What is copper plating? Purpose and designation of copper coating.

Copper plating is the process of applying a thin layer of copper metal to a product to give it the necessary properties.

Copper coatings are widely used mainly as a sublayer when applying multilayer coatings, as well as to improve soldering, create electrically conductive layers, seal threaded connections, and local protection of steel parts during carburization. In rare cases they are used to give a decorative appearance.

Copper is a pink metal with an atomic mass of 63.5, density 8.9 g/cm3, melting point 10830C, electrical resistivity 0.017*Ohm*mm. Copper is ductile, the hardness of copper coatings is 2500-3000 MPa.

Copper dissolves intensively in aerated ammonia and cyanide solutions, nitric acid, more slowly in chromic acid, weakly in sulfuric acid, and almost does not interact with hydrochloric acid. In air, copper easily reacts with moisture, carbon dioxide and sulfur compounds, oxidizes and darkens.

The standard potential of copper in relation to its monovalent nonions is +0.52 V, divalent ions +0.34 V.

Under harsh operating conditions, copper and its alloys should not come into contact with chromium, tin, steels, zinc, cadmium, aluminum and magnesium.

| Coverage designation | M - standard copper plating, gloss is not standardized M. b - shiny copper plating M24 - spark-proof copper plating (thickness not less than 24 microns) M. h - copper plating with decorative blackening (aging/patination) |

| Thickness | 6-100 µm (optimal, but it is possible to deposit greater thickness) |

| Microhardness | 590-1470 MPa (60-150 kgf/mm2) |

| Electrical resistivity at 18°C | 1.68⋅10-8 Ohm⋅m |

| Permissible operating temperature | 300oC |

Electroplating at home: copper plating

Why is copper so popular in electroplating? It has high adhesion (in other words, grip) to a wide variety of materials. This means that it adheres perfectly to products made of steel and tungsten, without flying off or chipping.

Copper is a beautiful bright metal that looks like pink-red nuggets. The material conducts not only heat, but also electric current - hence the high demand in the field of electrical engineering and instrument making. However, pure copper is difficult to find. More often it comes with various impurities.

Copper coatings:

- They are characterized by low resistance, which is used in electrical engineering

- Hides minor surface imperfections.

- It oxidizes quickly, which is used to obtain an “antique” effect.

There are two copper plating technologies. One occurs by immersing the product in an electrolyte solution (with or without current supply). The second method is a method of selective coating without immersion in a solution. Let's look at both.

Immersion method

At home, the surface to be electroplated should be carefully treated. For example, sandpaper and a brush. Afterwards, be sure to degrease the part and rinse it.

Further:

- The anode plate (two are possible) is placed in a container, which we will call a bath. The positive terminal is connected to the anodes.

- A part is suspended between the anodes on any convenient conductor, and the negative pole from the power supply is connected to it.

- The finished solution is poured into the bath - in this case, the coating level should be higher than the part is located.

- After connecting the electrodes to the current source, the operating current is set. This is approximately 1 A/sq.dm. coverings.

The duration of work depends on the required layer thickness, usually from 5 minutes.

Non-immersion coating

This method of copper plating has limitations - most often it is suitable for surface restoration. This method can only apply a small thickness of metal. There is no point in coating products using this method that can be copper plated in a bath. Procedure for galvanic copper plating at home:

- A “tampon” is prepared for applying the coating. Take a copper conductor and wrap a piece of artificial fabric (polyester is fine).

- The opposite end of the conductor is connected to the positive terminal of the voltage source.

- Fill the container with an electrolyte solution - this makes it easier to dip the pencil.

- The part is carefully cleaned and degreased, and then placed in an empty bath. There the product is connected to the negative terminal.

- The swab is moistened in the solution. Then it is passed over the surface of the product, painting it gradually.

The process lasts until the product is completely covered with a copper layer.

Kinetics of the galvanic copper plating process.

A large number of electrolytes have been developed for the electrolytic deposition of copper, which are usually divided into two groups: acidic and alkaline. There are both simple and quite complex compositions for copper plating.

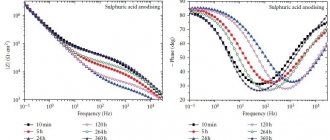

Cathode polarization curves for some of them are shown in Figure 1.

Figure 1 - Cathode polarization curves during copper plating from electrolytes: 1 - sulfate; 2 - pyrophosphate; 3 - cyanide; 4-cyanide with a high content of free cyanides.

2.1 Processes in acidic copper plating electrolytes.

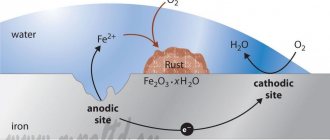

Acidic electrolytes include sulfate and fluoroborate electrolytes. Their main advantages are simplicity of composition and stability in operation, but they have low dissipative ability. It is also impossible to directly copper-plate steel from them due to the loss of contact copper, and, consequently, poor adhesion of the copper layer to the steel. As a result, copper plating is carried out after preliminary deposition of a copper layer (3-4 microns) from alkaline electrolytes or after deposition of a nickel layer (3-5 microns).

Of the acidic electrolytes, the most common is sulfate electrolyte. The main components of sulfate electrolytes are copper sulfate and sulfuric acid. The electrical conductivity of neutral solutions of copper sulfate is low, so sulfuric acid is added to them, which significantly increases the electrical conductivity of solutions at stirring temperature.

It is assumed that the discharge of divalent copper ions at the cathode occurs in two stages:

Cu2++ e → Cu+

Cu+ + e → Cu

The slow stage is the first reaction. The share of each stage in the overall kinetics of copper plating depends on the composition of the electrolyte and the electrolysis mode: current density, temperature, stirring.

The current efficiency of copper is about 100%, since hydrogen evolution does not occur at the cathode, since the copper evolution potentials have more positive values than the hydrogen evolution potentials.

Increasing the acidity of the electrolyte helps to reduce the solubility of copper sulfate, which leads to a decrease in the upper limit of the permissible current density. To increase the concentration of copper ions in the cathode layer, stirring is used. In this case, the acidity of electrolytes can be increased. The more intense the stirring, the higher the sulfuric acid content may be. An increase in temperature helps to increase the solubility of copper sulfate: at 25 °C - 23.05 g of CuSO4 per 100 g of water; at 100 °C - 73.6 g. Increased acidity contributes to the production of more finely crystalline sediments.

Near the anodes, along with Cu2+ ions, the solution may contain small amounts of monovalent copper ions, which are formed as a result of the reaction:

Cu + Cu2+↔ 2Cu+

When Cu+ ions accumulate in the solution, the equilibrium will shift to the left, and metallic copper will precipitate.

If the acidity of the solution is insufficient, cuprous sulfate will hydrolyze to form Cu(OH)2 or CuO2

Cu2SO4 + H2O ↔ Cu2O + H2SO4

As a result, the electrolyte will contain suspended particles of metallic copper and copper oxide, which, when included in the cathode deposit, make it dark, rough, and sometimes friable.

The presence of sulfuric acid promotes the oxidation reactions of monovalent copper:

Cu2SO4 + H2SO4 + 1/2O2→ 2CuSO4 + H2O Cu2O + 2H2SO4 + 1/2O2→ 2CuSO4 + 2H2O

Thus, sulfuric acid is primarily needed to prevent the accumulation of Cu+ ions and the hydrolysis of its salts.

Surfactants are sometimes added to copper sulfate electrolytes. These substances are introduced to increase cathodic polarization, which contributes to the production of finer-grained, dense, sometimes shiny, deposits. The beneficial effect of these additives is that they prevent the formation of build-ups on the edges and protruding parts of parts. The best additives are dextrin (no more than 1 g/l) and phenol or its sulfo compounds (1-10 g/l).

To obtain shiny copper coatings, a large number of shine-forming additives have been proposed, providing a mirror-like shine to the coatings, giving them ductility and reducing internal stresses.

When working with electrolytes to obtain shiny copper coatings, special attention must be paid to the anodes. The anodic process of copper dissolution is quite complex and is described in detail in the article.

Suspended sludge particles are usually the cause of coarse, rough sediment. In general, copper coating is especially prone to dendrite formation during copper plating in violation of the technological process, which includes the presence of sludge in the solution. In this case, the sludge particles become centers of crystallization and the current, instead of going to the nucleation of new copper grains, is spent on the fouling and growth of these particles. Dendrites can also appear for other reasons, one of which is also exceeding the permissible current density on protruding parts of parts. Examples of dendrites on a copper coating are shown in Figure 2. An example of a dendrite on a cylindrical cathode and a cross-section of such a dendrite are shown in Figure 3.

Figure 2 - Examples of dendrites on a copper coating.

Figure 3 - An example of a dendrite on a cylindrical cathode and a cross-section of such a dendrite.

The quality of the resulting shiny coatings is greatly influenced by the concentration of Cl- ions. At a reduced concentration, the gloss of the coatings decreases and burns form on the sharp edges of parts; at an increased content, stripes form on the coatings.

Harmful impurities in copper sulfate electrolytes are arsenic, antimony, some organic substances that form colloidal solutions, and anode sludge.

In addition to sulfate electrolytes, fluoroborate electrolytes are used. These electrolytes are highly stable; the resulting coatings are dense and finely crystalline, the dissipating ability of electrolytes is approximately the same as that of sulfate ones. The high solubility of copper fluoroborate allows the use of increased current densities. It is impossible to directly copper-plate steel parts from these electrolytes; a sublayer of nickel or copper from cyanide electrolytes is required.

2.2 Processes in alkaline copper plating electrolytes.

Alkaline electrolytes include cyanide, pyrophosphate and ethylenediamine electrolytes. Main advantages: high dissipative ability, production of fine-crystalline deposits, the ability to directly copper-plate steel parts.

2.2.1 Cyanide copper plating.

Cyanide electrolytes are quite common. The conditions for copper deposition from cyanide electrolytes differ significantly from the conditions for deposition in acidic electrolytes.

In cyanide electrolytes, copper is part of complex ions; the degree of dissociation, and, consequently, the activity of copper ions is very low. Therefore, the potential for copper release in them is approximately 0.9-1.2 V more negative than in sulfate solutions.

When the amount of cyanide is low, the anodes are passivated. If there is insufficient amount of free cyanide, when passivation of the anodes occurs and OH- ions are discharged onto them with the release of oxygen, then not all of the resulting oxygen is released in the form of a gas, but part of it is spent on the oxidation of cyanide into cyanite. A decrease in cyanide content also occurs due to their interaction with atmospheric carbon dioxide and the formation of carbonates (NaCN → Na2CO3).

The content of free cyanide has an opposite effect on the cathodic and anodic processes: the cathodic process requires a minimum cyanide content, and the anodic process requires a maximum. With a lack of free KCN, a greenish film of CuCN forms on the anodes due to the fact that copper ions are not able to form a complex compound. The free surface of the anode decreases, the current density increases, and anodic dissolution occurs with the formation of divalent copper ions, which are deposited on the anode in the form of an insoluble hydrate. In this case, the anodes are passivated and intense oxygen release is observed.

The main components of copper cyanide electrolytes are complex copper cyanide and free sodium cyanide. From the data presented it is clear that the degree of dissociation of complex ions is very small and decreases with increasing CN- content in the complex. This apparently explains the increase in cathodic polarization with increasing content of free cyanide in the electrolyte.

The copper content in the electrolyte usually decreases during operation due to insufficient solubility of the anodes. A decrease in the concentration of copper ions in electrolytes leads to the formation of porous deposits. In addition, when working with low-concentration copper electrolytes, only reduced current densities can be used.

Carbonate is a constant component of cyanide electrolytes. It accumulates as a result of cyanide oxidation by atmospheric oxygen, especially when heated:

2NaCN + 2H2O + 2NaOH + O2 = 2Na2CO3 + 2NH3

The presence of carbonates in small quantities is beneficial because it increases the electrical conductivity of electrolytes. However, when their accumulation exceeds 70 g/l, and in concentrated cases - up to 140 g/l, the anodes tend to passivate, and the coatings become porous. Carbonates can be removed using barium chloride and freezing, cooling the electrolyte to -5 °C. It should be noted that sodium carbonates precipitate more easily than potassium carbonates. Sulfates do not have a significant effect on the electrolysis process.

The introduction of depassivators into the electrolyte, which include Rochelle salt KNaC4H4O6•4H2O and potassium thiocyanate KCNS, makes it possible to increase the operating current density and eliminate passivation of the anodes, but at the same time the temperature of the electrolyte should be increased.

Highly copper-concentrated electrolytes containing depassivators allow the use of high current densities (up to 10 A/dm2) at elevated temperatures and stirring. In this case, it is possible to obtain a current efficiency close to 100%.

Sulfides introduced into the electrolyte play the role of a reducing agent, preventing the accumulation of Cu2+ copper ions in the bath.

To replace toxic cyanide electrolytes, pyrophosphate and ethylenediamine electrolytes are used.

Necessary tools for copper plating at home

“Ingredients” without which copper plating will not take place, but which can actually be prepared at home. Our galvanists claim that, first of all, we need:

- DC source. Selected depending on the size of the product.

- Anodes. Anode plates perform several functions. First of all, they supply current to the electrolyte, and secondly, they compensate for the loss of metal that goes into coating the product.

- Working electrolyte. Acidic, alkaline or pyrophosphoric solution. The composition of the electrolyte is selected depending on the starting metal. It must be remembered that any electrolyte is not universal and is not suitable for all jobs.

Features of galvanoplasty at home

Electroplating is the process of depositing copper onto a conductive or non-conductive surface of a product and then removing the coating from the negative matrix. This way you can get many very accurate copies from one product. At the same time, there is a condition: build up copper with a thickness of at least 200 microns so that the product turns out durable.

It is important to consider that if the surface of the product does not have conductor properties, then more effort will be required - namely, a special preliminary coating with graphite, silver or copper. Copper is considered the main metal for electroplating, but matrices can be grown from silver with a purity of 9999.

Electroplating training

We can conclude that copper plating today is one of the most relevant electroplating processes that anyone can learn. conducts training in the field of "Galvanics" for everyone! You will be able to choose a training program that is convenient for you, which is best suited for electroplating at home and beyond. All questions you may have can be asked by phone or email; our technologists will advise you on training courses.

Video guide to copper plating parts at home:

You can find out more details at the link:

Gordienko Anastasia Vadimovna Author of the materials Position: chief technologist of 6 Micron LLC Education: higher Experience in galvanizing: 11 years