Caulking of cast iron pipes is carried out when dismantling or repairing a sewer system that has become unusable. The caulking technology depends on the method of connecting the joints (type of seal): cement ones are carefully broken with a hammer, those filled with hot sulfur are heated with a blowtorch. Disassembling an old cast-iron sewer is more difficult than a recently assembled one, since over the years it rusts and the thickness of the deposits increases. In any case, it is labor-intensive process, cast iron, for all its advantages, is a brittle material and breaks under the direct application of force.

- LiveJournal

- Blogger

It is most difficult to disconnect cast iron sewer pipes at the junctions of apartment wiring and public risers; without experience, these areas are best left to specialists

Repair work on the street

If there is a need to repair a cast iron pipe that is located on the street, then you can use the same methods as described above. However, it is advisable to do additional fixation of the joined cast iron pipes so that deformations in the ground do not open cracks. If the pipe is adjacent to a septic tank, then the above methods may not work. The design of the septic tank is subject to seasonal fluctuations, and this can destroy the integrity of the connection being repaired.

In this case, the first step is to use liquid glass, which is filled on top in large quantities with mastic, which is used for gluing joints in panel houses. In principle, mastic perfectly seals cracks on its own, so if liquid glass is not available, you can do without it. However, it is still better to do sealing with it, it is more reliable.

When renovating, many people try to replace all outdated communications at once. It turns out that the most difficult thing to work with is cast iron sewer pipes that need to be dismantled. Previously, they were connected using cement, sulfur or aluminum. It turns out that the system was carried out for centuries. But now the end of the century has come. And at the same time, difficult work begins.

At first glance, it may seem that removing cast iron pipes is very easy. But here you need to work wisely. After all, if you apply too much force, you can damage the riser that connects several apartments at once. In this case, the anger of the neighbors is inevitable. There will be costs, time and a lot of work.

Before you start dismantling an old cast iron pipe, you need to familiarize yourself with some rules:

- turn off the water supply in the house;

- remove the hose from the flush tank on the toilet;

- clean the toilet carefully;

- remove from the premises all devices and objects that may interfere with the work;

- Cast iron is a brittle material. Pipes that are located far from the riser can be broken with a hammer;

- removal of pipes that directly approach the riser;

- Cuffs are installed on the bell. First, the bell is cleaned of lubricants.

Dismantling of cast iron sewerage

Every person in his life at least once faces the problem of major renovation of his home. The question always arises of repairing or replacing the sewerage system, electrical wiring, water pipes, because this is the first thing such repairs begin with. In most cases, before major repairs begin, cast iron sewer and water pipes are installed everywhere.

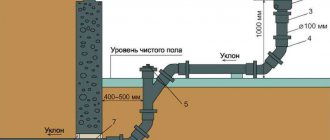

Sewage pipe connection diagram.

Before replacing them with new ones, you need to dismantle the old ones. In this article we will look at the question of how to disassemble a cast iron sewer. We will prepare the tools you will need for the job. Here is a list of what is needed:

- Bulgarian;

- chisel;

- blowtorch;

- gas mask, gauze bandage or respirator;

- hammer;

- screwdriver;

- pipe wrench.

First of all, before you start disassembling the system, you need to decide what the pipes are “planted” on, that is, what was used for the connection: sulfur or cable and cement.

Dismantling instructions

It is best to begin work on dismantling pipes that are located remotely from the riser. Here a hammer and chisel will help get the job done very quickly, since cast iron is a material that is brittle and cannot withstand impacts.

It is important to use a rubber hammer or with a polymer tip. A steel hammer will crush the cast iron into small pieces that can fall into the riser

Further, a congestion will begin to form there, which will be very difficult to eliminate.

Work with a hammer and chisel continues until it reaches the tee that leads to the riser. Then you can try to loosen the crosspiece manually. But you can leave the cross section completely. However, experts recommend removing cast iron from your home as much as possible.

The work of heating the pipes is carried out quickly by two people. One person can heat the pipes with a lamp, and another can remove the softened sulfur with a knife. When a large amount of sulfur has been removed from the pipes, the cross will quietly separate from the riser. If you cannot completely pull out the tee, you can cut it off with a grinder. The main thing is not to damage the riser.

Preparation for dismantling

Before you start sorting out the riser, it is necessary to carry out preparatory work. This stage includes the following measures: disconnecting all plumbing fixtures (toilet, bathtub, sinks, etc.) from the sewer system; clearing the area around pipes and risers; shutting off the water in all apartments above the dismantled area; warning neighbors about the inadmissibility of using sewerage during the work. It is important that no flammable materials remain in the dismantling area, since you will have to use an open flame. If there is a water supply system made of plastic pipes next to the riser, they should be securely covered with a screen or asbestos.

Return to contents

How to dismantle a cast iron pipe

If a pipe is “welded” to a wall or floor using sulfur or aluminum, it will be very, very difficult to destroy such a coating.

To get started, you must first turn off the water supply to the apartment. Then you need to free the bathroom from unnecessary items that you can damage during work. This includes the sink, washing machine, laundry basket, etc.

Next, you need to disconnect the flush tank from the water supply and dismantle the toilet itself. Problems may also arise here, since Soviet toilets were screwed to the floor conscientiously, in other words, tightly.

Try to unscrew the bolts that attach the toilet to the floor and remove it from its place. If you succeed, consider yourself half done.

Now comes the turn of the pipes themselves. Cast iron, as you know, is not particularly strong, so at some distance from the riser you can simply break the old pipe with a hammer. It is much more difficult to remove the remains of pipes from the old riser and clean them before installing new ones.

To dismantle pipes, you may need:

- A hammer with a rubber or plastic tip.

- Chisel

- Torch or blowtorch

- Mask

Quite a strange combination, isn't it? However, a gas mask is necessary to comply with safety precautions if the joints of sewer pipes in your bathroom are filled with sulfur.

The easiest way to remove sulfur is by heating it. However, when heated, the sulfur mass releases toxic substances into the air, which are extremely harmful for humans to inhale. That is why it is better to protect yourself with a gas mask in advance.

So, dismantling must begin at the point of greatest distance from the riser. Here, most craftsmen do not bother with the torch, but simply break the pipe with a hammer. This is much simpler, but can cause some complications.

Make sure that when broken, pieces of pipe do not fall into the sewer passage. They can cause serious clogs in the drain, which will be much more difficult to get rid of than getting rid of old pipes.

With a hammer, you can destroy the pipe up to the crosspiece inserted into the riser. Here it is somewhat different and filled with much more sulfur.

To free the pipe and cross from the layer of sulfur, you need to heat it. The impact of a burner or blowtorch can last for several hours, while harmful substances will be constantly released.

Before you start heating, isolate animals and household members, cover furniture or other furnishings located in the immediate vicinity of the riser, and put on a gas mask.

During the heating process, you can easily chip off pieces of sulfur until the pipe is sufficiently clean. Now, the cross inserted into the riser must be loosened if possible and removed from the riser.

The dismantling of the old pipeline is carried out as much as possible. That is, all possible pipes are removed, and others are installed in their place.

Connecting a new PVC pipe to an old cast iron riser will require certain operating skills. Please note that you must clean the connection area as much as possible from the same sulfur and rust.

To make the job easier, use a special coupling that is specifically designed to connect cast iron pipe and PVC pipe.

If you still have questions, take a look at ours and ask them there. Our experts will help you understand the intricacies of good construction and renovation.

How to connect new and old pipes

A rubber cuff is used to connect old and new sewer pipes. The cuff is pulled onto a plastic pipe and fits into a cast iron socket. There is one caveat:

The cast iron socket must be thoroughly cleaned before inserting a plastic pipe with a rubber product into it. Remove all layers from the inner walls. The easiest way to do this is with a chisel. It perfectly removes rust and other unpleasant things remaining in the sewer.

After cleaning the bell, you need to wipe it dry with a rag and, during connection, it is advisable to apply a small layer of silicone sealant to the inner surface of the bell or the outer surface of the cuff. Firstly, it will reliably fill all the pores and prevent the smell of sewage from entering the apartment. If a draft forms in the riser and, under certain conditions, all odors can penetrate into the apartment through the slightest cracks, so all connections must be absolutely airtight. Secondly, silicone will ensure absolute tightness even if the riser is clogged. Even if it is full, not a drop will spill into the apartment. If all connections are carefully sealed, water can only flow into the plumbing fixture. Its role is usually played by the bathroom.

The process of dismantling pipes connected by cement and cable

When discussing how to dismantle an old cast iron sewer connected with cement, it is worth noting that the process is not much different from the above, but is safer.

This is explained by the fact that sulfur releases carbon monoxide during melting.

And it all starts with cutting off a certain part of the cast iron pipe, for which you need to step back from the disconnection points by about 30 cm.

The hardened cement is knocked down using a hammer, which needs to be hit on a screwdriver inserted into the hole.

Dismantling the connection with cement and cable

It is important to know that you should not rush in this matter, because you may damage the bell. After breaking the cement at the joints:

After breaking the cement at the joints:

- you should try to loosen the main pipe. If you are interested in how to disassemble a cast-iron sewer without heating, then know that it is possible to remove the heel;

- If you can’t loosen the pipe even without a heel, then strong heat or a special wrench will help. For example, for pipes with a diameter of 50 mm you need tool No. 3, No. 4, but for a tee you will need another pipe.

Replacement of water and sewer pipes is usually necessary when the system is partially or completely worn out. And if you decide to carry out technical work without the participation of professionals, then you need to prepare in advance and know how to dismantle the sewer yourself.

Do-it-yourself repair work is dangerous because even when replacing a worn part, there is a possibility that the leak will reappear. As a result, if the sewer pipes are not trustworthy, it is better to completely change the entire system. But before this, it is necessary to dismantle the sewer.

By replacing pipes, it is possible to completely change the system of their arrangement, especially since today’s materials allow this to be done without any problems. Modern materials, for example, pipes made of metal-plastic, are more reliable, strong and durable than cast iron, and most importantly, sewer pipes are installed quite quickly and relatively simply.

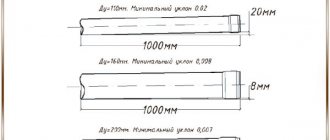

When replacing the entire riser, it would be more appropriate to replace all plumbing fixtures and outlets located on the equipment. In addition, you can change the entire route of the old collector. In this case, it is necessary to strictly observe the correct slope and diameter of the pipes.

Possible problems

In order to efficiently dismantle a cast iron pipeline, it is necessary to cut off the pipe as much as possible to the section where the transition into the socket begins. This will simplify the docking of new equipment. You will definitely need a grinder. If it is not there, then use a regular hacksaw, however, the dismantling process will take a lot of time.

In some cases, when demolishing a sewer system, a lot of problems and setbacks arise. However, there is no need to despair. In specialized stores you can buy adapter couplings that will help connect cast iron structures and PVC pipes.

There are often various difficulties encountered when working with plastic pipes. To easily cut a piece of pipe, cut it halfway around the perimeter. Next, you need to act by simply pressing and a slight rotational movement, after which the pipe will burst.

Important! The cast iron structure can be quite strong, making it difficult to remove from the riser socket. To correct this situation, several cuts are made around the pipe every 2 cm. This helps to remove the pipe from the riser.

When it comes time to connect plastic and cast iron pipes, heating will be required. The cast iron connections are first cleaned of sulfur, then the system is allowed to cool slightly. The final stage can be considered the installation of a new pipeline. To avoid any problems in the future operation of the sewer system, you should purchase pipes made from modern materials. These include metal-plastic and plastic.

Repair work on the street

If there is a need to repair a cast iron pipe that is located on the street, then you can use the same methods as described above. However, it is advisable to do additional fixation of the joined cast iron pipes so that deformations in the ground do not open cracks. If the pipe is adjacent to a septic tank, then the above methods may not work. The design of the septic tank is subject to seasonal fluctuations, and this can destroy the integrity of the connection being repaired.

In this case, the first step is to use liquid glass, which is filled on top in large quantities with mastic, which is used for gluing joints in panel houses. In principle, mastic perfectly seals cracks on its own, so if liquid glass is not available, you can do without it. However, it is still better to do sealing with it, it is more reliable.

Almost all Soviet buildings are equipped with cast iron sewer lines, since such pipes are durable and resistant to wear. But a cast iron pipeline requires the correct approach to use and dismantling.

Unlike drain pipes, which can last for decades, connections inside your home may require replacement sooner. Also, interventions in the sewer system may be forced during work on installing washing equipment or remodeling a bathroom. To do it according to the rules, it is not necessary to call and wait for a master; all the work can be completed by the owner himself, if he knows how to handle basic tools. Dismantling the sewer system should not take much time, but dismantling old products is more difficult. Let's figure out how to properly dismantle cast iron pipes.

Caulking a cast iron pipe

To hammer out a cement-lined sewer pipe, remove the seal using a special hammer. Strong impacts are unacceptable; the cement breaks off into small pieces. After this, the edge of the heel is looked for (a rope wrapped around the pipe to enhance the tightness) and an attempt is made to unwind it. There is no need to pull out the entire cable; it is enough to slightly free up the space and loosen the cast iron pipe entering the socket. It is most convenient to pull out the rope using a hook; if possible (free space), then a screwdriver is squeezed into the gap between the socket and the pipe. Only after the pipe begins to swing is it possible to pull the cast iron pipe out of the socket. To do this, it is pulled back in the transverse direction and scrolled in the end direction.

- pipes have grown together during operation;

- For sealing, they used sulfur rather than a heel with cement.

The remains are carefully chipped off with a chisel; it is important to avoid metal elements getting into the sewer. After this, the inside of the bell is cleaned and wiped dry with a rag.

It is more difficult to disassemble cast iron sewer pipes with a sulfur plug; heat treatment of the joint area is required - heating with a blowtorch to several hundred °C; the desired condition is determined visually (the pipe will turn red). In this case, the sealant burns through and the pipe becomes free. An important nuance: it is allowed to remove a cast-iron sewer pipe no earlier than 15 minutes after heating; it is impossible to loosen or impact the hot joints. As in the case of caulking pipes with a heel, impacts on the pipes are not allowed; a pipe that has become unusable is carefully unscrewed (without effort or pressure).

The same rules apply when replacing a toilet. It is recommended to disconnect the water supply, drain the tank as much as possible and. When fastened with studs or a nut connection, it is easier to replace the toilet bowl with your own hands: it is unscrewed, loosened and removed from the outlet pipe. It is almost impossible to remove a toilet bowl installed on cement mortar intact, in this case it simply breaks.

Hitting the sewer pipe is strictly prohibited; it is the same as directly hitting cast iron with a sledgehammer. Therefore, the blows are applied to the neck, and then the toilet is broken into pieces. When the base is disconnected, water flows out of it; it is advisable to prepare rags and a bucket in advance to collect it. It is necessary to clean the edges of the cast iron drain pipe from pieces of earthenware. This is done using a chisel or screwdrivers; this stage is very critical (the pipe goes into the floor, and if it is damaged, problems arise). At particular risk are common risers with tees (c) and old toilets with cement-covered joints; in this case, it is better to entrust the caulking to specialists.

WATCH THE VIDEO

The most difficult step when replacing an old pipeline is the dismantling of a cast iron pipe that has served its purpose. Previously, when constructing communications, pipes made of cast iron were used, the connection of which was made with cement mortar, sulfur or aluminum. Pipelines assembled using the last two substances are very difficult to destroy, so you need to prepare for lengthy dismantling work. And this article will tell you about the technology for their implementation.

Caulking of pipes connected by sulfur

It is easy to recognize the presence of sulfur in a seam. You need to bring the flame of a blowtorch or gas burner and heat the seam. If there is sulfur in it, it will begin to melt and emit unpleasant odors. It is recommended to start work from the far corner. The crosspiece connected to the riser is heated with a blowtorch and becomes loose. It is more convenient to do the work together. One person heats up the seam, the other shakes the structure. We must not forget about the use of protective gloves.

After loosening the structural element and melting the substance, you need to pull the cast iron pipe out of the socket and clean the area of sulfur residues. After completing all the work, allow the pipe to cool. When carrying out work, you need to use a respirator or gas mask to avoid breathing sulfur vapors. You should also use special work clothes. Compliance with safety regulations when working with open fire is mandatory. Then any pipe can be removed without any problems.

Dismantling the riser

It is necessary to follow the rules when disconnecting a vertical waste pipe:

- management services are notified and permission to carry out repair work is issued;

- riser users living above the floor are notified;

- repair operations are being carried out.

The presence of a compensator allows you to move the product in one direction or another up to 10 cm. It must be remembered that the vertical structure has a certain mass. Therefore it needs to be fixed.

The joints are treated with machine oil. By performing rotational-translational movements, the part is removed from the general structure. The absence of a compensator forces one to resort to radical methods - cutting the drain pipe.

PVC plastic sewer pipes can be processed with most plumbing tools:

- a hacksaw with a fine hardened tooth;

- hacksaw for metal;

- file;

- a sharp and durable knife and other tools.

Mechanized device – grinder, reciprocating saw.

When carrying out work, you need to pay attention to the presence of a number of other communication elements:

- pressure conduit;

- electrical system cable;

- storm drain.

Connections of sewer pipes that have served for 10 years or more can “stick” or “grow” to each other. A number of recommendations can help in such cases;

- treating the joint with WD-40 lubricant;

- wrap sandpaper around the pipe; make rotational movements through it - your hands will not slip, the circular force will increase;

- if the product is scrapped, then it is necessary to make a through hole across the part; by inserting a tube or metal rod, we get a lever;

- use the “barbaric” method of dismantling - cut the pipe into pieces, break it out piece by piece.

The methods for separating the PVC pipe parts used for the installation of an external main are exactly the same. But, it is necessary to determine the location of the damage and carry out excavation work.

How and what methods of uncoupling pipes is to be chosen by the home owner or invited specialists. The main thing is to determine the feasibility of one or another method of dismantling faulty parts.

Surely there was a lot of cast iron in the Soviet Union! All technologies were developed taking into account the use of this particular material. Cast iron is still in great demand in sewer laying. Of course, cast iron has many very significant advantages - it can withstand heavy loads, which makes it possible to assemble risers on many floors, it is durable, can perform its function in damp or cold rooms for decades, paint adheres well to a cast iron pipe, that is, it can be painted beautifully into design. In a word, a sewer pipe made of cast iron is a solid, durable thing. But this thoroughness lies its main drawback. It is very difficult to disassemble, if necessary, part of such a pipeline. And sometimes there is an urgent need for this. For example, you needed an additional outlet or the existing outlet became unusable. What to do?

It’s best when the work is done by a professional, a master of his craft. In this case, you can be confident in the quality and efficiency of the work performed. But this option is not always possible. Often you have to wait weeks for a plumber, and their prices are, to put it mildly, inflated. It happens that this “master” has no experience in such work. Not all those who wear plumber's overalls are plumbers.

Sewer repair

Repair of cast iron sewers is often carried out using “old-fashioned” methods. However, modern repair methods are much more effective. If a small crack or chip appears on the pipes, then it will be enough to use a bandage, a jar of liquid glass and cement. To begin with, the surface is prepared according to the standard procedure (cleaning and degreasing). Next, liquid glass and cement are mixed until a thick mass is obtained. The finished mixture is spread on the pipe and wrapped in a bandage, with each turn being treated with the mixture.

If the crack in the pipe starts from above, then you can apply a rubber bandage in the longitudinal direction. The overlap is bent and tightened with two clamps. If you have the financial opportunity, you can fill the entire surface with silicone. Silicone will be effective for a while, but since it is not intended to be applied over large areas and has poor adhesion to cast iron, its benefits will not last long.

Sewer system

Using a grinder, the pipe adjacent to the tee is cut at a distance of no less than 10 cm from the socket of the riser.

Dismantling cast iron sewer pipes begins with dismantling the riser. When doing this work yourself, you should know that previously cement-based solutions were used to perform sealing. Such compositions only become stronger over time. As a result, dismantling an old sewer system can be quite a hassle.

The most difficult part may be replacing the riser. After all, in the good old days, craftsmen filled with sulfur. To liquefy such solutions you need a gas burner or a blowtorch. When burning, sulfur solutions release harmful vapors into the atmosphere, so the use of a respirator by workers in such cases is simply a necessity.

This can lead to damage to elements located in the apartments adjacent above and below.

It follows from this that it is better to change the pipes of all neighbors in the riser at once.

Specialists perform dismantling of sewer pipes in the following order:

- cast iron pipes are cut using a grinder;

- first, 2 cuts are made horizontally, and the distance between them should be approximately 10 cm;

- using a chisel, break out and remove pieces;

- the tee is dismantled;

- The rest of the pipe is dismantled.

Dismantling of old sewerage

- Dismantled systems

- Dismantling principle

- Necessary tool

- Preparation for dismantling

- Carrying out work

Dismantling the old sewer system is an important stage in the overhaul and replacement of the sewer system in an apartment in a multi-story building. Contrary to the well-known saying that breaking is not building, dismantling an old sewer riser is a rather responsible and labor-intensive undertaking. In the old days, such structures were built from cast iron sections, and they were joined for centuries - hermetically and very firmly. In order to disassemble such a system with your own hands without damaging other sections of the riser, you need to apply maximum skill and effort.

Scheme for dismantling the old sewer system.

Removing a Cast Iron Pipe

Dismantling the riser begins with removing the pipe located between the tee and the ceiling. First, a ring-shaped gap is made on top of the section. To do this, at a distance of 12-16 cm from the ceiling, using a grinder, a cut is made in the pipe with a wall remaining of about 3-5 cm.

An incomplete cut is needed to prevent the tool from jamming during possible vertical movement of the column. Then, retreating 9-13 cm down, a similar cut is made, parallel to the first. The ring between the cuts is carefully knocked out with a hammer or using wedges.

The next step is sawing the cast iron section from the bottom. To implement this, an incomplete cut with a grinder is made at a height of 50-70 cm from the upper socket of the tee. The clamps securing the section to the wall are removed (they can simply be cut off with a grinder). The pipe is broken by rocking or hitting with a hammer at the place where the cut is incomplete and is removed from the column.

Removing the tee

The most important operation of the entire dismantling of the old sewer system is the removal of the tee from the socket of the lower section of the riser

As noted, there is an important condition: this bell must not be damaged. The simplest dismantling options are used when filling the joint with cement mortar

First, an attempt is made to disconnect by loosening.

A crowbar is placed in the hole in the remaining pipe, with its help creating bending forces in different directions. Most often, such loosening destroys the cement bond, and the tee can be removed from the lower socket. If the joint is destroyed, large cement pieces should be prevented from getting inside the pipe, that is, the cement is removed from the socket with a screwdriver or chisel.

If loosening does not lead to a positive result, then you will have to use a more labor-intensive method: the cement mass is destroyed using a chisel and hammer

Given the fragility of cast iron, this procedure should be carried out very carefully, and the impact force should be applied away from the walls of the socket. The goal is to provide a gap between the tee pipe and the socket walls

As cement pieces break off, they are immediately removed from the joint area.

The most difficult method of dismantling has to be used when filling the joint with sulfur. This composition is very durable and does not lend itself to the methods of destruction described above. In this case, heating the connection area using a gas torch or blowtorch is most often used. The work is carried out by two people. One worker heats up the joint, and the other loosens the tee.

When the mass melts, the tee is easily removed from the socket

Such work is carried out with the release of very harmful gases, which means it is necessary to take precautions (respirator and safety glasses)

Finally, extreme circumstances may arise when it is not possible to remove the tee from the lower section in any way (it is impossible to use heating, particularly strong pouring and other non-standard situations). In this case, the most undesirable option is used - the tee is cut off at a height of about 5-6 cm from the socket. The end of the remaining pipe is carefully leveled, and subsequently, when installing plastic pipes, you will have to use a coupling.

If you plan to install new plastic sewer pipes, then it is impossible to do without the rather labor-intensive dismantling of the old cast-iron sewer system. This process can cause a number of difficulties, so you should prepare in advance to solve emerging problems.

When a person makes major repairs in his apartment, then this type of work, such as replacing the sewer system, is one of the main ones. This is due to the fact that in most cases cast iron pipes are installed in residential premises.

Which tool will be used to dismantle sewer elements with your own hands depends on the material used for embossing.

Basically you should have on hand:

Embossing tool

- grinder - used to cut a piece of pipe;

- cutting and grinding discs;

- protective mask, goggles, headgear (in case of caulking pipes connected by sulfur);

- blowtorch - required for heating;

- hammer, screwdrivers of various lengths and thicknesses;

- pipe wrench;

- chisel.

Grinder and blowtorch

If you are dealing with cast iron elements, then your arsenal should include: a hammer drill, a chisel/steel wedge, a crowbar or nail puller, a pipe cutter, and an iron bucket filled with water.

Before you start work, it doesn’t hurt to draw up an action plan, which depends on how the sewer pipes are connected.

Hammer

Dismantling principle

The ideal option for replacing the old riser section is when you can disconnect and remove the tee and the entire pipe section up to the top tee. However, this option requires the consent of the neighbors above to unblock the hole in the interfloor ceiling and carry out work in their apartment (the upper joint is located in the apartment on the top floor), which in reality is rarely achievable.

Instructions for dismantling an old cast iron sewer riser.

Most often you have to be content with an area limited by the ceiling.

The technology for dismantling an old sewer riser is largely determined by the method of connecting its sections. It is the strength and solidity of this connection that creates the main difficulties. The fact is that when disassembling the tee, the bell of the lower section, which remains in operation after repair work, must not be damaged, which means the impacts should not cause chips, cracks and other defects to appear.

The main methods of connecting sections, that is, caulking seams, were: pouring with cement-sand or cement mortar, polymer-cement composition or sulfur. The most durable connection was ensured with the help of sulfur, which requires special methods for disassembly.

Return to contents

We analyze the internal wiring

This stage usually takes the least time. There is no point in keeping the pipeline inside the apartment intact, so there is no need to disassemble it. It is enough to simply cut off the outlet leading to the bathtub, sink and other plumbing fixtures using a grinder, and then saw or split it into smaller pieces and take it out of the apartment.

Dismantling the riser

Dismantling the riser must be done with extreme caution. First of all, you need to make a couple of horizontal cuts in the upper part of the pipe, at a distance of 10–15 cm from the ceiling

You should not saw through the pipe completely; it is better to leave a section of 3–5 cm in size intact. Then carefully knock out the ring formed between the cuts with a sledgehammer.

Next, the section is sawed from below at a distance of about half a meter from the tee/cross. After this, remove the clamps that secure the pipe to the wall. Then the section is split off along the saw line, removed from its place and removed from the room.

Tee analysis

The procedure for dismantling the tee/cross will depend on how its joint with the lower section of the sewer pipe is sealed. If cement is used as a sealant, the fan outlet is carefully loosened using a crowbar. During the process, you can try to break off and remove small pieces of cement putty using a narrow screwdriver. If the cement layer is very thick, knock it down with a hammer and chisel. Having removed the bulk of the putty, the crosspiece is carefully removed from the socket.

If the tee is sealed with sulfur, in order to remove it, it is necessary to heat it for a long time with a blowtorch or hairdryer. When heated, the sulfur putty will melt. The tap must be constantly loosened little by little to speed up the melting process. As soon as possible, it is removed from the socket.

If the fan outlet cannot be manipulated, it is simply cut off with a grinder at a distance of 5–6 cm from the lower socket. The remaining part of the riser is then cleaned, and new pipes are connected to it using special adapters.

Repairing a deteriorating sewer system. The technology of caulking depends on the method of connecting the joints (type of seal): cement ones are carefully broken with a hammer, heated with sulfur with a blowtorch. It is more difficult to disassemble than a recently assembled one, since over the years it rusts and the thickness of deposits increases. In any case, this is a labor-intensive process, cast iron, with all its advantages, it is a brittle material and breaks under the direct application of force.

Moments of disassembling cast iron

If you completely replace the structure with a plastic one, you don’t have to do any extra work and just break everything with a hammer. This is quite easy to do, because cast iron is considered a brittle material. However, if only part of the pipeline needs to be dismantled, the work must be done more carefully.

Before dismantling a cast iron sewer system, it is necessary to inspect the entire system to determine the area that will be repaired. Then the water supply must be turned off to prevent waste from entering the sewer system. Further disassembly is carried out in stages:

- The part of the pipe located below the connection is cut off.

- The pipe is disconnected from the socket. Chasing methods will be discussed in more detail.

- If you can’t easily remove the connection, use a blowtorch or make surrounding cuts 20 mm long.

When carrying out procedures, it is imperative to use all protective equipment due to the risk of injury of this work.

Caulking of a pipeline with a sulfur compound

Regardless of how the cast iron sewer was connected, before replacement it is necessary to carry out some standard preparatory work:

- turn off the water;

- disconnect the hose leading to the toilet;

- remove the toilet itself by unscrewing the bolts;

- clear the bathroom of appliances and furniture.

To determine whether sulfur was actually used when joining the pipes, you need to bring a blowtorch to the seam. When exposed to high temperatures, sulfur melts, accompanied by an unpleasant odor.

When dismantling cast iron sewer pipes, work begins from the farthest corner. The element must be broken with a hammer. It is better to use a tool with a plastic or polymer base, because metal nozzles can clog the sewer. Having found the cross leading to the riser, you need to loosen it as much as possible.

Then you need to prepare a blowtorch or gas burner. Warming up connections should be carried out by at least two people. While one heats and melts the sulfur, the other must loosen the structure. In this case, be sure to use gloves and other protective equipment.

When the connecting substance is completely melted, the crosspiece can be removed from the riser. In this case, you should be very careful, you must remember to remove the remaining sulfur, and then let the riser cool thoroughly. If the cast iron structure turns out to be too strong, you can always make a few cuts near the pipe that needs to be removed. This will make the extraction process easier.

Caulking of a pipeline with a cement connection

Dismantling cast iron pipes that have been connected with cement is practically no different from the above-mentioned option with sulfur, but is much safer.

This is because when sulfur melts, a lot of carbon monoxide is released. To begin dismantling, you need to cut off part of the pipe. In this case, it is worth retreating at least 30 cm from the junction. Hardened cement is removed with a hammer, which must be used to hit a screwdriver or chisel inserted into the hole. All procedures should be performed as carefully as possible so as not to damage the bell.

When the joints are freed from cement, you need to try to loosen the main pipe. In order not to treat the sewer with a blowtorch or torch, you need to remove the cable, but if this cannot be done without, you need to heat it very much or use a specialized wrench. For example, for a 50 mm pipe, use tools Nos. 3 and 4.

The crosspiece is located below on the main riser. To remove it, you can simply use a hammer and screwdriver. In this case, for some time you need to lightly tap on the tee itself in order to form a small gap between it and the pipe. Then you need to penetrate this opening, pry off the tee and remove it. Carrying out these manipulations will take a lot of time, in addition, this method can be ineffective.

The next option is to use a blowtorch or torch. Dismantling occurs much faster, but the price for this is an unpleasant odor that takes a long time to disappear. First of all, you need to cut off the bell of the cross. Then a heating device is placed into the pipe. A metal shield is placed on the top of the pipe to be able to regulate the draft inside the riser. When heating, you need to start rocking the pipe and, as soon as the opportunity arises, remove the dismantled tee.

You can also use a grinder. To do this, you must first cut off parts of the tee, leaving a small piece in the pipe. Then put a small disk that could easily get inside, and use a grinder to cut through the remaining parts of the structure, knocking them out with a hammer.

Required tools and materials:

- Hammer;

- Chisel, hammer;

- Strong knife;

- Small "grinder";

- 3-4 cutting discs with a diameter of 125 mm and 1 grinding disc;

- An old chisel, several screwdrivers of different widths, lengths and sharpness;

- Safety glasses, respirator, hat;

- Steel wedge for breaking cast iron pipe parts;

- two adjustable wrenches;

- a large nail puller or a small crowbar to use as a lever.

- Pipe cutter for cast iron pipes. Using such a pipe cutter will significantly speed up and simplify the process of dismantling the sewer, but such a pipe cutter is expensive and is rarely used on the farm.

- An old iron bucket half filled with cold water;

First, you need to determine how the cast iron parts were connected, first of all, the tee (1) or cross (2,3) with the socket (fitting part) of the pipe located in the lower ceiling. To do this, carefully clean the joint, usually it is located above the floor level. But if you have previously made an additional screed or laid tiles on the floor, the connection may be below the level of the existing floor, in which case you may need a hammer drill or chisel. You should work with both the hammer drill and the chisel very carefully so as not to damage the socket of the pipe remaining in the ceiling.

The joining could be done by caulking the seams with ordinary cement-sand mortar, cement mortar, polymer cement mortar, and - the worst option - filling the joint with sulfur. Using an old chisel or a sharp screwdriver, pick out the top layer of the seam between the tee (cross) and the shaped part of the pipe located in the lower ceiling to get to the sealant. If it feels hard to the touch and the chisel slides across the surface with an unpleasant squeak, reminiscent of the sound when you drag a knife across glass, then it is very possible that you have come across sulfur. To be sure, try to pick out a sample and try to set it on fire. If the picked sample ignites, burns with a blue flame and at the same time a caustic gas is released, then you are out of luck - it is sulfur. Then you will need