Types of low alloy steel

Structural low-alloy steels are classified:

- low carbon (up to 0.25% carbon);

- medium carbon (0.2-0.45%);

- heat resistant.

Types of low-carbon steels are presented in the table.

| Name | Marking examples |

| Chrome-silicon-nickel-copper | 10HSND, 15HSND |

| Chromium-silicon-manganese | 14ХГС |

| Manganese-nitrogen-vanadium | 14G2AF |

| Siliceous manganese | 14GS, 10G2S1, 09G2S |

| Manganese | 14G2, 14G |

Medium-carbon grades (35ХМ, 18Г2AF, 17ГС) contain more than 0.25% carbon and are used after heat treatment.

Heat-resistant metals have increased strength when working at high temperatures. They are used in the manufacture of metal elements of energy devices.

Due to the higher strength of low-alloy steels (compared to carbon structural steels), their use in the production of welded structures reduces weight and saves metal.

Due to these properties, the materials are used in railcar and shipbuilding, construction and other areas of industry.

Steel 09g2s 12: decoding

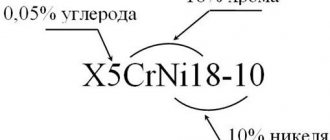

Understanding how labeling is formed allows you to clearly understand what product the manufacturer represents, as well as its main features. For those who are interested in details about 09g2s, the breakdown of steel is as follows:

- 09 – quantitative fraction of carbon content in the alloy (0.09%);

- G2 is manganese and its part in the entire volume fluctuates around 2% (the exact figure ranges from 1.3 to 2%);

- C - denotes silicon, the absence of numbers after the symbol indicates that it is less than 1%.

Thus, the decoding of 09g2s clearly looks like this:

| Element | Content, % |

| C (carbon) | up to 0.12 |

| Si (silicon) | 0,5 – 0,8 |

| Mn (magnesium) | 1,3- 1,7 |

| Ni (nickel) | up to 0.3 |

| S (sulfur) | up to 0.04 |

| P (phosphorus) | up to 0.035 |

| Cr (chromium) | up to 0.3 |

| N (nitrogen) | up to 0.008 |

| Cu (copper) | up to 0.3 |

| As (arsenic) | up to 0.08 |

| Fe (iron) | 96-97 |

As can be seen from the table, the interpretation of steel 09g2s is not limited to only three alloying components. In addition to carbon, silicon and manganese, it is supplemented by the following elements: nickel, sulfur, phosphorus, chromium, nitrogen, copper, etc. The percentage component of alloying metals is no more than 1-2 total%.

Marking 09g2s on a steel sheet

Also, for steel 09g2s, not only the alloying level is taken into account, but also other factors. Here are just a few of them that are significant for a particular case:

- constructiveness (purpose);

- eutectoid (structure: hexagonal, cubic, etc.; changes after hardening, etc.);

- production method (open hearth, conventional or electric steel);

- chem. steel composition 09g2s (in this case low-alloy).

As a result, analogues appear in relation to which questions like the following are often asked: is 345 steel 09g2s ? The designation C345 was introduced for builders , where the numbers do not indicate the chemical composition of the material, but its important property - the yield strength; for steel 09g2s it corresponds to the construction standards C345, which is reflected in a number of GOSTs (27772-88).

Below, several classic options are considered, including when one grade of steel corresponds to several strength classes.

Read also: Wear of parts and components

Process Features

Low-alloy steel is a material belonging to the group of satisfactorily weldable metals that are joined by almost all types of welding.

Requirements:

- equal seam strength;

- obtaining the required form;

- no defects.

Welding low-alloy steel is more difficult than low-carbon structural steel. It is more sensitive to thermal influences. It should be taken into account that a content of more than 0.25% carbon in the material can lead to the formation of hardening structures and cracks in the weld, and carbon burnout can lead to the formation of pores.

To avoid the formation of hardening martensitic structures, the part is heated, multilayer welding is used, observing a minimum time interval between the application of metal layers to the seam. The material of the coated electrodes is selected with a low content of phosphorus, carbon and sulfur. This helps to increase the resistance of the seam against crystallization cracks.

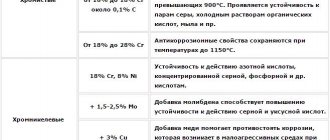

Connection of chromium-silicon-manganese steels

This type of low alloy steel is also called chromansil. The composition includes carbon 0.17-0.4%, manganese 0.8-1.1%, silicon and chromium - 0.9-1.2%. The material is inexpensive, has good elasticity and strength, and can withstand vibration. Disadvantage: poor heat resistance.

During gas welding, chromium and silicon partially burn out, which leads to the formation of oxides, slags and lack of fusion in the joint. To avoid oxidation of alloying additives, the work is performed with a normal flame, the power of which is selected from the ratio of 75-100 dm3 / h of acetylene per 1 mm of the thickness of the material being welded. Filler wire grades:

- low-carbon Sv-08 or Sv-08A - for non-critical structures;

- alloyed Sv-19KhMA, Sv-13KhMA, Sv-10KhGS, Sv-18KhGSA - for connecting critical objects.

The work process is carried out in one layer without interruption. The burner flame does not linger in one place to avoid overheating of the metal of the weld pool. To minimize warping, the seam is formed from the middle to the edges and back again. To avoid cracks, the welded element is cooled slowly.

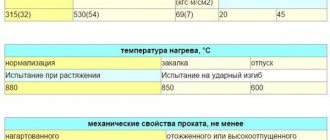

Critical parts are hardened at a temperature of 500-650°C, with exposure and subsequent heating to 880°C. Cool in oil. Then it is released by heating to 400-600° and cooling in hot water.

Welding of structural low-alloy steels

Materials contain:

- carbon up to 0.2%;

- alloying components – up to 2-3%.

The mechanical properties of these metals are higher than low-carbon ones. Silicon content in the range of 1-1.1% helps improve the strength and elasticity of the material. When it increases, the number of non-metallic inclusions in the weld increases, which complicates the welding process. Manganese from 1.6 to 1.8% enhances the material’s ability to harden, but technologically complicates the work process. An increased content of molybdenum, chromium, and vanadium negatively affects weldability.

Steels prone to hardening are welded:

- on soft mode without heat treatment (or in an oven);

- on hard mode with heat treatment in a spot machine.

The current strength when working with low-alloy materials is recommended to be 10-15% lower than when welding low-carbon steel. The pressure on the electrodes is 10-50% higher.

Welding is carried out using the same methods as for low-carbon steel - arc, gas and contact. Manual welding is performed with electrodes of the E-50A type, which will provide a seam with mechanical properties similar to the base metal.

Connection of steels 09G2S, 10G2S1, 10G2S1D

A distinctive quality of the low-alloy low-carbon steel grades 09G2S and 10G2S1 is the absence of a tendency to overheat and the formation of hardening structures. The work is carried out under any thermal conditions in compliance with process technology for low-carbon steels. Ensuring the uniform strength of the weld is achieved by electrodes E50A, E46A. The strength and hardness of the heat-affected zone is the same as that of the base metal.

Grade 10G2S1D is a low-alloy structural steel for welded products. When welding without restrictions, the process is performed without heating or heat treatment. The limited weldability of steel requires heating to 100-120° and heat treatment. Material that is difficult to weld requires additional actions: heating during welding to 200-300° and annealing after welding.

Welding electrode for gas welding

What characteristics should rods have for welding a pipe intended for a gas main?

Let's highlight several brands: OK-46, LB-52 and UONI-13\55. Rods of the OK-46 brand are considered universal, as they have a rutile coating. The listed consumables are well suited for parts with a wide gap, as well as for tubing work.

Let us mention one more electrode - LB 52U low-conductivity group with the main type of coating. Containing a small amount of hydrogen allows for a particularly strong weld, used for gas and oil pipelines made of durable steel.

When working with such a source material, the arc remains stable and completely penetrates the metal.

ESAB MTK-01K welding rods provide a decent level of seam in difficult areas, for example, such as rotary and non-rotary joints.

They can be used on parts made of carbon and low alloy steel. Suitable for operation on both direct current, direct and reverse polarity. Welding is easy, the arc burns stably, and there is minor metal spattering.

The best way to weld low alloy steel

The most acceptable method of welding low-alloy steel is manual arc welding. The process technique is similar to welding low-carbon steels. These materials contain no more than 0.25% carbon and have good weldability at any thickness of the parts being joined and air temperature.

Advantages of the method:

- versatility;

- simplicity;

- possibility of welding in any position in space and hard-to-reach places.

Selecting welding mode parameters

Welding is performed using direct current of reverse polarity.

The diameter of the electrode wire is selected depending on the type of welded joint, the thickness of the metal being welded and the position of the seam in space.

Dependence of wire diameter on connection type and metal thickness

Wire diameter, mm

Metal thickness (mm) for connections

Seam position in space

corner

T-bar

overlap

Technology

Manual arc welding is the most common method of joining materials for welding structures, in which manually:

- arc is excited;

- the electrode is fed and moved.

The work is carried out with coated electrodes. The method involves burning a welding arc from an electrode onto the object being welded. The edges of the product are melted, the metal of the electrode rod and the electrode coating are melted. The base metal and electrode material crystallize to form a weld.

Scheme of manual arc welding with covered electrodes

Electrodes and equipment used

Equipment includes:

- welding machine;

- launch equipment;

- set of electrodes;

- electrode holders;

- welding cables;

- other accessories.

Brand and type are selected taking into account:

- purpose of the product;

- degree of his responsibility.

Types of coated metal electrodes for manual arc welding of low-alloy steels are prescribed in GOST 9467-75.

Information on electrodes for welding low-alloy structural steels is presented in the table.

| Electrode brands | Additional information about steels |

| E50, E46, E42, E38 | Temporary tensile strength – up to 50 kgf/mm |

| E50A, E46A, E42A | Increased requirements for impact strength and ductility |

| E60, E55 | Temporary tensile strength from 50-60 kgf/mm |

Requirements for electrodes:

- ensuring their strength is equal to the base material;

- absence of defects in welded joints;

- ensuring durability of seams under different operating conditions;

- obtaining the required chemical composition of the weld metal.

How to weld tubing pipes

When working with pump and compressor pipes, you will need special electrodes that can cope with a rather complex task. We can recommend UONI brand rods 13\45 or 13\55.

Such electrodes are used for carbon and low-alloy steel parts. And tubing pipes are made of especially durable metal.

The seam using UONI brand products can withstand dynamic loads at low temperatures and high pressure.

The correct selection of electrodes for welding is very important, but the welding machine you use also largely depends.

An experienced specialist with a good amount of knowledge and experience can help you understand the intricacies of welding. And the correct selected mode on the equipment will ensure a positive welding outcome.

Steel 09g2s: characteristics and application

The main areas of use of this brand: sheet and shaped products. For hot-rolled strip, GOST 103-2006 standards are used, but steel circles are in accordance with GOST 2590-2006.

As already noted, steel 09g2s and analogues are easy to weld. The characteristics already listed allow the use of this material for products that require high wear resistance: beams, channels, corners.

Brand 09g2s, its technical characteristics, are necessary in the creation of vehicles, construction, oil and chemical industries. A wide temperature range allows the material to be used where severe deformations occur over a long service life. At the same time, the limiting temperature of -70 degrees facilitates the use of products made from St. 09g2s in harsh climatic conditions.

Steel 09g2s is used in the construction of RVS for storing petroleum products in the North

Steel 09g2s-15 also fits this description well. It is used for all of the above points. It only remains to add that in addition to welding, installation can be carried out using bolted connecting elements. The metal's resistance to chemical influences makes it interesting in the relevant industry. At the same time, high mechanical qualities are used for the construction of bridges, roads, port stations, etc.

The 09g2s-12 brand is also popular among builders. It also has stable plastic properties. It is distinguished by a special chemical composition, which includes arsenic. Used for the manufacture of pipeline fittings. Cannot be used in the food industry.

In the north of Russia, many kilometers of pipelines were built using just this brand. There, more than anywhere else, frost resistance and easy weldability of products are useful. This allows you to create complex, at the same time socially significant objects (metal structures) from 09g2s and analogues.

At the same time, for cities with a temperate or continental climate, steel 09g2s according to GOST standards of various numbers is suitable for beautifying streets. Square pipe is extremely popular as fencing, posts for billboards, installation of mobile trading platforms, and much more. For the same purposes, the rectangular configuration of products is used.

Steel 09g2s, the characteristics of which have already been discussed in some detail in this presentation, is of interest to welders, regardless of the method of performing work. Flanges made of this material are especially popular. Features of the work are described in GOST 19281-73. The craftsmen are quite welcoming to the news about the need to work with this brand.

The boiler tank itself is made of steel 09g2s

Steel 09g2s with different strength classes can be used for the production of steam boilers, as well as equipment used in the agricultural complex. Details about the requirements for steel 09g2s in GOST-5520 79.

Read also: Connecting a schneider telephone socket

An additional reason for using alloys of this brand is high efficiency, achieved not only due to low cost of production. The ease and speed of construction of buildings, structures, installation of equipment also allows you to optimize the costs of enterprises in various industries.