The grinder is used for construction work. When using it, it is necessary to strictly observe the safety regulations. Special glasses or masks are used. But in fact, these two devices have both disadvantages and advantages. Therefore, it is not possible to recommend one. You will learn what to choose depending on your individual characteristics.

Safety precautions

There are several types of protective equipment required when operating this device.

Individual protection means

A guarantee of eye safety when using an angle grinder is safety glasses . They have several varieties:

- Open type glasses. They resemble ordinary glasses for vision correction or sun protection, but have a denser structure and increased plastic thickness. These glasses protect your eyes from sparks and small fragments. Their disadvantage is their lack of protection from dust. When working with ceramics and stone, dust is generated that can cause eye irritation. In this case, the following type of glasses is suitable.

- Closed-type glasses. They fit tightly to the contour of the face and prevent dust from entering the eyes. They also protect your eyes from splinters and sparks. Some models have a ventilation system that prevents fogging of the inner surface of the lenses. This version of glasses will cost a little more, but it also has more advantages.

Glasses must be worn regardless of the nature of the material being cut or sanded.

Protective mask

Another safety device when working with an angle grinder is a protective mask .

It can be reinforced with a special mesh, which makes it stronger. This mask is much better than glasses, because it protects not only the eyes, but also the rest of the face. The main cause of injury is a split saw blade. Its fragments, flying at great speed, can injure not only the person working with the angle grinder, but also those nearby.

Principles of safe work

The presence of personal protective equipment undoubtedly reduces the risk of injury when using an angle grinder. But it is also worth remembering other safety requirements .

- Protective cover. This device must be on the angle grinder. Some careless operators remove the protection in order to put on a wheel of a larger diameter, which is not intended to work with this angle grinder. Sometimes the casing is removed in cases where it is necessary to use the grinder at an awkward angle. Such actions are unacceptable. Of course, the protective casing does not provide 100% safety, but in most cases it will protect you from injury. Recently, the protective cover for angle grinders has received a useful modification. It's called a dust extractor. From the name it is clear - this device helps direct dust particles in the opposite direction from the operator, which greatly simplifies the work.

- Hand protection. To prevent sparks and hot metal particles from coming into contact with the skin of your hands, it is recommended to use special welding gloves. Small sparks hitting the skin do not cause obvious pain. But when a large burning particle hits, it causes severe pain. At this moment, the hand may shake, thereby creating a traumatic situation. Gaiters will help prevent hot metal from getting on your hands.

- Selecting an abrasive wheel. To work with an angle grinder, you should only use a wheel that is suitable for it. If you use a circle with a diameter larger than expected, it may break without even touching

- with the cutting object. The fact is that different models of angle grinders have different speeds, and abrasive wheels have different speed resistance.

- You should also not use wheels with visible external defects, such as chips, deep scratches or cracks.

- It is forbidden to install a disk on the grinder for sawing wooden products. Firstly, it is dangerous - the saw blade may encounter a knot, which can cause the tool to be torn out of your hands. Secondly, the disk will very soon become unusable, because it is not adapted to such a load. The speed of a circular saw is much lower than that of an angle grinder.

- Sawing object. If the element being processed is small in size, you need to secure it with something. The best option for this would be to use a vice. It is strictly forbidden to saw the product with one hand while holding it with the other. In this case, the sawing element may be torn out of your hands.

If the product is large and installed motionless , it is necessary to ensure that the abrasive disc does not bite. General rules:

- Always unplug the angle grinder when replacing a blade. This is to prevent accidental startup.

- When choosing an abrasive disc, give preference to a trusted manufacturer.

- When working, make sure that the power cord is kept away from the sawing wheel.

- When using an angle grinder, avoid the possibility of hair and clothing getting wrapped around the rotating disc.

Peculiarities

Masks are the most reliable protective equipment when working with an angle grinder. They are much more effective than simple glasses for protection. After all, such products completely cover a person’s face from the ingress of solid particles and scale.

Externally, this means of protection looks like a small semicircular screen. It can be made from various heavy-duty and heat-resistant materials. Each mask has special fasteners for fixation. They can be either stepped or smooth.

Some models of such masks also have an additional visor made of polycarbonate. It is designed to cover the forehead while working with a tool, which increases the degree of protection and reduces the risk of human injury.

Some types of masks are produced together with a special metal mesh consisting of many small cells. This element allows you to increase the degree of human protection and avoid microdamage on the product itself during operation.

Currently, there is a wide variety of different masks for working with an angle grinder. They may differ in the method of attachment.

Head-mounted

Such masks are made together with small belts. They allow you to tightly hold the plastic part of the product on a person’s head. In addition, this type has a special rotating mechanism that allows you to attach the transparent mask screen.

Attached to the mask

In this case, the transparent part of the mask is connected to a special headdress. The product can be raised or lowered using a small device designed for fixation.

Often, masks for working with an angle grinder differ in the material that was used to make them.

Polycarbonate

They can protect a person from severe impact injuries. This polymer is an excellent protectant against solid particles. In addition, it is often used when working with hazardous chemicals and metal scales.

Polystyrene

Polystyrene is a highly durable material, but can become noticeably cloudy during use. Most often, this type of protective mask is used on construction sites and in chemical production.

A product made from this material can withstand even large metal fragments, wood chips and scale.

Reinforced metal mesh

These masks are made from many small cells. They are able to protect a person from large fragments and scale.

These types of protective equipment are most often used in large sawmills and mining mines.

The best way to protect your face while working with an angle grinder

An angle grinder, better known as an angle grinder, is a serious and dangerous tool. But it is quite difficult to do without the use of angle grinders during construction and even minor repair work. The use of an angle grinder reduces labor costs and speeds up the process. Therefore, when working with angle grinders, it is extremely important to follow safety precautions. One of the significant points is the protection of the face, because sparks, scale, small particles of metal, grinding disc and other materials can damage the skin and mucous membranes.

Protective glasses

A popular means of protection when working with an angle grinder is special glasses. They come in two types: open and closed.

- Open glasses look like regular ones, but are made of dense materials that can withstand sparks and small debris. Unfortunately, such glasses will not help when working with hard materials, and will not protect you from dust;

- Closed-type safety glasses adhere completely to the skin and prevent dust and any elements from entering the eyes.

Both options have a significant drawback: the glasses do not completely cover the face and are aimed only at protecting the eyes.

Protective shields

Special shields, or masks, for working with an angle grinder seem to be more reliable, but their cost is higher. Professionals prefer this category of protective equipment, because they protect not only the eyes, but the entire face. Masks come in different types and are made from different materials, which affects their appearance and cost.

The masks are attached using special belts or other fasteners and are held tightly on the head; the protective glass protects against the ingress of scale and dust particles and materials. Some shields have a visor that protects the forehead. In addition, shields are made with a special fine mesh - this is additional protection, including from damage to the mask itself during operation, which increases its service life. Overall, a face shield is more durable than regular glasses.

Review of the best models and manufacturers of glasses and masks

There are several dozen brands on the Russian market that offer personal protective equipment for the eyes, including glasses for working with angle grinders. But only some of them are directly manufacturers of personal protective equipment, and the rest are international and Russian brands owned by manufacturers and sellers of power tools, gardening and power equipment. In the first group, the most famous are the Russian JSC Suksun Optical-Mechanical Plant (trademark ROSOMZ) and two very well-known international companies: Uvex and 3M. In user reviews and reviews of safety glasses designed for working with angle grinders, models of power tool brands such as Zubr, Sturm, Styer and Fit, as well as ROSOMZ products, are noted among the lower and middle price ranges. Closed models with indirect ventilation ROSOMZ ZN11 Panorama, Zubr 110230, Sturm 8050-05-02 and Stayer 2-110291 are popular among grinder users. In the upper price range of personal eye protection, the undisputed leadership belongs to 3M and Uvex, and the latter’s products are also produced under such well-known brands as Makita, Hilti, Husqvarna and others. Here, in terms of price-quality ratio, owners of grinders distinguish the closed models 3M 2890, Uvex Ultravision 9301714, as well as the Russian ROSOMZ Surgut.

What to look for when choosing a protective shield

The safety of your face and eyes directly depends on the quality of the mask. Saving in this case can become deadly.

- You should choose trusted manufacturers with a reliable reputation;

- The mask must be equipped with a steam exhaust system to prevent fogging;

- The most durable materials: polycarbonate and polystyrene. They are usually chosen by professionals;

- The most important functions of the shield are impact resistance and heat resistance. These qualities are worth paying attention to first;

- Shading is an important element of a proper mask. In case of sharp flashes, a poor-quality light filter will lead to damage to the retina;

- If you have to work frequently and regularly with an angle grinder, then it makes sense to think about purchasing an elongated mask - this type will help protect not only your face, but also your neck.

How to make a casing for an angle grinder for a vacuum cleaner - the best ways

The advantages of making your own nozzle are as follows:

- There is no need to spend money on purchasing a device

- Possibility to make a device according to your requirements

- No need to travel around looking for the right device

There are many options for making a casing for an angle grinder for a vacuum cleaner, and when making it yourself, it is not at all necessary to make the kind of equipment that has already been invented. It all depends on personal abilities, capabilities, as well as the available material from which the nozzle is planned to be made. To make the work of making casings easier, let’s consider several options for converting an angle grinder into a vacuum cleaner.

Safety precautions when working with angle grinders

Compliance with solid waste is the key to safe work and high-quality results without negative consequences for health and life.

- Using a protective shield when working with an angle grinder is an important component of the process that cannot be ignored;

- In addition to the mask, before work, put on protective gloves and a suitable suit (preferably a special one) to protect not only your face, but also the rest of your body;

- For each type of material, use only a specially designed disc;

- Check tool fastenings and guards before starting work;

- Before work and after changing the attachment, check the tool at idle speed;

- Work in a comfortable and stable position;

- The most dangerous thing when working with an angle grinder is the rupture of a disk rotating at high speed. Splinters can cause fatal damage, so it is extremely important to purchase high-quality protective materials and use the machine in accordance with safety precautions.

Under no circumstances remove the protective casing from the angle grinder to lighten the weight of the tool!

Remember, life and health are the most important. Do not neglect safety precautions and use protective equipment to avoid damage to the skin and eyes.

Safety precautions when working with an angle grinder (grinder)

When using an angle grinder, you must follow a number of rules that will ensure the safety of working with this tool:

It is prohibited to use an angle grinder without a protective casing. The guard must be between the disc and the operator. This is necessary in the event of a disk failure, in order to protect the person who works with the angle grinder from being hit by disk fragments.

It is necessary to use discs that correspond to the “grinder” type in all respects: outer diameter, thickness, bore diameter, as well as maximum speed.

Before starting work, be sure to check the integrity of the abrasive disc - there should not be even the slightest cracks or chips on it. A circle that has received damage (even if invisible at first glance) as a result of a fall or impact cannot be used. This may cause the disc to break during operation and cause personal injury.

It is prohibited to use circular saw blades with an angle grinder.

The workpiece you are working with must be securely fixed to the work surface. The instrument should be held with both hands.

When cutting metal, there are very often cases when the circle jams; the angle grinder at this moment can throw the workpiece very strongly or slip out of your hands. All this happens in a split second, so the master must be prepared for such a situation and hold the car very tightly. This is very common among small angle grinders: work occurs at high speeds with a relatively small mass of the tool.

Be sure to wear safety glasses and a respirator before working. Failure to do so may result in sparks, abrasive dust, or even a splintered disc getting into your eyes, again causing serious injury. Use ear protection.

Wear protective clothing over the entire body. When cutting metal, the cutting temperature is very high. If even one particle gets on the body, it can cause a burn. It is best to use cotton clothing.

Keep the angle grinder at the same angle while working.

Use the tool strictly for its intended purpose.

Do not use a tool for a job that it was not designed for within the required power range (heavy duty tools require a heavy duty tool; light duty tools require a low power tool). Do not use the tool for purposes for which it is not intended.

It is important to follow the simplest rule: once you have completed the cut, turn off the tool. It can only be placed on the table after the disk has completely stopped.

Work zone

Keep your work area clean and well lit. Clutter, debris, and unlit areas of the workplace can lead to accidents. When working with power tools, keep unauthorized persons and children away from your work area. All tools should be kept out of the reach of unauthorized persons, preferably stored in a tool cabinet or room when the tools are not in use.

Remove service (installation) and fastening tools (wrenches, screwdrivers, etc.) before turning on the equipment. Tools or wrenches placed in the work area of the equipment may become caught in moving parts of the tool, which could result in injury to the operator.

Remove personal protective equipment before starting work. Removed personal protective equipment in the work area of the equipment may become caught in moving parts of the tool, which could result in injury to the operator. Slabs and large workpieces must be supported securely to reduce tip-over or jamming of the tool.

Work environment

Do not expose your power tool to rain, snow, or use it in wet or damp areas. Do not use electrically powered tools in places where there is a risk of explosion or fire due to the presence of flammable materials, flammable liquids, paints, varnishes, gasoline, etc., corrosive environments, flammable gases and explosive dust. As a precaution, it is recommended that you consult a fire safety professional regarding the appropriate fire extinguisher and how to use it.

Personal security

Use personal protective equipment when working with equipment. During work, it is necessary to use personal protective equipment in accordance with workplace safety regulations. The use of personal protective equipment reduces the risk of injury.

Clothing: Do not wear loose clothing, jewelry, or anything that could interfere with the job or get caught in moving parts of the tool. Hair: Keep hair away from moving parts of the power tool. To contain long hair, wear protective headgear.

Eye protection: wearing special protective glasses and masks is a mandatory requirement (ordinary glasses are not sufficient to protect the eyes).

Hearing Protection: The use of hearing protection is recommended during periods of prolonged operation.

Footwear: Where there is a risk of foot injury from heavy objects or the risk of slipping on wet or slippery floors, appropriate non-slip safety footwear should be worn.

Head protection: In cases where there is a risk of falling objects or impact with protruding or low-lying obstacles, a hard construction helmet should be worn.

Respiratory protection: In cases where the machining operation generates dust, use protective masks or special dressings. Use a respirator in cases where special respiratory protection is required during work.

Avoid unintentional starting.

For mains powered equipment: Before plugging the tool into a power outlet, make sure the switch is in the OFF position.

For cordless equipment: Before connecting the battery to the tool, make sure the circuit breaker (switch) is in the OFF position.

When transporting equipment, make sure that the switch is always turned off.

Dust removal equipment

If your power tool is equipped with a dust extraction device, make sure it is properly connected and in working order. The use of a dust extractor can reduce the dangers created by waste dust and shavings.

Disable power tools

When finishing work, ensure that the power tool is disconnected from the power supply. Also unplug the power tool before performing maintenance, lubrication, or making adjustments or replacing accessories such as blades, drills, cutters, etc.

electrical safety

The electrical wiring to which the equipment is connected must always be in good working order and have protection against short circuits (equipped with automatic switches or plug fuses).

If you discover damage to the insulation of the electrical appliance wire, you should carefully disconnect the electric heater from the power supply without touching the damaged area and contact an authorized service center. Do not operate a tool with a faulty electrical switch. The use of homemade electrical devices, such as electrical extension cords, electrical plugs, etc., is prohibited.

Before operation, make sure that the power source meets the technical requirements of the equipment being connected.

Do not leave equipment switched on unattended.

Avoid using multiple extension cords in series, as this may cause the cord to overheat and cause a fire. Do not operate the equipment if the cord or plug is damaged or if it has been damaged in any way. Contact a service center for inspection or electromechanical repair.

Avoid introducing foreign objects into the ventilation system of the equipment to reduce the risk of fire, electric shock, or damage to the equipment. Avoid any blocking of equipment while it is in operation. Avoid getting the power cord on the working (processed) surface. Do not allow electrical wires to come into contact with the work surface while working.

Do not run wires under any kind of covering. Do not cover wires with carpet or other coverings. Arrange the wires in such a way that they do not impede movement in the room and do not get tangled. Do not tie wires in knots.

It is unacceptable to hang the electrical wire on nails or metal objects. It is unacceptable to place wires and cords on gas and water pipes, behind heating radiators, etc.

When disconnecting the equipment, do not pull the plug from the socket by the cord. Always remove the plug from the outlet by grasping the body of the plug.

When connecting the equipment to the electrical network, ensure easy access to the outlet in case the electrical device is quickly disconnected from the network. Do not use twin-conductor extension cords or spools on power tools that have a ground loop. Always use three-conductor extension cords or reels with a grounding conductor connected to ground. If you must use a power tool outdoors, use only extension cords rated for outdoor use and marked as such (W or WA).

For extension cords up to 15 meters in length, use a wire cross-section of 1.5 mm2.

For extension cords longer than 15 meters, use a wire cross-section of 2.5 mm2.

Protect the extension cord from sharp objects, excessive heat, and placement in damp or wet locations. Repair any damage to the extension cord before use.

Check the power cord of the tool periodically. If it is damaged, contact an authorized service center to replace it.

Don't put in a lot of effort.

Remain alert, watch what you are doing, and use your general senses when operating power tools. Do not use power tools if you are tired, under the influence of medications, or under the influence of alcohol or drugs. Failure to pay attention when operating power tools can result in serious injury.

Be careful when working.

While working, do not be distracted and carefully monitor the material being processed.

Never release the tool from your hands until the moving parts of the tool have completely stopped. Rotating parts of the tool may become caught on the supporting surface, causing you to lose control of the tool. Take a comfortable and stable position with the tool. This will give you better control of the tool in unexpected situations. Work with dry hands, free of oil and grease. Use construction gloves.

Some parts of the equipment, while in working condition, heat up to high temperatures. To avoid burns, do not touch hot parts during operation.

Additional operating instructions

Use appropriate assistive devices (metal detectors, etc.) to locate hidden supply systems (hidden wiring, etc.) or contact your local utility company for fusion. Contact with electrical wiring may result in fire or electric shock. Damage to pipelines may result in the release of a substance that may be hazardous. Securely secure the workpiece. The workpiece installed in the clamping device is held more securely than in the hands.

ATTENTION! Processing some materials can be hazardous to health and requires increased safety precautions when working. It is important to take into account when working, the fact that asbestos-containing building materials, etc. are carcinogenic. Various combinations of materials can cause hazardous chemical reactions, including waste dust, etc. Consult the appropriate service at the enterprise before carrying out work.

Stay vigilant.

Before using the power tool, check all parts and components for damage.

Check the integrity of the power tool body, the correct adjustment of the moving parts, and make sure that they do not jam. Check the presence and functionality of all switches (especially ON/OFF) and parts. If necessary, contact an authorized service center for repair or replacement.

If a power tool requires mounting, make sure it is securely attached to a suitable workbench.

Lubricate and replace power tool accessories and parts promptly. Keep the ventilation slots clean and free of dust. Blocked ventilation slots can cause overheating and damage to the motor. Use only consumables recommended by the manufacturer and those that meet the equipment specifications. Use only high quality consumables.

Do not use damaged or worn tools and consumables, as this may result in injury.

ATTENTION!

It is prohibited to use (install and operate) grinding wheels and other consumables with a maximum permissible rotation speed of less than 11,000 rpm for disks with a diameter of 115-125 mm and less than 6,000 rpm for disks with a diameter of 180-230 mm. See the appropriate markings on disks, circles, and other consumables. The use of discs with lower maximum speeds can lead to dangerous damage to the operator during operation, as well as to the structure of the tool.

The machine is equipped with a removable metal protective casing, with a rotating function, instead of a non-removable casing. Always install a protective cover when working. Check that the casing is securely fastened before work. The housing must be installed on the operator's side in such a way as to protect the operator from loose parts during operation.

Important!

Repairs must only be carried out by qualified persons using original spare parts. Failure to comply with this requirement may result in significant danger to the user.

How do safety glasses work?

The means under consideration include the main and fastening parts. The main part is presented in the form of protective glasses and fastenings for them, and the fastening part consists of arms or straps. Glass is the base that provides reliable protection for the eyes. Fastening is mandatory, since the ease of use of protective equipment depends on the quality of fastening.

Additionally, safety glasses may include:

- Ventilation holes

- Arm Length Adjusters

- Fasteners of different types of fastening

- Gaskets made of rubber and fabric base

What is protective glass for such products made from? Various materials are used for this, namely:

- Glass with impact-resistant properties. The use of glass in the product provides more advantages, since visibility reaches 100%

- Polymer materials, since glasses made of polymers are popular because they are cheap, but any scratches on the surface distort visibility

- Plastic, such products are popular in cases where there is a risk of not only sparks and small particles getting into the eyes, but also shavings or splinters

- Silicone is a material that began to be used not so long ago for the manufacture of safety glasses. Its characteristics can be compared to plastic.

Types of safety glasses

Safety glasses are used not only for working with an angle grinder, but also when turning on a grinding machine, where the risk of small particles getting into the eyes is no lower than when operating an angle grinder. The products under consideration are divided into two types according to the degree of protection:

Closed-type glasses protect your eyes not only from small particles, but also from dust, smoke and even chemical formations. To secure this type of protective products, manufacturers offer special fastenings in the form of straps with clamps. The presence of a special regulator allows you to use glasses for different people. When using closed-type products, a phenomenon occurs such as the formation of condensation on the inner surface of the glass. To eliminate the occurrence of condensation, manufacturers have modernized their products by equipping them with special types of spraying. If the product is equipped with ventilation, the cost of such devices increases several times.

Open-type glasses are ordinary products that have special impact-resistant glass. They protect the eyes from direct contact with sparks and particles, but are not able to prevent the entry of smoke and dust. The disadvantage of such products is that when using them, you need to select a specific model according to the size of your head. Only the temples are used to secure the glasses on the head.

Both types of protective devices use different glass materials. Depending on how often you have to use an angle grinder or sandpaper, you need to make the appropriate choice regarding the closed or open type of protective devices.

Dust extraction from an old saucepan

If sheet steel is available, then it can be used as a basis in the manufacture of a dust extractor for an angle grinder. When carrying out such work, you will need a welding machine. If you don’t have a machine, you can make a nozzle from an old aluminum pan. The principle of making a device from an aluminum pan is as follows:

- The basis is taken from a part of the pan with the bottom. The bottom acts as one side of the nozzle, and the other side is made by bending the sides of the pan

- It is recommended to use rivets to connect sheet aluminum

- A hole of the appropriate diameter is drilled in the wall of the dust collector for fastening to the shaft of the power tool

- To secure the hose from an industrial vacuum cleaner, you will need to make a hole on the outside of the side wall to which to attach the neck of a plastic canister, bottle or plastic tube. It can be secured to the aluminum base using threaded connectors with washers

- The reliability of the connection between the hose and the nozzle is ensured by a metal clamp

Read also: Whirlpool dishwashers DIY repair

The principle of making a homemade nozzle is simple, so you can practice making casings from different materials. If you make a nozzle of two parts - movable and stationary, you will end up with a wall chaser for making grooves in concrete.

Comparison with protective masks when their use is necessary

Masks are analogues of protective devices. When working with an angle grinder, using a mask is important when you have to work with the tool for a long time every day. The first difference between a maxi and glasses is its size. It protects not only the eyes, but also the entire part of the head. Masks for working with an angle grinder are in demand when an angle grinder is the master’s main tool.

The second difference between the mask is its cost, which is several times higher than the price of the devices in question. Often masks are additionally equipped with protective nets over the glass, which allows for maximum protection of the face and head as a whole. When using an angle grinder, it is important to follow safety precautions, which will allow you to complete the work you started without getting injured.

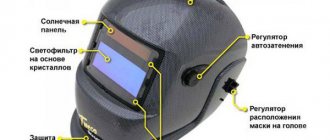

Welding mask with respirator

A welding mask with a respirator, unlike a standard half mask, protects the entire face from hazardous influences. A welder's mask with air supply consists of the following elements:

- Welder mask (shield) with a light filter and a protective casing for a tight fit.

- The air duct (hose) that connects (collet connection) the mask to the fresh air supply unit.

- The air supply unit (turboblock) consists of a fan, a filter and an autonomous battery (power source).

The removable battery needs to be recharged periodically using the included charger. Depending on the model of the respirator, the power source can operate without recharging for a different amount of time, at least 8 hours. The device can withstand about 1000 recharges .

Various materials can be used as a filter .

Modern models have different levels of air flow - from 140 to 250 l/min .

A light indicator or sound sensor notifies the welder of problems or deviations from the normal mode, for example, a decrease in air flow. The reasons for this may be a clogged filter or a decrease in battery charge level.

Put on the mask and start the feed unit immediately before welding. Earlier use will result in rapid battery discharge.

You should consider the principle of operation of the mask . The clean air generated by the fan enters the filter, and then through the hose under the mask, directly into the welder’s breathing zone. The exhaust air exits through a non-return valve.

Most models are additionally equipped with a fire-resistant belt for attaching the unit, an air pressure indicator and a replaceable filter.

Speedglas 9100FX Air

- Manufacturer: 3M (USA).

- Speedglas 9100FX Air welding helmet with Adflo purified air supply system.

- The presence of an auto-darkening filter (size 54 x 107 mm) with a degree of darkness of 5, 8 and 9-13. The welder can record any degree of darkness.

- The air supply system allows you to protect the performer from aerosols (up to 500 maximum permissible concentrations) and gases.

- The battery capacity allows continuous operation for 7-9 hours.

- Filter type – anti-aerosol.

[ads-pc-4][ads-mob-4]

Tips for choosing the right glasses for working with an angle grinder

When choosing the products in question, it is important to pay attention to some important points. These points include:

- The material from which the product is made. You need to choose models that have a high degree of protection. The presence of glasses on the nose when working with an angle grinder does not mean that the person is completely safe

- Availability of auxiliary protection against ultraviolet radiation. If your job requires you to work every day in the sun with an angle grinder, then it won’t hurt to purchase safety glasses with a special coating against ultraviolet radiation. Models called “Chameleon” are popular.

- Ventilation. If you prefer a closed type of product, be sure to make sure that the devices are equipped with ventilation. If the product does not have such a function, then you will need to remove the glasses very often to remove condensation from the inside of the glasses

No one can take care of a person’s own health except himself. In order to work with such a dangerous tool as an angle grinder without injuries or other incidents, you need to take a serious approach to the choice of protective equipment. If you do not follow safety rules, even an experienced specialist can get injured.

User manual

Before you start working with the angle grinder, make sure that the mask is securely fixed and that all fastenings are fastened to the correct size. Otherwise, the product may fall off during operation, resulting in serious personal injury.

And also remember that with repeated use or transportation, microdamages may appear on the protective shield of the mask. To avoid this, the product should be pre-coated with a special film. Moreover, it is applied both from the outside and from the inside.

If you are going to work with dangerous chemicals that can leave marks on the mask, then you should coat its outer part with a special composition in advance. But after completing the work, the mask must be thoroughly rinsed and dried.

It is recommended to buy such protective equipment only in specialized stores. Moreover, before purchasing, you should check all the quality certificates of these products. After all, a low-quality mask can lead to injury to a person while working with an angle grinder.

The following video will tell you how to make a protective mask with your own hands.

Design features of safety glasses

You can divide all existing safety glasses into several groups. The distribution occurs according to the type of material, design features and coverage area.

By lens material

Several materials are used to create protective glasses lenses. The most common of them are:

- Mineral glass. It has been used since the days of the USSR. The main advantages of the material are its high light transmittance and resistance to light impacts (damage, chips, scratches). The main disadvantage is the fragility of the product and the possibility of injury from chips.

- Organic glass (plexiglass) and plastic. The ability to transmit light of these materials is lower than that of mineral glass, but they are much more flexible. This allows you to withstand fairly strong impacts, and in the event of breakdowns, fragments practically do not appear. But due to a large number of scratches on the surface, the material may become matte, which will make it unsuitable for use. Therefore, the service life of glasses made of organic glass and plastic is not so long. Also, these materials are easily destroyed when exposed to chemicals and at high temperatures (200 degrees).

- Silicone. This material is the most flexible of all listed. It can easily withstand even very powerful blows, but does not cope well with minor damage. Silicone also quickly deteriorates when exposed to high temperatures (sometimes it can withstand up to 300 degrees, but most often it begins to lose its properties at 200). The surface becomes cloudy over time, so the service life is also quite short.

Tips for choosing the right glasses for working with an angle grinder

When choosing safety glasses for working with an angle grinder, special attention is paid to certain details. These include:

- Case material. To protect your eyes, choose a model that can reliably protect your vision. The presence of a thin frame with glass does not guarantee the safety of the operator.

- Additional protection against ultraviolet rays. If you work with an angle grinder often in the fresh air, it requires the presence of sunlight. To protect your eyes from bright rays, it is better to buy protection with a special coating against ultraviolet radiation. “Chameleon” models have become widespread among craftsmen.

- Ventilation. If a closed model is used when working with an angle grinder, pay attention to ventilation. When there are no holes on the surface, you have to often remove the protection and wipe off condensation.

- Price. You can't skimp on quality. If, when purchasing, it is clear to the naked eye that a cheap model will quickly deteriorate, it is better to buy a more expensive one.

- Convenience. Immediately upon purchase, the model is tried on. The frame should not be too tight or restrict movement, or fall off the ears. Otherwise, you will have to be frequently distracted while working, and this can lead to serious injuries.

Important! No one except the operator will take care of eye protection during operation. To ensure tasks are completed quickly and with pleasure, safety precautions are followed.

Stand for grinder + (Video)

This device is a small machine with which you can easily, safely and very accurately cut metal pipes, profiles or rods. It consists of a base or small table attached to the ground or to a metalworking table.

The machine is assembled in a simple sequence:

- install a hinge on the base;

- We weld the supporting pipe to the hinge;

- We attach the U-shaped plate for attaching the grinder to the pipe;

- We put a rubber handle on the supporting pipe;

- install the disk and check its position.

Read also: Polish for stainless steel refrigerator

As a result of some simple work, we got a machine or stand for an angle grinder. Now the grinder can rise and fall down on a hinge onto the part installed for cutting. In order for the angle grinder to rise up without loads, we install a spring on the pipe.

It is necessary to install two fixing angles on the table. At the base of one corner we make a groove around the circumference for a bolt. It will be needed when a pipe or profile needs to be cut at a certain angle. Then we install this corner with a slot at the same angle to the plane of the grinder’s cutting disc.

Parallel to the corner with the arc slot, we install a corner that can be moved towards the part to fix it on the table. The pipe or profile will simply be inserted between two corners. This is enough to perform fast and precise cuts.

By installing a supporting transverse metal bar on the machine table, you can strip the material using a steel brush mounted on the angle grinder shaft.

Care and storage rules

Most models, even made from durable material, quickly wear out and fail. Therefore, before each use, you should carefully inspect the frame for damage. If there are severe chips, deep cracks and scratches on the surface, and the elastic band is stretched and loose, it is better to purchase a new model.

To remove adhering dust and dirt, the surface should be periodically wiped with a piece of damp cloth. The hardware store sells special material impregnated for disinfection. It is better to store the protection in a special case that protects it from damage.

To work with an angle grinder, special safety glasses are used. They protect the organs of vision from foreign objects and dust. There are many models on sale, among which it is not so easy to choose the right glasses. When purchasing, it is better to rely on the material of manufacture, price, ease of use and other characteristics. The more carefully you care for your safety glasses, the longer they will last.

Do-it-yourself dust collection cover for an angle grinder

Hello, dear readers and DIYers! Many of you have had to work with a grinder, and perhaps even grind concrete with a diamond bowl. Then you know how much dust is produced during this process. In this article, the author of the YouTube channel “Men's Craft” will tell you how you can quickly make a special casing for dust removal.

This homemade product is very easy to make, and is made from affordable materials using a minimum number of tools.

Materials. — Plug with a diameter of 160 mm for PVC pipe, corner — Rubber strip — Secondary glue — Steel clamp — Self-tapping screws with a press washer — Sandpaper.

Tools used by the author. — Screwdriver — Crowns — Step drills — Hair dryer — Grinder — Cutting disc — Diamond grinding bowl for concrete — Vacuum cleaner — Square, ruler, marker, screwdriver, file, metal scissors. Manufacturing process. The basis for the casing will be a plug for a PVC pipe with a diameter of 160 mm. The master marks the center on it and drills a hole with a stepped drill.

After repeating the heating process, insert a plastic corner into the hole.

The edges of the hole turned out to be a little longer; the author cuts them off with a grinder, leaving about 15 mm of margin. The edges are smoothed with a file.

The front slopes of the plug should also be shortened slightly.

He heats up the plastic and inserts a corner into it like this. Its joint can be additionally fixed with hot glue.

Now the master measures the rubber band to the required length and cuts it with scissors.

Many cuts are made on one edge of the tape; this is necessary to increase its elasticity and tighter contact with the surface.

Now the tape is glued with second glue along the perimeter of the body.

That's all, you can connect a vacuum cleaner and process the walls, level their surfaces, or remove paint.

The author's video can be found here.

[media=https://www.youtube.com/watch?v=-S_1g965rhw]

Source

Become the author of the site, publish your own articles, descriptions of homemade products and pay for the text. Read more here.