Home / Consumables

Back

Reading time: 4 min

0

2293

There is a technological difference between argon arc (TIG) and classic RDS welding. The main thing in this difference is the complementary elements that will create the set of equipment necessary for work.

Initially, you will need the ability to work with argon arc welding. As well as a filled gas cylinder and filler rods, which are also called “filler wire” or “welding wire”.

- Introduction

- general information

- Types of filler rods Corrosion-resistant

- Aluminum

- Copper

- Nickel

- Polymer

Introduction

The production essence of this element is to fill the welding joints evenly and tightly. This occurs when the wire edge melts when exposed to elevated temperatures.

The molten metal is mixed with the metal of the part. And sometimes this becomes the very basis in creating a weld.

This article provides general information about the performance characteristics of the element, and the types of its varieties, such as:

- corrosion resistant;

- aluminum;

- copper;

- nickel;

- polymeric.

Types and characteristics of welding filler material

The creation of argon arc and gas welding contributed to the emergence of an effective filler material for obtaining high-quality welded joints of parts. Additives, meeting all operational requirements, make it possible not only to save metal, but also to increase the strength of the entire structure.

For arc method

With a wide variety of welding types, argon arc welding has become widespread, where argon is used as a protective inert gas.

Additives for this method of joining metal parts are strong, rigid, plastic rods of a certain diameter and fixed length.

general information

A welding filler rod is a metal or polymer wire that is used to create a weld, as well as for an additive as a replacement for welding.

This is a mandatory element in production with argon arc or gas welding.

The length of standard welded wire is 1 m. It is sold rolled into reels, which makes it easier to transport and use.

However, when sold in reels, the sample may be longer than one meter. During operation, the rod is allowed to unwind if necessary.

This welding material is suitable for working with all types of metals, as well as polymers.

The filler rod is selected in accordance with the composition of the metal (polymer) for which it will be used. Their compositions should be similar.

The use of different types of metals for the rod and the main part leads to a decrease in the quality of the weld.

However, this is not the only parameter when choosing TIG filler wire. Keeping in mind the characteristics of the metal of the part being welded, you also need to make sure that the purchased working element is uniform and clean.

The presence of stains, dirt inclusions, signs of corrosion and other elements of poor quality is unacceptable.

During welding work, light spattering and evaporation of the rod is allowed, but the level of these indicators should be low.

Types and characteristics of welding filler material - Welding Profi

Source:

What is a welding filler rod?

Reading time: 4 minutes

Unlike classic RDS welding, argon arc welding involves the use of additional components. You will need a gas cylinder, your skills and, of course, welding rods. Welding rods are also called filler wire or simply welding wire.

This material is used to uniformly fill the joint between two parts. Under the influence of high temperatures, the rod melts and mixes with the base metal or even forms the basis for forming a weld. In this article we will tell you everything about the use of welding rods.

general information

A welding rod is a wire made of metal or artificial polymer used for addition to the welding site and forming a weld. Must be used for argon arc welding (aka TIG welding) and gas welding.

A standard welding rod is about 1 meter long. For the convenience of the welder, the rods are wound into reels and sold in this form. If necessary, the rod can be unwound. If the rod is wound into a bobbin, its length can exceed 1 meter. Welding rods are used for welding all types of metals and polymers.

The filler rod for TIG welding must have the same or similar composition as the base metal you are welding. You cannot weld stainless steel with a copper rod, and vice versa. You will, of course, get a weld, but its quality will be unsatisfactory.

The TIG filler rod must be selected based on more than just the characteristics of the base metal. Make sure the bar looks uniform and clean before purchasing. It should not show signs of corrosion, dirt, stains, etc.

When welding, the rod may spatter and evaporate a little, but not in huge quantities.

If you purchase a rod with the above defects, the seam will be uneven and of poor quality.

Such a connection will not meet the requirements and the part will simply be written off as defective.

Varieties

There is no single classification of welding rods because there are too many of them. After all, the welding rod is selected in accordance with the metal, and there are several dozen varieties of steel alone. Therefore, rods are divided according to the type of work. For example, for welding stainless steel or PVC parts. Next, we explain in detail what properties each of the conventional types of rods has.

Corrosion-resistant rods

Such rods are used for welding steels that are resistant to corrosion. With their help, high-quality welding of stainless steel is performed. The seams are resistant to any type of corrosion, be it pitting or intercrystalline corrosion. The filler rod for stainless steel can also be used for surfacing.

Aluminum rods

Aluminum rods are used for working with aluminum. Often silicon, zirconium or magnesium is mixed into the aluminum rod composition. Therefore, the resulting seams do not crack even when exposed to high temperatures. Aluminum rods have high thermal conductivity, so they melt along with the base metal and mix evenly with it.

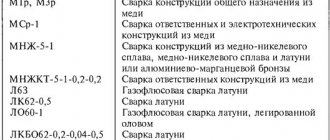

Copper rods

The copper welding rod is distinguished by its thermal conductivity and fluidity. These characteristics allow high-quality soldering of copper, regardless of the size of the part.

Such rods are necessary both for minor work with electrical devices and for welding large-sized sea vessels.

Types of filler rods

There is no single classification. This was due to their level of diversity. There are samples corresponding to each type of metal.

And, for example, there are several dozen types of steel alone. In accordance with this, filler wires are divided according to the type of work.

This classification divides rods into several types.

Corrosion-resistant

Stainless steel filler rods

This type is designed for processing varieties of steel with increased resistance to corrosion. For example, they are used for welding stainless steel.

Corrosion-resistant welds are resistant to both pitting and intergranular corrosion.

This type of work element is also used in surfacing.

Aluminum

Filler rod ER4043 for aluminum

Designed for aluminum welding. Often these wires contain an additional metal, such as silicon, magnesium or zirconium.

This is done to ensure that welding seams created using aluminum wires do not crack at high temperatures.

Having high thermal conductivity, this type melts simultaneously with the metal of the part, and the seam is uniform and uniform.

Copper

This type is characterized by high thermal conductivity and fluidity during production.

Such performance indicators make it easier to work with copper parts, ensuring the quality of the weld regardless of the size of the element.

This variety works well when working with small electrical equipment.

But it is also suitable for welding work with large-sized parts (ships, for example). The copper type creates an even, strong weld with reduced porosity characteristics.

Nickel

This type is used for welding nickel and its alloys. Characteristic features are strength and high resistance to oxides.

Such indicators are also typical for rods used in processing nickel parts.

Great Encyclopedia of Oil and Gas

Page 2

Filler materials for welding aluminum alloys must contain alloying elements that reduce the crystallization interval and increase the solidus temperature of the alloys. [16]

The filler material contains 0 002 - 0 006% C; 2 - 8% Ni, and the content of other alloying components corresponds to the composition of the steel being welded. [17]

The filler material for gas welding is made of cast iron in the form of sticks or rings with a cross-section from 5x5 mm to 10x10 mm. Welding is carried out with a reducing carburizing flame of a torch. First, the cutting edges are heated to the melting temperature. When the edges are heated, a layer of flux is applied to them to deoxidize the metal. Flux should be stored in a dry place, in containers that do not allow moisture to pass through. [18]

In this case, the filler material is introduced into an electric arc burning between the part and the tungsten electrode, as in gas welding. Welding is carried out without flux, since argon reliably protects the molten metal from oxidation and helps to obtain a weld with high strength without pores and oxides. [19]

The additive material is introduced into the suspension in dry form, and the dose of the material is very significant and amounts to 3–4 weight for sewage sludge. [20]

The filler material is steel wire of the same grade. [21]

Filler materials used in the manufacture of vessels and their elements must meet the requirements of the relevant standards or technical specifications. [22]

| In order to make a seam, as usual, filler materials are often used. Such materials are used in order to be able to provide not only the geometry of the seam that you set for yourself when starting work, but also those operational characteristics that will guarantee the absence of defects. As practice shows, the composition of the filler material very rarely differs from the material that will be weldable. How is filler material developed? The development of filler material is carried out in full accordance with those specific groups of metals that need to be welded or alloys, or even entire individual grades. It is important to remember that the composition of the filler material should be much cleaner than that being welded in terms of impurities, and it should also contain less gases and slags. The filler material is essentially a metal wire with a solid cross-section or a flux-cored wire. In addition, the filler material can be:

What indicators are considered important for filler wire? If we talk about characteristics, then it is worth paying due attention to the quality of the filler material. Its surface must be ideal, and its diameter must not have any deviations. In addition, ovality and other indicators are taken into account. What needs to be done to maintain the quality of the filler material? By and large, such materials have a long shelf life, provided that they are stored correctly. It must be taken into account that the filler material must be well packaged or even preserved. Transportation must also be approached responsibly. As a rule, the filler material is formed into special coils or skeins, which are impregnated with a preservative lubricant. The top of such skeins must be covered with a special film that will not allow moisture to pass through. Today, of course, there are other options for forming filler materials that do not require the use of a preservative lubricant. When purchasing, be sure to pay attention to the certification documents that will tell you about the manufacturer. The tube must contain a certificate that will contain information about:

When preparing the material for work, you need to thoroughly clean the filler material. When welding, there should be no traces of grease or other irritants left on the wire. You can get by with simple degreasing to remove oxides - this process will not take much time. Remember that in order to start welding, the filler material must comply with standards (GOST), as well as technical specifications. Using filler materials, you can weld cast iron, steel, aluminum, copper, titanium and many other alloys. |

| Approximate modes of manual argon-arc welding. [23] |

Filler materials and electrodes are selected taking into account the steel grade and the nature of the aggressive influence of the environment. [24]

The filler material used in welding is usually the same as the material of the parts being welded. However, the seam is a weak point of the connection, and the permissible stresses for it are taken to be less than the permissible stresses for the base metal. This is explained by the stress concentration at the welding site, the heterogeneity of the structure of the weld material and adjacent layers of the base metal, the inclusion of slag and oxides, the fragility and hardness of the weld when it cools quickly. [25]

The filler material is introduced into the welding zone evenly, without transverse vibrations, resting the end of the rod on the edge of the weld pool. [26]

The filler material consists of powdered metal oxide and powdered aluminum and is melted in a crucible. The thermite mixture is alloyed with an additive of ferroalloys, carbides, oxides and pure elements; their 20% addition to the charge reduces the temperature of the poured metal and increases the yield of filler material up to 50%; the remaining 50% is slag. [27]

Filler materials are selected depending on the technological variant of welding and the nature of surface wear during surfacing. [28]

No filler material is used. [29]

The filler material is added in molten form to the weld, filling it and fusing it with the base metal being welded. The quality of the filler material largely determines the strength of the welded joint. Some elements included in the filler material tend to burn out during welding (C, Mn, Si, etc. The surface of the wire must be clean from scale, rust, oil and other contaminants. The wire must melt calmly, without boiling or splashing. The latter is determined by the presence on the surface of the wire there are oxides that are reduced by flame hydrogen according to the reaction FeO H2 Fe 4 - H2O, and the resulting water vapor, insoluble in liquid steel, causes spattering of the metal. [30]

Pages: 1 2 3 4

www.ngpedia.ru