03 Oct 2018

There is a list of equipment without which your own production of work gloves is simply impossible. Moreover, on the market you can find equipment both domestic and foreign; equipment from different manufacturers differs from each other in performance characteristics, technical specifications and, of course, price.

The minimum required list of equipment includes:

- Knitting machine

- Overlock machine

- PVC Coating Machine

- Packing machine

Let's consider each unit of the glove knitting workshop separately.

Main types of equipment

Today, Russian manufacturers offer equipment and auxiliary tools for the production of gloves in a wide range and at attractive prices. But before purchasing machines, it is important to pay attention to such parameters as:

- operating conditions;

- specifications;

- rating of manufacturers;

- price.

To set up the production of gloves, you will definitely have to purchase the following main types of technological equipment:

- knitting machine;

- overlock;

- machine for applying a PVC layer to the inside of gloves;

- packaging machine;

- storage basket for dumping semi-finished products.

Knitting machine

The knitting unit is the most important one in the production of work gloves. Models vary by class: 5,7,8, 10, 13, 15 depending on the number of loops per inch. The higher the class, the finer the knitting for the production of cotton gloves. For the production of blanks, the machines are equipped with bobbins. The models are fully automated and work on approximately the same principle. The main task is to set the required number of rows and loops, then display the indicators on a digital monitor.

Purpose of overlock

Overlock as a machine for the final stage of production of work gloves. The glove overlocker is equipped with a cuff overlocking function, i.e. it helps improve the properties of protective products for gloves.

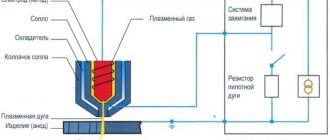

Glue application installation

Machine for applying a PVC layer to the inside of gloves. Thanks to this unit, it is possible to apply screen printing using a standard matrix.

After applying the PVC layer, the gloves must be dried in a drying chamber. The machines are fully automated. Polyvinyl chloride is supplied from containers, and the composition is applied in a thin layer. Thanks to the device, it is possible to apply any design and logo. The accuracy of the sketch is ensured by the built-in sensor and the matrices included with the device for drawing the drawing. Productivity can reach up to 1300 pairs per hour.

Packing machine

Packaging machine for packing gloves with a capacity of up to 200 pairs per hour. But the products are already packed into boxes, bags or sacks by hand. When purchasing a GD-T brand packaging machine, it is possible to apply bank gum.

The machines are supplied with matrices and sensors that are responsible for the accuracy of drawing the pattern in certain places.

Chinese manufacturers offer equipment with the ability to apply PVC layers of different thicknesses and patterns to gloves on the palm side. As a rule, screen printing is applied with a standard matrix, then the product is sent to the drying chamber.

Popular models, rating

Russian manufacturers of equipment for the production of cotton gloves are considered the best, but models from Europe and China are presented on the market.

AURORA

AURORA specializes in the production of knitting machines models - 10C-12-1, 7C-12-1, 15C-12-1 with a productivity of up to 15 pairs per hour. They are fully automated, equipped with a computer and a speed controller with the possibility of working with different raw materials. The cost is low - 190–365 thousand. R.

JOMDA

JOMDA classes – 7, 10, 13 with a capacity of up to 163 pairs per hour. The models are equipped with a computer with the ability to use different yarns.

SALUT-02

SALUT-02 is an energy-intensive overlocking machine with a productivity of 1500 pairs per day and the presence of a function for processing cuffs to increase the value of products on the market. Price 40–45 thousand rubles.

SALUT-02

PPM-1-M2

PPM-1-M2 as an inexpensive model with raw material consumption of up to 9 g per 1 pair for applying PVC, thereby giving the gloves greater strength and durability. Cost – 180–200 thousand rubles.

GD-DA

GD-DA knitting glove machine with knitting classes 10, 13, 150G and a capacity of up to 330 pairs per day. Power – 250 kW, weight – 250 kg, dimensions – 1250x650x1750 mm.

BX203

BX203 is a knitting unit with knitting classes 7.10G, productivity - 360 pairs per day, power - 250 kW and production of glove sizes - S, M, L, 2L.

SALUT-02

Overlocker from Russian manufacturers with a working shaft rotation speed of up to 4000 stitches per minute, weight of 45 kg, engine power of 0.2 kW, productivity of up to 1500 pairs in 8 hours.

Overlock glove

PPM-1-M2

PPM-1-M2 is a unit for applying spot PVC coatings with a productivity of up to 250 pairs per hour, plastisol consumption - up to 9 g per 1 pair, weight - up to 160 kg. The average cost is 80 pairs per day.

GPM-09

GPM-09 is an easy-to-maintain and energy-intensive packaging machine, thanks to which gloves acquire a marketable appearance and retain their shape. The production process is fully automated. The package contains 12 pairs of gloves. Productivity – 3000 pairs in 78 working days. Cost – 5000 rub.

MG-C-7/10G

Glove machine from Korean manufacturers. All production cycles are included in the work. The unit has convenient navigation for the tasks of the desired knitting mode, automatic processing of edge loops and trimming material at your fingertips. Productivity – up to 360 pairs per hour. Cost 200,000 rub.

JACK BX203-10G

This is an inexpensive analogue from Chinese manufacturers. Fully automated, it works on the principle of one-piece knitting with the ability to use any threads for knitting (mittens, mittens, gloves). The unit is equipped with a high level of self-control, a smooth transition to manufactured products and a built-in device for deposition of waste parts. Price 200–210 thousand rubles.

Payback period

Manufacturing gloves as a business has a number of features. The payback period of an enterprise depends on a large number of factors. One of the main factors is the price of the knitting machine. Budget models have low productivity, which negatively affects the speed of production. More expensive equipment allows you to produce large volumes of products, but the payback period for the device will increase.

Let's look at the payback period of the Korean model, which allows you to produce about three hundred and fifty pairs of gloves during a working day:

- The level of investment for renting premises, purchasing equipment, purchasing raw materials, registering a business and wages of employees is 500,000 rubles.

- The cost of one pair of gloves varies from 12 to 15 rubles. Taking into account all production costs, the profit from one pair of gloves will be about 7 rubles. This means that one machine brings a monthly net income of 52 thousand rubles.

- In order to earn 300,000 rubles monthly, a novice entrepreneur needs to purchase at least five devices.

A well-drafted business plan will allow you to establish successful production with a stable income, which will pay for itself in just a couple of years

. Based on the above example, we can conclude that the payback period for the business will be about one year. You can reduce this time period by organizing a workshop in your own garage or summer cottage.

Product selection

Business and the quality of products in the future will depend on the purchase of the right high-tech equipment. When choosing machines, you need to pay attention to:

- quality, since cheap analogues will lead to poor quality, frequent breakdowns and a slowdown in the production process;

- availability of certificates to avoid buying counterfeits;

- the power of the equipment and customer reviews can be read on the Internet;

- technical equipment, because when producing gloves, it is necessary to take into account the technology of glove production.

Many modern models are multifunctional and equipped with an electronic control unit for quickly setting up production and producing high-quality products. Taking into account the ratings of manufacturers, it is better to buy from reputable companies offering warranty and post-warranty service.

It is possible to purchase additional machines to give the gloves more advantages:

- strength;

- environmental friendliness;

- air leakage;

- low cost.

If you have a limited budget, you can start by purchasing Chinese equipment with fairly good performance and automatic computerized control.

According to experts, to thoroughly start a business for the production of work gloves, it is enough to purchase 5 machines. But the profitability of production will be influenced by many other factors:

- performance;

- power;

- speed degree.

If desired, today it is possible to lease equipment, but it will be more expensive than buying used equipment. But you can count on receiving high-quality equipment.

Sales of gloves

PVC-coated gloves and mittens are considered a universal way to protect your hands from dirt and minor damage during physical work. Work gloves are in demand by a wide audience of buyers: from wholesale buyers from construction companies to private buyers looking for two or three pairs for their dacha.

However, this does not mean that marketing them will be easy. High competition, mass domestic and Chinese production prevent many newcomers from breaking into the market, much less gaining a foothold in it. In order not to be left with thousands of unclaimed pairs on hand, think through 3-4 sales channels in advance.

The optimal solution would be to contact several potential wholesale buyers with a commercial proposal in advance and conclude a supply contract with them.

Try sending similar offers to retail chains, but don’t count too much on this option - it’s difficult for beginners to get onto supermarket shelves.

Cost of equipment

For those new to the business, it is recommended that they first purchase used equipment for the production of gloves, since knitting machines for applying PVC are expensive. In order to save money, you can purchase equipment for only 65–70 thousand rubles. The cost of fully computerized machines is 250–300 thousand rubles.

Computer-controlled machines cost from 300,000 rubles. When choosing, it is important to take into account the technical and operational characteristics of the units, since you can incur large losses in the event of malfunctions and equipment breakdowns.

Approximate prices:

- knitting machine with a productivity of 16 pairs per hour – 250–270 thousand rubles;

- glove overlocker with a productivity of 190 kg per hour – 110–11 thousand rubles;

- knitting machine with an electronic control unit - up to 400,000 rubles;

- device for applying PVC with a productivity of 800 kg/hour on average - 930,000 rubles;

- packaging machine with a productivity of 430 kg/hour – 45,000 rub.

The cost is directly affected by productivity and the country of manufacture. In terms of price and quality, units from Japanese manufacturers are leading today. Price – 200,000 rubles.

The advantages remain with computerized units with a high level of self-control and a smooth transition to the production of other products. The cost of such units is over 200 thousand rubles. Although needle breaks or thread breaks may occur.

If your budget is too limited, you can buy Chinese analogues with good performance, automatic adjustment and combined control. Prices for used equipment are much lower.

Documents for starting a business

In order to avoid getting into a lot of problems with the law, it is best to start registering your business before it even starts operating. That is, it is better to buy a machine for making gloves at the same time as completing the paperwork. To formalize the form of ownership of such a small enterprise, you need to choose between registering yourself as an individual entrepreneur (IP) or becoming a limited liability company (LLC). It should be taken into account that if you plan to cooperate with enterprises, then you will need a tax regime that will allow you to work with VAT. If you plan to sell your products to wholesalers and not to enterprises, then you can choose the simplified taxation system (STS), which provides two options for calculating tax - 6% of total revenue or 15% of profit.

When choosing between an individual entrepreneur and an LLC, it is worth taking into account that the entrepreneur, in the event of any violations, is liable with all his property, and the LLC - only in the amount of the authorized capital. But fines for individual entrepreneurs are significantly lower than for LLCs. It's up to you to decide.

Features of production equipment

Any equipment used in the production of gloves requires regular maintenance to maintain the quality and competitiveness of the product. It is important to timely modernize existing equipment in order to regulate your business and ultimately make a good profit.

Payback up to 1.5 years when purchasing complete equipment - up to 300,000 rubles. The sale of cotton gloves is a fairly stable and sustainable business. But when opening your own workshop, it is important to competently approach drawing up a business plan, studying public demand and supply, calculating preliminary costs and drawing up a detailed diagram.

Market analysis

PVC coated gloves are a fairly popular product. They are required not only in production and construction, but also in everyday life. Therefore, the demand for such products is quite high.

The cost of gloves for wholesale purchases ranges from 11 to 13 rubles. In the retail network, they can be sold at a price of 16 to 20 rubles per pair of gloves. You can organize sales of products through:

- construction stores;

- stores selling garden tools;

- wholesale companies that supply consumables to enterprises.