How to check welds

In fact, a variety of methods can be used to examine welds, for example, ultrasonic, magnetic, chemical, capillary and other high-tech methods. However, the classic one, which is still relevant and in demand today, is a simple visual inspection. Its purpose: to make sure that the seam is of high quality, well welded, and has no undercuts, sagging, burns, excessive scaliness or other flaws. The advantages of this type of research are quite obvious: it does not require large expenses, it is accessible and quite informative, but along with this there are also disadvantages: the subjectivity of the examination, low reliability, the ability to examine only the visible part of the seam.

Visual inspection can be carried out both with the naked eye (usually, if we are talking about large, clearly visible seams), and with the help of various devices, such as lenses, microscopes, endoscopes, flaw detectors, etc.

They are used to identify the smallest hidden defects that are difficult to detect by simply examining the outside of the weld (for example, microscopic cracks, nicks, delamination, fractures, etc.). At the same time, there are devices that are intended only for use in laboratories and those that can be used “in the field.” The latter are able to withstand any temperature and weather conditions (including those that have an increased coefficient of radiation, chemical, bacteriological, etc. danger to humans).

A simple optical method for confirming the quality of metal welding

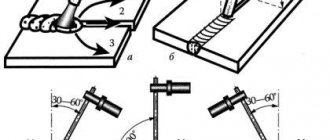

Control of any welding joint begins to be carried out even when the weld is directly created. Visual inspection is part of the welder’s work, and he periodically conducts an external inspection (for lack of penetration, undercutting and leg fidelity) several times until the entire scope of work is completed. This is also the oldest method of monitoring the final work and its essence has not changed significantly, but the implementation methodology has improved in recent years. Weld check

Theoretical definition and tools for implementation

Visual-measurement control (VIM) of welds is an external inspection of fairly large welded structures, both with the naked eye and with the help of various technical devices to identify smaller defects that are not amenable to initial visualization, as well as using converters of visual information into telemetric information. VIC refers to organoleptic (carried out by the senses) control methods and is carried out in the visible spectrum of radiation. A visual inspection in search of theoretical defects is carried out from the outside of the weld, where, if they are detected, minimal measurements can be taken using optical instruments and tools, and a visual inspection report can be concluded.

Inspectors use several types of tools when performing visual inspection of welded joints.

- Survey, telescopic, floor magnifiers;

- lenses;

- microscopes;

- endoscopes, etc.

To carry out monitoring under various operating conditions:

- Instruments for workshop purposes. Operating temperature range from +5 °C to +20 °C, conditions of complete rest, normal atmospheric pressure, moderate humidity.

- Field use devices. Operating temperature range from -55 °C to +60 °C, conditions of moderate shaking, vibration, precipitation.

The use of these devices allows for a more accurate search for defects and visual-optical quality control of welds on any objects.

Visual-optical control is the second stage of visual control with a wider, increased range of examination due to the use of optical instruments. Depending on the application, the method is intended for three main groups:

- To search and analyze hidden objects. The following devices are used: endoscopes, borescopes, video systems, periscope flaw detectors.

- To carry out inspection of objects remote from the flaw detector’s workplace. Range of application – a distance of no more than 250 mm from the controller’s eye. Equipment used: telescopic magnifying glasses, binoculars, spotting scopes.

- For examining small nearby objects. The range of application from the specialist's eye is at a distance equal to or less than 250 mm. Equipment used: magnifying glasses, microscopes.

Visual inspection of welds is also required in conditions where the human senses are unsuitable for work. In areas such as: elevated temperatures, dangerous background radiation, external chemically active environment and others. And also in conditions where the configuration of the object under study and its design do not allow a full analysis of the quality and measurement of defects in welds (for example, due to the large height of the object or its underground location). Then, in addition to optical instruments, the following are used to search and analyze hidden objects:

- remote control platforms;

- thermal imaging installations;

- lighting devices;

- automatic transport systems;

- controlled robots.

Thus, visual information converters make it possible to control the welding seams of a bath of hot metal during the remelting process.

Measurement control is an important component of VIC, which is carried out in accordance with strict control rules and regulatory documents governing quality. It consists of assigning a category or type to a defect according to one of the characteristics in the form of a specific physical quantity obtained through practical measurement. Measuring instruments and their metrological indicators are specified in regulatory documents. Measuring tool

During measurement control, the following tools are used, which may be included in the mandatory set of a technical supervision inspector or supplement it:

- measuring magnifiers;

- checking squares 90 0 pattern;

- protractors with vernier;

- calipers, calipers and calipers;

- probes;

- micrometers;

- pipe wall meters and indicator thickness gauges;

- micrometers;

- calibers;

- metal length meter (tape tapes, steel measuring rulers);

- micrometric and indicator bore gauges;

- templates: special, radius, threaded, etc.;

- UShS-2, UShS-3 (templates for geometric parameters of seams);

- surface plates;

- a set of special accessories.

This control method, VIC, refers to methods that are feasible with a minimum set of tools. It consists of collecting information and is based on the qualifications of a specialist, the human factor, but allows you to draw up a visual inspection report of welds, which is considered an objective document.

The essence of external control

The quality of the formation of welds on the surface can be easily assessed during professional inspection. The characteristic of a “high-quality” or “poor-quality” seam is quite arbitrary, since this is a comparative value.

Quality control of welds and inspection of structures, pipelines, and buildings are carried out in three interrelated stages.

Step-by-step procedure for conducting the VIC

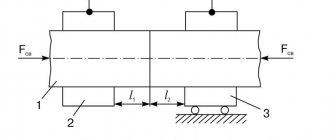

- Visual (measuring) control. Preliminary inspection of the seam for corrosion and possible defects with primitive measurements: width, thickness, leg.

- Quality control of welded joints. Quality control is carried out to clarify the parameters of visible defects (after concluding a preliminary inspection report), the size of defects and distortions of welds (percentage deviation from the permissible standard).

- Detailed (instrumental) research and recording of results. More precise methods are used:

- eddy current method for determining the degree of weld wear and metal bending fatigue;

- ultrasonic testing of welded joints to detect serious deep defects;

- penetrant flaw detection for surface and through defects and so on.

Timely and high-quality inspections make it possible to identify the destruction of a seam or weldability defect in the early stages and then clarify the causes of the defect using any non-destructive flaw detection method.

Advantages and disadvantages of this technique

Advantages of the VIC method:

- A simple and accessible method.

- When collecting information about the quality of a design, it allows you to obtain up to 50% of the total volume.

- It is not labor-intensive and does not require expensive equipment.

- Easily tested and re-tested.

Disadvantages of VIC:

- The human factor, which influences 100% of the results.

- Low reliability of the results obtained, subjectivity.

- Used only to search for large defects (at least 0.1 - 0.2 mm) and suspected possible ones.

- Limitation of the study to only the visible part of the structure.

- The technical competence of employees is important; they must correctly select the measurement method, comparative template or standards and give an accurate assessment of the measurement results.

In terms of the method and quality of diagnostics, even imperfect visual inspection of seams is a necessary method, both at the stage of complex diagnostics and throughout the entire technological process. Universal welder template

Why is weld inspection necessary?

The purpose of such an in-depth examination is quite obvious: as a rule, any structures that use welding are designed to withstand a certain, fairly serious load (this is especially true for building structures). And any deviation from technical standards that occurs during their manufacture threatens that the structure will not withstand and will break, which in turn can lead not only to financial losses, but also to a threat to the life and health of people.

Often, welds are checked not only after the structure is manufactured, but also during its operation - this is due to the fact that they may be subject to corrosion and other adverse effects. Also, regular checks are necessary when surfacing several layers on a worn-out structure, while each completed layer is monitored, the length of the weld, the thickness of the base metal are measured, and these data are compared with the established standard for this area, taking into account its load.

The frequency of inspections is determined by legal norms, as well as internal regulations of the company.

Timely and high-quality visual inspections make it possible to detect seam failure as early as possible, as well as understand the causes and find a way to eliminate them.

Areas of implementation of this technique

External inspection of the weld is carried out before the stripping, thermal or treatment procedure, as well as after its implementation.

When assessing the quality of a weld, VIC is used:

- As an informative method of describing the general external state.

- As a theoretical method for assessing the internal condition of a seam and as a reason for recommending a more accurate inspection.

- As an evaluation method of the operating conditions of a given seam, structure, system and the entire product.

- As a monitoring method for identifying gross violations of the technological process.

- As a method for preliminary conclusion during decommissioning or recording an emergency situation.

- As a predictive method of possible locations of structural failure for a specific set of visible defects found.

- As a final method for assessing and concluding on the correctness, safety and stability of the technological process of manufacturing or repairing a structure.

Visual and measurement control is a very effective method of checking and double-checking the quality of industrial materials and welded joints when performing construction work and when receiving a certificate of completion of construction, a certificate of commissioning, as well as various other technical certificates.

(organization)

ACT No. _______ dated _____________ visual and measuring control

1. In accordance with the work order (application) No. __________________ completed

visual and measuring

inspection

of a welded butt joint,

indicate the type of inspection (visual, measuring)

pipes with a diameter of 76 mm

__________________________________________________________ name and dimensions of the controlled object,

___________________________________________________________________________ documentation code, specifications, drawing, heat (batch), control object number

welded by welder __________ Ivanov I.I.

__________ stamp No. ____ last name, first name, patronymic

The control was carried out in accordance with the technological control chart No.____, RD 03-606-03

__ name and/or code of technical documentation

2. During inspection, the following defects were revealed:

_Exceeding seam reinforcement - 6 mm (67), underestimating seam width - 4.0 mm (163), undercut

__ characteristics of defects (shape,

_1.0x5.0 (50), undercut 0.5x7.0 (149), surface pore 0.8 (100)

____________________ dimensions, location and/or orientation for specific objects)

____________________________________________________________________________

3. Conclusion based on the results of visual and measurement control:

_The weld does not meet the requirements of the normative and technical documentation and is considered unsuitable

________________

____________________________________________________________________________

The control was carried out:

_______________________________________________________ _( _________________) _ qualification level, qualification certificate No. Full name

Head of work on VIC: ______________________________ _( _________________) _ Full name

Control of welds is a necessary part of the approval of various structures before operation. The methods and results of verification actions are reflected in a special act.

FILES

Sample report of visual inspection of welds

If you need to draw up a weld inspection report that you have never done before, use the sample below and read the comments to it - they will help you draw up the required document without errors and ambiguities.

- First of all, enter the name of the enterprise into the act, then assign a number to the document, indicate the date and place of its creation.

- Next, enter into the report the positions and full names of the workers who inspected the weld (if these are representatives of different enterprises, indicate the names of each of them).

- After this, proceed to the main part: include information about the performer of the work: position, full name, then enter here data about the welds that were examined: their number, steel grade and other identification values.

- Indicate the instruments and devices that were used during the inspection, all the methods used, their results, and also give recommendations on additional examination methods.

- At the end, be sure to summarize the current control and sign.

Necessary devices

To carry out monitoring under various operating conditions, the following instruments are required:

- Instruments for workshop purposes. Such instruments can operate at temperatures from +5 °C to +20 °C at normal atmospheric pressure and moderate humidity.

- Field use devices. Such devices can operate in a temperature range from -55 °C to +60 °C and can withstand moderate shaking and precipitation.

When carrying out measurement control, the following tools are used:

- measuring magnifiers;

- testing squares;

- goniometers;

- calipers and depth gauges;

- probes;

- pipe wall meters and thickness gauges;

- micrometers;

- calibers;

- tape measures, rulers;

- special templates, etc.