- Full title

- Purpose

- Technology.

- Application

- Ranges

- Description of the model range, configuration and modifications

- Specifications

- Offer from the official dealer of Ideal-werk - Technomeridian company

- Announcement!

- welding of metal band saws;

- welding of wood band saws;

- welding of stainless steel band saws for meat and fish;

- welding of band knives for leather, textiles, foam rubber, etc.;

- welding (joining) of a strip (strip) in continuous lines (profiling, coating, etc.) in the photo:

Technology

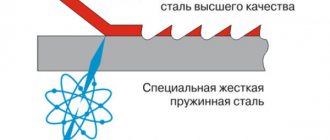

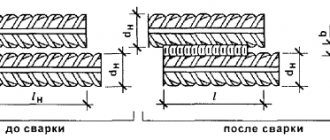

The strip web is unwound from the coil and cut to size, taking into account the allowance for melting and upset and taking into account the preservation of the tooth pitch after welding. Although for flash butt welding on BAS type machines the quality of end preparation is not as important as for resistance butt welding (see BSS resistance welding machines), but still, the higher it is, the greater the chances of getting a good seam. Therefore, it is important to use good guillotine shears for cutting band saws (see guillotines AHE, APE from IDEAL-Werk) to obtain a joint without burrs and strictly perpendicular to the back of the band saw.

For large volumes of production of ring-welded band saws and knives, special machines are used for unwinding the saw from a coil and measuring cutting taking into account the tooth pitch (see machines for unwinding and automatically cutting a band saw to size from a coil).

Next, the ends of the blade (or strip) are clamped in the clamp jaws of a butt welding machine for welding BAS band saws. For welding small flat sections, as in this case, a current supply on one side is sufficient, so the electrode jaws are located on the bottom side, and on the opposite side are hardened steel pressure plates or segments. The installation of the saw to be welded in the jaws is carried out with the ends centered at the center of the adjustable distance between the clamps, called the installation length.

The drive of the clamps in BAS butt welding machines, manual, pneumatic or hydraulic, is implemented in proportion to the maximum applied upsetting force. Next, after starting the welding cycle, a slight pressure is applied to the ends through a movable clamp to create electrical contact and an electric current is applied (in fact, the pressure cyclogram is a little more complex, but the above reflects the essence). The movement of the movable jaw with the clamped end of the band saw is controlled by a motor through cams. The upsetting force is not applied to the joint immediately, this is what distinguishes the method from the resistance welding method implemented in the “devices” for welding band saws using the BSS IDEAL-Werk resistance welding method. In the melting interval of the welding cycle, the contacting peaks of micro-irregularities of the ends instantly melt and explode due to the high density of the flowing current, causing abundant sparking and splashing of metal in the plane of the joint. As a result, oxides, fats and other contaminants are removed from the joint, and if the planes of the ends are not aligned due to relatively poor trimming, then as a result of melting, their alignment occurs.

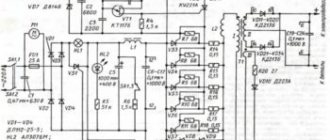

At the end of the melting interval, when the cam rotates to a certain angle, the full specified upsetting force is applied to the movable clamp by a spring, pneumatic or hydraulic drive. Adjustable parameters of the welding cycle:

- welding current

- welding time

- upset force (with sufficient clamping force)

- movement of the movable jaw during upsetting under current

- time and distance of melting (in a general sense – a cyclogram of the process)

After welding band saws made of alloy and high-carbon steels, it is necessary to anneal the seam to restore the ductility of the weld metal. In semi-automatic tabletop butt welding machines for welding band saws models BAS 040, BAS 050, BAS 060 and BAS 065 manufactured by IDEAL-Werk, the opening of the clamps to the installation length increased for annealing and the centering of the seam is done manually. In the fully automatic butt welding machines for band saws and knives BAS 051, BAS 052, BAS 100 and BAS 120 (discontinued) and in the new generation BAS 3xx machines, the clamps are moved apart and the band saw is re-engaged while maintaining the centering of the seam between the clamp jaws.

Annealing is carried out with visual control by the operator of the annealing temperature by the color of the heated metal and time control with a button. By installing the potentiometer, you can adjust the annealing current. When installing a pyrometric control and annealing control system on a butt welding machine for welding band saws BAS, you can set annealing programs and carry out annealing in automatic mode.

During contact butt welding, a burr with sharp, torn edges is formed on the seam. It is cleaned on grinding (cleaning) machines SMH and SMP manufactured by IDEAL-Werk, using abrasive cup-shaped wheels. Devices for stripping seams on band saws after welding are equipped with clamps with pads and an adjustable backing for the blade under the seam. The selection of grain size, its hardness and binder is also important so that abrasive wheels are consumed less and the seam does not burn out, i.e. repeated heat treatment as a result of heating when deburring with abrasive. Deburring is an important operation after welding a band saw because... its remains will act as stress concentrators during operation of the band saw.

When butt welding strips in continuous lines, automatic welding machines IDEAL BAS 330 (or BAS 100) and IDEAL BAS 340 (or BAS 120) flash welding are advantageous in that the welding cycle time and automatic seam cleaning are quite short (10 -15 seconds with the deburring device installed), which is important for lines operating at high speeds.

Band saw welding machines

As a rule, a machine for welding band saws works like this: the ends of the saw are clamped in clamps, joined, and then a current is passed through them, which melts and welds the edges of the ends. Current is supplied through electrodes, which are connected to clamps.

There are different types of such devices. Next we will look at how they differ. Conventionally, they can be classified into three groups.

Resistance welding machines

These devices are cheap, compact, not very productive and are intended for small volumes of work - for example, for repairing saws at industrial sawmill sites.

Features of the technology require high quality seam preparation, high quality electrodes, good adjustment of clamps and correct mode settings.

Reflow welding machines

The performance is significantly higher; such devices can be classified as middle class. They operate on the principle of continuous reflow and are intended for welding all types of blades, including bimetallic ones.

Features of the technology are high requirements for the surface of blades and electrodes, the need to maintain the correct tooth pitch taking into account metal losses. A correctly selected mode is characterized by a good, even melting process throughout the entire welding process.

Automated flash welding machines

The welding process is automated; the operator only needs to install saws into the machine and remove the welded blades. Such devices have good performance and are usually used in service centers.

In addition to welding machines, when welding band saws, some auxiliary equipment is required - blade guillotines, stripping machines, pyrometers, and so on.

Application

BAS band saw welding machines are the most common in the world and in Russia for welding band saws (of course, among companies providing professional services for welding band saws). Ideal-werk developed these machines before anyone else and has been refining these machines for TENS of years, and continues to improve. An example of the latter is the new generation of automatic machines for welding band saws - the BAS 300 series. The simplicity and sophistication of the design allows the machines to be “in service” for up to 20 years or more! No one has been able to repeat the success of Ideal Verka. Copies of BAS 050-01, such as the Chinese FL-50, are of course cheaper, but, among other things, they are not durable.

The main application of BAS butt welding machines from IDEAL-Werk is, of course, ring welding of band saws and knives. Many companies throughout the country provide services for the supply of ring-welded band saws and knives.

In addition, it is beneficial for factories with a large fleet of metal band sawing machines or woodworking factories with a large number of sawmills to have this joint welding machine in place in order to purchase blades in coils.

With a small number of sawmills (or when welding wood saws up to 50 mm for your own needs), we can recommend inexpensive, relative to BAS series band saw welding machines, BSS resistance welding machines for wood band saws. However, repairing saws on BSS resistance welding machines is not an easy task.

Do not forget that the machines for welding bandsaw blades of flash welding BAS are full-fledged butt welding machines of resistance flash welding and can also be used:

- for welding strip rings

- for joining workpieces made of high-carbon steels, alloy steels, spring and spring steels.

- when modifying electrodes and clamps, for welding small parts of round or rectangular cross-section.

Equipment

Machines for welding band saws are divided into stationary and mobile. The latter are pulsed units using the principle of a welding inverter. Stationary machines for welding band saws operate on a three-phase 380 V network and have increased technological capabilities.

The sequence of operation of the machine for butt welding of band saws is as follows. The workpiece is fixed in a clamping device, which has two sides. The left, stationary part is electrically isolated. The right one – movable – is connected to the ground electrode. After clamping the edges of the torn saw blade, both parts are brought closer together and clamping pressure is applied to them. The source of pressure can be:

- Mechanical transmissions of the “screw-nut” type (for portable devices).

- Spring (also used in homemade devices).

- Compressed air energy.

- Hydraulics.

Most designs use a pneumatic clamp, which is convenient since you will still need a fairly powerful fan to cool the welding machine.

During the heating process, the compressible edges of the blade melt. After this, the pressure must be maintained for some time in order to remove fusible impurities from the weld. At the same time, energy consumption is practically not reduced. This disadvantage is absent in machines for welding band saws, which implement the contact flash welding method. In this case, pressure is not applied to the workpiece all the time, but only at the final moment of the process, when the current (due to large gaps) has already heated the edge of the blade to a sufficiently high temperature.

Ranges

The IDEAL-Werk company has existed since 1923. Since that year, the founder of the IDEAL-Werk company, Clemens Jungelblodt, has been developing technologies for soldering band saws and then butt welding. IDEAL-Werk has the greatest experience in this area.

In addition to BAS butt welding machines for flash welding, IDEAL produces:

- resistance butt welding machines – BSS machines;

- electric arc MIG-MAG or TIG welding machine BLS (for wide strips of wood).

On machines from the BAS range it is possible to weld

- wood strips with a width from 5 to 206 mm;

- metal strips with a width from 3 to 105 mm;

- band knives for textiles, foam rubber, etc. width from 5 to 120 mm;

- stainless steel band saws with a width of 5 to 60 mm;

- low-carbon steel strip with a cross-section of up to 360 mm².

Band saw welding process

Let's look at welding technology. As mentioned above, it is divided into several stages, which will be considered in order.

Fabric preparation

Before welding the fabric, it must be prepared. Preparing the saw consists of several steps.

Blade cutting

The fabric is cut using special guillotine shears. If there are none, you can cut the blade using a chisel or cutting machine. If welding is supposed to be carried out along an area that was welded before, then 5 millimeters must be cut off on each side of the previous seam.

The blade is cut between the tops of the teeth. An allowance of about one and a half millimeters is left on each side. The cutting line should be strictly perpendicular to the back of the saw.

Band saw, a very flexible but fragile tool

Stripping the ends

The prepared canvas must be cleaned. To do this, they are cleaned of contaminants and, if necessary, cleaned with acetone or alcohol. The edges are treated with abrasive material, removing burrs and irregularities - this is conveniently done on a sharpening machine.

This is followed by welding of the fabric. The prepared fabric is fixed in the machine and welded.

Installing the saw into the machine

The prepared blade is mounted in the clamping mechanism of the machine for welding band saws so that the edges of the blade completely coincide and are located in the middle of the space between the clamps. The force, upsetting mode and upsetting stroke are selected depending on the blade - the documentation for the devices contains tables with information about the modes for various blades. The selected mode is set by turning the control handles.

Welding the blade

The machine is started by turning the switch or pressing a button. In this case, current begins to flow to the electrodes and melts the metal at the junction. The movable clamp goes to the stationary one and forms a weld bead at the seam site.

An important parameter is the current supply time. As a rule, with automatic welding it is one or two seconds, with manual welding it is controlled by the operator.

If the welding was unsatisfactory, suitable settings are selected and recorded; in the future they are used for welding similar sheets.

The electrodes must be clean. Poor contact between the electrodes and the blade increases resistance and disrupts the welding process.

To connect saws, special installation is required

Model range, modifications and equipment of BAS IDEAL machines

Model range of BAS machines:

- semi-automatic machines for welding table-top band saws with manual clamps: BAS 040, IDEAL BAS 050 01, BAS 060-01

- semi-automatic machines for welding table-top band saws with hydraulic clamps: BAS 050-11, BAS 065-11

- automatic floor-mounted machines for welding band saws with pneumatic alligator-type clamps and pneumatic upsetting drive: BAS 051, BAS 052 (models discontinued from 2021, see BAS 310 and BAS 320)

- automatic machines for welding band saws, floor-mounted, with vertical hydraulic clamps and pneumatic drive upsetting: BAS 100, BAS 120 (models discontinued from 2021, see BAS 330 and BAS 340, and for wide band knives BAS 330 BM and BAS 340 BM)

- semi-automatic machines for welding band saws, floor-mounted for wide band saws on wood, with manual and hydraulic clamps and pneumatic upsetting drive: BBA 121, BAS 160, BAS 210 (models discontinued from 2021, see BAS 360)

- Resistance welding machines for band saws of the new (!) BAS 300 series: BAS 310, BAS 320, BAS 330, BAS 340, BAS 360

(Similar in characteristics to the previous series - BAS 051, BAS 052, BAS 100, BAS 120, BAS 210)

BAS machine equipment:

As standard, butt welding machines for band saws - BAS - are equipped with a button for manual annealing control, with visual temperature control.

As additional equipment, IDEAL-Werk offers:

- potentiometers for desktop machines for manual adjustment of welding current with visual temperature control;

- systems for pyrometric control and automatic control of the annealing cycle;

- automatic centering stop for automatic machines IDEAL BAS 051, BAS 052, BAS 100, BAS 120, BAS 310-340;

- automatic loading device for narrow webs for automatic machines IDEAL BAS 051, BAS 052, BAS 310, BAS 320;

- controller of welding parameters for automatic machines;

- hydraulic deburring device for automatic strip welding machines BAS (for models IDEAL BAS 100, IDEAL BAS 120, BAS 330, BAS 340).

Modifications of BAS machines:

- Horizontal clamps

- When using shaped electrodes, BAS machines are applicable as butt welding machines for welding other products: welding the shank to the working part of the tool (drills, spindles with a threaded end, etc.), welding parts of kitchen stoves, etc. and so on.

Welding band saws - devices, technology

Band saws are widely used throughout the woodworking industry, carpentry, furniture industry, etc. They are used in various sawmills, band saws and band dividing machines.

A feature of band saws is a continuous cutting surface, which is a ring of metal tape with teeth. To make band saws, a pre-prepared tape is welded into a ring. Welding is also used to repair broken saws. The technology of welding band saws will be discussed in the article.

Band saw welding technology

It is divided into several stages - preparation, sharpening, welding and setting the teeth of the resulting saw. Due care must be taken at all stages. Let's take a closer look at the technology.

Repair of band saws has its own characteristics

Technical Specifications of Band Saw Welding Machines

| Model | BAS 040 | BAS 050-01 050-11 | BAS 060-01 | BAS 065-11 | BAS 051 (310) | BAS 052 (320) | BAS 100 (330) | BAS 120 (340) | BBA 121 | BAS 150 | BAS 160 | BAS 210 (360) |

| Rated power (50% duty cycle), kVA | 3,5 | 4,5 | 10 | 20 | 7,5 | 25 | 25 | 45 | 25 | 120 | 45 | 70 |

| Width of welded metal band saws (bimetallic, tungsten alloyed), mm | 3 — 27 | 6 — 34 | 10 — 41 | 10 — 54 | 6 — 41 | 6 — 54 | 15 — 81 | 25 — 105 | 67 — 130 | |||

| Width of band saws for wood, mm | 5 — 40 | 6 — 50 | 10 — 60 | 10 — 60 | 3 – 50 | 6 — 50 | 15 — 100 | 25 – 120 | 25 — 120 | 70 — 150 | 25 — 160 | 35 — 215 |

| Width of stainless steel band saws, mm | 5 — 20 | 6 — 30 | 10 — 40 | 10 – 40 | 6 – 30 | 10 — 50 | 25 — 50 | 25 – 60 | 25 — 60 | 30 — 80 | ||

| Width of band knives, mm | 5 — 20 | 6 — 30 | 10 — 40 | 10 — 40 | 6 – 50 | 6 – 50 | 25 — 80 | 30 -120 | 60 — 150 | 30 — 120 | 40 — 120 | |

| Max. cross-section of welded strip made of stainless steel, mm2 | 40 | 75 | 90 | 90 | 100 | 150 | 200 | 250 | 200 | 250 | 360 | |

| Max. clamping width, mm | 40 | 50 | 60 | 60 | 50 | 50 | 90(100) | 120 | 120 | 150 | 160 | 217 |

| Net/gross weight, kg | 80/100 | 140/185 180/220 | 250/350 | 290/390 | 460/560 | 460/560 | 600/700 | 625/725 | 300/- | 430/- | 660/- | |

| Packaging dimensions WxDxH, cm | 59 73 64 | 100 88 68 | 115 100 90 | 115 115 115 | 120 107 138 | 120 107 138 | 100 135 170 | 100 135 170 | — | — | — |