Knowledge of how to select a drill for a dowel is relevant in situations where it is necessary to drill a hole to fix this fastener in it. Dowels are used in cases where it is necessary to fasten various objects to the wall surface - furniture elements, photographs, paintings, etc. The reliability of the fastening will largely depend on how correctly the drill is selected to create the hole in which the dowel will be placed.

First, we select a dowel depending on the wall material and the weight of the object, and then we select a drill based on the wall material and the size of the dowel

What to consider when choosing a drill for a dowel

Selecting a drill to create a hole in which the dowel will be fixed should take into account:

- the material from which the wall itself is made, as well as its finishing;

- expected loads of the fastener.

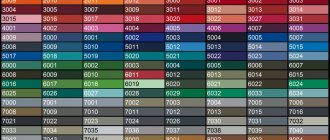

You should also choose a drill depending on the diameter of the fasteners used. On the outer surface of factory-produced dowels, as a rule, there are markings that allow you to correctly select drills of the appropriate diameter for them.

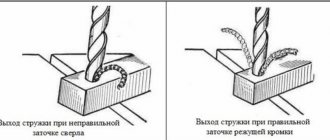

Table 1. Selection of drill and screw for dowel

It is important to know not only how to choose a drill for a dowel, but also how to drill a hole correctly. If it is necessary to drill a hole in the wall for a dowel, the diameter of which is 10 mm, then first use a drill with a diameter of 8 mm and an impact drilling mode. After the hole is drilled, the tool is replaced with a drill with a diameter of 10 mm and is used without using the impact drilling mode. This approach will allow you to get a hole in the wall of the required diameter with smooth and neat edges.

If you need to drill a concrete wall, it is better to use a Pobedit drill, which can handle such a durable material without any problems. The selected cutting tool must be at least 3 mm longer than the dowel itself. If you neglect this requirement, the dowel will not completely fit into the resulting hole, in the final part of which dust and pieces of crumbled material, as a rule, accumulate. In addition, the shape of the bottom of the hole may not match the shape of the tip of the fastener.

Calculate the drilling depth with a margin relative to the dowel length

Basic selection principles

The correct choice of drill for the dowel should be based on the following:

- When calculating which hole to drill for the dowel, it is worth considering the type of wall into which the rod is installed and what it is covered with.

- Weight of attached furniture and maximum possible loads.

Considering the above parameters, you can choose the appropriate tool correctly. To make it easier, you need to take into account the factory size of the drill and fasteners, as well as the tensile strength of the dowel. There are markings on the tool, based on which it is easy to select the desired model.

If the wall material is very strong, for example concrete, you should choose two types of drills and different operating modes of the drill. To begin with, you should take a drill several sizes smaller than the dowels, switch the drill to impact mode and make the necessary hole. Then, using a gimlet of identical size with fasteners, in normal mode, bring the hole to the required parameters.

With the help of such manipulations, you can carry out work faster, do not overload the drill, get an ideally shaped hole and maintain the integrity of the wall and its coating. The rod in the hole should not rotate and move freely in it. Instead of a drill, it is better to choose a hammer drill, as it is more powerful and productive.

If the wall material is loose, it is better that the drill size is several sizes smaller than the rod (for example, for an 8 dowel, a drill size 6 or 7). This will allow the fasteners to be installed tightly, even in the event of excessive destruction of the wall structure.

When choosing the type of drill, you should pay attention to pobedit ones, given their high strength and durability.

The length of the hole should be several millimeters longer than the length of the dowel. This is necessary to ensure that it fits tightly into the niche over its entire length, since dust can accumulate in the hole.

How to fasten light weight objects

In order to fasten objects that are light in weight, use a quick mounting dowel. It is usually used for fastening lightweight objects to building structures made of brick and reinforced concrete.

As a rule, to solve this problem, a dowel is selected, the diameter of which, like the transverse size of the drill, is 6 mm. In this case, the length of the fastening element depends on the thickness of the wall of the object being fixed with it. If you need to select a dowel for mounting on the wall, then its length should be at least 4 cm, but if the mounting is on the ceiling, you need fasteners at least 6 cm long.

Installing a Butterfly Dowel in Drywall

The work of installing butterfly dowels in drywall is not particularly difficult; you can easily handle them yourself, without the involvement of professional craftsmen.

The most popular size of such dowels is 10x50. Most plasterboard structures are secured with a butterfly dowel of this size.

The installation sequence is as follows:

First of all, the required markings are carried out; Using a drill or hammer drill, a hole of the required diameter is drilled in the base

It is impossible not to note the extraordinary versatility of this anchor fastener - with equal efficiency it can be used for fastening both drywall and chipboard, plywood, MDF and other materials.

When choosing the optimal self-tapping dowel, you should take into account not only the diameter of the head and the length of the leg, but also the material from which the base is made.

As for the maximum permissible load that such dowels can withstand, it is 28 kg.

Trade marks

Butterfly dowels for drywall from the following manufacturers are in greatest demand on the domestic market:

Butterfly dowel and its advantages

Butterfly dowels for drywall are characterized by a number of undeniable advantages that make them stand out among many competitive offers.

The most valuable among them are:

- Convenience and ease of installation work;

- Easy screwing of the fastening screw;

- Possibility of reuse without reducing the quality and reliability of the connection;

- The presence of longitudinal ribs that prevent the element from turning;

- Long period of effective use;

Increased connection strength, achieved by expanding the contact area of the dowel to the base by straightening additional supports.

The use of butterfly dowels under drywall allows you to securely fix the sheets with a minimum of effort, regardless of the configuration of the base and the complexity of the structure being formed.

Working with such fasteners is characterized by its simplicity; the main thing is to choose high-quality screws and strictly follow the instructions for their use.

Video on installing a butterfly dowel in a plasterboard wall

Securing medium weight items

Fixing objects of average weight is performed using impact-type dowels. In this case, the transverse dimensions of the dowels, as well as the corresponding drills, must be at least 8 mm. The dowel chosen for these purposes must go into the wall to a depth of at least 6 cm, and when attached to the ceiling surface - to a depth of 8 cm. To securely fasten an object of average weight (up to 10 kg) to the wall or ceiling, you must use 4 dowels at the same time.

It is convenient to hang medium-weight objects on quick-installation dowels if the design allows the use of through fastening

Application of the tap

Before you start threading, you need to determine the diameter of the preparation hole and drill it. To facilitate this task, a corresponding GOST was developed, which contains tables that allow you to accurately determine the diameter of the threaded hole. This information makes it easy to select the drill size.

To cut metric threads on the inner walls of a hole made with a drill, a tap is used - a screw-shaped tool with cutting grooves, made in the form of a rod, which can have a cylindrical or conical shape. On its side surface there are special grooves located along its axis and dividing the working part into separate segments, which are called combs. The sharp edges of the combs are precisely the working surfaces of the tap.

Tap: design and parameters

In order for the turns of the internal thread to be clean and neat, and for its geometric parameters to correspond to the required values, it must be cut gradually, by gradually removing thin layers of metal from the surface being treated. That is why for this purpose they use either taps, the working part of which is divided along the length into sections with different geometric parameters, or sets of such tools. Single taps, the working part of which has the same geometric parameters along its entire length, are needed in cases where it is necessary to restore the parameters of an existing thread.

The minimum set with which you can sufficiently perform machining of threaded holes is a set consisting of two taps - rough and finishing. The first one cuts a thin layer of metal from the walls of the hole for cutting metric threads and forms a shallow groove on them, the second one not only deepens the formed groove, but also cleans it.

Types of thread taps and their differences

Minimum set of taps

Combination two-pass taps or sets consisting of two tools are used for tapping small diameter holes (up to 3 mm). To machine holes for larger metric threads, you must use a combination three-pass tool or a set of three taps.

To manipulate the tap, a special device is used - a wrench. The main parameter of such devices, which can have different designs, is the size of the mounting hole, which must exactly match the size of the tool shank.

Some types of tap drivers

When using a set of three taps that differ both in their design and geometric parameters, the sequence of their use must be strictly observed. They can be distinguished from each other both by special marks applied to the shanks and by design features.

- The tap, with which the hole for cutting metric threads is processed first, has the smallest diameter among all the tools in the set and cutting teeth, the upper part of which is heavily cut off.

- The second tap has a shorter fence and longer combs. Its working diameter is intermediate between the diameters of the other tools in the set.

- The third tap, with which the hole for cutting metric threads is processed last, is characterized by full ridges of cutting teeth and a diameter that must exactly match the size of the thread being formed.

Set of three taps

Taps are used primarily for cutting metric threads. Much less often than metric ones, taps designed for processing the internal walls of pipes are used. In accordance with their purpose, they are called pipe, and they can be distinguished by the letter G present in their markings.

Installation of objects with significant weight

To fasten heavy objects (furniture cabinets, shelves, TV stands, etc.), you must choose a dowel, also of the impact type. In this case, the diameter of such a dowel, as well as the transverse size of the drill, must be at least 10 mm. Such dowels are buried 6 cm into the walls, and 8 cm into the ceiling. For reliable fastening of heavy objects, as a rule, at least 6 dowels are used.

To fasten the horizontal bar and ladder, anchor bolts are used, the diameter of which must be at least 8 mm. Such bolts are buried 6 cm into the surface of the walls, and 8 cm into the ceiling.

The procedure for installing an anchor in a concrete wall

Types of anchor bolts

Anchor bolts used to secure various objects are divided into three main types:

- anchor bolts with a nut, which, after installing the fastener, is tightened with a spanner or open-end wrench (with the help of such bolts, hidden fasteners are performed);

- anchor bolts with a self-locking nut, which is tightened using a Phillips-type screwdriver (such bolts can be used for fastening in places that are visible);

- double-expansion anchor bolts are the most reliable fasteners that are used to fix even very heavy objects.

Main types of anchors

Fastening with anchor bolts

More reliable fastening of heavy objects is provided by anchor bolts. The diameter acceptable for significant loads is from 8 mm. The following types of fastenings are distinguished:

- with nut. After installing such an anchor, the nut is tightened with a wrench;

- with a hidden head. Tighten with a “curly” screwdriver;

- double-spacer - with two spacer sleeves - for fastenings that experience significant loads, for example, window and door frames.

The drill bit for anchors is selected differently than for plastic dowels: 1 - 2 mm larger. It is recommended to select the required value based on the information presented in the table of values or according to the marking of the anchor.

How to fasten on unreliable surfaces

Very often there is a need to fasten objects on unreliable surfaces, which include plasterboard walls, building structures in old brick houses, etc. When fastening on such surfaces, the following recommendations should be followed.

- It is better to choose dowel elements from nylon, and their diameter should be 10–12 mm. The diameter of the Pobedit drill, with which the hole for the fastener will be made, should be 2 mm less than the transverse size of the selected dowel.

- Drilling must be done in one step, without changing the drill, and the impact mode should not be used so as not to destroy the walls of the hole being formed.

Securing objects to plasterboard walls using butterfly dowels

To perform reliable fastenings, it is important to take into account the condition of the surfaces, choose the right cutting tool and correctly carry out the drilling process itself. Important parameters that should also be taken into account are the dimensions and weight of the item being secured. In addition, it is necessary to select the correct screw for the dowel to ensure reliable fastening of the object to the surface of the wall or any other building structure.

Types of fasteners

Construction stores offer a wide range of dowels.

Photos of products clearly demonstrate the diversity of their designs, materials of manufacture and purpose. The most common product is the universal polypropylene dowel. It has a traditional design in the form of a sleeve, into the cavity of which a self-tapping screw is screwed. This element is suitable for concrete, brick and stone foundations. The design of the product is equipped with special spacers, with the help of which the element is securely fixed in the hole.

To perform complex external work, a spacer construction dowel with a locking edge is used, which eliminates the possibility of fasteners falling into the hole.

Nylon dowels are equipped with fastening antennae, thanks to which the products are securely fixed in the holes. They can be used on any surface.

Drywall dowels are used for mounting them into porous concrete and sheets of gypsum fiber and plasterboard. They can be made of plastic or metal. The last option is called dowel molly. Before hammering in a dowel of this type, there is no need to first prepare the hole, since its tip has the appearance of a sharpened drill.

Dowel for plasterboard walls

Facade dowels are made of polypropylene or nylon. They have directional antennae for secure fixation at the base. Such fasteners can be used for any surface. They are produced without sides, which eliminates the possibility of shedding or cracking of the facing plaster.

The frame dowel is intended for installation of door and window frames, cladding through layers of thermal insulation and plaster. The products are made of metal. They are often called thermal insulation dowels, which can be of two types: for working with hard and soft materials.

Types of dowels with special design

Dowel nails are made of polypropylene, nylon or stainless steel. Thanks to the presence of knurling in the form of reverse cones, reliable retention of the product in the base is ensured. They are widely used for quick and extensive installation of skirting boards, sheathing, windows, timber, metal profiles, cable ducts, plywood to concrete, brick or stone surfaces.

Butterfly dowel for hollow structures

The butterfly dowel is characterized by increased wear resistance and the ability to withstand high loads even in hollow surfaces. Such products are made of metal.

The adjusting dowel is used to install the sheathing under the sheathing. It has a special design containing a certain element that allows you to adjust the position of the product relative to the surface to which it is attached.

The dowel-clamp has the shape of a loop with characteristic tendrils for fastening along the edges of the product. Such elements are designed for mounting electrical wiring to the base. The wire is inserted into the clamp, and its edges, in turn, are inserted into holes previously created in the wall and fixed with tendrils.

A special type of fastening element is an umbrella dowel, which is designed for installing thermal insulation made of polystyrene or mineral wool. This product has a wide round cap that holds the insulation. They produce plastic and metal dowels.

An umbrella dowel is often used to hang ceiling chandeliers

The Molly umbrella dowel is a nail with metal arms that provide reliable fastening of structures to hollow surfaces with uniform load distribution.

Types of dowels

In stores you can find a large selection of different dowels. But each of them is created for one purpose or another.

| The simplest, but suitable for most types of work, including stone, concrete and brick. When screwing in the self-tapping screw, the dowel material is wound onto the metal, thereby securing the structure |

| It is also made of polypropylene, but has special spacers, due to which it is held inside the hole |

| Allows you to quickly and efficiently fasten windows, sheathing, skirting boards, beams, cable ducts, metal profiles, as well as plywood into concrete, stone or brick surfaces. Made of nylon or polypropylene, nail made of steel |

| Designed for mounting various elements into sheets of plasterboard or gypsum fiber, as well as porous concrete. This fastener is made of plastic or metal. The second option (also called a “molly” dowel) does not require pre-drilling holes, since the tip of the metal dowel looks like a feather drill |

| As the name suggests, it is made of nylon. It can be used in almost any situation and on any surface. Due to the presence of fastening antennae, the nylon dowel is securely held in the wall. Self-tapping screws for such a dowel usually have a diameter of 0.02-0.16 cm |

| Designed to perform serious installation work. This fastener can withstand enormous loads even if there are hollow walls. Made from metal |

| With its help, the sheathing is attached for future cladding. The main feature of this type of fastener is the ability to regulate (adjust) the position of the elements relative to the base to which they are attached |

| A special type of dowels designed for installing thermal insulation made of mineral wool and polystyrene. The appearance of the fastener fully explains its name: a wide round cap, the main purpose of which is to hold the insulation against the wall. “Umbrellas” are made of both plastic and metal. But “umbrellas” are also called another type of dowels designed for working with drywall, mostly with hanging structures. This metal “umbrella” Molly is a nail with metal shoulders that are securely attached to a hollow structure, evenly distributing the load. Using this type of dowels you can easily hang any chandelier in a suspended ceiling |

| It looks like a loop made of plastic (nylon), with “antennae” along the edges, due to which the fastener will be held. Clamps are designed for mounting electrical wiring to the wall. Working with this type of dowel is very simple: first, a hole of the required diameter and depth is drilled, and then the required wire is simply pressed with a clamp, the edges of which are inserted into the previously drilled hole. They can also be used to attach small-diameter corrugated pipes |

Frame dowelIt is made of metal, since its area of application is very specific. Designed for installation of window and door frames. A metal frame dowel is also suitable for fastening the sheathing through a layer of plaster and thermal insulation. |

Fastening to structures made of weak materials

The definition of “weak” materials includes plasterboard, porous (light) concrete, and hollow brick.

The general rule for drilling holes in the listed materials is to exclude the impact mode.

It is recommended to use nylon dowels. Their diameters should be larger than for structures made of solid concrete or brick. The diameter of the hole is 2 mm smaller than the dowel hole.

Butterfly dowels are suitable for fastening to walls made of sheet material (plasterboard, chipboard, OSB, etc.).

Installation type

There are two ways to install the fastener:

- Manual . You will need a hammer drill, screwdriver or hammer. You will have to drill a hole, insert a sleeve into it with your own hands, and then screw or drive in the rod.

- Automatic . Installation is carried out using a gun. Use a special nail without a dowel with a strength of 53-56 HRC on the Rockwell scale.

The second option benefits from high installation speed. But the first is good because the standard rod can be pulled out without damaging the material or design.

Fastener selection

What happens if you insert a universal dowel with two spacers into aerated concrete? It will fall out quickly. The structure of the block is too porous and soft to hold conventional fasteners. Therefore, you need to choose wisely. Let's give some recommendations:

- Let's understand the material . For brick and concrete, regular spacer sleeves or gun dowels are suitable. Foam concrete and aerated concrete are fragile; bushings with cutters or screw ribs will be needed. You can secure the suspension to drywall using butterfly fasteners.

- We look at the type of suspension . A mushroom plate dowel will help to install thermal insulation and waterproofing. An ideal option for lathing, brackets or facade profiles would be a façade dowel-nail.

Video

See how to insert a dowel into a wall by choosing the right drill:

This video shows how to attach a hanger for a plasterboard sheet into concrete using a dowel-nail:

The procedure for most types of work requires drilling a hole for the dowel. In view of this, we recommend that you familiarize yourself with information about how to choose a drill for a dowel. So, after reading this information, you will be able to hang many different related items, for example, paintings, shelves, kitchen cabinets, baguettes, photographs, etc. The reliability of fastening the above-mentioned objects depends on the rules for choosing a drill for the dowel.

Installation Features

Installation of dowel-nails is carried out in the following order:

- Mark a center point for drilling.

- Make a hole 5-6 mm deeper than the length of the dowel.

- Use a hammer to carefully hammer in the bushing.

- Fix the nail with light blows.

If you need to secure the suspension, leave a distance of 2-3 mm from the head of the rod to the sleeve. It is better to blow out the hole or clean it with a special brush, otherwise dust and crumbs will weaken the holding power of the fastener.

Marking

Manufacturers of dowel-nails stamp markings directly on the side surface of the sleeve. There are only 2 numbers:

- External diameter.

- Length.

For example, the inscription 6x40 means that the diameter of the dowel is 6 mm and its length is 40 mm. Visual information makes it possible to determine the size of the fastener, even if the box or packaging is lost. It's comfortable. Just look at the sleeve to understand what kind of drill is needed and how deep the hole should be.