GOST 8713-79 on submerged arc welding

Welding, in which the zone of molten metal is protected by flux, was invented quite a long time ago - in the 19th century. This technology was developed by N. Slavyanov, and the first automated welding machine for its implementation and the practical basis for its implementation were created already in 1927 by D. Dulchevsky. Almost immediately after this, automatic submerged arc welding began to be actively introduced into production processes at large domestic industrial and construction enterprises.

Throughout the entire period of existence of this technology, both submerged arc welding itself and the equipment for its implementation have been constantly evolving. The issues of improving the method and technology for its practical implementation were dealt with by leading research institutes of the Soviet Union: Institute of Electric Welding Units of the Soviet Union, Central Research Institute of Heavy Engineering, Institute named after E.O. Paton and others.

Submerged arc welding diagram

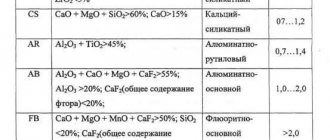

The technology of automatic submerged arc welding is regulated in detail by GOST 8713-79. There is also a classification of welding methods under a protective layer of flux, which can be used to join steels and alloys with a nickel and iron-nickel base. GOST 8713-79 distinguishes two such methods: mechanized and automatic submerged arc welding. And these varieties are divided into the following subspecies:

- mechanized: performed on weight (MF), with a pre-made weld seam (MFsh), using the remaining lining (MFo);

- automatic: performed on a lining (AFo) and using a flux pad (AFf), with preliminary welding of the weld root (AFk), using the so-called copper slider (AFp), performed in weight (AF), with preliminary welding ( AFsh), welding on flux-copper backing (AFm).

Some types of seams used in submerged arc welding

Also, GOST 8713-79 specifies the types of welded joints obtained using these methods, which can be:

- one-sided type; double-sided; butt one-sided - locking, which can be made with a straight or curved bevel of both edges, with a symmetrical bevel of one edge, with a broken type bevel, without a bevel at all - with subsequent gouging, with flanging and asymmetrical bevel of both edges;

- angular double-sided and single-sided types, in which there may be no bevels, they can be asymmetrical, and also made with flanging;

- lap seams made without bevel, on one or both sides;

- tee seams of two- and one-sided type.

An example of submerged arc welding can be seen in the following video:

GOST 11533-75 lists the requirements for automatic and semi-automatic methods for submerged arc welding of parts made of carbon and low-alloy steels. These welding methods include:

- semi-automatic arc welding performed using a steel backing (Ps); welding of semi-automatic type (P) and semi-automatic with welding seam (PPsh);

- automatic welding performed with a preliminary weld seam (Apsh);

- automatic submerged arc welding performed on a special steel backing.

Single-sided automatic submerged butt welding technology

Single-sided welding is used when welding minor metal structures, or in cases where it is not possible to perform double-sided welding due to design features.

Features of one-sided butt welding are a large amount of liquid metal, a large penetration depth and overheating of the weld pool. All this can cause liquid metal to leak out through the gaps and disrupt the formation of the weld. In order to prevent this, it is necessary to weld the joint from the reverse side, thus closing the gap, or to cover the reverse side of the seam with a metal (copper or steel) backing, or to close this gap from the reverse side with a layer of flux.

There are four most common methods for one-sided automatic welding of butt seams, which allow you to make a weld of the required configuration and obtain high quality welding. Let's consider these methods in more detail.

Automatic flux-cored welding technology

Variants of this welding method are shown in the figure on the right.

The essence of this type of welding is that under the parts to be welded, pos. 1, a layer of flux, pos. 2, is placed, the thickness of which is 30-50 mm. The flux pad fits tightly to the edges to be welded and is pressed against them as a result of the influence of the own weight of the parts being welded, or through a rubber hose containing air. The air pressure in the hose depends on the thickness of the metal being welded and is 0.05-0.06 MPa when welding thin metal and 0.2-0.25 MPa when welding thick metal. The flux layer prevents leakage of liquid metal through the gap and ensures good formation of the weld and high quality welding. Approximate modes of automatic single-sided butt welding performed on a flux layer are presented in the table below:

Submerged arc welding technology

Automatic and mechanized types of welding under a layer of flux differ from traditional technology in that the arc, when performed, does not burn in the open air, but under a layer of bulk substance with a number of special properties, which is called flux. At the moment the welding arc is ignited, the metal of the part and the electrode, as well as the flux used, begin to melt simultaneously. As a result of metal and flux vapors formed in the welding zone, a gas cavity is formed, which is filled with the resulting vapors mixed with welding gases.

An example of the appearance of a seam after submerged arc welding

The cavity formed during such welding is limited in its upper part by a layer of molten flux, which performs not only a protective function. The molten metal of the electrode and the part being welded, interacting with the flux, undergoes metallurgical processing, which helps to obtain a high-quality weld.

When the arc is removed from a certain welding zone, the molten flux solidifies, forming a hard crust on the finished seam, which is easily removed after the product has cooled. If automatic submerged arc welding is performed, then unused flux is collected from the surface of the part using a special suction device equipped with automated equipment.

In the video, the master explains some of the nuances of welding using flux:

Submerged arc welding, performed both mechanized and automated, has a number of significant advantages.

- The process can be carried out using currents of significant magnitude. As a rule, the current strength when performing such welding is approximately in the range of 1000–2000 Amperes, although it is quite possible to increase this value to 4000 A. For comparison: conventional arc welding is performed with a current strength of no more than 600 A, a further increase in the current strength leads to severe spattering of metal and the inability to form a weld. Meanwhile, increasing the current allows not only to significantly speed up the welding process, but also to obtain a welded joint of high quality and reliability.

- When welding is performed under a layer of flux, a closed arc is formed, which melts the metal of the part to a great depth. Thanks to this, the edges of the part to be welded do not even need to be prepared for their better weldability.

- Since submerged arc welding modes involve the use of high current, the speed of the process increases significantly. If we compare the speed of welding performed under a submerged arc layer, which is measured in the length of the seam obtained over a certain period of time, then it can be 10 times higher than that of conventional arc welding.

- The so-called gas bubble, formed when welding under a protective layer of flux, prevents metal spattering, which makes it possible to obtain high-quality welds. In addition, this significantly reduces the loss of electrode metal, which amounts to a maximum of 2% of the mass of the molten material. In this case, not only electrode material is saved, but also electrical energy.

General diagram of submerged arc welding

The choice of welding mode performed under a submerged arc layer is carried out according to the following main parameters:

- diameter of the electrode wire used;

- type of current and its polarity;

- the speed at which welding is performed;

- voltage to form a welding arc.

Additional parameters that influence the determination of the submerged arc welding mode are:

- particle size, composition and density of the flux used;

- value of electrode wire extension;

- a parameter that determines how the electrode and the part being welded are positioned relative to each other.

Welding technology

As with any other technique, parts must be processed and prepared before automatic submerged arc welding. Processing each metal is a separate story, but there are general rules for all.

First, the elements are cleaned of residual dust and dirt and examined for corrosion, deformation and irregularities. Then the metal surface is treated with a grinding machine or a simple metal brush with coarse teeth.

And only after these stages can the process itself begin.

Since welding will be performed automatically, you do not need to heat the arc, monitor the direction of the electrode, or control the speed at which the wire will be fed.

You just need to select the settings and welding mode and correctly load the flux material and parts.

For such installations, there are different types of filler wire. Its material should usually match the material from which the elements being processed are made. The spool of wire is loaded into the recess of the mechanism that will feed it.

Equipment used for submerged arc welding

Let's take a look at existing submerged arc welding equipment. When it comes to carrying out welding work in a production workshop, before starting the welding process, the parts to be welded are securely fixed on a special assembly stand or using other devices in order to completely eliminate possible unplanned movements of the elements being welded during work.

Welding tractor (manufacturer: Multitrac)

When laying pipelines, special mobile welding heads are mainly used for welding joints, and in the production of sheet structures, either stationary installations or universal mobile ones (for example, a welding tractor) are used. The submerged arc welding tractor is a self-propelled trolley with an electric motor on which an automatic welding head is installed. Such a device can move along the parts being welded along a rail track or directly along the parts themselves.

Welding column and welded part on roller supports

In workshop conditions, mobile or stationary welding columns are also actively used, which, in combination with roller bearings or rotators, are used for welding longitudinal and circumferential seams.

Automatic submerged arc welding technology - where and how it is used

Every welding master knows how the oxygen environment affects the seam - not in the most positive way. Once in the area of the base metal that has reached the melting point, it oxidizes the solid metal and various alloys.

There are ways to get rid of this problem. You can treat the metal with antioxidant substances, or you can use auxiliary materials, such as fluxes.

Using flux in combination with automatic equipment is the primary method used by welders. Thanks to “this pair” the seams are smooth and resistant to oxidative corrosion.

Flux helps in welding even “difficult” metals, such as non-ferrous or stainless steel. Automatic equipment does not require much effort from the technician, and the flux itself provides protection for the connection.

In this article we will share the technique of automatic submerged arc welding, describe what it is, and also talk about the pros and cons of this method.

Equipment used

To perform automatic submerged arc welding, the following technical equipment will be required:

- Welding plate. Installation of welding slabs will require a concrete base, since the slabs themselves are made of materials that are resistant to constant high temperatures and temperature changes.

- Floating wire. It usually has a thickness of 0.3 to 12 mm, and is made from the same material as the materials being welded.

- A non-consumable electrode that has a heavy alloy core and a ceramic braid.

- System supplying flux particles. It consists of a reservoir and a hose, the diameter of which will be sufficient to work with the electrode.

- A control system that is more developed in automatic devices and less developed in semi-automatic ones.

Automatic welding under a layer of flux is not difficult to perform, because most of the process will be automated, and the welder will only need to correctly configure the equipment and select the correct flux agent for welding.

Source