Tuning and auto gadgets / From Ekaterina Larina

- Does it make sense to change the spring suspension to pneumatic

? Features of using hydro, pneumatic and conventional suspension

- Manufacturing procedure

Assembling the front struts

- Video: installation

You can argue about pendants endlessly. Some people speak out for modern “pneumatics”, while others speak for spring “classics”. However, all car enthusiasts agree that air suspension really gives the car additional stability and maneuverability. Some of them, if desired and have basic skills, can make and install it on a car with their own hands.

Air suspension diagram

The air suspension on the car is built according to a four-circuit design with 8 valves, 2 valves per cushion - one valve for air supply, the second for return. The scheme will allow you to effectively control each air spring: lower the left side, raise the right side or vice versa, lower the front of the car and raise the rear, etc.

Fig.1 Moskvich-2140

Fig.2

Installation of air suspension using the example of a VAZ

When creating an air suspension for a VAZ passenger car, the most difficult process is installing air bags instead of shock absorber struts. The best option is to use the original rack housing.

VAZ with air suspension

First, the front suspension is disassembled. To install the air cylinder, you may have to bore the body or adjust the cushions to the diameter of the glass using the same turning. There is an option to create an adapter, where one part will fit tightly into the body in place of the shock absorber, and the other will become the basis for the air spring. Determine all these operations locally, taking into account the specific car model and the type of cylinders used.

The air inlet connection must be properly protected when installed on the machine together with the rear cylinders. At the next stage, tubes are laid and connected to the receiver and pneumatic cylinders. In the trunk we install the receiver itself with pressure gauges in the cabin. Taking into account the high load on the front axle of the car at the front, the pressure must be set within 8 atmospheres, and at the rear it is usually enough to reach 6 atmospheres.

Secure the compressor well and lay out the electrical wiring, install toggle switches, unit switches, and fuses. Place all of the listed elements where it is convenient for you. The main thing is that you have the opportunity to constantly monitor the pressure in the system. If you plan to frequently change air suspension modes, consider the ability to control the compressor from a remote control.

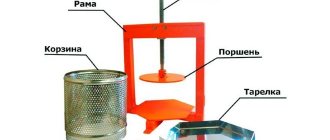

Air suspension components

Unfortunately, they do not produce ready-made air suspension kits for domestic cars, so I assembled the air suspension with my own hands. The main components of the air suspension are air springs from America . Having studied the range of produced airbags, taking measurements with a ruler so that the air pillows would fit in place of the springs and not rub against the lower arms, an order was made.

Also, solenoid valves were delivered from America. In addition to all of the above, we purchased: fittings, tees, nipples, etc., a compressor - from a car store, an oxygen hose - from the construction market.

For the front suspension, RE-5 air springs from the American company Slam Specialties were chosen. The outer diameter, depending on the load and pressure, is 130-139 mm. If the diameter was larger, the air bags rubbed against the sides of the lower arm. In addition, the RE-5 has built-in bump stops, so the car's standard bump stops are not needed. For the rear suspension, Dominator 2500 cushions were purchased.

Fig.3 PP

How to make an air suspension with your own hands and install it

The key to the success of this enterprise is the correct selection of materials and preparation of tools. So, for work you will need standard equipment that almost every driver has:

- angle grinder (grinder);

- metal brush;

- hammer;

- knife;

- sealant.

The choice of materials will require special ingenuity from the master, since sometimes affordable elements can be used instead of expensive recommended products. To make your own air suspension, you will need to buy:

- racks included (regardless of the reliability of the existing racks, you will need to purchase a new pair);

- air suspension cushions (the most budget option is from a Scania car of the fourth generation);

- receiver (you can save significantly on the purchase of this element if you have a gas cylinder from a VAZ 2109. The cylinder already contains a valve mechanism for “return” and is resistant to high air pressure);

- two pairs of solenoid valves (the best option is valves with a pressure of up to 25 atmospheres);

- several different PVC pipes and fittings to connect them. It is important to select tubes with a diameter of 6 mm and 8 mm - they are mounted in different parts of the system;

- The compressor is one of the main elements of the pneumatic system; its choice should be taken as responsibly as possible: it is better not to skimp on quality;

- control unit - any simple unit will do, the main thing is that it is equipped with three toggle switches;

- pressure gauge - it is recommended to buy two devices at once (one is mounted between the compressor and the receiver, the other - in the cabin at the driver’s request);

- moisture and oil separator - any.

Having prepared all the necessary material and tools, you can begin assembling the air suspension.

Manufacturing procedure

The front struts with pneumatics are made according to a more complex design than the rear struts. Therefore, we present two technologies.

Assembling the front struts

- Knock off the cap from the stand and use a grinder to clean off the paint layer.

- Press the adapter onto the stand; to ensure maximum softness, spacer rings can be added under it.

- Fittings or tubes with a small diameter can be connected to the air supply holes in the adapter.

- A pneumatic cushion is installed on the rack. It is necessary to calculate the height of the bump stop in advance, otherwise if there is a strong impact on the road, the spring may fail.

- To seal the connection, a copper press washer and sealant are used.

- Next, the support bearing is attached to the rack. It must be fixed in such a way that when the steering wheel is turned, the rod does not turn inside the shock absorber.

- The air tube is connected to the cushion socket.

- The pneumatic front strut is ready to be installed on the machine. The second rack is made using the same principle.

Rear strut assembly

- Trim the spring cup a little and clean it of paint.

- Cut threads for pneumatics to the end of the strut rod.

- Before putting the air spring on the rod, we install a press washer for sealing.

- The bump stop can be omitted, in which case the rear of the car will be lowered very low and at the same time create a unique smoothness of movement.

- The air spring must be pressed onto the shock absorber completely.

- After this, you can add air.

Video: how to assemble a rear pair of shock absorbers with air springs

Installation procedure

To install new suspensions, you will first need to remove the struts from the car. Even a novice driver can cope with this procedure - just jack up the car. After which the work will need to be carried out in the following order:

- Install the rack into an existing hole (the option of creating new holes is allowed).

- Remove the rubber bands and stretch the air supply tubes. Secure the tubes with clamps to the car body.

- The cylinder (receiver) is mounted on a special bracket, which is located next to the gas tank.

- The tubes from the airbags are routed through the steering rods. They will need to be brought into the engine compartment and routed to the relief valve and the valve that is installed on the receiver.

- Next, the pneumatics are connected to the toggle switches of the control unit.

- After which the installation is considered complete.

Video: installation

How to check

Immediately after installing homemade pneumatics on the shock absorbers of the car, you will need to make sure that the system is working. To do this, pressure is pumped up to 8 atmospheres. You should make sure by ear that there are no leaks in the system (no characteristic hissing of air can be heard).

After which it is necessary to set the pressure in the system for the front airbags to 8 atmospheres, for the rear ones - 6. The first time it is better not to rush into pumping air, since the compressor can pump over the system.

Next, it is recommended to adjust the vehicle's wheel alignment.

Air suspension valves

The electromagnetic type valves for the air suspension were controlled under a voltage of 12 volts. The valves have a flow area of 15 mm and this allows them to pass a huge amount of air through themselves, which will make it possible to very quickly pump and bleed air from the air bag. With these valves, the Mosvich will rise and fall in one second. The valves are connected with 0.5 inch plumbing threaded fittings.

Fig.4 Air suspension components

At the very beginning, the Berkut R17 compressor was used for the air suspension, but its performance was rather weak. Therefore, it was replaced by the Berkut R20 compressor, which is half the price of a similar design Viair 400P.

Fig.5 Berkut R20

Does it make sense to change the spring suspension to pneumatic?

Available statistics indicate that most owners of budget vehicles are dissatisfied with the handling and stability of their cars when cornering. Replacing a conventional spring suspension with a pneumatic one can immediately change ordinary movement indicators:

- create the required ground clearance;

- increase smoothness by increasing sensitivity;

- make car trips more comfortable;

- eliminate body sagging even at maximum load.

However, before changing a conventional suspension, for example, on a VAZ, it is recommended to calculate all the disadvantages of such a replacement:

- high cost of assembled air suspensions;

- if any of the suspension elements fail (for example, a valve, compressor or receiver), you will have to change the entire system - replacement for spare parts will not be possible;

- Unlike spring suspension, air suspension reacts worse to changes in temperature conditions and reaction with road chemicals.

Air suspension is a rather controversial issue. It's hard to say whether this is good or bad... Firstly, it's expensive. The installation itself is expensive, even if you do it yourself, and then maintenance must be done, and if repairs, then again, expensive! I wouldn’t put it on a Moskvich or a VAZ

Yurets

https://vsepoedem.com/story/pnevmopodveska-svoimi-rukami

Features of using hydro, pneumatic and conventional suspension

Do not forget that modern cars can be equipped with a hydraulic suspension, which works thanks to a special fluid. Hydraulic suspension is considered more reliable than pneumatic suspension, as it provides a service life of up to 400 thousand kilometers. However, hydraulic elements are sensitive to the level of lubrication and, if they dry out, fail.

A conventional spring suspension has minimal cost and is easy to repair or replace. When both hydraulic and air suspensions are expensive, and in the event of damage to any element, the entire unit immediately loses its functionality. However, when comparing hydraulic and air suspensions, most drivers choose “pneumatic” due to its greater availability and wider range of settings.

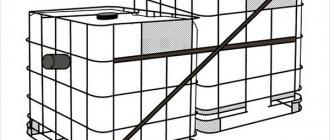

Receiver

The receiver for the air suspension is an air cylinder with a volume of 20 liters from the brake system of a KAMAZ vehicle. Some modifications were made: the U-shaped supports were welded, cut from a channel and painted. It has 5 holes - two at each end, and one for draining condensate.

Fig.6 Receiver

Reviews

- Dmitry, 29 years old. I installed an air spring on my VAZ. I would like to note that the ride quality has become much better. I can handle the roughness of Russian roads much easier than when I had standard shock absorbers. And most importantly, there is nothing complicated in the device, and the wear resistance is an order of magnitude higher.

- Roman, 26 years old. I recently purchased a wonderful house outside the city. But driving my car on country roads is akin to suicide. After consulting with more experienced car owners, I decided to try installing air springs. Since I myself am a complete zero in the technical part of the car, I immediately drove it to the service center, deciding to entrust this matter to professionals. Installing air springs on my Ford didn't take long. And the result exceeded my expectations. My iron horse flies through the countryside as if on wings. No bumps are scary for him, no holes cause problems now. I'm happy.

- Vladimir, 32 years old. I decided to change the air springs myself. Still, you need to get to know your car from the inside. Someday this might save me a lot of money. In the meantime, I did this for the first time and to say that I was tired in the process is to say nothing. Firstly, they are very difficult to get to. By the time I figured out which screws were responsible for fastening the air spring, I was relieved. Secondly, they are not easy to get. And what can we say about installing new products and attaching them back... In general, this is a labor-intensive task and, at first, takes a lot of time. But if you get better at it, the process will undoubtedly go faster. Still, it’s convenient to drive on Russian off-road roads with them.

Installing air springs on the front axle

The main feature of the front axle of cars from the 60s to the 80s is the placement of shock absorbers inside the springs. Therefore, we had to place the shock absorber differently. We also had to move the brake lines. The PP fastenings were made using metal pads 3 mm thick. The upper one is attached to the cross beam and the lower one is attached to the lower arm.

Fig.7 Front axle

Fig.8 Disassembled front suspension

Fig.9 Air bags

Fig. 10 Shock absorber on a new mount

Fig. 11 Front axle with air spring

Fig.12 Front air suspension

How to make air suspension

The air suspension developed in our company is installed instead of standard springs or serves as an additional elastic element to the spring leaves.

DIY air suspension

16001200Do-it-yourself air suspension Do-it-yourself air suspension - find out how to properly install the air suspension on your car yourself

Select one of the air suspension kit mounting options and determine the optimal installation location:

- For spring suspension - the location where the bump stop is attached.

- For a spring suspension - at the place where the spring is installed, where the pneumatic element will be placed.

Next, you should measure the places intended for installing special air spring mounting brackets. In this case, you need to take into account the design of the standard suspension:

- Overall and connection dimensions.

- Allowable free space.

- Working stroke of standard suspension.

It is also necessary to consider the purpose of the pillow:

- To compensate for the load capacity, bellows-type pillows are installed.

- For a comfortable ride, install a sleeve-type cushion.

Based on the design features of the suspension and the desired result, a suitable air spring is selected.

It is best to make brackets for attaching air bags yourself or order them from a specialist. For the manufacture of brackets, you can use carbon structural steel with a protective coating 6 mm thick or alloy steel of similar parameters.

Installing air springs on the rear axle

A 5 mm thick corner was attached to the spar, which served as an upper support for the Dominator 2500 PP. The lower mount of the PP was made of several plates, which were secured between the springs and spacers. Spacers were needed so that in the lower position the body would lower onto the bump stops. The spring leaves were reduced to 3 pieces, and the stepladders were replaced from IZH-2715, since they are longer.

Fig.13 Details

Fig.14 Rear inflated PP

Fig.15 Rear air suspension

Air suspension control

Air suspension controller installed inside the car

Any high-quality air suspension is equipped with a controller that is installed in the cabin. On its display, the driver can see both the pressure in the air bags and in the receiver. The car owner can choose pressure measurement units at his own discretion. The control units of high-quality four-circuit suspensions allow drivers to choose from several preset modes with a certain ground clearance (in particular, the Air-Lift air suspension, discussed above, has 8 such modes). The driver can select the desired mode with just one click of a button.

Moreover, over time, the driver will not need to click buttons at all, since the system will gradually “learn” the car, “get used” to its operating conditions, to the driving style of the car owner, and will itself maintain the optimal pressure in the air bags.

The air suspension is turned off from the same controller. When turned off, the system sets the average ground clearance, after which the air springs begin to work like regular spring shock absorbers.