Manual arc welder's tools and accessories

In addition to the welding inverter or transformer welding machine, the welder also uses a fairly large number of tools. This is the well-known grinder, and clamps, and a slag hammer, where would we be without it.

This site article about manual arc welding will provide a list of tools and accessories for the welder. The article will be useful, first of all, to novice electric welders who are just learning the basics of an amazing, and at the same time difficult profession - a welder.

Main types of assembly and welding devices

To obtain a high-quality seam, product parts must be correctly positioned in space relative to each other. To perform this action, special devices of various types are used for assembly and welding.

They are divided into:

- assembly;

- welding;

- assembly and welding.

The first ones are used for installing and securing parts of a structure using tacks, welding pliers, welding clamps, and other simple mechanical devices.

Welding fixtures are used to connect pre-assembled products fixed in a certain position. These also include mass clamping. The third option allows you to combine the two operations listed above.

It is worth noting that the assembly mechanisms must allow free movement of parts of the structure. They will heat up during operation and their size may change.

If the parts are placed close to each other without the possibility of movement, then deformations may occur due to thermal effects.

When working with large parts with low rigidity, tools should provide the ability to connect only the edges of the parts, and not the entire structure.

When planning welding work, it is necessary to provide in advance the possibility of access to the joints. If parts are located at right angles, corner clamps should be used. If possible, you can spot weld parts of the structure.

Then it is enough to throw the ground terminals of the welding machine over the product and you can start working. Sometimes you can use a lot of the details themselves. Under their own weight, they can be quite reliably positioned in the required configuration.

However, this option is not always applicable, so it is always better to have welding pliers on hand.

Technological equipment of welding installations

Flux-holding devices are used to create the necessary layer of flux in cases where this layer is not retained by the edges of the parts being welded. Flux-holding devices can be fixed or movable. Schemes of some of them are shown in the figure.

Flux pads are used to prevent leakage of molten metal into the gap between the edges. A layer of flux is pressed against the underside of the weld, holding the weld pool and forming a back bead.

Installation and securing devices

In order for the master to do his job efficiently, the parts being connected often need to be secured in a certain way. In simple workshops, universal devices are widely used to solve this problem.

The most popular mechanisms are those that allow you to simultaneously install and secure parts of the structure.

Scheme of a clamp for welding work.

The following welding fixtures are used for this:

- corner clamps;

- welding vice;

- locking clamps, etc.

If you have to work with large parts, then a special frame is made for this. Products are installed on it at an angle of 90 degrees. With this installation, it is possible to obtain a guaranteed correct arrangement of parts on the plane.

An angle clamp for welding helps to maintain a right angle between parts of the product. Then, using resistance welding pliers, you need to grab the parts in several places. After completing these operations, you can put ground terminals on the structure for grounding and start working.

If you have to join small parts, you can use a clamp or hand-held resistance welding pliers.

Additional welding equipment for automatic welding

The automatic welding process cannot be carried out without the use of special auxiliary devices, which are designed to reduce technological time during high-precision operations in mass production.

We recommend articles on metalworking

- Steel grades: classification and interpretation

- Aluminum grades and areas of their application

- Defects in metal products: causes and search methods

The use of auxiliary welding equipment is widely used in enterprises producing parts and assembly units from metal for the mechanical engineering, railway industries, in the construction and housing and communal services systems, in the agricultural industry and in everyday life.

Types of auxiliary welding devices and types of equipment:

- pipe rotation devices;

- roller supports;

- welded columns;

- welding positioners;

- mobile carriages for hoists and hoists;

- lifting devices;

- installations for special purposes;

- transfer mechanisms;

- automatic devices.

Welding rotators are devices in which a fixed part is capable of rotating at a certain speed to perform certain types of welds. This simple design is often used in mechanical engineering. It is compact, not heavy, equipped with grooves for fixing workpieces, a handle for tilting the part, a foot pedal for starting and stopping, and an emergency shutdown button.

Roller supports are used for the manufacture of external and internal seams with uniform rotation of cylinder-type parts and various pipes. The package includes a section with and without a drive. The first type model includes several roller supports with its own rotation drive. The second type of structure consists of a frame to which the mechanism rollers are attached. The sections are securely fixed to the floor surface.

Welding columns are used for reliable fixation and movement of parts. In some cases, they are used together with roller support structures to create convenience when applying a welding seam. The device includes a cabinet, a console, carriages, a moving drive, rotating elements and lifting mechanisms. At the buyer's request, additional equipment may include a welding column and an electrical power source.

Rotators are devices designed to install parts in a position convenient for welding by rotating them around an axis. Products of any configuration are attached to them. The functional purpose of such devices is to force a displacement of the center of gravity of parts through the use of a manual or mechanical drive. Most of these mechanisms rotate the load by 90° or 180°, and in some cases with a certain angular step. Turning facilitates further manipulation of the load during its movement.

Mobile carriages are designed to move the torch, cutter, hose holder and welding machine in different directions relative to the product. They serve to simplify manufacturability and control parameters. Their movement is carried out along rail guides pre-installed in the sections. This is a very practical way to use auxiliary equipment.

Devices with magnets

Magnetic clamps are classified as installation and fastening mechanisms. This means that they allow you to correctly position the parts and secure them. This operation is carried out using strong magnetic elements.

What advantages does this welding device provide? Let's figure it out.

Welding using magnetic corners.

The main advantages include:

- the ability to quickly connect parts;

- installation of parts at different angles using a magnetic angle for welding;

- significant reduction in time for preparatory work;

- small dimensions;

- the presence of a magnetic field activator in some models;

- possibility of quick and easy cleaning of magnets.

The main disadvantage of such devices is the limitation of their use depending on the material. Non-magnetic metals, wood, etc. do not allow the use of magnets.

On the other hand, magnetic welding fixtures allow you to fasten parts at any angle to each other, and they are more versatile than, for example, clamps.

Magnetic clamps are truly convenient mechanisms that eliminate bulky clamps and the need for resistance welding.

In addition, on the Internet you can find a large number of reviews devoted to the manufacture of homemade devices for welding work. For example, you can make your own magnetic square for welding with your own hands or a magnetic mass for welding.

DIY process

The required design can be created using available tools. Among the features of the work carried out, we note the following points:

- Rectangles 4 cm wide of various lengths are cut out from the purchased sheets. After this, two rectangular plates are prepared. The first elements are used to create the main part of the body, the others to fix the moving part. The metal is pre-cleaned of rust and other contaminants.

- A special auxiliary element made of metal plates and corners is welded to the main clamp.

- Another sheet of steel is welded to the smaller side. Washers of the selected diameter are welded into one blank.

- The nuts must be laid on edge. Due to this, the movable rod is located parallel to the clamp.

Making a homemade clamp

The weld should go from the outside. This design allows you to fix the elements to be connected and ensure their immobility during welding.

Homemade welding fixtures are almost in no way inferior to purchased versions. Before you begin to assemble a clamping or locking mechanism, you need to consider how it will be used and what properties it should have.

Pipe welding equipment

Using pipe welding equipment correctly, the master will be able to complete the assigned work quickly and efficiently. In everyday life, a wide range of different devices are used for welding profile pipes. These can be both professional and homemade options.

The main task of such mechanisms is to correctly install the parts in the desired position.

According to their functionality they are classified into:

- stops;

- squares;

- templates;

- prisms.

The first type is used to fix the workpiece on the main surface. The second option allows you to install parts at a certain angle. Prisms position the pipes in the desired position in relation to existing parts of the structure.

The described mechanisms allow you to reliably install pipes and fix their position from accidental displacement.

Devices for welding pipes.

These include:

- clamps for welding work;

- alligator clips;

- screeds;

- spacers

The clamp is a universal mechanism, widely used when performing various works with metal parts. They are among the most important devices, without which almost no work can be done.

The clamp can have different shapes and designs. For example, there are quick-release clamps with a cam mechanism.

Clamps are often more convenient for working with pipes. They are more suitable for such use. Their use is very simple, the part is secured by changing the jaw with the screw of the clamping handle.

Ties are used to bring two parts together. The length of such a mechanism varies, depending on the tasks assigned.

It is very convenient to assemble the entire structure using a welding jig. It allows for high welding precision. This device is especially often used in professional workshops and production.

To securely fasten parts of the product, the conductors are equipped with crocodiles of 500 or 200 mm, depending on the work being performed. Of course, these parameters may be different. At home, you can limit yourself to hand-made spot welding pliers.

Types of welding equipment

The active use of welding began about a century ago, simultaneously with the development of such an industry as heavy engineering. Nowadays, neither enterprises producing electronic goods, nor construction organizations, nor machine-building complexes can do without them. It is also difficult to imagine some types of production without their use. For reliable connections of metal structures using a welding seam, welding machines have been created that include standard components.

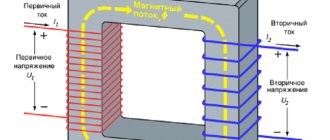

For welding work, key importance is given to the transformer and rectifier (or inverter), which are connected to an alternating current network with a voltage of 220 or 380 V. With their help, the mains current is converted into welding current, which creates the necessary values of current-voltage parameters. Step-down transformers are designed to convert the voltage of electrical networks to the required values during welding work. Inverters are also called pulse devices. This type of equipment is most often used by welders due to its light weight.

During the welding process, the joint zone and the parts themselves are heated to temperatures above +200 °C, therefore, to fix and hold it during positioning, certain holding and fastening equipment is required. Auxiliary devices are divided by functionality, performance parameters and operating principles.

- In terms of functionality.

The equipment is divided into the following types:

- Universal. It is used when welding parts of various configurations. It is characterized by small dimensions and weight, and is not applicable for mass or serial production. Such equipment includes various clamps, vices or spring-type clamps.

- Special. Designed to perform repetitive operations of the same type. It is used in medium-scale and large-scale production to reduce production time, since changing equipment for fixing parts needs to be done only once, after the entire batch is completed. Special types of equipment include designs of assembly stands for welding, special templates and jigs.

- By type of production.

The equipment is divided into the following types:

- For use in serial or mass production. The advantages of this equipment: ease of installation on the stand or removal of parts from the stand, as well as being equipped with additional limit stops and templates for quickly changing workpieces.

- For use in single or small-scale production types. They are often used in everyday life of households or private households, or for the manufacture of prototypes, when a quick change of parts is not required.

- By the nature of the work.

Equipment is divided into the following types:

- Drives for manual fixation of the workpiece (using screw or spring clamps or eccentric design).

- Mechanized drives (using hydraulic or pneumatic forces or electric drives) controlled by operators.

- Automated drives equipped with mechanisms that operate automatically from a power drive. The workpiece is secured and released without the participation of a welding operator.

In addition to standard equipment, equipment is used that increases the speed and manufacturability of processes. In mass large-scale production, multi-position or carousel systems are used, which significantly reduces the installation and removal time of workpieces.

They can also be divided into portable or mobile, stationary or rigidly attached to the foundation.

Gas lenses

The use of gas lenses improves the quality of seams. This is especially true when working with metals that are sensitive to oxidation.

The quality of seams is largely determined by the flow of shielding gas. At a high speed of argon movement, a rarefied zone is created in the nozzle area, which facilitates the capture of air and its supply to the bath. At low speeds, oxygen also enters during breaks in the inert gas flow.

Gas lenses are used when it is necessary to provide reliable protection of the metals being connected. This is especially true for materials with high chemical activity, which include, for example, titanium.

Gas torches are also used when joining simple shaped structures. With the use of this device, the gas flow becomes more orderly and less sensitive to the movement of transverse masses.

At the same time, using them for parts of products with complex shapes is difficult and sometimes impossible. In addition, they increase the consumption of shielding gas.

When using this mechanism, it is important to correctly and securely fix the parts of the products together. This can be done using resistance welding pliers or plumbing tools such as a welding clamp, clothespin and other homemade or professional equipment.

It is better to carry out all welding work on a conductor. This will greatly facilitate the process of joining various metal elements. For welding cable wires, it is necessary to select the correct lugs depending on the task at hand.

Manual Welding Auxiliary Equipment

A ballast rheostat is a device that is designed to stepwise regulate the current level during the welding process, creating falling parameters of power sources.

The oscillator is an additional equipment to the power source and is designed to ensure non-contact ignition of the arc and stability of its ignition. At a significant (3÷8 kV) voltage and an increased (about 300 kHz) current frequency, it is possible to ionize the arc gap with a spark discharge without the electrode coming into contact with the surface of the part.

The voltage limiter reduces the open circuit voltage to 12 V in up to 1 second. after the welding arc has died down. This device is widely used in manual arc welding in rooms with hazardous conditions, from inside various metal containers and in other positions inconvenient for welding.

The welding cable is an important additional element of welding equipment and is a conductor of large currents. It consists of copper wires with a diameter of 0.1 to 0.2 mm, intertwined into strands, and these in turn are woven into a cable coated with rubber insulating material.

| Wire cross-section, mm2 | 6 | 25 | 35 | 50 | 70 | 95 | 120 |

| Permissible welding current, A | 100 | 140 | 175 | 225 | 280 | 335 | 400 |

Electrode holder – designed to secure and hold the electrode.

Specifications:

| Type | Welding current, A | Electrode diameter, mm | Weight, kg | |||

| PV = 35% | PV = 60% | PV = 100% | minimum | maximum | ||

| ED-12 | 160 | 125 | 100 | 1,6 | 3 | 0,35 |

| ED-20 | 250 | 200 | 160 | 2,5 | 4 | 0,4 |

| ED-25 | 315 | 250 | 200 | 3 | 5 | 0,45 |

| ED-31 | 400 | 315 | 250 | 4 | 6 | 0,5 |

| ED-40 | 500 | 400 | 315 | 5 | 8 | 0,65 |

| ED-50 | 630 | 500 | 400 | 6 | 10 | 0,75 |

A hand torch is the gas welder’s main tool among all types of welding equipment. It is designed to generate a gas welding flame to heat and melt metal. When arc welding, the W-electrode is fixed in a certain position, electric current is supplied to it, an arc is formed, shielding gas is supplied to the welding zone, and live parts are cooled with air or water.

Devices for secondary protection during argon arc welding

All safety measures and labor protection requirements require mandatory grounding of all electrical circuits.

They include several circuit elements, which include:

- welding machine;

- cables;

- clamping pliers for the product;

- burner;

- product.

When using resistance welding pliers, such as fillet welding, grounding is also very important as the work is carried out with very high currents.

Bottom line

Preparation for welding work often takes much more time than the actual process of connecting parts of the structure. To ensure high quality, parts must be reliably and correctly aligned for welding in accordance with the drawings.

For these purposes, the following are widely used: welding clamps, welding pliers, resistance welding pliers, welding clamps, etc. Correct installation of parts of the structure can be done not only using mechanisms, but also using spot welding.