Is it possible to solder stainless steel to copper?

Soldering copper to stainless steel, although it is a rather complicated process, is still possible. The fact is that the connection of stainless steel to stainless steel and copper to copper occurs much more often, since the final quality of the connection is much better. But in various situations, when you need to make such a connection, you have to compromise on quality. Especially for such cases, special solders are produced that allow you to make a reliable connection that meets operational requirements. While for other types of soldering the use of flux is not always necessary, here it is necessary to carry out a full range of procedures, including tinning, and also to use all additional materials.

What else you should know about soldering stainless steel

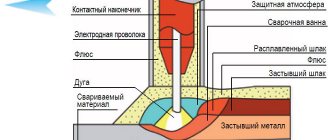

In cases where special requirements are imposed on soldered joints of stainless steel products, special grades of solders can be used, which include materials based on nickel and phosphorus, as well as nickel, chromium and manganese. Solders of the second group are used, in particular, in cases where soldering is performed in a protective gas environment consisting of a mixture of argon and boron trifluoride. When performing soldering using this technology, pure copper can be used as solder, which wets the metal well and forms a reliable connection.

When using copper solder, the soldering area will differ from stainless steel in a characteristic yellow color

Nickel-based solders make it possible to obtain joints with high strength. However, such materials also have disadvantages, which include low ductility. That is why such filler material is not used to connect stainless steel structural elements that will be subject to shock and vibration loads during their operation. In addition, a soldered seam made of such a material is very critical to low temperatures. Soldering with nickel group solders, which melt at temperatures exceeding 1000°, can be performed in dry hydrogen, argon and vacuum.

Thus, soldering stainless steel products (large pipes operated under pressure, dishes, pieces of furniture or interior design) has its own nuances, which must be taken into account when choosing both soldering modes and consumables. There are many reference books, guided by which, you can optimally select all the necessary materials and obtain a high-quality, reliable and beautiful soldered connection.

How to do soldering at home

Problems such as joining stainless steel parts using soldering and soldering stainless steel to copper are often encountered at home. Products made of stainless steel have been actively used in everyday life for many years, therefore, when for some reason they become unusable, any home craftsman has a natural desire to repair them himself. It should be said right away that soldering stainless steel parts is not so difficult, the main thing is to strictly adhere to the technology, as well as stock up on the appropriate tools and consumables.

Master the soldering technique on simple connections, and then try working with more critical parts

Before you start soldering stainless steel, it is very advisable not only to study the theoretical material on this issue, but also to become more familiar with the rules for its implementation using training videos.

To solder stainless steel products, you will need the following tools and consumables:

- a soldering iron powered by electricity with a power of at least 100 W;

- special soldering acid, which will be used as a flux;

- file or sandpaper;

- solder, specially designed for joining steel parts, based on tin and lead;

- cable made of steel;

- metal tube.

Soldering materials and tools

When choosing a soldering iron for working with stainless steel, you should opt for a tool with a power of 100 W. Using a more powerful device to perform such work is simply not practical.

The process of soldering stainless steel parts is carried out according to the following algorithm.

- First of all, it is necessary to thoroughly clean the area of the future connection, for which sandpaper or a file is used.

- After preparing the surfaces of the parts to be joined, it is necessary to apply flux to them, which, as mentioned above, uses soldering acid. The main task of the flux is to ensure high-quality tinning of the parts to be joined.

- After the surfaces of the parts to be joined are treated with flux, it is necessary to tinning them, which consists of applying a thin layer of solder consisting of tin and lead to them. If tinning was not successful the first time, then it is necessary to repeat this procedure, preheating the parts to be joined.

- Even after heating the products and re-processing them with flux, tinning may not be successful - the solder will simply roll off the surface of the parts, rather than lie on them as a thin film. In this case, you need to use a brush with metal wires, which can be easily made from a tube and steel cable. Before using such a brush, it is also necessary to apply flux (soldering acid) to the surface of the parts and only then, heating the future joint with a soldering iron, clean it with a metal brush. This simple technique allows you to effectively clean the surface of a stainless steel from an oxide film, which, as a rule, is the main obstacle to high-quality tinning.

- Once a thin layer of tin has been applied to the products to be joined, you can begin to solder them. This procedure is performed using a soldering iron and solder, which is used to fill the joint between the parts.

Welding copper and its alloys: technology

Before you start welding copper and its alloys, you must carefully prepare the product . Measured blanks are cut using a grinder, lathe or milling machine. For copper with a thickness of 6-18 millimeters, you need to prepare the edges. They should be V- or X-shaped. (For large volumes, it would be advisable to purchase an edger-beveler.)

Read also: Specific conductivity of metals table

Before starting work, the seams are thoroughly cleaned of contamination and oxidation. For copper welding to be successful, it is necessary to protect the bath from exposure to oxygen. For this, it is recommended to use electrode wire, which must be alloyed with aluminum and phosphorus. In some cases it is necessary to heat the copper .

It connects well when working with consumable electrodes. It is important to know that the length of the arc should be 4-5 millimeters. Using pulsed-arc welding technology in argon, you can make any types of seams, even ceiling ones, and weld very thin metal. It is recommended to place padding elements under it.

Distinctive features of copper

Copper can conduct heat six times more than regular iron. Because of this, welding must be performed with increased thermal energy, and in some cases even preheating of the base metal is possible.

Under normal conditions, copper is inert, but when heated it reacts with oxygen, hydrogen, phosphorus and sulfur. Oxygen is capable of oxidizing copper at high temperatures, and above 900 °C the oxidation rate increases significantly. This is due to the fact that the initial composition of copper contains oxygen in a bound state. Cuprous oxide forms a eutectic with a lower melting point (1065 °C). The melting point of copper is 1085 oC. Therefore, the oxygen contained in it worsens its positive indicators.

Welding difficulties

The high thermal conductivity of copper (6 times higher than that of iron) requires the use of a welding arc with increased thermal power and symmetrical heat removal from the welding zone. Recommended types of welded joints are butt joints and those with similar heat dissipation characteristics.

The high fluidity of copper (2-2.5 times higher than that of steel) complicates the welding of vertical and ceiling seams. It is possible only with minimal weld pool sizes and a short residence time of the metal in the liquid state. When welding butt joints in the lower position with guaranteed penetration, in order to avoid burn-through, it is necessary to use pads made of graphite, dry asbestos, flux pads, etc.

The active ability to absorb gases (oxygen and hydrogen) during melting, leading to weld porosity and hot cracks, requires reliable protection of the weld metal and welding materials from contamination with harmful impurities.

Due to the tendency of copper to oxidize with the formation of refractory oxides, it is necessary to use filler material with deoxidizing gels, the main ones being phosphorus, silicon and manganese.

The large coefficient of linear expansion of copper (1.5 times higher than that of steel) entails significant deformations and stresses, and the formation of hot cracks. They can be eliminated by preheating structures: copper up to 250-300°C, bronze up to 500-600°C

Solder Types

Stainless steel products can be soldered with both soft solders made on the basis of tin and lead, and hard types of filler material, which includes more refractory metals.

Soft solder, due to the fact that it is based on tin, is a low-melting material characterized by high ductility and fluidity in the molten state. What is especially important when soldering stainless steel products is that it has good deoxidizing ability.

Properties of soft solders

More reliable connections both in production and at home can be achieved by soldering using hard solders. The metals from which they are made melt at a higher temperature than tin, which makes it possible to obtain reliable and durable connections with their help. Very often, materials of this type are produced on the basis of technical silver, which can contain up to 30% in their composition.

Main brands of silver solders

One of the popular types of hard solder is the HTS-528 material, which is successfully used for soldering not only stainless steel, but also copper, brass, bronze, nickel and other metals. Conveniently, it is produced in the form of a rod, the surface of which is already covered with a layer of flux. When working with such solder in a production environment or at home, you should keep in mind that its melting point is 760°.

HTS-528 solder is a rod coated with red flux. In addition to stainless steel, it is suitable for cast iron and non-ferrous metals

Flux for brazing stainless steel

Any connection of two metal parts is a priori not a simple procedure. Soldering stainless steel with copper refers to this type of procedure.

Working with stainless steel is even more difficult than with other types of materials, since it is quite difficult to melt and combines very poorly with other materials. Therefore, to solder stainless steel parts, you need to use proven methods that have been proven over the years.

When soldering any other material, as a rule, no problems arise, but not with stainless steel.

The entire soldering process is clearly regulated by state standards, however, there is one unusual feature.

Each type of metal is connected differently to a particular material; accordingly, for each type you need to use different solder and flux, which will be selected exclusively for this material.

But if you need to connect non-homogeneous (different) metals, you need to use fairly rare, highly specialized consumables.

This type of stainless steel soldering is widely used both in large industries and in domestic settings. It can be used to create sealed containers, solder copper parts, etc. This soldering method is not as common as others, but you still need to know how to do it and all its features.

Flux preparation

When soldering stainless steel, you should be very careful about choosing a ready-made flux or the recipe for making it yourself. The classic flux composition, which can be prepared at home, includes the following components:

- borax (70%);

- boric acid (20%);

- calcium fluoride (10%).

For soldering small-sized products, you can prepare a flux that will consist only of borax and boric acid mixed in equal proportions. Having mixed the components of the flux in dry form, it must be diluted with water and treated with the resulting solution at the site of the future connection.

Features of tin soldering

Solders based on tin-lead mixtures are distinguished by high quality connections at an affordable price . This is the main reason for the popularity of soldering stainless steel with tin at home. The method has proven itself best when sealing small cracks or connecting small parts. Products subject to temperature loads during operation are recommended to be soldered using silver compounds. An example is distillation tubes, which are operated at high temperatures under pressure.

The use of tin as a filler material when soldering stainless steel is not widespread in industry due to the low temperature threshold of the connection.

Advantages

The use of low-melting solders has the following advantages:

- easy procedure for soldering small parts;

- preparatory procedures do not take much time;

- low cost of consumables;

- You can use either a household electric soldering iron or a gas burner.

Flaws

The method has the following disadvantages:

- low connection strength;

- the low melting point of tin reduces the scope of application of sealed parts;

- competent use of molten tin requires certain professional skills from the master.

Modes

Tin-lead solders are used with the following parameters:

- the maximum burner temperature is 240 Cº;

- minimum power of the soldering device – 40 W;

- surface exposure interval – no more than 10 seconds;

- The thickness of the solder, regardless of the form of manufacture, should not exceed 4 mm.

Equipment used

The quality of work depends on the selected materials needed to repair the equipment. The home handyman will need:

- Sandpaper (coarse).

- Industrial brush.

- Flux (soldering paste).

- Soldering torch (electric soldering iron).

- Metal rod (filler material).

- Painting tape.

- Clean rag.

- Protective clothing (goggles, gloves, respirator).

The thermal conductivity of austenitic stainless steels is low and their coefficient of expansion is high, so care must be taken to ensure that the surface is heated evenly. A powerful soldering iron will help avoid deformation and heat massive products.

Useful tips

To perform stainless steel soldering efficiently, you should use the recommendations of experienced specialists.

- The power of a soldering iron, which must effectively heat the metal being joined, is in the range of 60–100 W, but it is better to opt for a 100-watt device. To solder large parts, such as stainless steel pipes, you will need a gas torch rather than an electric soldering iron.

- When choosing an electric soldering iron, it is better to opt for models equipped with tips that do not burn.

- The most economical and universal type of solder, which makes it possible to obtain high-quality connections for stainless steel products, is tin-lead rods. If you are soldering dishes that will come into contact with food or liquids, it is better to use pure tin as solder, which does not contain harmful impurities.

- The room in which soldering work is carried out must be well ventilated.

- When performing soldering, be sure to use personal protective equipment so as not to harm your health.

Copper Welding Machine

Quality welding machines for copper:

- — semi-automatic and automatic machines;

- — TIG – devices;

- — inverters.

Popular models are produced by TESLA, SPETSELECTROMASH, ESAB.

BUDDY TIG 160 from ESAB (pictured on the right) has two and four stroke torch firing modes. It can be used to join stainless steel and most other types of metals. It is compatible with almost any generator.

RENEGADE ES 300i ESAB inverter stores several welding parameters in its memory. Automatically sets the best starting parameters based on the configured current. It is lightweight but has high power.

Inverter machines allow you to weld copper rods; they generate a current of 60-110 amperes. For them you need to buy copper/carbon electrodes. HUNTER company produces semi-professional models, for example, MMA 257D, designed for continuous operation for two hours.

TESLA is known for reliable devices such as MMA 265, 275, 255. They have a non-contact arc excitation function. They connect to a regular household network without any problems. They are convenient for welding copper and its alloys, non-ferrous metals.

For welding with electrodes

Pulse-arc welding of copper plates is possible with tungsten electrodes in an argon atmosphere using an Orion 150s or 250s . They are lightweight and allow you to weld copper efficiently and reliably. The inverter welding device Resanta SAI-220 PN can be connected to a network with a voltage of 140-220 volts. It is easy to move with, it is equipped with a forced cooling system, so it does not overheat.

For wire welding

To perform copper wire welding work, the semi-automatic inverter Energomash SA-97PA20 is used. It has a light weight of 13 kilograms. It allows you to work with wire of different thicknesses 0.6-0.9 mm.

Smooth material feeding is ensured by the Shyuan MIG/MMA-290 model at a speed of 2.5-13 meters per minute. The device makes it possible to use 1-5 kilogram cassettes and allows you to work with electrodes.

The inverter semi-automatic welding machine Soyuz SAS-97PA195 is characterized by the presence of a 60 Volt idle speed function. It has an operating voltage adjustment range of 15-23 volts. A wire of 0.8-1 mm is suitable for it. It has a light weight of 10 kilograms, it is comfortable and reliable.

For welding copper wires

The TS-700-2 welding machine can connect copper conductors with a cross-section of 22 square meters. mm. It is compact, lightweight, weighs only four kilograms, is powered by a regular network, and consumes a little more than 1 kW. It can be carried in your bag. One carbon electrode is enough to make 700 welds.

It is recommended to weld copper strands using universal inverter machines, for example, RESANTA SAI-160, QUATTRO ELEMENTI A 160 Nano 643-255, SVAROG ARC 160 Easy Z213 H. The German device FUBAG IQ 160 makes it possible to set a current of 10-160 A. Its weight is almost seven kilograms, cost 7 thousand rubles (at the time of writing this article).

SVAROG ARC 160 Easy Z213 H from a Russian manufacturer has a stepless current regulator. It is convenient to use because the cable is connected via special connectors. Its weight is 4 kilograms, the approximate cost is 9 thousand rubles.

The functions of devices that greatly facilitate the welding process are:

— protection against sticking;

— the device does not respond to a current drop;

For your home, it is better to buy a device with a power of up to 4 kW. A current of 160 amperes is enough to weld metal 5 mm thick. The main selection criteria are the purpose of use, cost and set of functions.

>

Recommendations

There should not be even small specks of dust or paint stains left on the surfaces before soldering. It is not advisable to overheat the products - so that they do not have time to cool down, you just need to work more energetically. If you do not have sufficient experience, it is recommended to practice in advance on obviously unnecessary parts. It is necessary to learn to determine the achieved temperature by eye.

It is worth considering that soldering copper is a rather dangerous business. It is imperative that you wear protective gloves while doing it, and before touching the processed part, you should make sure that it has cooled down. Ideally, you should work either outdoors or with good ventilation. Soldering metals with hard and acidic solders is only possible when using a respirator and insulating glasses.

All equipment used is checked in advance. A vice or clamp will help secure the parts to be joined. In order for the solder to flow in the required direction, the corresponding area must be heated. You need to work only in clothes made of materials that are not subject to ignition. Before adding metals and salts to the melt, they must be heated, completely removing water.

Violation of this rule may result in a sudden release of heated substance or its splashing. Hygroscopic fluxes are mixed only with tools with a preheated surface (for the same reason). Components susceptible to evaporation or burnout are placed last. When they are introduced, it is necessary to strengthen monitoring so that the alloy does not overheat. Molds and molds for solders must be kept clean and additionally heated before pouring solder (flux).

Each tool must be used only strictly for its intended purpose. It is necessary to apply fluxes to the required places with a brush or a porcelain spatula. To make the powdered flux safer and less atomized, it is mixed with suitable solvents and converted into a paste form. It is advisable to cover work tables and other used surfaces with materials that are easy to clean. When constantly soldering copper, it is reasonable to equip each workplace with an individual hood.

The following video talks about soldering copper pipe.

How to cook copper: methods

For successful and high-quality copper welding, inverters, semi-automatic machines, gas machines, and argon machines are most often used. Manual, semi-automatic and automatic welding of cuprum and its connections can be performed with consumable and non-consumable electrodes. To work with copper and steel, automatic arc technology and flux are used.

The electroslag method is recommended for joining products with a thickness of 30-55 millimeters. Using an inverter, you can use a carbon electrode, for example, ESAB OK Carbon, Weldline CARBONAIR PLUS . The store offers a wide selection of manufacturers. Welding copper with a graphite type of electrode has proven itself to be excellent. Below are several subheadings that provide more detailed descriptions of the best methods for welding copper and its alloys.

Inverter

You can select the electrodes most suitable for copper welding using inverters by visiting the corresponding section of the website. The recommended brand is Komsomolets 100. The inverter is designed to create a constant voltage, current of reverse or direct polarity. You need to work with a short break. Weld sections of 30-40 millimeters, after which they should cool naturally. The angle of inclination of the electrode should be 10-20 degrees.

Semi-automatic

When working semi-automatically, welding is carried out with copper wire; although it is thin, it is of very high quality and allows you to achieve good results. If the metal thickness is more than 6 millimeters, then it is recommended to prepare the edges with a grinder or chamfer. They should be V-shaped with a blunting of up to 4 millimeters. To ensure that the seam is not porous, welding is performed without transverse vibrations.

When working on a semi-automatic machine, you can use M2 wire with a thickness of 2 mm. Recommended voltage 30 V, 300 A. Work is done with transverse movements. In this case, flux K-13, AN26, wire M1-3 can be used. The strength of a copper weld made on a semi-automatic machine is not inferior in terms of performance to the base metal.

Argon

Argon serves as an excellent protective agent. Tungsten types of electrodes are used in the work. The role of the additive is performed by the wire. The work is carried out on direct current of reverse polarity. Thin copper products are connected without heating. Welding is recommended to be done from right to left. It is necessary to maintain an inclination angle of 90 degrees for the electrode and 15 degrees for the rod. Depending on the thickness of the metal, gas consumption ranges from 7-18 liters per minute. Welding current is set from 80 to 500 amperes.

Gas welding

In order for the weld to be strong and of high quality when gas welding copper, it is necessary to monitor gas consumption. If the copper is thinner than 10 mm, 150 liters per hour of work will be enough, and if it is thicker, then 200 liters will be required.

If the workpiece is thicker than 10 millimeters, then two burners can be used. The technology involves the use of fluxes. They contain boron. Alloying of the metal and its deoxidation using filler wire are allowed. The method is also suitable for joining copper alloys. It is important to know that the filler wire must be identical in composition to the base metal being welded .

Video

You can watch a short video that clearly shows the process close-up.

Carbon electrode

Copper welding with a graphite electrode is common; a carbon analogue is often used. There are different methods for doing it. The arc can burn immediately between a pair of electrodes. She can be independent. It can be ignited between the electrode and the workpiece being welded. The technology is similar to gas welding. BrKMts3-1 wire is often used. Work may be performed outdoors. Connecting copper with a carbon electrode will fully meet the requirements for mechanical properties.

Carbon electrode inverter

Carbon electrodes ESAB ARCAIR

Carbon electrodes melt at a temperature three times higher than the copper they weld. Their consumption when operating an inverter is small. They heat up instantly. The carbon rods melt at a small current. To work with them you need to have experience. The resulting seam is usually distinguished by its quality, good oxidation resistance, density and strength. The angle of inclination of the rod should be up to 30 degrees. The current is set in the range of 35-130 amperes, which depends on the thickness of the copper. An inverter and carbon electrodes can be used to connect wires and twists. Such devices are light and convenient.

Read also: Hitch for hiller on walk-behind tractor

Welding nichrome with copper

Welding nichrome with copper with a carbon electrode allows you to achieve good results. The arc will burn well and steadily , its length reaches 30-50 mm. The electrode does not melt, but its end heats up to a high temperature. It produces a powerful thermionic reaction, which gives it the ability to burn stably even at a current of 5-10 A. The carbon type of the electrode slowly evaporates when working with copper and nichrome. It practically does not stick, which makes the work much easier.

Carbon welding at home

Welding copper with carbon electrodes at home is possible using a simple, inexpensive inverter. It can be powered from a regular network. He is not picky about conditions. Carbon electrodes are affordable for everyone. With their help, you can connect wires and seal holes in a car radiator. To learn how to use them, a non-professional can only read a few tips and watch videos.

Soldering with a gas torch: repairing a kettle

First, you need to thoroughly clean the soldering area with sandpaper and remove scale near the damaged area. To solder a stainless steel kettle with a gas burner, you need to follow these instructions:

- Heat the connection with a flame, smoothly moving the device. The heating will be sufficient when the solder begins to melt upon touching the metal.

- Apply flux (rosin or phosphoric acid) to the soldering area.

- Apply tin to the damaged area, while continuing to heat the area with the burner so that the substance melts and fills the entire defective area.

- Sand the seam with a metal brush.

- Wipe the sealed area with alcohol to clean its surface from scale and oxides.

During soldering work, you need to monitor the oxygen level. To determine this parameter, you need to look at the flame, the normal shade of which is blue. In an oversaturated composition, the color will be pale, which indicates an excess of oxygen. If you ignore this requirement, there is a high probability that the stainless steel will begin to oxidize.

Flaws

In addition to the undeniable advantages, soldering stainless steel with tin solder also has some disadvantages:

- difficulty in sealing seams on inclined and vertical planes caused by the high fluidity of tin;

- insufficient strength of permanent connections for large structures;

- reduction in the permissible temperature range of soldered parts due to the fact that the tin will simply melt if the material is exposed to temperatures above 231.9 °C.

Advantages

- This method allows solving complex technological operations;

- This is one of the few ways to achieve such a connection;

- The procedure itself occurs quite quickly and does not require additional tools, since an ordinary burner is sufficient for this;

- Modern developments of solders provide relatively high compatibility of metals during soldering;

- The process is available for both home and industrial needs.

Flaws

- The quality of soldering is inferior to other methods in terms of reliability;

- Finding the right solder is difficult;

- The flux oxidizes quickly, so the action must be carried out without delaying the start of heat treatment;

- Often, low-melting solders are used, which makes the processing process more complex, since you need to carefully regulate the temperature and ensure that nothing spreads.

Methods

There are several ways to make a connection of this kind, and they no longer depend on what kind of solder is used for soldering stainless steel to copper, but on the processing tool. Thus, two main ones stand out: soldering with a soldering iron and a torch.

In the first case, when using a soldering iron, this tool is used for relatively small parts. It is more convenient for them to connect small things, since there is no risk of overcooking them with too much heat. At the same time, the soldering iron itself is inferior in power to the torch and cannot work with hard-melting materials. They are also inconvenient for processing large surfaces, since in this case the process will be too long and the flux may oxidize by then.

The torch is the more commonly used method. It can be used for soldering stainless steel with copper, brass and other solders. Here you can easily process large surfaces and make hermetic connections. The process itself is much faster than with a soldering iron, and it is also possible to heat the workpiece to the desired temperature. The speed of the procedures does not allow the flux to oxidize.

Soldering copper with a stainless steel torch

Solder selection

The final result of the work depends on the correct selection of solder, since it ensures the filling of the joint, which must be completely covered with material that must be well grasped on the surface. One of the simplest options is to solder stainless steel with brass. After all, this is a very common solder, which is also used for soldering stainless steel to stainless steel. In some cases it can be used without flux.

It is inferior in its properties to others, but is more common and accessible, so it is mainly suitable for simple connections that do not bear a lot of responsibility.”

Stainless steel is also soldered with copper-phosphorus solder, which improves the quality of the connection with copper. This is a more expensive material, but is better suited for critical connections.

Tin-silver solder, such as Castolin 157, is an excellent soldering method, but the material cost is higher than others.

In the simplest cases, radio-technical solder can be used, but depending on the production technology, it is better to choose specialized consumables.