult working conditions.

Features of the welding profession

A welder is a representative of a working profession who is engaged in connecting parts and structural elements made of metals using thermal effects. For these purposes, it most often uses the energy of an electric arc and a gas torch, although in some industries there are technologies based on heating materials with a laser beam, electron beam, ultrasound and even X-ray radiation.

To imagine the importance of this specialty, just look at how much a welder earns per month. Indeed, welding is the fastest and most effective way to assemble pipelines and building structures, connect parts of mechanisms and household appliances, repair car bodies and ship plating. Therefore, craftsmen of various skill levels can be found almost everywhere - from a small garage workshop to a research station in Antarctica or a high-tech satellite manufacturing plant.

Welder salary in the USA

The salary of a welder in America depends on the place of work. The minimum salary is established in 14 states. This is due to the fact that people work in hazardous conditions. Many specialists work individually - with their own equipment.

A welder in the USA earns differently. It depends on the enterprise. In a small company, a specialist receives a salary of $7 per day. The average salary is $18/1 hour. Some specialists earn from $25-32/1 hour.

Information on salaries in the USA is presented here.

Types and specializations of welders

The first ideas for the industrial application of welding arose more than a hundred years ago after studying the phenomenon of electric arc discharge. Since then, individual scientists and entire institutes have created several dozen technologies for thermal joining of materials, differing in physical principles and scope of application. Highly qualified welding specialists can confidently master several of them, but ordinary welders prefer to work in only one or two directions. Among them:

- Arc welding. It is performed with coated metal electrodes. The welding arc occurs due to the supply of an electric current of 50–200 A to the holder;

- Plasma welding. It is produced by a thin stream of gas heated with an arc to a temperature of 30,000°C. Plasma can be used to both weld and cut metal;

- Gas welding. A mixture of oxygen and acetylene is used here. The torch from the burner heats up to 5000°C, which causes melting of parts and filler wire;

- Electroslag welding. The parts and filler material are heated until melting with slag through which a current is passed. The slag protects the metal from oxidation;

- Electron beam welding. It is performed with a directed beam of high-energy electrons in a vacuum chamber. Requires 10 times less resources than arc welding;

- Laser welding. The metal is melted with a high intensity laser beam. Thanks to the precision of the technology, it is possible to weld parts no thicker than a hair;

- Contact welding. The parts are heated by friction under pressure. When they start to melt, the movement stops. The material cools and crystallizes;

- Diffusion welding. Conducted in a vacuum. The parts are heated almost to the point of melting and connected under enormous pressure, which causes mutual diffusion of atoms;

- Thermite welding. Here the welding area is covered with thermite powder, which is ignited by an electric arc and burns at a temperature of 3500°C;

- Gas cutting. It is produced by gasoline, kerosene or acetylene, which burns in a high-pressure oxygen stream. Can cut parts up to 300 mm thick.

Welding qualifications

Of course, even a person with an initial level of training can weld a swing and the frame of a greenhouse for a dacha. But when it comes to connecting oil pipelines, making building structures or ship plating, the work of a welder becomes very responsible. Therefore, within the profession there are six qualification categories, which mean the employee’s ability to solve problems of varying degrees of complexity. The assignment of the appropriate rank and its annual confirmation are carried out by special certification centers, where anyone can apply:

- 1st category is for students and trainees. Their qualifications allow them to carry out simple welding work and cut metal parts without tolerance requirements, heat workpieces for craftsmen and perform temporary tack work on structures;

- 2nd category allows a specialist to connect lightly loaded elements with lower and vertical seams without requirements for their strength and geometry, to weld or tack simple parts before carrying out the main welding work;

- Category 3 includes approval for welding the main elements of metal structures and low-pressure pipelines. The craftsman needs the skills to perform sealed, loaded seams and the ability to read design documentation;

- Level 4 is assigned to most qualified welders. They are capable of connecting critical parts of structures and pipelines with sealed seams with grooves, welding steel, cast iron and non-ferrous metals in all positions;

- Level 5 shows high professional training. The specialist has the right to weld critical loaded parts and high-pressure pipelines, make sealed seams in all positions with any grade of metal;

- Level 6 means that a specialist can weld the most complex parts with high mechanical loads and obtain seams with ideal parameters. Sometimes the director of a company does not earn as much as a 6th grade welder earns.

What does the salary depend on?

The payment depends entirely on the following indicators:

- Experience.

- Discharge.

- Place of work.

Specialists without experience cannot count on large salaries. On average across the country they receive about 30,000 rubles. If you work in Gazprom, the salary will be higher, but the requirements for employment in this company are high. Working with flammable objects in extreme conditions requires an appropriate category (6 category). These are the most valuable employees who can earn at least 150,000 rubles per month.

Advantages and disadvantages of the profession

Unfortunately, the prestige of blue-collar jobs has suffered greatly in recent years. Young people no longer strive to study plumbing or master woodworking: they are much more comfortable dreaming of becoming an official or thinking about what kind of business it will be profitable to open after the crisis. However, contrary to the general trend, interest in the welding profession has decreased slightly. How can this be explained:

- In terms of average wages, welders are significantly ahead of representatives not only of workers, but also of many engineering and office specialties;

- A beginner does not need to spend several years and hundreds of thousands of rubles on training, since one can become a welder from scratch after professional courses;

- There is a catastrophic shortage of specialists on the labor market, and if qualified, a welder can easily find a job in any country in the world;

- If you work in your specialty for a couple of years, you can collect a serious client base and come up with many profitable business ideas for a welder;

- If a welder has an official work experience of 25 years, he is entitled to preferential pension benefits.

Unlike other professions, most of the disadvantages of the welding profession are well known. Therefore, it is almost never chosen under the influence of a momentary impulse: as a rule, beginners have a great idea of what awaits them. In particular:

- Working conditions here are far from greenhouse. Specialists have to work both in the icy wind and under the scorching sun in a heavy protective suit;

- The harm to health from radiation, evaporating gases and combustion products is hardly justified by how much a welder earns;

- The activity is highly dangerous. It is often necessary to weld seams in gas tanks and oil pipelines under pressure, at height and under water;

- Sometimes managers force the welder to sacrifice quality for the sake of speed and low cost of work, but he himself will have to answer for accidents;

- Career growth requires effort and considerable ingenuity. Without initiative and enterprise, you can work in one place all your life.

What time do welders retire?

Welders are retiring early. More precisely, they have the right to retire earlier than workers in other professions. However, early care is not possible for everyone.

Early retirement is granted if the employee has worked for at least ten years. At the same time, documents confirming the type of welding work performed by the company employee must be submitted.

If you have 10-12.5 years of experience as a welder and 20-25 years of general experience, you can safely apply for a pension. Information about the work, as well as documents confirming the harmfulness of the position, must be attached to the application for a pension.

Upon early retirement, a specialist must provide the following documents:

- documentation for welding equipment;

- job descriptions;

- certification card;

- a personal account opened for an employee by the company;

- orders according to which protective equipment and other documents were issued.

People in the following professions can retire early:

- gas cutters;

- electric welders;

- electric and gas welders.

At the time of early retirement, the employee must be at least 50 or 55 years old. The exact age depends on the type of welding work that was performed.

What does a welder do?

When they come to the conclusion: “I want to become a welder,” young people usually have a good idea of what they will have to do. Indeed, in such a profession there are no unobvious responsibilities, and the employee’s tasks come down to high-quality and correct connection of parts with each other. Although, if we describe them in accordance with the requirements of welding technology, the list will be quite long:

- Studying design and technological documentation for products that need to be manufactured by welding;

- Checking the serviceability of components and assemblies of welding equipment, power supplies, hoses and electrical wires, preparing them for work;

- Cleaning the proposed welding areas of parts and structural units using manual, electric and pneumatic tools;

- Determination of the spatial location of future welds connecting the components and parts of the workpiece;

- Temporarily securing structural parts for welding in accordance with drawings, using clamps, clamps or temporary tack points;

- Determination of the optimal welding technology in terms of labor intensity and strength, taking into account the possibility of subsequent defect detection of the weld;

- Selection of a suitable filler material or type of electrodes, taking into account the thickness, type, chemical composition and strength requirements of the parts being welded;

- Preliminary and maintenance heating of product elements before welding in accordance with the thermal regimes prescribed by the technology;

- Surfacing of individual parts and seams in a structure with filler materials to eliminate defects and ensure the specified thickness and strength of the connection;

- Direct welding of parts made of different grades of steel, non-ferrous metals and alloys using arc, gas, plasma or laser methods;

- Checking the assembled product for compliance with the geometry and strength requirements prescribed by the design and technological documentation;

- Cleaning welds from splashes and sagging, removing scale from them using manual, pneumatic or electric tools;

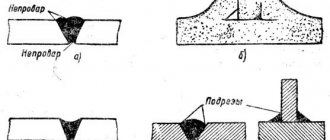

- Manual or mechanical removal of detected weld defects, slag inclusions, undercuts, voids and lack of fusion;

- Checking the geometric parameters, strength characteristics and density of the seam using visual, x-ray or ultrasonic methods;

- Carrying out welding work taking into account safety requirements, notifying management about emergency situations.

The situation with welders on the labor market

You can’t do without welding either in construction, or in mechanical engineering, or in the processing and oil-extracting industries. The performance of mounted objects depends on the quality of welding seams. Mistakes can lead to catastrophic consequences. Therefore, a lot depends on the qualifications and conscientiousness of the welder.

In our country there is a personnel shortage in blue-collar professions. Most competent specialists are near retirement age. There are not enough good young specialists for everyone, so a welder with experience and qualifications can easily find a well-paid job.

The welding process is fascinating

What qualities does a welder need?

Many young people try their hand at being a welder, but some of them begin welding substrates for microprocessors within a few years, while others continue to make fences for their dachas. The reason here is that the presence of certain personal qualities separates the master from the amateur.

What does it take to become a welder?

- Attentiveness. When performing welding work, the master should not be distracted for a second. It is enough to move the tool a little to get a defect;

- Spatial thinking. When assembling products, you always have to imagine how the parts will be connected and what relative position they will occupy;

- Smartness. There are very few standard situations in a welder's work. Often you have to come up with a technical solution to a problem literally on the fly;

- Restraint. Calmness is necessary not only for soberly solving sudden problems, but also for maintaining caution when working with dangerous equipment;

- Coordination. Manual welding requires uniform guidance of the electrode literally millimeters from the surface of the parts, and almost blindly;

- Endurance. A person with poor physical fitness is unlikely to be able to wear heavy protective clothing in the heat or move heavy pipes in the icy wind;

- Equilibrium. Sometimes parts have to be connected in different conditions, including upside down and at height. Such provisions should not cause disorientation;

- Accuracy. If a weld seam causes horror by its very appearance, sagging and drips, then with a high probability it contains unacceptable defects;

- Responsibility. The welder cannot afford to relax control over the quality of work, since the consequences of weld failure sometimes lead to disasters;

- Health. It is impossible to become a welder with diseases of the joints and lungs, poor vision and hearing, and impaired motor skills of the limbs.

Salaries in the Northern region

Now the authorities are trying to attract the interest of Russian citizens to the Northern region, since this part of Russia is sparsely populated and developed.

At the same time, in the north there are quite a lot of useful natural resources, the main of which are gas and oil. Since many welders are not ready to move to the North for one reason or another, employers offer them an alternative - a rotational work method. In this case, the employee does not change his place of residence, but simply leaves for work for several days or months, and it is worth noting that the duration of the shift should not exceed three months.

A welder of the 1st category, as well as the third and fourth, will not be allowed to work in the North, since his qualifications are not sufficient to perform the work offered in that region.

Even a 5th grade welder is not always able to get such a job. Despite the requirements that allow only a narrow circle of specialists to work, it is difficult to say how much welders earn in the North, since each company offers its own salary.

But still, the lower threshold of payment that can be provided to welders in the Northern region is quite high, even compared to Moscow, and at the moment the salary exceeds the 100 thousand rubles mark.

What knowledge does a welder need?

It seems strange to many people that the income of accountants, sales managers and other office employees lags significantly behind what a 3rd category welder earns. But such a difference becomes completely logical if we compare the level of theoretical training of an ordinary clerk with what a welding specialist needs to know to professionally perform his duties. This:

- Types, structure, components and dimensional characteristics of welds, methods of indicating them in the drawing;

- Types, brands, physical properties and chemical composition of materials welded by electric arc, gas and plasma;

- Characteristics of various filler materials and electrodes, features of their selection depending on the types of steels and alloys being welded;

- Design, principle of operation and operating rules of welding equipment, auxiliary devices and instrumentation;

- Methods and technologies for welding and surfacing of products from different grades of carbon and stainless steel, cast iron, non-ferrous metals and alloys;

- Techniques for welding and surfacing parts with different tools with a vertical, lower and upper seam location;

- Features and procedure for temporary assembly of product elements for welding using clamps, clamps and tack points;

- Rules for preparing and cleaning areas and edges of parts for welding using mechanical, manual and pneumatic tools;

- Methods for cutting edges for butt, tee, lap and fillet welds, depending on the requirements for strength and tightness of the joint;

- Features of the choice of modes of preliminary and maintenance heating of parts for welding different grades of metals and alloys;

- Reasons for the appearance, methods of preventing and eliminating defects in welds, stresses and mechanical deformations of connected parts;

- Technological requirements for the geometric and strength parameters of seams, methods for their defect detection and testing for compliance with quality;

- Fire and personal safety rules when operating electrical, gas and plasma equipment in different environments.

How much do welders earn in Moscow?

Salaries in the Moscow region are among the highest, although they are inferior to monthly payments to specialists in the north.

On average, a welder’s salary in Moscow is 20% higher than the Russian average, and is about 70,000.

A novice specialist of the 1st-2nd category can count on an income of 40 thousand rubles, and an experienced welder of the 5th category - from 80 to 100 thousand.

As in other regions, NAKS welders are most valued in Moscow - such professionals can earn up to 200,000 rubles. Pipeline welders and specialists working with non-ferrous metals and stainless steel also have high wages.

What skills does a welder need?

In any profession, indicators of a specialist’s qualifications are his knowledge and skills. You can understand welding technologies at the level of the atomic structure of metal, but if a worker is unable to quickly and confidently apply smooth and beautiful seams to parts of any complexity, he is unlikely to think about how much a welder earns in America and how to become a professional in demand on the market. Of course, mastery does not appear out of the blue, because on average it takes 8–10 years to train an expert, but in the end, the specialist must confidently master such subjects as:

- Ability to read and understand technological and design documentation for welded products of varying levels of complexity;

- Skills in checking the serviceability, performance and safety of various types of electric arc, plasma and gas welding equipment;

- Experience in performing basic metalworking operations necessary for preparing, cleaning and cutting components and parts of a product before welding;

- Ability to configure control and switching elements of technological equipment to select the correct welding mode;

- Skills in setting the required speed, intensity and duration of preliminary and maintenance heating of parts;

- Experience in welding parts from different grades of carbon and stainless steel, cast iron, non-ferrous metals and alloys using arc, plasma and gas methods;

- Ability to perform butt, tee, lap and fillet welds of various locations manually, semi-automatically and automatically;

- Skills in surfacing components and parts with various filler materials, including those in aggressive environments and under pressure;

- The ability to identify and eliminate obvious and non-obvious defects in welds, determine the causes of their occurrence and take preventive measures;

- Experience in using measuring instruments to determine the geometric and strength characteristics of a weld.

Average salaries of Russian welders

The average monthly salary of welding specialists in Russia is 47-49 thousand rubles, which is approximately 1.5 times higher than the average salary in the country’s economy.

In Moscow

In the Moscow region, welders earn between 30-200 thousand rubles per month. Average earnings are 60-70 thousand rubles. This corresponds to the average salary indicators for the Moscow economy. Today, the demand in the labor market in the capital for welding specialists is great; about 1,200 vacancies remain open. Employers undertake to pay workers in this profession 30-130 thousand rubles.

In the regions of Russia

The highest earnings are among welders in the Tyumen region and the Yamal-Nenets Autonomous Okrug; they receive 110-120 thousand rubles monthly for their work. The average salary of welders in St. Petersburg and Volgograd corresponds to the average monthly income of this category of Russian workers - 48-50 thousand rubles. In Yekaterinburg, Novosibirsk, Krasnoyarsk, Omsk, Perm, Samara, Ufa and Chelyabinsk, average salaries are at the level of 33-40 thousand rubles.

in Kazan, Rostov-on-Don, Voronezh, Saratov, Nizhny Novgorod earn less - 27-32 thousand rubles. The lowest incomes for welding specialists in Krasnodar are 20-25 thousand rubles.

How to become a welder?

Taking into account the fairly extensive requirements for professional knowledge and skills, the possibility of independently mastering the specialty of a welder raises doubts. At the same time, it cannot be said that a prerequisite for the master to perform his functions is the study of any fundamental disciplines and scientific theories. Therefore, a newcomer has a choice: undergo simplified training and immediately start working, or spend several years and get a serious basis for further career development. How to become a welder:

1. Enroll in courses. The option is more suitable for quickly mastering the profession, since it is impossible to fit materials science, welding techniques in an inert environment or X-ray defect detection rules into a 250-300 hour program. Where to study:

- Educational at MSTU named after. Bauman (from 15,000 rubles);

- Moscow City Vocational Training Center (from 26,900 rubles);

- Center for additional professional education (from 30,500 rubles).

2. Enroll in a technical school. Secondary specialized institutions train high-class craftsmen who can work with various technologies, understand the physical foundations of welding and confidently read design documentation. Where you can study:

- College of Urban Planning, Transport and Technology (135,000 rubles per year);

- College of Modern Technologies named after. Panova (90,000 rubles per year);

- College of Architecture and Construction No. 7 (120 rubles per year).

3. Go to university. Universities train not ordinary welders, but engineers. Such specialists are engaged in the development of technologies, the creation of new welding methods, and the improvement of defect detection and control methods. Where you can study:

- National Technological University MISiS (209,000 rubles per year);

- Russian Technological University (1,900,000 rubles per year);

- Chemical-Technological University named after. Mendeleev (232,000 rubles per year).

Salary levels in other countries

Knowing the average salary in Russia, it becomes interesting how much welders earn abroad.

Thus, the average salary in Europe will be 1,700 euros, however, everything will depend on whether it is the western or eastern part. So, in Eastern Europe, the average salary of a welder is 1,500 euros, and in Western Europe it tends to 2,000 euros and further - the further west, the higher. One of the highest salary levels - 2,700 euros - was recorded in Germany. It is important to consider here that each country has its own requirements for the qualifications of welders, and the amounts are indicated without tax deductions.

How can a welder get a job?

Recently, employers have been suffering from a shortage of qualified personnel, which is explained by the low prestige of blue-collar professions among citizens and the reluctance of young people to give up office comfort even for the sake of a decent salary. Therefore, novice welders are unlikely to have problems finding the first place:

- It is easier to search for entry-level vacancies in the Job Center. But you should not hope for a favorable place, since mainly budget organizations are represented here;

- To find a job in a serious company, it is better to visit a recruitment agency. Such intermediaries often work with large enterprises, including foreign ones;

- Domestic private companies prefer to recruit welders through job sites. The highest paid positions require traveling on shift;

- Many companies publish offers to job seekers on their websites. Typically, the qualification requirements for candidates are listed here in detail;

- It’s also worth personally visiting the HR department of the company you like and asking if they have any vacancies and how much a welder earns on average.

Currently, 95% of enterprises are looking for specialists in electric arc and gas welding. Since these are the technologies that are studied in colleges and courses, a beginner will not have to master additional areas even before starting his career. But it’s wiser to get rid of the illusion that getting a good job will be easy:

- A newcomer should not tell the employer about his complete lack of experience if he has at least once held a welding machine in his hand and successfully connected a couple of parts. By understanding the principles of welding, you can understand everything on site in just a week of internship;

- The main requirement for the first job is the opportunity to gain the most important practical skills and experience in welding complex parts. Salary, career growth or thoughts about what business to open for a welder remain secondary;

- You cannot immediately get a job involving responsible or complex welding. A professional test will show the incompetence of the applicant, and a defective, inept seam can lead to very sad consequences;

- At every convenient opportunity, it is necessary to train to perform seams of various complexity, position and type of cutting, especially with a semi-automatic machine. This skill will be extremely useful when moving to a higher paying job.

Additional bonuses

As an additional bonus, organizations that invite welders to work on a rotational basis pay workers for accommodation, meals, and travel to and from the place of work.

Also, all categories of specialists are provided with special clothing, personal protective equipment, tools and equipment.

In addition, harmful working conditions for welders require additional annual leave of at least 7 days. Some types of work, incl. outdoors means an increase in vacation by 12 days.

Welder career

The most obvious way of professional growth for a specialist seems to be a gradual increase in qualifications and assignment of a higher category, up to the fifth or sixth, which allows one to qualify for the maximum salary in the industry of 120–150 thousand rubles. How to become a good welder:

- At the first stage, the beginner’s goal is to master common types of welding - acetylene, argon arc, electric, semi-automatic. If this cannot be done in the first company, it is worth drawing up a strategy for transitions from one place to another;

- With experience, you can begin to acquire skills in welding critical complex structures - construction supports and beams, high-pressure pipelines, tanks and sealed tanks for liquefied gas and petroleum products;

- Next, it is recommended to undergo certification and receive a NAKS certificate. This allows you to apply for highly paid jobs servicing the same Gazprom oil pipelines and nuclear energy facilities, and also adds 25–30% to your salary;

- If you learn the language, you can go to mining and construction projects in Europe, America and China. Of course, ISO 9606 certification is expensive, but compared to what a welder makes in the US, it's peanuts.

A vertical career for a welder is rather an exception, since among representatives of blue-collar professions there are not many who want to occupy the manager’s chair. But there are no objective obstacles to a specialist’s transition to management, although in some cases this will require at least a correspondence higher education:

- If you have a diploma, a welding foreman can become a technician. The responsibilities of this specialist include preparing design documentation, determining requirements for connection parameters, technical control and searching for causes of defects;

- The next step is the position of welding production engineer. Of course, he knows how to work with a torch, but he is engaged in improving welding technologies, designing, developing technical standards and monitoring their compliance;

- Moving into management means promotion to chief welder. In his position, it is necessary to manage welding work and production in general, plan the timing of orders, and coordinate the costs of labor and material resources.

If you have your own equipment, the ability to weld structures can become the basis of entrepreneurial activity. There are many small business options for a welder, including the production of stairs and gratings, canopies and fences, barbecues and benches. Some craftsmen specialize in repairing car bodies or assembling water supply and heating systems, which brings them quite a serious income.

How to increase your salary

If a welder feels that he is not being paid enough, he can always try to increase his income. And for this, first of all, you need to improve your qualifications, because the higher the rank, the higher the salary. And while work on the project is underway, your experience will also increase.

It is worth paying attention to employers. In addition to a good salary, they often offer to take advanced training courses at the company’s expense. Any such opportunity is worth taking advantage of.

Despite the fact that there are not enough welders and the market needs them, not everyone is looking for vacancies for themselves, but is trying to follow the path of self-employment. A welder with good experience and rank can start his own business, becoming an individual entrepreneur or even a legal entity, hiring a small staff.

It will be difficult to take on any kind of work, so welders starting their own business focus only on one type of activity. For example, you can only do car repairs, work with water and heat supply systems, take on the dismantling of any structures or, conversely, create metal objects according to customer drawings. It will not be difficult to choose a direction or come up with your own if you carefully study the services in demand in the region or a particular city. This will quickly help you adjust your plan and start your own business. However, such employment, even as an entrepreneur, implies great responsibility. Therefore, in addition to professional ones, other skills may be required.

Every welder can make good money. The market is full of offers, and the shortage of qualified and ambitious specialists remains high. And if a welder works hard to improve his knowledge and skills, such efforts will pay off with a high salary.

How can a welder find clients?

Of course, a welder is unlikely to have to worry about how to create a business from scratch and not lose it - after all, his main entrepreneurial asset will be knowledge and skills that will not disappear anywhere in any development of the situation. But they will not benefit him without basic marketing skills. In other words, a welder as an independent craftsman needs to learn how to look for clients. How to do it:

- To attract private customers, summer residents and farmers, it makes sense to place advertisements in local newspapers. You can highlight them with color for a small fee;

- It is useful to put stickers with contacts and a list of services on the rear window and doors of your personal car, especially if it is intended for an audience of car enthusiasts;

- At every opportunity, you need to distribute business cards. No one knows in advance when and in what situation he will need the help of a welder;

- It is advisable to post advertisements on the territory of cottage villages, garage cooperatives and gardening associations. There are a lot of potential clients here;

- You can publish proposals on bulletin boards such as Avito and similar resources. They should be updated periodically to keep them current;

- It is useful to register on special job exchanges, where ordinary citizens and small organizations find craftsmen to perform various jobs;

- Using any free website builder, you can make yourself a one-page website with a list of services in a day. It is better to promote it using contextual advertising;

- You can sometimes go to construction forums and provide answers to welding-related questions. They start turning to a reputable master quite quickly;

- To find customers among organizations, it is most effective to send out commercial proposals. If you have time, you can do cold calling.

How much does a welder earn?

If you study the information about what salaries are offered to welders or how much truckers earn in Russia, it will become obvious that in specialties related to the performance of responsible and complex duties, the level of income can be more than decent. Moreover, the employee has the opportunity to partially influence the amount of his remuneration, taking into account factors such as:

- Experience. A specialist with extensive experience has the skills to perform complex and important seams, so he is trusted with highly paid orders;

- Qualification. The difference between the income of a master of the highest category and how much a 1st category welder earns can be literally enormous;

- Specialization. Manual welding with an electric arc and semi-automatic is considered simpler than argon or laser, which also affects salaries;

- Complexity of work. Obviously, with equal time spent, welding an oil pipeline pays better than making a greenhouse for a country house;

- Region. The income of a specialist somewhere in Crimea lags significantly behind what a welder earns in Moscow or on a drilling rig near Nizhnevartovsk;

- Place of work. Even with tasks of equal complexity, a welder in Surgutneftegaz and Gazprom is paid many times more than in the housing department of the Sovetsky district of Ryazan;

- Type of production. For carrying out work at high altitudes, under water or inside gas tanks, craftsmen are awarded additional bonuses.

Many specialists are not satisfied with the pay at their main place of work, receiving additional income from completing private orders in their dachas and garages. Therefore, official statistics do not allow us to know exactly how much welders in Russia earn per month. But in general, for the industry, employer proposals look like this:

Welder salary, thousand rubles

| Job title | Electric welder | Gas welder | Argonist |

| Moscow | 65–100 | 70–150 | 80–150 |

| Saint Petersburg | 50–90 | 80–120 | 60–90 |

| Ekaterinburg | 45–70 | 60–100 | 60–80 |

| Krasnoyarsk | 50–80 | 60–110 | 70–120 |

| Chelyabinsk | 60–80 | 80–100 | 90–110 |

| Volgograd | 50–80 | 60–90 | 70–100 |

| Novosibirsk | 50–70 | 70–100 | 90–120 |

| Ryazan | 50–70 | 60–100 | 85–110 |

| Orenburg | 40–60 | 75–90 | 80–100 |

| Kaliningrad | 60–70 | 80–100 | 80–100 |

Income of welders in other countries of the world

In European and North American countries, the pay for welders is significantly higher than in the Russian Federation. This is due to the high level of income of the population as a whole. In the CIS, rates are charged lower. Argon welders are most valued abroad. The level of monthly payments by country has the following picture:

| A country | Amount in dollars |

| Belarus | 100-400 |

| Kazakhstan | 150-180 |

| Ukraine | 290-1100 |

| Poland | 800 |

| Lithuania | 800 |

| Czech | 1 100-2 900 |

| Germany | 1 200-3 500 |

| Estonia | 1 500 |

| Canada | 1 500-3 500 |

| USA | 3 000-5 000 |

| Finland | 3 700 |

| Israel | 5 000-6 600 |

| Australia | 5 000-30 000 |

| Norway | 5 300 |