- Types of Source Contamination Protection

- Methods for waterproofing concrete and metal caissons for wells

One of the reasons for the decrease in the quality of water supplied from a well is the penetration of foreign impurities into the water intake area. They may be contained in infiltrates of perched water exposed to technogenic impacts. Contaminants also penetrate into the mouth of the casing as a result of flooding with rain or melted snow water, and rising groundwater levels (GWL).

What is a caisson and why it may be needed: option with a private well

This is the name of a special chamber that can provide comfortable access to the mouth. This makes it easier to install a pump for a well and protects its top from external influences. For each such tank, you should calculate the dimensions and depth to which it will go underground to ensure thermal and waterproofing. In addition, all equipment must fit inside it.

This device is mounted above the borehole - this makes it much easier to pick up and interact with the mechanisms.

It is often installed immediately after drilling - building a house always requires a huge amount of water. The equipment allows you to protect the source from freezing in winter and clear it of debris.

Each pit must meet the following conditions:

- Through it there is constant access for flow measurements, sampling, as well as for preventive maintenance and any repairs.

- The casing to be used must be 50 cm larger than the diameter of the pipeline. If the model is submersible, then the diameter of the pump and pipes should be equal.

- What size caisson will be useful depends on how conveniently the station is located and whether there is room for automation if you plan to install a submersible electric pump.

- The height of the equipment also depends on the dimensions of the equipment used, usually it is not less than 2.4 meters.

Is it necessary to insulate a well from the cold?

The well is insulated for the winter for the following reasons:

- If a well for sand or an artesian well has an upper casing pipe located in a caisson pit, then when water passes through the pipes from the head into the house in the open section of the caisson, it can freeze and, as it expands, damage the water supply.

- If the water level in the well is high, its presence close to the surface can cause freezing and corresponding damage to the casing pipes - in this case, the well will become impossible to use.

- Any submersible electric pump has a check valve in the area of the outlet pipe; it is built into the pump model itself or installed separately by screwing onto the upper fitting. Thus, it prevents the flow of water into the well and it is always in the pressure pipe. A similar situation is observed with surface electric pumps, where a check valve is installed at the end of the supply hose. In severe frosts, water may freeze in the suction section of the HDPE pipe and its supply to the premises of the house with pumping equipment will stop due to the ice plug.

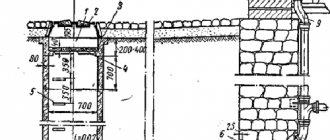

Rice. 2 Scheme of caisson design and well insulation

- In many caisson pits, surface pumps and equipment are installed - if the pump is shallow underground along with automatic equipment, they also need protection from the cold due to the constant presence of water in them when turned off.

- The need for insulation also arises when the owners are absent for a long time and if during operation the well is subjected to short-term mothballing - frozen water in the casing and pressure pipes will make its further supply impossible.

- Some types of wells do not have a caisson pit - the upper casing pipe is located at or slightly above the ground surface. In this case, you need to think about the fact that the well needs to insulate its mouth to ensure uninterrupted water supply.

Rice. 3 Connecting the electric pump via a downhole adapter

Caissons for water: types and characteristics

They are always formed from materials that are capable of showing high tightness and are resistant to moisture on the surface. You should not use those that absorb liquid well.

Therefore, in production they use:

- brick;

- concrete structures - rings, squares;

- steel containers;

- plastic cameras;

- polymers and sand options.

Main tasks of the tank:

- Protect the well and its top from any precipitation and all kinds of dirt and debris.

- Do not allow the mouth to be washed out by groundwater or sewage. They can penetrate down the casing from the outside and enter the source, rendering it unusable. This can be life-threatening.

- Provide maximum thermal insulation. This way you will avoid freezing due to cold weather.

- Serve as a convenient platform through which you can lower and retrieve pumping equipment through the top hatch.

Depending on what the caisson well was made of, some of its characteristics change. Let's look at this in more detail.

Brick or concrete rings

One of the most common options. You can find different sizes on the market, the largest of which is 2 meters. If there are more than one elements of the well, then it is important to take those that have a tongue-and-groove type lock. This will help ensure that they are secured to each other.

In the standard case, these products are marked KS - wall wells. If there is a lock, then add Z, if there is a bottom - D.

When using this type, the following features can be highlighted:

- Price. Most of this equipment can be classified as budget. On average, the price of 2 linear meters with a height of 1 m will cost 30-40 USD. Therefore, you can assemble a finished layout for less than $100. But shipping can be quite expensive.

- Many standard sizes. Different diagonals and heights allow you to choose the most suitable option.

- Variety of species. You can create a tank from pieces with or without a finished bottom or lid. There is an option to assemble and install all the individual parts.

- Easy to install. There are no difficulties in this matter. You just need to dig a hole of the required size and move the rings there, and then cover them.

But there are negative features that are worth considering:

- Waterproof. The structure will not allow water to pass through, but can be saturated with it. As a result, there will be increased dampness in the chamber, and metal parts will rust faster.

- Thermal conductivity. In cold weather, everything can freeze in the source due to the fact that the concrete cools quite quickly.

Metal

There is another popular economical material. Let's figure out what it is - a real metal caisson in a private well for water supply and protection. It is created from a single sheet of steel with a thickness of 3 to 6 mm. The inside and outside of the tank must be treated with waterproofing.

MBFT-75 Membrane for 75GPD

SF-mix Clack up to 0.8 m3/h

SF-mix Runxin up to 0.8 m3/h

Peculiarities:

- Easy to install. Due to its large mass, the product will remain stable in the ground, and installation is carried out through a hole in the bottom.

- Lasting. It is not afraid of loads and earth movements, and is easy to secure in a pit.

- Sealed. Does not allow liquid to pass through, especially if the welding is factory-made.

- Inexpensive. The cost can be called acceptable. But it is important not to end up with a private company that makes equipment in artisanal conditions.

The main disadvantage this material has is thermal conductivity. When arranging it, you will also have to think about how to protect the entire frame from frost, since the metal elements cool down greatly. For example, owners often cover them with foamed polyethylene.

Plastic

One of the most modern types, lightweight, moderately durable and easy to immerse and secure.

Besides:

- Excellent thermal insulation. Compared to other models, they have the lowest conductivity and retain heat well inside. The walls are usually about 8 mm thick.

- Durable. Most varieties can last about 50 years. At the same time, they will not lose their quality properties throughout the entire period.

- Sealed. Well protected from moisture. Also, a rubber cuff suitable in size is put on the head.

But it is important to remember that they are more expensive than similar metal products.

Sand polymers

These are composite materials; they appeared on the market relatively recently, but quickly became popular. Typically, such a container is made up of 2-3 rings, a top plate, a hatch and a bottom. This way it becomes airtight and does not lose its properties. To make the equipment sufficiently rigid, sand is added to the polymer matrix.

The price of this variety is relatively small. But this is not their only advantage:

- Do not collapse under external influence. It does not react and is not subject to corrosion. At the same time, it has excellent resistance to frost, which is also a plus.

- Easy to install. All elements are made in the form of simple connecting parts using the tongue-and-groove principle. Therefore, it is quickly and easily assembled to any desired size.

- Light weight. No special equipment is needed to deliver or load the caisson inside the pit. Each plot weighs no more than 60 kg. It is not difficult to transport.

In addition, they can be used for a long time, more than 100 years, without loss of properties.

What to choose?

First of all, analyze your financial abilities. If you do not want to spend a lot of money on waterproofing, choose rolled materials. They are much cheaper and are sold almost everywhere. For successful installation of sheets, no special skills are required; simply apply several layers of primer and cement.

If the caisson is located close to groundwater, you will have to make asphalt insulation. It is more reliable than others, but at the same time it is quite difficult to implement. An experienced team of workers will quickly cope with this task, but a beginner may make several mistakes.

For example, incorrectly calculating the distance from the brickwork to the well will cause the entire structure to become fragile and unstable. Another option is poor-quality masonry. If it is laid unevenly and with gaps, the tank will freeze in winter.

Isolation from groundwater using bitumen mastic is an easy way, but it does not provide complete safety. If the caisson is located on a hill, one mastic will be enough. Otherwise, choose another option.

Exterior finishing is always more reliable than waterproofing a caisson from the inside. Unfortunately, there is not always easy access to the caisson. If it is located near the house, it is better to insulate the inner surface. This way you can avoid unnecessary financial expenses and hassle.

In addition, the service life of the container is much longer with exterior finishing. The correct selection of insulation, insulation and installation method will prevent the liquid from freezing at the wellhead.

Previous articles Next articles

Related Posts

- 04.01.2017.

Self-production of a caisson

- 04.01.2017.

Natural and forced ventilation of the caisson in the garage

- 07.11.2016.

What to do if condensation forms in the caisson

- 02.11.2016.

Basic installation recommendations

This product has quite a lot of positive aspects. It is not heated, the risk of freezing is very small. It copes well with the main purpose - to protect the source from debris, rain and other precipitation.

During installation, remember several important nuances:

- Sometimes it is squeezed out or broken by the soil and its pressure. Therefore, he has to be “anchored”. This applies not only to lightweight structures - even metal structures will benefit from this. A concrete slab is poured under the future location, and then everything else is attached.

- It is not necessary to make a concrete foundation in elevated areas that do not flood. But even then, we advise you not to make do with just a sand cushion; a good base is always needed.

- The ideal height is about 2 meters. This will make it easier to work with, and more convenient to place and bury.

- Even if all conditions are met, we recommend ditching the heating cable for electricity. This will be a great help in case of force majeure situations.

After we have figured out what a caisson for wells is and how it works, we propose to consider how to install it without wasting extra time.

It is worth noting that this technology alone is not enough. We recommend that you first study the composition of the water that the family plans to drink.

After the analysis, install an appropriate filter that will reliably protect communications and people from impurities, debris and unnecessary trace elements. You can select and purchase equipment on our website - ovteh.ru. Specialists are ready to help and answer all questions.

Why is waterproofing needed?

Direct purpose is related to the features of installation of protective structures. When installing concrete containers, small gaps and cracks in the cement mortar remain between the rings.

Proper welding of an iron caisson eliminates any holes between the sheets. The main problem during its operation is moisture, which forms on the inner surface of the structure due to condensation. Water can also reach pumps through precipitation. Waterproofing a caisson made of metal solves all of the above troubles.

Another advantage of the procedure is protection against corrosion, which is especially important in metal structures. Droplets of water on the walls lead to rust and gradual destruction of the material.

Learn more about installation and connection procedures

The task is similar for all varieties, but there are some features that we will discuss below.

AMETHYST - 02 M Residential building for up to 10 people or up to 2 cubic meters/day.

Aeration unit AS-1054 VO-90

Main table dispenser AquaPro 919H/RO (hot and cold water)

First, you should prepare a pit - at least 30 cm larger than the caisson itself. This will make it more convenient to install, place pipes, adjust them if necessary, and combine sleeves for passages. This will also make additional insulation and strengthening possible.

The bottom of the pit is covered with a sand cushion of 20-30 cm (this must also be taken into account when calculating the volume of required digging). Later, this backfill is spilled with water to make it denser. A concrete slab with steel reinforcement is already cast above it.

We do not recommend placing anchor bolts in advance - the chance of making a mistake is too high. In this case you will have to re-drill. It is better to install the equipment first and then secure it.

Users often wonder: what is kison, while making a mistake in spelling the name. We examined the principle of operation of the product and its essence, and talked about general recommendations. And now we suggest delving into the topic of correct installation on the territory, because its feasibility often depends on this.

If the rings are made of concrete

Here the system is the same as when creating a well. The main difference is in depth - in this case it will be much less.

It is better to fasten the parts together with steel plates. This will help protect the structure if the soil shifts. It is advisable to additionally fill the seams with cement mortar, without adding sand or other particles.

It is worth noting that concrete, unfortunately, allows moisture to pass through, albeit in small quantities. Therefore, he will need waterproofing and insulation to protect him in the cold.

In addition, a base under the rings is required, since the support area is too small. We recommend approaching the equipment with the principle that everything will last for decades, which means it must be done with high quality.

If metal products

Here you will also need a cast plate for the base and anchors. Even before installation in place, the container should be covered and treated with insulation, and the inside should also be primed. Even for stainless steel this is a prerequisite. You also cannot do without insulation.

The casing pipe is simply lowered into a sleeve hermetically welded to the bottom. Other inputs are welded with special bushings. Fittings will be screwed into them to set up the main line and supply the power cable for the electric pump.

If plastic tanks are installed

Working with this material is reminiscent of manipulating metal. The only difference is that instead of welding, glue will be used, and the tubes will be passed through couplings, and not through bushings. They can be closed with sealing lids if they are not needed.

There is no need for insulation or waterproofing here, but protection is required so that the equipment is not crushed by the soil. It’s easy to comply with this condition; just fill the gap between the wall and the pit with a solution and fillers. Moreover, it is allowed to take only one part of the cement. Sand and crushed stone are suitable as impurities.

This must be done even if stiffening ribs are visible on the surface. With proper protection, it can last for decades.

Methods

Before any work, the surface of the container must be thoroughly cleaned. Slag, burrs and small irregularities damage the waterproofing of the metal caisson. Then a compound is applied to the walls to prevent corrosion.

There are three ways to protect the caisson from water:

- Bitumen mastic. The most popular option. You can buy the necessary solution at the store or even cook it yourself.

- Asphalt mastic. A very labor-intensive method, but at the same time the most effective. It also protects the caisson from low temperatures.

- Roll materials. It will cost less than other solutions. You can use any roll waterproofing material, for example, roofing felt.

Bitumen mastic

If you decide to prepare the solution yourself, prepare a boiler for boiling bitumen. Its volume should be approximately three times the amount of substance. You will also need gasoline. It is not recommended to replace it with kerosene or other fuel.

Manufacturing process

After installing the boiler on fire:

- Continue heating the container until foam appears on the surface of the solution.

- Once ready, measure the required amount of gasoline. For primer you need three times more than bitumen. The first layer requires equal amounts of the two components. The following layers contain three times more bitumen than gasoline.

- Gradually pour fuel into the bitumen mixture and stir. The solution is ready.

This mastic is suitable for interior work in a metal caisson. The composition should be applied evenly in several layers. Pay special attention to sheet joints and corners, as this is where the most liquid accumulates.

Bitumen mastic

Roll materials

To protect the surface with sheets of waterproofing material:

- Apply primer to the outside surface. Here you can use bitumen mortar; it perfectly bonds cement and roofing felt. It is necessary to form at least three layers of primer. Do not violate fire safety rules when handling gasoline.

- Fill all uneven areas and potholes with a solution of cement and sand. You can add thickened PVA glue to the mixture.

- Apply another layer of primer to the cement mixture and cover with bitumen.

- Apply three layers of sheets of waterproofing material to the outer surface of the caisson. To do this, use a blowtorch. In this case, the seams of each new layer should be in a different place, that is, overlapping. Additionally, go over them with a blowtorch and bitumen mastic.

Roll material

You can extend the life of sheets using brickwork. Do it after the final stage of work on the outside of the building. The bricks will press the sheets against each other due to their weight.

Asphalt mastic

Suitable for external waterproofing only. Before work, brickwork needs to be built around the well at a distance of about 20 cm. A special asphalt mastic should be poured into the cavity between the surface of the caisson.

Asphalt mastic

This method is more difficult than others and requires a large number of workers. An inexperienced worker can only damage the housing through improper installation. This mistake will lead to the unusability of the cellar and large material waste.

Please note that if the tank is located in a swampy area, in the fall or spring the floor in it may fill with melt water. To eliminate this annoying mistake, load the cellar with additional materials.

How to make a caisson without costs or helpers

Some varieties can be created without professional help and the purchase of expensive components. It’s worth trying to assemble a brick or concrete container; some specialists will even be able to weld a product from sheet iron. But at home, the quality is often worse than in production. How this is done is described below.

Warm brick option

This is one of the most budget-friendly and easiest ways to create protection for your water supply. To build it, you will need building materials of almost any quality left over from the construction of a house or other outbuildings. You will also need some concrete and sand.

Main table dispenser AquaPro 929CH/RO (cooling/heating)

Floor dispenser AquaPro 311 (empty, without cooling)

Floor-standing dispenser AquaPro 6207CH (cooling/heating/room temp.)

Subsequence:

- a pit is dug taking into account all parameters;

- a concrete pad is poured;

- a wooden box is assembled to provide an even frame and protect against soil pressure;

- dilute the cement mortar in a ratio of 1:4;

- installation is in progress - it is important not to forget to insert the sleeves in certain places;

- so that the walls fit most tightly to the insulation, spacers are placed inside;

- a square steel sheet with the center on the side is often used as a cover;

- After complete drying, the inside of the container should be treated with waterproofing.

Warm method from concrete pouring

This method of obtaining a container for equipment and a well requires much more work, but it is also possible to do it yourself. It’s easier to do it if you turn on the concrete mixer or order the required amount of ready-made mortar. Mixing by hand is long and difficult.

Subsequence:

- dig a hole of a suitable size;

- compact the bottom, lay an insulating film, fill with the mixture;

- cut sheets of insulation according to the dimensions of the cube;

- Weld the mesh on the outside, put the formwork on the inside;

- to build the walls, you will need boards or panels tightly fitted to one another, which are fixed to the timber;

- pour concrete, preferably using a concrete mixer or machine;

- bayonet, tap or otherwise get rid of bubbles and unevenness in the mass;

- cover with cellophane so that everything dries without cracks;

- use a finished slab as a lid or fill it in a similar way;

- After all actions are completed and the surfaces have completely dried, everything needs to be treated with waterproofing.

Protection Features

According to the rules, insulation of the water supply system must be ensured along its entire length, starting from the point where the pipe enters the house, to a point located 20-30 cm lower than the soil freezing depth characteristic of the area. Whether it is necessary to insulate a caisson for a well depends on the climatic conditions in the region.

The cause of ice plugs in the well is uneven water supply, when interruptions in the operation of the well are sufficient for its crystallization. If the external part of the water supply system is laid below the ground freezing level, its insulation is not required.

For thermal insulation of the wellbore and underground section of the pipeline, materials that are highly hygroscopic cannot be used. The best choice for them would be polyurethane foam insulation with a bitumen-impregnated shell.

How does a caisson work?

This tank has only two main tasks, which we have already discussed above:

- protect from freezing;

- Prevent the entry of moisture, debris, drains, and chemicals.

This is a cylinder that simply serves as a kind of heated or insulated well. It is equipped with a lid, most often with a bottom, while it is sealed and reinforced, increases the strength of the entire structure and minimizes the likelihood of the ground collapsing.

Water supply pipes lead from it to the house.

How to insulate a well - consider materials

You can insulate a well using several methods, the main ones being:

Use of insulation. The construction industry uses a large number of insulating materials, which are successfully used to protect wells from the cold. Most of them are made on the basis of synthetic porous components that have low thermal conductivity due to the presence of air cells in the structure, others contain fibers adjacent to each other through air gaps.

Heating elements. Basically, wells are insulated with an electric heating cable, which differs in operating principle and power per linear meter. The advantage of this method is the regulation of the heating temperature of its shell, and in modern self-regulating modifications - the difference in heating temperatures of individual sections of its surface along its entire length, depending on the state of the environment.

Caissons. Caisson chambers are made from building materials and are factory produced from various components. One of the ready-made popular models are plastic types, which have low thermal conductivity due to the physical properties of their polymer shell.

Rice. 4 Heating cable for water well

Thermal insulation materials

Alone, thermal insulation materials are used in a region with a mild climate and with constant use of a well - after all, they only increase the freezing time of water in the well source. One of the common options is to use them as additional insulation together with an electric cable when solving the question: how to insulate a water supply system to the ground.

When used as protection against cold, the following materials are most often used:

- Expanded polystyrene (foam plastic) and its extruded version, Penoplex, are foamed synthetic materials with an air content of about 95%, which ensures their low thermal conductivity. Excellent for thermal insulation of external and internal surfaces of caisson chambers, external and underground pipes when used as shells due to their rigidity and low moisture absorption.

- Foamed polyethylene (Penofol), has many varieties with a different name, is available in the form of sheets of various thicknesses or cylindrical shells for thermal insulation of pipes. Well suited for cases where it is necessary to insulate the internal surfaces of underground chambers and pipes without external load, leading to compression of the soft material and a decrease in its thermal insulation properties.

Rice. 5 Well insulation - main heat insulators

- Mineral and glass wool. Mineral and glass wool, due to their high moisture-absorbing properties, are rarely used in a humid environment with constant water intake and use; one of the options for their use is preserving the wellhead for the winter by closing the well head. To do this, they make a special house or box into which they push soft cotton wool and cover the neck of the casing pipe coming out of the ground with it.

- Other materials. When operating a well, it can be insulated with lesser-known materials, which include Penoizol and polyurethane foam PPU; their main disadvantage is the use of special equipment for coating. The technology consists of applying a liquid composition of two mixed components to the insulated surface using special sprayers. After they harden, a porous structure with a high content of air cells is formed. Their main disadvantage is the softness of the surface and difficulty in obtaining an even coating. Another insulation material includes expanded clay; due to its cheapness, it can be used to sprinkle coffered pits and ditches submerged in the ground for water pipes going into the house.

Rice. 6 Example of using polyurethane foam insulating water pipes

Using a heating cable

The advantage of a heating cable is its ability to heat the water supplied to the line - this allows it to avoid freezing during very severe frosts or long time intervals in water consumption if draining it from the system is difficult. There are two main ways to place a heating cable - inside the pipeline and outside; in the latter case, it is necessary to use additional insulation in the form of a shell.

For water intake from a well, HDPE pipes are usually used, which have low thermal conductivity - this leads to the fact that the electrical cable on their surface will be less effective during operation than inside the pipes. There are also two main types of electrical cables - resistive and self-regulating, the latter have higher efficiency due to heating of their sheath depending on the temperature of the surrounding water.

Considering that the cost of self-regulating devices is not much higher than resistive ones, a short section of several meters is usually used, and energy savings can be significant, self-regulating modifications when choosing heaters are the best option.

Typically, electrical cables are supplied in a set of a certain length with a thermostat; many models have special three-inlet fittings for connecting to the HDPE pipeline.

Rice. 7 Heating cable - application features

Natural materials: 1 type

Sawdust can be used to insulate a well

Since you can insulate a well for the winter with your own hands without much expense, and this is sometimes very important, we can use the resources that are available in nature. It could be:

- upper peat,

- expanded clay,

- sawdust,

- straw,

- and even dry leaves.

But, as you understand, most of them are susceptible to rotting. Therefore, before using, for example, sawdust, it would not hurt you to treat them with special compounds.

To do this, you can use two types of solutions - penetrating and film-forming. In our case, the first option is much more reliable, since, starting from 15% moisture content, the structure of the wood is destroyed. You can use various products, and one of them is Aidol Langzeit-Lasur, which perfectly protects wood from the destructive properties of water.

Artificial materials: 2 types

Mineral basalt wool

But for the northern regions of our country, natural materials are not enough, and since it is -30⁰C or even -40⁰C outside, and the soil freezes to two or more meters, it would be better to use synthetic materials. For these purposes it is widely used:

- penoizol,

- polystyrene,

- as well as various types of mineral wool - glass and basalt wool.

There is another type - this is slag wool, which is obtained from blast furnace slag melts. But this material contains particles of iron that will rust from moisture, and the insulation will sag, losing its properties; it is not very suitable for us.

Of course, the price of synthetic materials is much higher than that of sawdust purchased at a sawmill, for example. But here the quality and service life are significantly improved. In addition, they can be laid for the winter without a caisson, which greatly facilitates the labor process, because this is a winding material, not a bulk one.

Insulation technology for reinforced concrete caisson

Between the caisson and the heat-insulating layer it is necessary to leave a ventilation gap 3-4 centimeters wide.

As a rule, a caisson made of reinforced concrete has a circular cross-section, since reinforced concrete well rings are used as the material for its construction.

Since the thickness of the reinforced concrete caisson itself is from 5 to 10 centimeters, when operating such a well in a mild climate, the caisson does not need to be insulated. Natural insulation materials are used for reinforced concrete caissons, among which sawdust is the most widely used.

Between the caisson and the heat-insulating layer it is necessary to leave a ventilation gap 3-4 centimeters wide. The ventilation gap will improve the thermal insulation of the caisson and increase the frost resistance of the well as a whole.

To ensure a ventilation gap around the caisson at the required distance, it is necessary to install the frame. When insulating a caisson with sawdust, reinforced mesh is used as a frame. The space between the frame and the ground surrounding the caisson is filled with sawdust. The caisson is covered with a lid on top, which protects the insulation from the effects of external destructive factors.

Insulation technology for plastic caisson

Mineral insulation can be used as a thermal insulator for plastic caissons.

The design of plastic caissons, as a rule, includes special shelves designed for laying insulation. Mineral insulation, as well as polymer-based thermal insulators, can be used as a thermal insulator for plastic caissons.

The insulation is laid in the shelves provided for this purpose, but if there are no such shelves, then when using mineral, basalt and glass wool, the insulation is fixed around the caisson using a special calcined wire. Just like reinforced concrete, the plastic caisson is closed on top with a lid.

Metal caisson insulation technology

Thermal insulation materials are attached around the caisson by strapping the structure.

The design of the metal caisson does not provide for the presence of special shelves intended for laying insulation; therefore, it is necessary to install the heat-insulating layer at some distance from the caisson in order to provide a ventilation gap between the caisson and the heat-insulating layer.

Thermal insulation materials are attached around the caisson by tying the structure with special calcined wire. The caisson is closed on top with a lid that protects the insulation from external influences of destructive factors, and the caisson itself from clogging.

Insulation of caissons with polyurethane foam

Polyurethane foam creates a double monolith with the surface of the caisson, which ensures greater structural rigidity.

The optimal thermal insulator for caissons is polyurethane foam, since the thermal insulator has high adhesion, which provides it with reliable adhesion to any surface. Due to the properties of the insulation, the polyurethane foam thermal insulation layer does not require a ventilation gap, since air circulates freely in the thermal insulation layer.

When insulating a caisson with polyurethane foam, there is no need to make a 30-centimeter thermal insulation layer, since the energy efficiency of polyurethane foam is much higher than that of mineral and organic insulation, therefore, a 3-4-centimeter polyurethane foam layer will be enough for reliable thermal insulation of the well.

Polyurethane foam creates a double monolith with the surface of the caisson, which ensures greater structural rigidity. For methods of using polyurethane foam, see the page “Insulation of various industrial facilities using polyurethane foam.” It is advisable to use polyurethane foam for insulation of metal and plastic caissons.

Easy to use

If everything was done correctly, then no special maintenance will be required. In some cases, if it is a brick or concrete tank, insulation is necessary, if it is a steel tank - periodic anti-corrosion treatment.

Metal containers require regular inspection and sealing of seams, and very rarely additional welding.

Construction of cellars-caissons

Modern metal cellars can have almost any shape (round, square, hexagonal). In their manufacture, metal sheets of various thicknesses are used. The quality of the product is largely determined by the accuracy of the connecting seams.

There should be no cracks, holes or other defects in the soldering or welding areas through which moisture can penetrate. The floor and walls of a metal caisson must necessarily be made of metal, while the upper part can be covered with wooden flooring or a concrete slab.

The caisson must have 1 or 2 manholes with a width of at least 1 m. If there is only one manhole, then it is intended both for loading provisions and for lowering people. If two openings are provided, then one will be used for products, and the second for people. The dimensions of the manholes should not be large, but they should be enough for comfortable use.

It is also mandatory to install a durable and comfortable ladder, at least 50 cm wide. The ladder must be rigidly attached to the caisson body.

Installation of a metal cellar in the ground.

Earth work

It is necessary to install a reinforced concrete caisson during the dry season, because the groundwater is deep and the ground itself is dry. If you have an area where groundwater persists for a long time, then give up concrete rings. Of all the materials, this one has the poorest airtightness. Choose plastic or steel. If you choose concrete, then seriously consider waterproofing it. Since the diameter of the rings is 1.5-2 meters, the pit in the ground is needed 2 times larger. The reserve will be needed to protect the structure with insulation. You can dig it out by hand or with an excavator. If there is little water in the ground, then you can reduce the pit and leave a gap of 20 cm. Dig so that the casing pipe is in the center of the hole. You also need to go 1.5-2 meters into the ground. Then the level of soil freezing will be higher, and a full-length person will fit into the caisson. All loose soil must be removed from the bottom of the hole to create a perfectly flat surface.

Repair of metal walls

Repair of a metal cellar involves the elimination of defects formed on the metal surface. If the caisson is located in a garage or in a house, then repairs will be complicated due to limited space.

In the case where the damage is insignificant and strictly local (for example, if single traces of the spread of the corrosion process were found), then the most common welding can be used to completely and efficiently eliminate them. However, you should not simply weld the damaged areas, because water will penetrate through such seams even more actively in the future. It is necessary to install a gasket and a metal patch, wedge the surface, and remove moisture. It is recommended to entrust the work to professionals.

If the corrosion damage has an irregular shape, then it needs to be calibrated using a drill. Next, you need to make a cone-shaped chop from dried birch wood (its diameter should slightly exceed the diameter of the hole obtained after calibration), and then hammer it.

Under the influence of moisture, such a plug will begin to swell, as a result of which the flow will completely stop and water will stop penetrating into the cellar. At the same time, the wooden plug must be filled with cement mortar, adding liquid glass to it.

If the damage is serious and it is not possible to repair it yourself, it is recommended to seek help from professionals who can choose an acceptable method to solve any problem. If the repair is associated with damage to the waterproofing or thermal insulation layer, then the patch in them must be made of the same materials that were used for insulation earlier (for example, if a layer of bitumen mastic is damaged, the defect area must also be filled with mastic solution).

Website editor-in-chief, civil engineer. He graduated from SibSTRIN in 1994, since then he worked for more than 14 years in construction companies, after which he started his own business. Owner of a company engaged in suburban construction.

Requirements for insulating materials

The insulation for the caisson must meet certain requirements.

The material must have a low hygroscopicity rate. Otherwise, having absorbed water, it will freeze and the entire insulating layer will be destroyed. If the material used is hygroscopic, it must be covered with a moisture-proof shell.

The insulation must have increased resistance to soil pressure. A decrease in thermal conductivity under load will lead to a deterioration in the quality of insulation.

The insulation material must be resistant to insects and rodents. Having made passages in it, they can get to the pipes and expose them, which will lead to freezing of the water supply.

There are two groups of insulation materials. The first are substances that can withstand frosts down to 15 degrees. These are usually natural materials - sawdust, expanded clay, peat. They are used in areas with milder climates. Their advantage is their availability and ease of use. But these materials are short-lived, and the insulation procedure has to be repeated every season.

Insulation materials designed for northern regions can withstand sub-zero temperatures of 15 degrees and below. They are:

- foamed plastics of different compositions - polystyrene or polystyrene;

- fibrous materials made from glass melts or slags, united under the common name - mineral wool.

The need to protect the head

Insulation is also necessary when the well head is located below the freezing level of the soil. Uninsulated walls have increased thermal conductivity, which is why the temperature inside the well can drop below zero. How to insulate a caisson for a well for the winter? The method of insulation does not depend on the shape of the caisson. But cylindrical chambers are more economical; less material is required for their arrangement. At the same time, insulation of rectangular caissons is much easier and faster.

To insulate a caisson for a well with penoplex, it is necessary before the end of the warm season:

- dig out the casing to the depth of soil freezing with some reserve - up to 20-40 cm;

- order products made of penoplex or polystyrene foam, the shape of which corresponds to the geometry of the casing;

- cover the column with polystyrene foam or polystyrene foam and seal all cracks with polyurethane foam;

- put foam cylinders on the pipe and foam all joints;

- dig out a water pipe and its entry points into the house and well;

- cover them with mineral wool, and on top of it with film or foil.

Insulation of the caisson

Depending on the material, caissons are:

- concrete;

- metal;

- plastic;

- wooden.

If the caisson body is sealed, it does not require waterproofing. You can insulate a metal caisson from the inside using one of the modern materials:

- polystyrene or foam;

- basalt or glass wool;

- polyurethane foam.

Particularly difficult is the process of attaching the material to the walls of the chamber, since they are not provided with shelves for laying insulation. The thermal insulation layer is mounted at a short distance from the walls to provide an air gap. Metal caissons use a double lid, inside which insulation is also placed.

To insulate concrete caissons, mainly natural materials are used - sawdust, dry leaves, straw. A frame made of reinforced mesh is mounted around the concrete rings at a distance of 3-4 cm. It creates an air layer with low thermal conductivity. The space between the frame and the walls of the pit is filled with sawdust. The top of the well is closed with a lid that protects the insulating material from external influences.

Insulation cable

One of the most effective ways to insulate a caisson for a well is to install a heating cable. Its advantages:

- in resistance to external damage;

- automatic temperature control;

- durability;

- environmental friendliness

The disadvantage of the method is the high cost, which is determined by the costs:

- for equipment;

- its installation;

- further maintenance.

To install the cable you need:

- dig a hole slightly deeper than the freezing level of the soil;

- wrap the casing pipe with a cable, the number of turns of which depends on the characteristics of the device and is indicated in the attached instructions;

- lay a layer of insulating material on the cable;

- cover the entire structure with waterproofing to protect it from groundwater;

- Upon completion of installation, fill the hole with soil.

Regardless of the mode of use of the well, it is recommended to provide additional protection during its installation. The pipeline is installed using heat-insulating materials. Their thickness is selected taking into account the structure and pressure of the soil. Often, when installing a well, pipes of different diameters are used. An air gap is formed between them, retaining heat under the soil layer.

Caisson waterproofing - suitable materials

Regardless of what kind of waterproofing material is planned to be used, the surface of the cellar is first properly prepared - it is cleaned of slag in the welding areas, burrs are removed, as they can compromise the integrity of the insulation, and the surface is treated with special compounds that prevent the formation of corrosion.

Bitumen mastic

Painting waterproofing of a caisson is one of the most popular methods. For the work, you can purchase a ready-made composition in a specialized store or make it yourself by welding bitumen mastic (can only be done if you have experience).

To make mastic with your own hands, you need to load bitumen into a metal cauldron or tank to 1/3 of its volume, put the container on the fire and keep it there until foam stops forming on the surface. Next, a small amount of gasoline is poured into the second container, into which molten bitumen is poured in a thin stream. Mastic proportions:

- To prime the surface of the cellar, use one part bitumen and three parts gasoline.

- For the first paint layer - one part bitumen and one part gasoline.

- To apply repeated layers - three parts bitumen and one part gasoline.

Ventilation of a metal caisson

Unlike a cellar, you don't need to maintain humidity levels. It is important for the caisson to be dry inside. For this purpose, an insulated caisson cover is used, which must remain insulated all year round. There is no need to open it idle and let warm air inside. Ventilation leads to the fact that moist air, hitting the cold walls, causes condensation in the caisson. And then the fight against condensation begins.

The right thing to do would be to make the caisson as airtight as possible, no ventilation!

Cheap metal caissons

It is widely believed that a caisson is a box that has no specific features other than the size and thickness of the metal. In addition, this box is buried in the ground and is not visible. Therefore, in order to save money or trust the foreman, the cheapest caisson of all possible is often purchased. Typically this is a cylindrical barrel, painted black and with a lid covering the entire diameter. At the bottom, the welder cuts a hole for the casing pipe, then it is installed on it and the place where the pipe enters the caisson is welded. So what are the downsides, you ask?

- The installation of a caisson for an artesian well is carried out as is, no additional waterproofing is done. It would be correct to use adhesive waterproofing based on bitumen or anything else based on bitumen. It will last up to 100 years, regardless of whether the caisson wall is 3 mm or 4 mm.

- During welding, paint burns out at the point where the casing pipe is inserted and after a short time corrosion begins there.

- It is almost never possible to properly weld the pipe entry point, because the hole for the casing pipe is uneven and cracks or small holes remain. After a while, water will begin to flow from there, and your cheap caisson will be full of water. Later, this water will rise above the head and begin to drain into the well, along with all the microflora. No matter how tight the head is, this will happen sooner or later. The correct way out of the situation is to buy a caisson with a sleeve for inserting the casing pipe, therefore, welding then takes place inside the caisson and the waterproofing will not burn, but it is not so cheap.

In addition to a caisson from a barrel for a well, there is another way to save on a caisson - to make a concrete caisson (the consequences are about the same).

Installation of rings

Only a truck crane can install the rings. We place the first ring on the waterproofing layer. We fill all the joints between the ring and the base with a waterproofing mixture. Generously lubricate the upper cut of the ring with this mixture and place the next one on it. We lubricate the end again, and place the floor slab on the second ring. A truck crane is no longer needed. Remove any mixture that goes beyond the rings with a spatula. The edges of the caisson must be smooth, especially on the outside. We lay a welded mesh of reinforcement at the bottom of the well and fill it with concrete 400. Its composition is: cement - 10 l, sand - 11 l, crushed stone - 24 l. The layer thickness is 12 cm. The prepared concrete is also poured into the rim of the slab. Reinforce the fill at the top of the well to prevent cracking.

Equipment and materials

We prepare everything necessary for constructing a well in this way.

List of tools and equipment:

- excavator;

- truck crane;

- shovels;

- Bulgarian;

- roulette;

- bubble level;

- concrete mixer;

- boards;

- wood hacksaw;

- hammer;

- rule;

- concrete trowel;

- knife;

- roller;

- burner;

- spatulas;

- hammer drill with crown.

Installation diagram of a caisson made of concrete rings.

- sand;

- crushed stone;

- cement;

- reinforcing mesh;

- nails;

- knitting wire;

- rings of wells with a diameter of 1 or 1.5 m;

- well floor slab;

- well cover with shell;

- bitumen roll waterproofing;

- primer;

- bitumen mastic;

- waterproofing mixture;

- penetration for concrete;

- sheet polystyrene.