All summer residents are familiar with the benefits of durable and high-quality greenhouses. This also applies to other structures made of polymer. But to obtain a high-quality result, just purchasing polycarbonate sheets will not be enough. You also need to take care of the fasteners. One option is a thermal washer for polycarbonate.

Proper use of thermal washers in compliance with all recommendations will allow you to achieve the desired result - your structure will be strong and reliable. Thermal washers are an opportunity to eliminate several problems at once related to heat loss, leakage, or dust or small debris getting into the cavities of the polymer.

Thermal washer for polycarbonate

Features of polycarbonate

When working with polycarbonate, the methods inherent in conventional roofing materials are not suitable. In this case, some of its features should be taken into account.

Cellular polycarbonate

- The performance of polycarbonate differs significantly from the characteristics of materials of natural origin. This is due to the fact that polymer plastic is obtained as a result of organic synthesis.

- Polycarbonate is highly durable, so working with it requires high-quality tools.

Technical characteristics of polycarbonate

- When working with polymer you should be extremely careful. High strength does not make it invulnerable, as it remains very fragile.

- The optimal temperature range for working with this material ranges from -45 to +120 degrees. Any temperature movement outside the range will make working with polycarbonate more difficult. When exposed to extreme temperatures, the material will break down.

- The coefficient of thermal expansion of polycarbonate exceeds 1.5 percent, which makes some changes in the way it is attached. If sheets are tightly fastened at low temperatures, they can rupture, and at high temperatures they can swell.

- The appearance of polycarbonate is very attractive, so you need to use fasteners that will not affect its aesthetic qualities.

- The fastening elements used must have a high level of anti-corrosion protection. This is due to the fact that they will be exposed to weather influences.

Polycarbonate fastening

Fasteners must have anti-corrosion protection

There are a large number of work requirements, but thanks to modern technologies, there is an excellent solution to “fastening” issues - the use of thermal washers, with the help of which the problem of point fastening of polycarbonate sheets fades into the background.

Thermal washer for polycarbonate (universal)

Prices for cellular polycarbonate

cellular polycarbonate

How many thermal washers are needed per polycarbonate sheet?

If there is a need to determine exactly how many thermal washers will go on one sheet, then it is worth first calculating the perimeter of the material used. The resulting value is divided by the selected step distance, as a result of which you can get the number of fasteners that will go on each polycarbonate sheet.

If you plan to use monolithic building material in your work, then it is important to understand that thermal washers in this case can only be used when the thickness of the material does not exceed 5 mm.

Often, when constructing structures, material with a thickness of 16 mm or more is used. In this case, it is recommended to avoid drilling polycarbonate sheets and use clamping strips. During the installation process, it will be necessary to fasten it on both sides, and there must be a support point on one of the sides. In such situations, it is best to use thermal washers with self-tapping screws, taking steps from 10 to 20 cm.

Thermal washer - what is it?

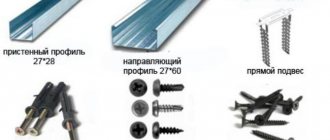

Thermal washers are special fastening parts used for point fixation of polycarbonate sheets. These elements are used for metal, wood and plastic structures.

Installation of polycarbonate to a metal frame

When developing thermal washers, all the characteristics of the polymer fabric were taken into account, including:

1.1. Preparation for installation

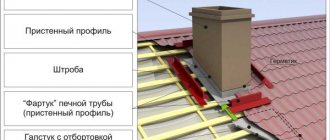

Polycarbonate panels are suitable for installation on vertical, horizontal and arched structures. The first task is to study installation technology. After which you can begin preparing the material and tools for installation. It is recommended to pay special attention to the processing of the ends of the panels.

Each panel sheet has a special film that indicates the side with a special layer for protection from ultraviolet radiation. When installing polycarbonate, it is important that this side faces outward. Otherwise, the material will quickly become unusable. Removal of the factory film must be carried out at the completion of installation work.

Thermal washer design

The design of the thermal insulation washer includes three main parts.

Thermal washer for fastening cellular polycarbonate

- Leg , the length of which can reach 16 mm. In some cases, you can find longer options.

- A special seal that acts as a polymer fastener. It also protects the structure and the sheet cells themselves from moisture getting inside.

- Top plug . People call it a “hat”. The list of tasks of the plug includes improving the appearance of the building (when constructing a greenhouse, the use of plugs gives it a more aesthetic appearance), although many builders forget about this important detail. In addition, the “hats” protect the structure from moisture or debris. In this case, they play the role of a protective cover.

Complete set of thermal washer for polycarbonate

4.2. Wood

Wooden frames are very popular. The environmentally friendly material is easy to use, but requires additional processing. Most often, wooden beams are used to create such structures. To build a durable structure, it is important to pre-treat the material with special antiseptic solutions.

There is one more point when using a wooden frame that you should pay attention to - the coefficient of expansion of the material as a result of exposure to moisture, which affects the density of the fastening. Experts recommend using thermal washers as fasteners for installing polycarbonate on a wooden frame.

Unlike a metal structure, installation should begin from the edge of the frame. When installing, the edge of the panel should extend slightly beyond the edge of the beam. The connection should be tight enough. During installation, the joint of the panels is placed above a wooden beam.

Why are thermal washers needed?

High-quality fastening of polycarbonate to a frame made of any material is always accompanied by the use of thermal insulation washers. Every salesperson in a hardware store knows about this, so when purchasing polymer you should be advised to purchase thermal washers. Their quantity depends on the number of sheets used, but it is better to buy elements with a reserve.

Important! Some people are sure that purchasing thermal washers is nothing more than a waste of money. This is not true, because it is impossible to go broke on such purchases. The standard factory packaging contains 50 elements (their color is the same in the packaging).

Polycarbonate point fixing

Insulating properties

Every summer resident is well aware of the need to maintain temperature conditions in the greenhouse. In winter it is very difficult to do this due to various cracks or leaks between the sheets. In this regard, severe frosts can harm the plants being grown, which greatly complicates the situation. With a correctly installed thermal insulation washer for fastening polycarbonate sheets, this problem can be solved. Moreover, the effect will be much better than when using a homemade seal.

Monolithic polycarbonate - properties and application

To learn everything about the use and properties of monolithic polycarbonate, be sure to read this article! In addition, we strongly recommend reading the material on how to cut polycarbonate with your own hands.

Operational period

If you use regular mounting bolts without thermal washers (bare bolts), then the likelihood of external liquids getting into the cavities of the polycarbonate sheets increases significantly. The term “external liquid” means sap from trees growing above the greenhouse, or rainwater with dust. It is extremely difficult to remove accumulated dirt, because this requires dismantling the structure, washing and blowing with compressed air. In this regard, few people do such cleaning, so all these liquids remain in the sheets forever. This leads to deterioration of the properties of the material and its gradual destruction.

The constructed structure, reinforced with thermal washers, will be much stronger, which will not give strong winds any chance of destroying it. The greenhouse owner does not have to worry about individual sheets of polymer being torn off the structure under the influence of strong hurricane winds.

Thermal washer

Aesthetic side

Although many do not pay attention to this point, the appearance of a polycarbonate structure still plays a big role. A greenhouse will look much nicer in a beautiful design, for which there are thermal insulation washers. When selecting parts to match the color of polycarbonate sheets, the overall picture will remain undisturbed, and the fasteners themselves will be invisible.

Thermal washer

Corrosion protection

Plastic washers can protect metal self-tapping bolts from the formation of corrosive build-ups. This will preserve the appearance and structure for many years. Of course, you can avoid such troubles by purchasing better quality screws. But no one is safe from counterfeiting, because for very decent money you can buy a low-quality product. The situation is similar with the purchase of self-tapping bolts. It’s better not to spend money on expensive bolts, but buying thermal insulating washers is the most effective option.

Plastic washers protect metal screws from corrosion

Prices for thermal washers

thermal washers

1.5. Creating holes for attaching sheets

It is important to note that marking and drilling holes for further fastening of sheets must be carried out taking into account certain rules. The distance from the edge of the panel should be about 2 cm, if the diameter of the hole does not exceed 3 mm. It is recommended to use standard wood drill bits to create holes. Drilling is best done at low speed, controlling the temperature of the working area. Proper creation of holes guarantees a reliable connection, ensuring a tight fit of the sheets to the frame.

Types of washers

For the production of thermal washers, various materials are used, differing from each other in various parameters (strength level, transparency and service life).

There are three main materials used in the manufacture of this product:

- stainless steel (stainless steel);

- polycarbonate;

- polypropylene.

The service life of manufactured fasteners may vary. This will depend on the material chosen for production. For example, products made of polypropylene will last no more than 4 years, those made of polycarbonate - up to 15 years.

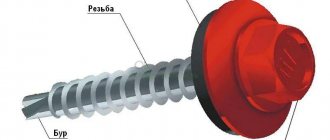

Steel thermal washers

Stainless steel thermal insulation washers are usually used for work in windy areas. They are also used if the coverage area of the object being constructed is too large. Often steel is installed on a profile made of metal. This gives the structure a beautiful and organic look. The thickness of the thermal washer reaches 0.8 mm, and the diameter is 33 mm. The inner part of the washer, intended for the self-tapping screw, has a diameter of no more than 6 mm.

Thermal washer for fastening polycarbonate metal

The shape of the steel washer is similar to a small plate, in the recess of which there is a polyurethane gasket. This is a very durable material, and therefore durable (such a gasket can last more than 40 years).

Important! The metal of the washer and its size do not guarantee reliable fastening of plastic sheets. Correct construction is important - only this factor can affect the reliability of the structure. To strengthen the coating, it is advisable to screw thermal washers every 20-30 cm.

Alternative option. Thermal washer "Spacer" rubber with a metal ring

Polypropylene thermal washers

Products made from polypropylene are produced in both colored and transparent versions. This allows you to create color harmony when constructing a greenhouse or any other structure made from polycarbonate sheets. The diameter of the fastener, made of polypropylene, is 35 mm, and the height is 12 mm. Polypropylene thermal insulating washers allow the use of self-tapping screws whose thickness is no more than 6 mm.

Polypropylene thermal washers

Among all the advantages of polypropylene washers, it is worth highlighting their low cost and beautiful appearance. But before buying, you need to familiarize yourself with their disadvantages. For example, the material used is “afraid” of ultraviolet rays. Under the influence of ultraviolet radiation, polypropylene gradually deteriorates (complete destruction will take approximately 3-5 years). This will cause the sheet covering to vibrate strongly from the wind, and, as a result, will collapse over time.

It is advisable to use polypropylene washers in places protected from direct sunlight (inside buildings or in shaded areas).

Polycarbonate thermal washers

Products made of polycarbonate are practically not inferior in their characteristics to steel thermal insulating washers.

Polycarbonate thermal washers

Polycarbonate thermal washers have many advantages.

- Aesthetics . Products made from polycarbonate have a beautiful appearance, which allows you to complement the overall design of the structure.

- Optimal washer design . Thanks to this, the connection of polycarbonate sheets is strong, and their structure remains intact.

- Resistance to strong temperature fluctuations . The influence of extreme cold or heat will not allow the material to lose its original qualities.

- Duration of operation . Thanks to protection from ultraviolet rays, the material is able to maintain its structure for 15 years.

Thermal washers with UV stabilizer for structures made of cellular polycarbonate

The design of the polycarbonate washer includes:

- stem (its length should correspond to the length of the sheet);

- ring sealing;

- special cover;

- steel self-tapping screw, the tip of which is coated with a layer of zinc.

The lid plays the role of not only a decorative element, but also protection (it does not let moisture and dust into the product). A special leg protects the sheet from creasing. When twisted, it rests against a metal or wooden frame, thereby preventing overtightening of the fastening element.

Fastening polycarbonate using thermal washers

Tools and equipment

To carry out work on fixing the panels, you need tools, main and auxiliary equipment. The choice depends on what frame is attached to and how the material is mounted, as well as on the complexity of the design.

To carry out the work you need:

- screwdriver;

- electric drill (with drills for wood or metal);

- electric jigsaw for cutting polycarbonate;

- a vacuum cleaner for collecting small chips and dust from the honeycombs after cutting;

- device for cutting aluminum profiles;

- self-tapping screws;

- bolts with nuts;

- various washers;

- rubber, plastic, silicone gaskets for washers (umbrella or flat);

- ladder;

- metal ruler;

- measuring tape (roulette);

- level.

Installation instructions

Installation must be carried out in compliance with certain recommendations. Violating them will not only move you away from the desired result, but will also lead to damage to the roofing.

How to drill mounting holes

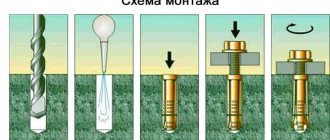

Table. Step-by-step installation of thermal washers.

| Steps, illustrations | Brief description of actions |

| Step 1 | Pre-measure the width of the thermal washer leg. The diameter of the drill used should be slightly larger (about 1-2 mm). |

| Step 2 | Drill a hole in the required location. The recommended distance between the washers is 20-30 cm. |

| Step 3 | Insert the thermal washer into the prepared hole. Its leg should go all the way to the base. |

| Step 4 | Screw in a regular self-tapping screw. The applied force should be small so that the sheet does not bend. If you have overtightened the screw, you can loosen it a little. |

| Step 5 | Close the screw on top with a protective cover (cap). This will allow the holes to be sealed. |

Which thermal washer is better: with a leg or a universal one?

Many believe that due to such an element as the leg of the thermal washer, a more reliable seal is achieved, the chance of “squeezing” the sheet with a self-tapping screw is reduced (the resting leg gets in the way) and the risk of “leaks” is reduced. It should be remembered that usually the polycarbonate itself and thermal washers for it are produced in different places, so tolerances on the thickness of the sheet and plastic may differ by about 1 mm. Due to this, conditions may arise for leaks to occur at all fastening points.

Experts advise when using universal thermal washers to slightly “pinch” the fasteners. In cold weather, “pinching” is compensated by reducing the thickness of the polycarbonate sheet.

Source

Installation tips and tricks

- It is necessary to drill holes on plastic sheets only at an angle of 90°. This is a prerequisite for using any type of thermal insulation washers. Otherwise, a number of unpleasant moments may arise: damage to the material, distortion of the head, violation of insulation, and so on.

Holes must only be drilled at an angle of 90°

Installing polycarbonate like this is a waste of money!

Installation of polycarbonate sheets using a thermal washer

Important! If you are attaching long panels (from 6 m), then it is advisable to drill holes that have an oval shape. In this case, they should be elongated in the direction of the channels.

The video provides instructions for attaching polycarbonate sheets using thermal washers. The fastening is made to a metal frame.

1.3. Panel cutting technology

Polycarbonate sheets are sold in standard widths of 6 or 12 m. To create a canopy or partition, and depending on the frame of the future building, you most often have to resort to cutting panels. This procedure must be carried out very carefully, otherwise there is a risk of damage to the protective film and the ends of the sheets, which will lead to their rapid wear.

To cut sheets, experts recommend using a high-speed circular saw with carbide blades. Fine, unset teeth ensure the most even cut possible. During the cutting process, the panel must be firmly fixed. It is important not to damage the protective film. After cutting, clean the internal cavities from chips to avoid further accumulation of condensation in these places.

5.3. Aluminum profiles

Aluminum profiles are quite often used for the installation of cellular polycarbonate. It is great for panels of varying thicknesses. Includes special rubber seals that ensure reliable sealing of joints. Aluminum parts combine perfectly with plastic, additionally giving the structure high load-bearing characteristics. It has a long service life of 20 years.

The connecting profile is used to connect individual sheets together. It is considered the optimal choice when installing such translucent structures as canopies, canopies, gazebos, ceilings in swimming pools and others, providing reliable thermal insulation. Used for mounting monolithic polycarbonate panels with a thickness of 8-25 mm.

5.1. Polycarbonate profiles

The one-piece connecting profile is designed for connecting sheets of cellular polycarbonate when creating small structures. It is a 6 m long strip, along the edges of which there are special grooves into which polycarbonate panels are inserted. The profile can be easily installed on sheets up to 10 mm thick. When fastening, it is necessary to leave a small gap in case the material expands when exposed to temperature. When choosing a profile, it is important that its dimensions correspond to the thickness of the polycarbonate sheets.

The detachable connection profile is easy to install. It consists of a base and a lid that allow you to completely close the connection. When installing a split profile, the base is first fixed, after which polycarbonate sheets are attached to it and the lid is snapped on. When assembled, it does not curl.