Characteristics of steel ropes according to GOST 2688-80

Metal ropes and twisted slings based on them are necessary and critical elements of transport and construction equipment, industrial equipment and lifting devices. Steel wire ropes with organic and metal cores are used throughout. Interstate standard 2688-80 defines the types of double lay products with an organic core and linear contact of steel wires. Cables of a similar design, but with a metal central strand, are produced in accordance with GOST 7668–80.

Examples of symbols for steel ropes

- Rope 16.5 - G - I - N - R - T - 1960 GOST 2688 - 80 Rope with a diameter of 16.5 mm, cargo purpose, first grade, made of uncoated wire, right-hand cross lay, non-unwinding, straightened, high precision, marking group 1960 N/mm2 (200 kgf/mm2), according to GOST 2688 - 80

- Rope 12 - GL - VK - L - O - N - 1770 GOST 2688 - 80 Rope with a diameter of 12.0 mm, for cargo purposes, grade VK, made of uncoated wire, left one-sided lay, non-unwinding, unstraightened, normal accuracy, marking group 1770 N/mm2 (180 kgf/mm2), according to GOST 2688-80

- Rope 25.5 - G - VK - S - N - R - T - 1670 GOST 7668 - 80 Rope with a diameter of 25.5 mm, cargo purpose, grade VK, galvanized according to group C, right-hand cross lay, non-unwinding, straightened, increased accuracy , marking group 1670 N/mm2 (170 kgf/mm2), according to GOST 7668 - 80

- Rope 5.6 - G - V - Zh - N - MK - R - 1670 GOST 3063 - 80 Rope with a diameter of 5.6 mm, cargo purpose, grade B, galvanized according to group Zh, right lay, non-unwinding, low-twist, straightened, marking group 1670 N/mm2 (170 kgf/mm2), according to GOST 3063 - 80

Features of design and materials

Steel rope GOST 2688–80 consists of six wire strands , which are twisted into one concentric surface around an organic core.

Natural and artificial materials are used as an organic core, such as:

- sisal;

- hemp;

- cotton yarn;

- nylon threads;

- nylon;

- polyethylene.

The core material is impregnated with a lubricant, which protects it from rotting and increases the life of the product. GOST 15037–69 lubricants are mineral oils containing solid hydrocarbons and copper salts. The organic core provides the necessary elasticity and flexibility of steel cables.

Each LK-R metal strand consists of 19 round wires twisted into three layers. The outer layer contains wires of different diameters, which ensures a linear type of contact in the strands, uniformity and strength of the rope surface. Cables with LK-R strands have high wear resistance and performance.

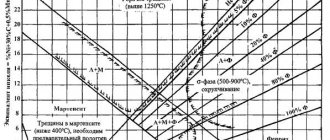

A design feature is the direction of twisting of the rope elements. The direction of twisting of the wire in the strands can be left or right. The combination of directions of elements during laying determines the properties of the cable. Single-laid ropes are flexible, wear-resistant, but easily unwind under load. Non-unwinding structures are made using cross or combined laying methods.

Round wire for steel cables is made from carbon steel without coating or with a galvanized outer layer.

Protective lubricant for steel ropes

The main purpose of rope lubricant is to protect the metal from corrosion. Additionally, the lubricant protects the organic core of the steel rope and reduces abrasive wear of both the external and internal wires of the rope.

Various lubricants are used in production - SK-50, KS-U, Torsiol, Elascon, Nyrosten, etc.

Rope lubrication codes of Severstal Ropes JSC

| Lubrication code | Organic core** | Metal core | Strands of rope | Rope | ||

| S P | PP | strands | generally | |||

| S(A) | — | without lubrication | without lubrication | without lubrication | without lubrication | without lubrication |

| A0 | soaked | — | blurred | without lubrication | without lubrication | without lubrication |

| A1 | soaked | without lubrication | blurred | without lubrication | blurred | without lubrication |

| A2 | soaked | without lubrication | blurred | blurred | blurred | greased |

| A2* | soaked | without lubrication | lubricated*** | without lubrication | lubricated*** | without lubrication |

| A3 | soaked | greased | blurred | without lubrication | without lubrication | greased |

| A4 | without lubrication | without lubrication | without lubrication | greased | blurred | without lubrication |

| A5 | without lubrication | without lubrication | without lubrication | greased | blurred | greased |

| A6 | without lubrication | without lubrication | without lubrication | greased | without lubrication | greased |

* - for lubricants Nyrosten T55, Nyrosten A19/200

** — sisal — S, hemp — P, polypropylene — PP

*** - lubricated without wiping

OJSC MMK-METIZ rope lubrication codes

| Lubrication code | Organic core | Metal core | Strands of rope | Rope | |

| strands | generally | ||||

| A0 | not soaked | without lubrication | without lubrication | without lubrication | without lubrication |

| A1 | — | blurred | greased | greased | without lubrication |

| A2 | soaked | — | — | blurred | without lubrication |

| A3 | soaked | blurred | greased | blurred | greased |

| A4 | soaked | without lubrication | without lubrication | without lubrication | without lubrication |

Rope lubrication codes of SE "KHSPKZ "SILUR"

| Lubrication code | Organic core | Metal core | Strands of rope | Rope | |

| strands | generally | ||||

| Dry | without lubrication | without lubrication | without lubrication | without lubrication | without lubrication |

| A1 | greased | blurred | without lubrication | blurred | without lubrication |

| A2 | greased | blurred | blurred | blurred | blurred |

| A3 | greased | lubricated* | lubricated* | lubricated* | lubricated* |

* Lubricated with rubbing.

OJSC "BMK" rope lubrication codes

| Lubrication code | Organic core | Metal core | Strands of rope | Rope | |

| strands | generally | ||||

| A0 | not soaked | without lubrication | without lubrication | without lubrication | without lubrication |

| A1 | soaked | blurred | without lubrication | without lubrication | without lubrication |

| A2 | soaked | blurred | without lubrication | blurred | without lubrication |

| A3 | soaked | blurred | greased | blurred | greased |

| A4 | soaked | blurred | greased | blurred | lubricated* |

* Lubricated without wiping.

Classification and labeling

The range of products with an organic core and a steel wire sheath is determined by GOST 2688–80. Steel ropes are divided according to mechanical properties, purpose, type of wire material, laying method and direction, manufacturing accuracy and degree of balance.

Classification differences

Cables are divided into types according to their intended purpose:

- GL - cargo-carrying vehicles, which are used for ascent, descent, and movement of people and cargo.

- G - cargo, they are used for transporting and securing cargo.

The following grades are distinguished based on their mechanical properties:

- 1 – quality is normal.

- VK - high quality.

- B - increased quality.

By type of wire used:

- without external covering;

- with a galvanized layer.

Depending on the density of zinc, the following types of galvanized wire are distinguished: Coolant, S, Zh. Cables made of wire coated with Coolant are suitable for use in particularly harsh conditions and aggressive environments. For standard operating conditions in air, wire ropes made from uncoated or coated Group C wire are suitable.

In the direction of twisting the wire:

- Left lay - denoted by the letter L.

- Right lay - no designation.

By combination of wire and strand directions:

- Single-sided lay: with the same direction of wires and strands in the rope.

- Cross: with the opposite position of the wire and strands.

- Combined: when strands of the right and left twisting directions are used simultaneously when laying the cable.

By laying method:

- Non-unwinding - denoted by the letter N.

- Unwinding - no symbol.

Based on manufacturing accuracy, designs are distinguished:

- increased accuracy - T;

- normal.

The balance of a metal rope is determined by the fact whether straightening - straightening the strands - was used in the process of its production. This process removes tension from the cable so the product remains straight after twisting.

Symbol

All symbols specified in GOST are used when marking ropes.

The first digit of the marking is the cross-sectional diameter of the cable, followed by the designation of the type of purpose, quality mark, coating group, direction of lay, curl characteristics, indication of straightening, accuracy and designation of the marking group. For example: Rope 28 - G - 1 - L - 1670 GOST 2688–80. The designation of untwisted unstraightened cables of right-hand lay, normal precision manufacturing and made of uncoated wire will be shorter due to the lack of letters and numbers of the symbol. Only the diameter, purpose, quality group, left lay direction and marking group are indicated.

Straightened, non-unwinding cables of improved quality and manufacturing precision, made of coolant-coated wire, will have the following markings: Rope 21 - GL - V - coolant - N - R - T - 1470 GOST 2688–80.

Types of ropes

1. The ropes differ in design:

- single lay (spiral) - consisting of one, two or three layers of wire twisted into concentric spirals. Single lay ropes twisted only from round wire are called ordinary spiral ropes. Spiral ropes that have shaped wires in the outer layer are called ropes of a closed (Fig. 1, g) and semi-closed structure; When broken, each shaped wire is held in the rope by adjacent wires. Single lay ropes intended for subsequent weaving into a rope are called strands;

- double lay (Fig. 2, a) - consisting of six or more strands twisted into one concentric layer. These ropes can be single-layer or multi-layer. Multilayer lay is characterized by increased flexibility and a large supporting surface, and in addition, it can impart anti-twist properties to the rope. Single-layer six-strand double lay ropes are widely used. Double lay ropes intended for subsequent laying are called strands;

- triple lay (Fig. 2, b) - consisting of strands twisted in a spiral into one concentric layer.

a) b)

Rice. 2. a- double lay rope; b- triple lay rope

2. Based on the type of contact of the wires between the layers, the following types of ropes are distinguished:

- with point contact (TC type: Fig. 3, a). Strands with point contact of wires are produced in several technological operations, the number of which depends on the number of layers of wires. Wire lays have different pitches along the layers of the strand, and the wires cross between layers. This arrangement of elements increases their wear during shear during operation, creates significant contact stresses that contribute to the development of fatigue cracks in the wires, and reduces the coefficient of filling of the rope section with metal;

- with linear touch (LK type: Fig. 3, b). Such strands are produced in one technological step, while the constancy of the wire laying pitch in all layers of the strand is maintained. To obtain a linear touch, the diameters of the wire and strand are selected depending on the design of the latter. Thus, in the top layer of rope strands of type LK-0, wires of the same diameter are used in layers, strands of type LK-R have wires of different diameters in the outer layer, and in strands of type /7/S-Z, wires are used that fill the space between wires of different diameters . There is a type of rope with a linear touch of the wire between the layers and having layers in the strands with wires of both different and identical diameters - LK-RO. In three-layer linear touch strands, there are various combinations of the above types of strands. It should be noted that the performance of ropes with linear contact of wires in strands, with the correct choice of rope design, is much higher than the performance of ropes with point contact of wires;

- with point-linear contact (rope TLK-O). Strands of point-linear touch are obtained by replacing the central wire in strands of linear touch with a seven-wire strand: in this case, a layer of wires of the same diameter with a point touch is laid on a two-layer strand of the LK type. The design of these strands makes it possible to produce them on spinning machines with a relatively small number of bobbins. In addition, TLC strands, with appropriate selection of laying parameters, have increased non-twisting properties;

- with a combined linear-point contact of wires between layers (type 6/7) - the result of screw rolling of round initial strands of the LK type into triangular ones.

3. Characteristics of ropes based on core material have the following types:

- with an organic core (OC). Most rope designs use lubricated organic cores of hemp, manila, sisal or cotton yarn as the core at the center of the rope, and sometimes at the center of the strands, to provide the required flexibility and resilience. It is also allowed to use cores made of asbestos cord and artificial materials (polyethylene, nylon, nylon, etc.);

- with a metal core (MC). It is advisable to use a metal core in cases where it is necessary to increase the structural strength of the rope when multilayer winding it on a drum, to reduce the structural elongation of the rope during tension, and also when operating the rope under conditions of elevated temperature. One of the most common designs of this type is a double lay rope made of 6-7 wire strands located around a central seven-wire strand. The metal core can be made of ordinary rope or soft wire with a tensile strength of no more than 900 N/mm2.

4. Characteristics of ropes in the direction of lay have the following types:

- right lay;

- left lay (L).

a B C D

Rice. 3. Direction and combination of directions of rope lay: a - left cross lay; b - right cross lay; c - left one-sided lay; g - right one-sided lay

5. According to the combination of lay directions of double lay ropes, the following types of ropes can be manufactured:

- with the same direction of laying of wires in strands and strands in a rope. Such ropes are called one-way lay ropes (O): they wear out less and are more flexible, but they unwind easily, especially under load;

- with the direction of laying of wires in strands opposite to the direction of laying of strands into a rope. Such ropes are called cross-lay ropes; their ability to unwind is much less than that of the first type of rope;

- with the simultaneous use of strands of the right and left lay directions in the rope. Such ropes are called combined lay ropes.

Triple lay ropes are made mainly by cross lay with the opposite direction of lay of strands, strands and wires. Strands of flat rope are laid so that the right and left lays alternate. In single lay ropes, the lay directions of individual layers alternate, which provides the rope with non-twisting properties under load. All layers of wires in TK and TLC strands are twisted in the same direction.

The direction of lay is set as follows: for spiral ropes - in the direction of lay of the outer layer wires; for double lay ropes - in the direction of lay of the outer layer strands in the rope; for triple lay ropes - in the direction of lay of the strands in the rope.

6. Characteristics of ropes according to the method of laying ropes have the following types:

- untwisted, in which the wires are not freed from internal stresses arising during the process of twisting wires into strands and strands into a rope. Strands, strands and wires in this case do not retain their position in the rope after removing the bandages from its ends;

- non-untwisting (N), in which, when laying wires into a strand and strands into a rope, internal stresses are removed by straightening and preliminary deformation in such a way that after removing the dressings from the end of the rope, the strands and wires retain their given position. Non-unwinding ropes have a number of advantages compared to unwinding ones: somewhat greater flexibility and a more uniform distribution of tensile forces on the strands and wires, increased resistance to fatigue stress, and no tendency to disrupt straightness when unfolding.

7. Depending on the degree of twist, the types of ropes are distinguished:

- rotating;

- low-rotating (MK). These ropes should be distinguished from non-unwinding ones. In low-twist ropes, thanks to the selection of laying directions of individual layers of wires (in spiral ropes) or strands (in multi-layer double lay ropes), rotation of the rope around its axis is eliminated when the load is freely suspended. A low-twist rope can be made either non-unwinding or unwinding. A prerequisite for the manufacture of low-twisting ropes is the arrangement of the strands in two or three concentric layers with the opposite direction of lay of each concentric row of strands. In this case, the rotational moments of all strands of the rope are balanced, which prevents the overall rotation of the rope around its axis.

8. The characteristics of ropes according to the degree of balance of the rope have the following meanings:

- straightened (P);

- unstraightened.

9. According to mechanical properties, ropes are divided into:

- high quality brands - (VK);

- brands of ordinary quality (B);

- brands 1-1.

10. Depending on the type of wire surface coating, ropes are:

- without cover;

- with zinc coating:

— for particularly severe aggressive working conditions (OJ), — for severe aggressive working conditions (W), — for moderately aggressive working conditions (C); with a rope with a diameter of 3.1-5.0 mm coated with low-density polyethylene.

11. According to their purpose, ropes are divided into the following types of ropes:

- cargo (elevator) (grades B and B), used for lifting and transporting people and cargo (GL);

- cargo - for transporting goods (G).

12. The characteristics of ropes in terms of the accuracy of rope manufacturing have the following meanings:

- normal accuracy;

- increased accuracy (T).

13. Based on the cross-sectional shape of the strands, ropes are distinguished:

- circular-stranded (their cross-section is close to a circle);

- shaped strands (triangular, flat and oval stranded), having a significantly larger surface of contact with the winding organ than round stranded ones, and characterized by a variety of cross-sectional shapes, both of the rope itself and its elements, as well as the physical and mechanical characteristics of the wires and cores. In particular, flat ropes are made by stitching together several round ropes with an even number of strands (from four to twelve), and their cross-sectional shape is close to rectangular. Flat ropes are made from strands with alternating right and left lays and are stitched with strands or rods. Their width in some cases can reach 250 mm.

Twisted round ropes have different lays: single spiral (open, semi-closed and closed types), double from round or shaped (triangular, oval, etc.) strands (from 3 to 8), triple. They can also be low-twist (the number of strands is from 18 to 31 with the opposite direction of lay in individual layers). The diameter of twisted round ropes reaches 100 mm. In combined twisted ropes, the steel strands are covered with a layer of hemp threads or plastic. Stranded ropes consist of tightly packed groups of steel wires or spiral ropes, crimped with spiral wraps or clamps. They are usually assembled at the site of use, and their diameter can reach 1.5 mm, and the breaking force (depending on the diameter) is 1000 N/mm2. Braided ropes are made by interlacing an even number (usually four) of strands, of which one half has a right-handed weaving direction, and the other half a left-handed one; their cross section is a square.

Marking groups, dimensions and weight

The last digit in the rope designation is a marking group that indicates the strength characteristics of the rope. The higher the number, the stronger the cable and the greater the load it can withstand during operation.

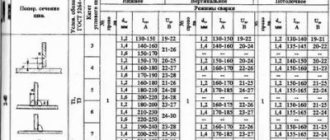

According to GOST 2688-80, ropes are produced with a cross-sectional diameter from 3.6 to 56 mm with strength characteristics from 1370 to 1860 N/mm 2 (140-190 kgf/mm 2). The standard tables indicate the diameters of the ropes, all wire layers of strands, strength characteristics and the approximate weight of 1 thousand meters of cable. The weight of a steel rope GOST 2688–80 can be determined by multiplying the weight value of 1 thousand meters of cable taken from the table by the length of the rope and dividing the resulting value by 1000.

1 thousand meters of rope with a diameter of 12 mm weighs approximately 520 kg; with a diameter of 21 mm - 1630 kg. The weight of one meter of a product with a thickness of 37 mm will be approximately 5 kg, and one meter with a thickness of 56 mm will be 11.6 kg.

Scope of application

The main purpose of steel rope is to perform rigging, towing and lifting operations. High strength combined with flexibility allows the use of metal products in this category to equip lifting equipment and heavy equipment. This includes drilling equipment, cranes, and excavators. In addition, steel wire ropes are used in the production of mechanisms for raising and lowering freight and passenger elevators.

Hoisting ropes with linear contact of wires are used in the creation of:

- lifting installations in metalworking shops;

- mine lifting equipment;

- drilling rigs and mining machines;

- earthmoving and road equipment;

- cableways.

Ship cranes and truck cranes, hoists, winches and scrapers, elevators, drum winches and hydraulic elevators are equipped with steel cables.

The valuable properties of metal cable include its flexibility and the ability to manufacture load-handling devices that can withstand severe mechanical loads. Steel cables and additional elements in combination with which they are used are subject to strict requirements for compliance with state standards.

Excellent mechanical characteristics and corrosion resistance allow it to be used in the construction of critical structures - bridges, overpasses. Concrete structures reinforced with metal cord acquire the necessary strength and the ability to withstand large dynamic and static loads.

The main parameters for choosing ropes are flexibility, strength, load capacity, as well as the maximum tension values. To increase the resistance of metal products to aggressive environments, they can be subjected to additional processing. The scope of application of the rope depends on the material of manufacture, purpose and brand.

Rope. Types and device. Material of manufacture and application

Rope is a woven or twisted fastener made from natural or man-made fibers. Its strength depends on the number of strands used in manufacturing, their material and the method of weaving.

Ropes are widely used to perform various types of work in construction, securing cargo during transportation, etc. Unlike cables, they have higher flexibility and can be tied into reliable knots, and are also lightweight.

Despite these advantages, ropes are not as strong as steel wire weaves, and in addition, their service life depends on operating conditions, in particular humidity.

Classification of ropes by thickness

The diameter of the rope is the first criterion that affects strength. The thicker the weave, the greater the load it can withstand.

All ropes are usually classified into 4 categories:

- Twine.

- Cords.

- Ropes.

- Ropes.

Twine is twisted fiber products that are intended for one-time use.

They are usually made from natural raw materials such as flax or hemp. Twine made of synthetic materials and even paper is also found. Its diameter ranges from 1 to 4.8 mm.

The main purpose of twine is for knitting when packing.

The cords have a small diameter, but are highly resistant to tearing, which is due to the use of special fibers for weaving them. They can also be made from simple materials that are not durable, which is not required, since such products are used only for knitting.

Cords made from modern synthetic fibers have high reliability and load-carrying capacity, which is why they are used in mountaineering. They are lightweight and do not take up much space. The cords usually have a protective weave, which, like a cover, protects the power core hidden inside from chafing. They can be used repeatedly. Cords are twisted and braided.

Description

Steel rope GOST 2688-80

is a metal product that consists of an organic core and twisted steel wires. The core is the basis of the structure and gives the product flexibility. It acts as a shock absorber, resists radial pressure when the rope is loaded and prevents its transverse deformation.

It can be made from:

- polypropylene, polyethylene;

- hemp or cotton fiber;

- viscose, nylon, lavsan;

- cord, sisal.

To protect the core from premature destruction and rotting, it is impregnated with special anti-corrosion compounds that do not contain acids and alkalis. Rope lubricants are used to impregnate the core:

During operation, when the rope is bent, the lubricant penetrates into the gaps between the wires, ensuring their uniform lubrication and protecting the metal from corrosion. Thanks to rope lubrication, long-term preservation of the core is ensured, friction and wear of internal and external wires are reduced when the rope operates on blocks. The lubricant retains its qualities in a wide range of operating temperatures from -50 C to +50 C. Protective lubricant is used both in the manufacture of products and during operation. The composition is applied in a continuous layer with a thickness of at least 0.2 mm.

Double lay metal rope consists of six strands, which are made from wires of different diameters in the outer layer of the strands. Structural diagram of the rope 6×19 (1+6+6/6)+1 oc This design minimizes the risk of rupture and deformation of the product.

Ropes with linear contact of wires of the LK-R type have high performance, which allows them to be used for work in difficult conditions. Products in this category are resistant to abrasive wear and high end loads. Thanks to a wide range of standard sizes, you can choose a product with optimal technical characteristics

.

Recommendations for the use of various rope designs

Each rope design has advantages and disadvantages that must be properly taken into account when selecting ropes for specific operating conditions. When choosing, you should maintain the necessary relationships between the diameters of the winding elements and the diameters of the ropes and their outer wires, as well as the necessary safety margin to ensure trouble-free operation.

Single lay ropes made of round wires - ordinary spiral ones (GOST 3062-80; 3063-80; 3064-80) have increased rigidity, so they are recommended for use where tensile loads on the rope predominate (lightning protection cables of high-voltage power lines, fences, guy wires and etc.)

Double lay ropes with linear touching of the wires in the strands, while being easy to manufacture, have relatively high performance and have a sufficient number of different designs. The latter allows you to select ropes for work under large end loads, with significant abrasive wear, in various aggressive environments, with the minimum permissible ratios of the diameter of the winding element and rope diameter.

Ropes of the LK-R type (GOST 2688-80, 14954-80) should be used when, during operation, the ropes are exposed to aggressive environments, intense alternating bending and work in the open air. The great structural strength of these ropes allows them to be used in many very stressful operating conditions of crane mechanisms.

LK-O type ropes (GOST 3077-80, 3081-80; 3066-80; 3069-80; 3083-80) work stably under conditions of severe abrasion due to the presence of increased diameter wires in the upper layer. These ropes are widely used, but their normal operation requires a slightly increased diameter of blocks and drums.

Ropes of type LK-Z (GOST 7665-80, 7667-80) are used when flexibility is required, provided that the rope is not exposed to an aggressive environment. It is not recommended to use these ropes in aggressive environments due to the thin filling wires in the strands, which are easily corroded.

Ropes of the LK-RO type (GOST 7668-80, 7669-80, 16853-80) are distinguished by a relatively large number of wires in the strands and therefore have increased flexibility. The presence of relatively thick wires in the outer layer of these ropes allows them to be successfully used in conditions of abrasive wear and aggressive environments. Due to this combination of properties, the LK-RO type construction rope is universal.

Double lay ropes with point-linear contact of wires in strands of type TLK - O (GOST 3079-80) should be used when the use of ropes with linear contact of wires in strands is impossible due to violation of the minimum permissible installation ratios between the diameters of the winding organs and the diameters of the wires of the rope or if it is impossible to ensure the recommended safety factor.

Double lay ropes with point contact of wires in TK type strands (GOST 3067-88; 3068-88; 3070-88; 3071-88) are not recommended for critical and intensively operating installations. These ropes can only be used for non-stressful operating conditions, where alternating bends and pulsating loads are insignificant or absent (slings, bracing ropes, temporary timber fastenings, support and brake ropes, etc.)

Multi-strand double lay ropes (GOST 3088-80; 7681-80) , depending on the accepted directions of laying of the strands in individual layers, are made ordinary and non-twisting. The latter ensure reliable and stable operation on mechanisms with free suspension of the load, and the large supporting surface and lower specific pressures on the external wires make it possible to achieve a relatively high performance of the rope. The disadvantages of multi-strand ropes are the complexity of manufacturing (especially pre-deformation), the tendency to delamination, and the difficulty of monitoring the condition of the internal layers of the strands.

Triple lay ropes (GOST 3089-80) are used when the main operational requirements are maximum flexibility and elasticity of the rope, and its strength and supporting surface are not of decisive importance. Organic cores in strands are appropriate when the rope is intended for towing and mooring, where increased elastic properties of the rope are required. Due to the use of wires of small diameters compared to the wires of double lay ropes, triple lay ropes require pulleys of significantly smaller diameters for normal operation.

Triangular strand ropes (GOST 3085-80) are characterized by increased structural stability, a very high fill factor and a large supporting surface. The use of these ropes is especially suitable for high end loads and severe abrasive wear. It is recommended to use these ropes both in installations with friction pulleys and in multi-layer winding on drums. The disadvantages of triangular strand ropes are sharp bends of the wires on the edges of the strands, increased rigidity of the rope, and the complexity of manufacturing the strands.

Flat ropes (GOST 3091-80; 3092-80) are used as balancing ropes in mine hoisting installations. The advantages of these ropes include their non-twisting properties. However, the manual operations involved in sewing ropes and the relatively rapid destruction of the collar during operation limit the extent to which these ropes can be used in industry.

Specifications

Steel ropes manufactured in accordance with GOST 2668-80 standards have a cross-sectional diameter from 3.6 mm to 56.0 mm. Products are classified according to several criteria. Ropes with increased manufacturing precision are designated by the T index. Depending on the purpose, they are:

- GL - cargo-carrying, intended for installation on elevators;

- G - cargo, which are used for the installation of all other mechanisms.

Steel cables are manufactured with right (R) and left lay, which is designated by the index L. The direction of lay is:

- K - combined;

- O - one-sided;

- cross

According to the method of laying the strands, ropes are divided into:

- N - non-unwinding;

- MK - low-rotating;

- unwinding.

The use of ropes with combined lay and cross lay makes it possible to reduce the torsion of the suspended load. The same direction of lay of the wires creates a greater degree of twist. The opposite direction of the twisted strands gives the effect of low twist (MC). Products marked H have a number of advantages over other types:

- during operation they do not form loops or knots;

- loose ends do not unwind or unravel;

- the cable does not make circular rotations when cutting or removing bandages.

Twisted ropes

The most common are twisted three-strand ropes (Laid three-stand). The design is simplified - three separately twisted (in one direction) strands are then twisted all together (in the other direction).

| Polyester rope. twisted |

Depending on the final number of twists, they can be soft (soft) - a small number of twists. In this case, the greatest strength of the rope and the lowest elongation are achieved structurally.

In this case, there will be low resistance to abrasion and a high tendency to catch and pull out strands (formation of “tufts”) - hard - a large number of twists. Lowest strength, highest elongation and high abrasion resistance.

-medium hardness (medium) – average number of twists. The most common of the three designs.

- Such ropes are made from natural fibers, metal wire, synthetic - multifilament, monofilament threads. Combined - synthetic/synthetic, synthetic/natural fibers, synthetic/metal

- Pros: - easy to manufacture (cheap)

- -convenient for splicing (weaving - splish, fire).

- Disadvantages include: - tendency to “unwind” (it is necessary to fix the ends of the rope)

- - tendency to form loops (and knots) when the rope is unloaded, in a free state

Other types of twisted ropes will not be considered in this article due to their relatively low prevalence. A general comparison of performance with other types of ropes can be seen in the conclusions.

Braided ropes

The general characteristic is the yarn count of the rope, i.e. the number of strands from which it is braided. The yarn count corresponds to (or is a multiple of) the number of bobbins on the braiding machine.

| 16-strand braiding machine. | The photo shows the machine. It produces 16-strand double weave rope. The place where the threads join is called the weaving point. |

Ropes in this category can be divided into two large groups - with and without a core:

Braided ropes without core

All ropes in this group will have an internal cavity. The higher the spunness, the larger the diameter of the cavity. For example, for 8-strand ropes the cavity is insignificant, and by touch it is very difficult to distinguish them from a rope with a core. But a 24-strand rope without a core will already resemble a stocking (easily wrinkled to a flat state).

8-strand L type ropes. (plaited rope).

| Schematically, braided 8-strand L type rope. | 8-strand polypropylene rope L type. |

The figure shows that this rope structure is achieved by interweaving double strands. The strength and linear weight of such ropes are comparable to three-strand twisted ones (with the same diameters). However, they are not prone to the formation of loops and twists.

Simple hollow n-strand ropes (hollow single-braid) These are ordinary braided ropes. Below is an 8-strand rope.

This structure is achieved by simply interweaving the strands. In general, the braiding machine uses 8 bobbins with thread, four of which move clockwise and four counterclockwise.

Such ropes are simple to make and easy to use.

| Schematically, braided 8-strand rope. | 8 strand polypropylene rope |

Diagonally braided ropes (twill braid) Similar to the previous type, they have a void in the center. Visually, they are easily distinguishable from simple wicker ones.

This structure is achieved by interweaving the strands with an offset. For example, a machine uses 12 bobbins of thread, six of which move clockwise and the remaining six move counterclockwise. However, unlike the previous look, each left strand is “covered” by two right strands. And vice versa, each right strand is “covered” by two left ones.

| Schematic, 24 strand diagonally woven rope | 24 strand polypropylene rope with diagonal weave |

Diagonal braided ropes have a slightly thicker braid than similar simple braided ones.

Solid braid ropes can be divided into a separate group. Thanks to the special type of machines on which such ropes are produced, it turns out to be filled with thread inside, i.e. without voids. Such ropes are widespread in America.

| Solid weave rope | To produce such ropes, slightly different braiding machines are used - some of the spools with thread move as usual, in a circle (clockwise and counterclockwise), and some progressively (back and forth). In this case, the first and second are intertwined with each other. |

Braided ropes with core

Bundles of threads, braided cores, twisted cores can be used as a core. There are also more complex designs; they are used for special-purpose ropes.

The core and braid can be made of different materials. This combination is used to obtain certain properties.

For example, abrasion-resistant material can be used in the braid, while a lighter or stronger material can be used in the core.

Ropes with a braided core (Double-braid, braid-of-braid rope)

As a rule, a braided 8- or 12-strand fast-pulling rope is used as a core. The braid consists of a larger number of strands (usually 16 strands or more) and has a dense weave.

| Braid - polyester, 16 strand, diagonal weave, core - 8 strand braided, polyester | Braid - polyester, 24 strand, diagonal weave, core - 8 strand braided, Trevo |

Ropes with parallel twisted strands (parallel stand rope)

They are ropes in which the core strands are located parallel to the central axis of the rope. One of the most common examples in this group is Kermantle rope - safety ropes.

The core consists of three-strand twisted cords, the braid is usually 24, 32 or 48 strands.

Ropes of this type are very effective (the strength of the threads is used by 80-90%, while on simple braided ropes only about 60%) and at the same time they do not have the disadvantages of conventional twisted ropes.

| 48 strand static rope | Leader cable 24 strands, braid - diagonal weaving, core - parallel twisted strands |

Results As a result, you can display a comparison table (you must understand that this information is conditional, and the ropes being compared must be of the same diameter and from the same material).

| Rope type | Strength | Rigidity | Elongation | Price |

| Three-strand, twisted | average | average | high | low |

| Simple wicker | high | soft | average | average |

| Double weave (with core) | very high | average | low | high |

| With parallel cores | very high | female | very low | high |

When using article materials, a link to the original source www.remera.ru is required

Features of rope production

Ropes made of galvanized wire have increased resistance to corrosion and are used in the following areas:

- in the timber rafting and woodworking industries;

- transport construction and shipbuilding, aircraft manufacturing;

- in metallurgy and mining industry;

- production of construction equipment;

- in creating production lines.

Price

product depends on its diameter, type and grade of steel used. The material for the manufacture of metal cables is low-alloy steel rope wire. It has a round cross-section and is made from special wire rod of classes PC, VK, KK, which ensures high ductility of the finished product. Based on surface type, rope wire is divided into:

- light, without zinc coating with a diameter of 0.2 to 4.6 mm;

- galvanized, diameter 0.18-4.5 mm.

Structural and spring steel grades 45-85 are used as raw materials for the manufacture of wire. The choice of steel grade depends on the purpose of the final product. Reinforcing ropes are made of steel 70, 75, 80, 85. For aircraft ropes, the wire is made of steel grades 50.55, 60, 65.

It is possible to use corrosion-resistant steels of grades 5Х17Н12Мо2, 17Х12Н7, 5Х17Н12М2. Steel alloyed with silicon, manganese, chromium, nickel and molybdenum shows good anti-corrosion qualities and is resistant to atmospheric moisture.

Rope packaging

Buy

The product can be in coils, wound on wooden or metal reels.

The length of the cable in the coil depends on its diameter and is 200, 500 and 1000 m. When placing an order, the required rope length is indicated in the contract concluded with the manufacturer

.

The maximum deviation in length should not exceed 5% for ropes with a length of less than 400 m. For products with a length of more than 400 m, the permissible deviation is 20 m for every 1000 m.

Recommended bay dimensions:

- internal diameter is at least 15 product diameters;

- outer diameter no more than 1.2 m;

- height no more than 0.8 m.

It is allowed to wind several sections of rope of the same size onto a reel. In this case, the ends are firmly fixed, the outer end is tied and fixed on the inside of the cheek of the reel. For binding the following are used: strands, ropes, tapes, wire, organic core.

At the customer's request, GL ropes are wrapped in polymer film or waterproof paper, and the reels are sheathed with boards. The coils are firmly tied with soft wire or strands of rope at four or six points, while the fastening areas must be evenly located around the circumference of the coil. Packaging of products that are shipped to northern regions or sent by sea is carried out in accordance with GOST 15846-79.

Each cable is supplied with a certificate and a tag, which is attached to the reel or coil. It indicates the serial number of the product, symbols, length and weight parameters.

What is the difference between a straightened rope and an unstraightened one?

GOST 14954 ropes can be produced with varying degrees of balance - straightened (a more balanced rope) or unstraightened. Straightened ropes undergo additional straightening; for this, the rope product is passed through a roller mechanism, from which the finished product, using traction and receiving mechanisms, is fed for winding onto reels or drums. As a result of straightening, technological stress is removed, which increases its straightness and durability.

Steel rope G-V-N-R-T-1770 cargo GOST 2688-80 diameter 15mm.

is engaged in the production and sale of spare parts for automobiles, crawler cranes and other special equipment. One of the company's activities is the sale of cargo ropes for truck cranes and other special equipment. You can buy rope 15-G-V-N-R-T-1770, find out about its availability or price in any convenient way: by filling out an application through the online store, sending it by e-mail or calling the manager (see the “contacts” tab) ).

Steel cargo rope 15-G-V-N-R-T-1770 with a diameter of 15.0 mm (GOST 2688-80) is used on truck cranes, in hoisting machines, for overhead roads and cable cranes, in earth-moving and road equipment, for lifting installations in the metallurgical industry, on ships, timber rafting, forestry and other machines.

Steel rope GOST 2688-80 is a double lay cargo cable of the LK-R type with a linear contact of wires between layers at different diameters in the outer layer of a strand of structure 6x19 (1+6+6/6)+1 organic core. The product is made of uncoated and galvanized wire.

Steel ropes with technical specifications GOST 2688-80 are used to replace the invalid GOST 2688-69.

Decoding of standards, characteristics of G-V-N-R-T-1770:

- G - cargo rope

- B - brands of normal quality;

- N - non-unwinding;

- R - straightened;

- T - increased manufacturing accuracy;

- 1770 – marking groups (H/mm^2).

You can buy ropes and cables of various modifications and designs at. Manufacturer prices. Guarantee. We organize delivery to the cities of Ufa, Saransk, Yakutsk, Vladikavkaz, Kazan, Kyzyl, Izhevsk, Abakan, Cheboksary, Barnaul, Krasnodar, Krasnoyarsk, Vladivostok, Stavropol, Khabarovsk, Blagoveshchensk, Arkhangelsk, Astrakhan, Belgorod, Bryansk, Vladimir, Volgograd, Vologda, Voronezh, Ivanovo, Izhevsk, Irkutsk, Kaliningrad, Kaluga, Petropavlovsk-Kamchatsky, Kemerovo, Kirov, Kostroma, Kurgan, Kursk, St. Petersburg, Lipetsk, Magadan, Moscow, Murmansk, Nizhny Novgorod, Novgorod, Novosibirsk, Omsk, Orenburg, Orel , Penza, Perm, Pskov, Rostov-on-Don, Ryazan, Samara, Saratov, Yuzhno-Sakhalinsk, Ekaterinburg, Smolensk, Tambov, Tver, Tomsk, Tula, Tyumen, Ulyanovsk, Chelyabinsk, Chita, Yaroslavl, Khanty-Mansiysk, Anadyr , Salekhard, Grozny, Maykop, Ulan-Ude, Gorno-Altaisk, Makhachkala, Nazran, Nalchik, Elista, Cherkessk, Petrozavodsk, Syktyvkar, Yoshkar-Ola, Novy Urengoy, Surgut, Salekhard and other cities of Russia, CIS countries, the cheapest and most convenient transport company for you.

When steel rope GOST 14954 is considered defective

The design of the GOST 14954 type LK-R rope used as an element of a load-lifting crane, meeting ISO requirements, has the following expression: 6x19(1+6+6/6)+7x7(1+6). The product is considered defective if the number of wire breaks in it is as follows:

- When using this type according to GOST 14954 in a mechanism belonging to the classification (mode) group M1, M2, M3, M4:

- cross lay rope with the number of wire breaks in a section of length 6d1) - 5, the number of wire breaks in a section 30d - 10

- single-sided lay rope with the number of wire breaks in a section of length 6d - 2, the number of wire breaks in a section 30d - 5

- for a cross lay rope, the number of wire breaks in a section of length 6d should be 10, the number of wire breaks in a section 30d – 19

- for a single-sided lay rope, the number of wire breaks in a section of length 6d should be 5, the number of wire breaks in a section 30d – 10