It is important for all heat supply organizations to find materials that reduce energy losses on the way to consumers. Now one of the most effective energy-saving materials is polyurethane foam, used for thermal insulation of pipes. Otherwise they are called polyurethane foam pipes.

Polyurethane foam is a type of plastic that is better in thermal conductivity than other polymers and old thermal insulation materials, and can not only reduce energy losses, but also protect heating mains from freezing. In fact, this material has been used for a long time, but in the past, polyurethane foam was made in the form of slabs, and this made it inconvenient to use for insulation.

Then polyurethane foam pipe insulation appeared in the form of a “shell”, which was used to cover the pipelines after installation. Now, some manufacturers produce products already insulated with a layer of material.

Application of heat-insulated pipes PPU ots

Thermally insulated pipes, insulated with polyurethane foam insulation and protected with a galvanized shell, are widely used when laying new economical overhead heating networks. Also, heat-insulated PPU pipes in galvanized steel are used for transporting oil and gas products, as well as cold and hot water supply.

The result of the development of materials for heating mains of a new generation was the PPU OC pipe. Such an effective solution has become a real boon for city services and other enterprises using pipelines. As you know, the old heating mains, laid several decades ago, have outlived their usefulness. Soviet heating mains require more and more maintenance, and this comes with huge heat losses and other troubles, so thermally insulated PPU pipes have become an ideal replacement for the technologies of the last century.

Development of pipe insulation technology

Many different techniques were tried for thermal insulation of plumbing and heating systems before technical progress reached the use of polyurethane foam pipes.

Mineral wool, polystyrene, and later polypropylene foam in the form of thermal insulation boards were used as working materials to protect networks from freezing and corrosion. The thermal conductivity of such insulators was 2-3 times higher than that of polyurethane foam pipes, and the service life was no more than 5-7 years (modern solutions can last 30 years or more).

Further development of technology led to the appearance of polyurethane foam shells, and the best today are considered to be pipes where a layer of polyurethane foam is sprayed onto the pipe directly during the production process.

What are polyurethane foam pipes

Pipes with PPU insulation are the result of applying a layer of polyurethane foam to the surface of finished fittings in order to improve the technical characteristics of the product.

Basically, pipes that have been factory-filled with thermal protection comply with GOST requirements and are used in industry (heat pipelines, oil and gas pipelines). However, products with a smaller diameter can be used for heating stations in residential apartment buildings.

PPU pipe, unlike its analogues, which do not store thermal energy even at ambient temperatures above 0, is a frost-resistant product. This quality allows the use of polyurethane foam structures outdoors in open areas, which facilitates the engineering structure of wires for moving oil and gas products.

The scope of use of polyurethane foam pipes is very wide, ranging from structures in residential buildings to large-scale oil production systems.

What is PPU insulation with PE shell

Polyurethane foam pipes with a protective shell are widely used for underground or above-ground methods of laying pipeline routes.

Depending on the operating conditions, the protective shell can be made of polyethylene or galvanized:

- Polyethylene (PE). The material is a synthetic polymer that is resistant to chemical and temperature influences. In addition, PE is a good dielectric, with low adhesion and excellent strength characteristics.

- Galvanization (GZ). It is produced by applying a protective layer to the metal, which, when oxidized in air, is capable of forming a dense film that reliably protects the metal from corrosion.

Polyethylene is able to provide a greater level of water protection; it is better to use it when laying pipes underground, while for above-ground pipeline networks it is worth giving preference to products with a galvanized shell.

In comparison with other options for pipe material, products with PPU insulation in a polyethylene shell have a number of undeniable advantages:

- PPU insulation has a positive effect on heat loss rates. If for traditional methods of thermal insulation this value reaches 15-25%, then here it will not exceed 4%.

- Resistance to temperature fluctuations. The products are designed to operate in a temperature range from -80 to +130 degrees.

- If the installation technology is followed, it is completely waterproof.

- Protection against corrosion and rot.

- Reliability and environmental safety of materials.

- Anti-vandal characteristics. It will be difficult for potential attackers to find applications or markets for the elements of the protective shell and thermal insulation layer.

- Long service life of the finished pipeline.

Regardless of the type of shell, the pipe material can be equipped with conductors of the ODK (operational remote control) system, which makes it possible to monitor in real time the condition of the protective coating, promptly responding to identified faults.

General information about PPU thermal insulation

Pipes insulated with polyurethane foam (PE) are now very widespread in the installation of various utility infrastructure networks. They are used for both underground and above-ground route laying methods. In rare cases, a polyethylene pipe with polyurethane foam insulation is used, where plastic is used instead of steel.

The upper protective shell can also be made from galvanized sheets. It all depends on future operating conditions:

- Polyethylene (PE) is used for underground installation. This material is a polymer that copes well with temperature changes, resists various chemical influences, and also has high strength characteristics.

- For above-ground installation, galvanization is used. Production involves applying a layer of protection to sheet metal, which during oxidation forms a film that resists corrosion.

Polyethylene perfectly protects the product from moisture, so it is always used for underground installation. For above-ground installation, a more reliable solution would be to use galvanization.

Scope of application

The scope of application of pipes in a polyurethane foam shell is quite extensive. Excellent durability and reliability indicators allow them to be successfully used when laying pipeline networks for a wide variety of purposes:

- Heating networks (heating, hot water supply).

- Water supply networks.

- Industrial pipeline networks.

- Gas pipelines.

- Pipelines for the needs of the oil industry.

The use of polyurethane foam pipes in a protective sheath of polyethylene reduces the time for constructing pipeline networks by up to 3 times, reduces the cost of their maintenance by up to 9 times, and the cost of repairs by up to 3 times.

Considering the estimated service life of the products, as stated by the manufacturers, is at least 30 years, their use seems very profitable and convenient.

Why is it necessary?

Among the main areas of activity of insulation for modern polyurethane foam pipes are:

- Thermal insulation of walls of residential buildings in industrial and civil construction.

- The process of manufacturing sandwich panels and prefabricated structures.

- Production of refrigeration equipment: refrigerators, cold warehouses and special chambers.

- Decorative finishing of furniture items.

- Automotive industry.

- Thermal insulation made of durable polyurethane foam for pipeline structures.

- Production of synthetic materials, including leather.

- Radio engineering and electronics.

No less popular is the household application: in the manufacture of sponges, washcloths, and furniture fillers as foam rubber.

Scope of use

PPU pipe design

The standard product consists of three layers:

- The main working pipe, which is made of high-strength steel, meets all GOST standards.

- Polyurethane foam insulation - a high-tech synthetic material protects the pipe from moisture (hygroscopicity), does not allow contaminants to accumulate on the walls of the pipes, increases the service life and retains heat in comparison with the glass wool used for insulation in the previous generation of pipes.

- Shell - insulation layer can be protected by galvanization or polyethylene. The type of shell is determined by the markings on the product.

Modern types of pipes sometimes contain an additional element - the signal wire of the operational remote control system - ODK. It is a metal wire running in a layer of polyurethane foam along the entire length of the pipe.

The UEC online reads complete information about the condition of the pipeline and the presence of certain defects: breaks in the working pipe, protective coating, joint areas, or the UEC wire itself.

Technical characteristics of polyurethane foam pipe

| No. | Index | Value/dimension |

| 1 | Density | 40-60 kg/sq.m. |

| 2 | Strength (permissible load) | 200 kg/m3 |

| 3 | Coefficient of thermal conductivity | 0.025-0.032 W/m*K |

| 4 | Hygroscopicity (water absorption) | 0.1-0.2 kg/sq.m. per day |

| 5 | Flexural strength | 1.5 kg/sq.cm |

| 6 | Working pressure, maximum | 1.6 MPa |

| 7 | Media operating temperature, maximum | 130 °C |

| 8 | Peak media temperature, maximum | 150 °C |

| 9 | Heat loss, maximum | 4 % |

Material prepared for the website www.moydomik.net

Performance characteristics of polyurethane foam pipe

| No. | Index | Value/dimension |

| 1 | Minimum laying depth for channelless installation | 500-700 mm |

| 2 | Maximum laying depth | 3,000 mm |

| 3 | Reducing the installation time of heating systems when using polyurethane foam pipes in comparison with traditional pipes | 3 times |

| 4 | Reducing the cost of servicing heating networks with polyurethane foam pipes | 9 times |

| 5 | Reducing the cost of repairing heating systems with polyurethane foam pipes | 3 times |

| 6 | Estimated service life | 30 years |

Polyurethane foam pipes are of interest to housing and communal services, industrial and oil refining enterprises; they are unlikely to be useful in private households.

Cost of PPU pipes

For those wishing to buy or get an idea of the cost of polyurethane foam pipes and shaped elements, we provide approximate prices

Price list for PPU pipes SZTGK (North-West Pipe Waterproofing Company)

Studying the products of different manufacturers, it is not difficult to notice that on the website of each of them there is a price list for polyurethane foam pipes. However, it should be understood that this price is not final, because it is derived from many factors and is constantly being revised. In the case of significant volumes of purchases, the price is subject to negotiation.

Specifications

Pipe design in polyurethane foam insulation

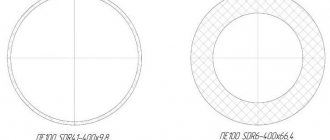

Terminology: t – steel pipe: electric welded, VGP, seamless, galvanized; d – diameter of steel pipe; s – wall thickness of the steel pipe; D – diameter of the shell-pipe; n – type of polyurethane foam insulation according to GOST 30732-2006; PPU – thermal insulation made of polyurethane foam; PE – polyethylene shell; OTs – galvanized shell or pipe; el/sv – electric welded pipe; b/sh – seamless pipe; VGP – Water-Gas-Pipe; SODK – operational remote control system.

Description: 1. Centralizer (centering support); 2. Insulation made of polyurethane foam (polyurethane foam); 3. Pipe shell (PE or OC); 4. Steel pipe; 5. System of operational remote control (ORS).

Symbol:

Pipe t dxs/D n PE(OC)

Example designation:

Electric pipe 108×4.0/180 PPU PE SODK

Pipes in PPU insulation made of PE polyethylene

| Outer diameter of steel pipe | Nominal diameter of steel pipe | Standard wall thickness of steel pipe | TYPE 1 | TYPE 2 | ||

| Diameter of PE shell | Wall thickness of PE shell | Diameter of PE shell | Wall thickness of PE shell | |||

| d,mm | d,mm | s,mm | D,mm | S,mm | D,mm | S,mm |

| 32 | 25 | 2,0 | 90 | 3,0 | 110 | 3,0 |

| 38 | 32 | 2,8 | 110 | 2,5 | 125 | 3,0 |

| 45 | 40 | 2,8 | 110 | 2,5 | 125 | 3,0 |

| 57 | 50 | 3,5 | 125 | 3,0 | 140 | 3,0 |

| 76 | 70 | 3,5 | 140 | 3,0 | 160 | 3,0 |

| 89 | 80 | 4,0 | 160 | 3,0 | 180 | 3,0 |

| 108 | 100 | 4,0 | 180 | 3,2 | 200 | 3,2 |

| 133 | 125 | 4,5 | 225 | 3,5 | 250 | 3,9 |

| 159 | 150 | 4,5 | 250 | 3,9 | 280 | 5,6 |

| 219 | 200 | 6,0 | 315 | 4,9 | 355 | 5,6 |

| 273 | 250 | 7,0 | 400 | 5,6 | 450 | 5,6 |

| 325 | 300 | 7,0 | 450 | 5,6 | 500 | 6,2 |

| 426 | 400 | 7,0 | 560 | 7,0 | 630 | 7,9 |

| 530 | 500 | 7,0 | 630 | 7,9 | – | – |

| 630 | 600 | 8,0 | 800 | 8,9 | – | – |

| 720 | 700 | 8,0 | 900 | 10,0 | – | – |

| 820 | 800 | 8,0 | 1000 | 11,2 | 1100 | 13,8 |

| 920 | 900 | 10,0 | 1100 | 12,4 | 1200 | 14,9 |

| 1020 | 1000 | 11,0 | 1200 | 13,8 | – | – |

Pipes in polyurethane foam insulation made of galvanized steel OC

| Outer diameter of steel pipe | Nominal diameter of steel pipe | Standard wall thickness of steel pipe | TYPE 1 | TYPE 2 | ||

| Diameter of OC shell | Wall thickness of the OC shell | Diameter of OC shell | Wall thickness of the OC shell | |||

| d,mm | d,mm | s,mm | D,mm | S,mm | D,mm | S,mm |

| 32 | 25 | 2,0 | 100 | 0,5 | 125 | 0,5 |

| 38 | 32 | 2,8 | 100 | 0,5 | 125 | 0,5 |

| 45 | 40 | 2,8 | 100 | 0,5 | 125 | 0,5 |

| 57 | 50 | 3,5 | 125 | 0,5 | 140 | 0,5 |

| 76 | 70 | 3,5 | 140 | 0,5 | 160 | 0,5 |

| 89 | 80 | 4,0 | 160 | 0,5 | 180 | 0,5 |

| 108 | 100 | 4,0 | 180 | 0,5 | 200 | 0,5 |

| 133 | 125 | 4,5 | 225 | 0,5 | 250 | 0,5 |

| 159 | 150 | 4,5 | 250 | 0,5 | 280 | 0,5 |

| 219 | 200 | 6,0 | 315 | 0,5 | 355 | 0,5 |

| 273 | 250 | 7,0 | 400 | 0,5 | 450 | 0,5 |

| 325 | 300 | 7,0 | 450 | 0,5 | 500 | 0,5 |

| 426 | 400 | 7,0 | 560 | 0,7 | 630 | 0,7 |

| 530 | 500 | 7,0 | 630 | 0,7 | 710 | – |

Read also: Cutting tempered glass at home video

The wall thickness of the steel pipe and polyurethane foam layer can be adjusted at the request of the customer. The wall thickness of the pipe and fittings must be equal. All pipeline elements have an end free from insulation on both sides. Its length ranges from 150 mm (for pipes with diameters from DN 25 to DN 219) to 210 mm (for pipes from DN 273 to DN 1020).

The quality of products is ensured through high-quality materials and semi-finished products, control at all stages of production.

PPU pipes (polyurethane foam insulation) in a polyethylene - PE or galvanized - OTs protective shell with the UEC system. Sales from the manufacturer of heat-insulated PPU steel pipes.

When creating heating and hot water supply systems, one of the main requirements is thermal and waterproofing, thanks to which the structure lasts longer and the temperature losses of the transferred liquid and air are significantly reduced. PPU PE insulation copes well with both tasks, and at the same time has high performance characteristics compared to similar products.

Installation of polyurethane foam pipes

Installation work requires a number of preparatory activities. Pipes are carefully inspected for chips, cracks, cuts, and other external defects. If found, they need to be welded or covered with heat-shrinkable film.

After this, using a pipe layer or crane, the pipe sections are carefully laid in the prepared trench. It is advisable to lay a sand cushion at the bottom of the trench. The maximum depth for laying polyurethane foam pipes is 3 meters.

The pipeline is installed directly at the bottom of the trench using welding. Cutting of polyurethane foam pipes is carried out by a gas cutter, and the insulation layer must be removed in advance with a hand tool. The estimated service life of the finished pipeline is at least 30 years.

Types of polyurethane foam insulation

Polyurethane foam insulation is carried out using the insulated joint method or by installing a shell. The main material for the work is polyurethane. Previously, most of the heat was lost due to high humidity. Using shells this problem was solved.

The shell has the following advantages:

- Can be used in areas where the temperature drops sharply in winter. The maximum operating temperature is -190+150 degrees.

- Has high moisture resistance characteristics. The figure is no more than 2%.

- Light specific gravity. It is enough to connect the fasteners with the grooves. If a certain area is deformed, it is easy to replace; the insulation is reused for dismantling.

- Not exposed to chemicals.

- Density - 40-60kg/m.

- Resistant to mechanical damage.

Types of polyurethane foam insulation

The protective shell can be made of any materials: galvanized steel, foil, fiberglass, paper.

Structure of polyurethane foam insulation

During the construction process, it is important to select high quality materials for insulating joints. With high-quality sealing of fasteners, the service life of the structure increases. One of the current methods is to use a heat-shrinkable sleeve.

To carry out insulating installation of joints, it is necessary to take care of the preparatory operations. To do this, you will need to attach a special coupling to one end of the pipe with the choice of the optimal diameter. It is important to carry out all operations carefully so as not to cause mechanical damage to the structure or reduce waterproofing. Next, carry out welding work.

Next, you need to check the result obtained and remotely monitor the condition of the connection conductors. If no errors are found, you are allowed to begin installation work on the thermal insulation connections.

Types of pipes with PPU insulation

Expanding the scope of use dictates the demand for an increase in the range of products. Based on the material used to make the outer coating, pipes are usually divided into two categories:

- pipe covered with a layer of polyethylene. Finds application in the construction of underground networks for various purposes.

- galvanized pipe. It is more suitable for the construction of above-ground pipeline structures, since the protective properties of polyethylene here are not always effective against the destructive power of temperature changes, solar radiation and other aggressive environmental influences.

Products also differ in the thickness of the external insulation layer:

- 1 PPU. Generally accepted marking for standard thickness of polyurethane foam layer. The product is suitable for use in temperate and warm climates.

- 2 PPU. Thicker type of insulation. Better suited for cold climates.

Dimensions and symbols

General parameters of polyurethane foam pipes:

| outer d pipe | internal d | wall thickness | shell thickness |

| 32-1020 mm | 25-1000 mm | from 2 to 11 mm | 3.0-14.9 mm |

| outer d pipe | internal d | wall thickness | shell thickness |

| from 32 to 530 mm | 25-500 mm | from 2 to 7 mm | 0.5-0.7 mm |

PPU pipe st. 32x2 2 PPU-PE with ODK GOST 30731-2006.

- 32 – outer diameter of the pipe,

- 2 – wall thickness of the working pipe,

- 2 PPU – insulation type,

- PE – type of outer covering (for this marking – polyethylene).

PPU pipe manufacturing technology

The production of polypropylene pipes is simple and is carried out in the following sequence. There are several stages, they depend on the outer shell.

For galvanized products, the process goes through the following steps:

- A layer of foamed polyurethane (popularly called polyurethane foam) is applied to a special, closed form where the steel pipe is located.

- After the layer has hardened, the workpiece is wrapped in galvanized sheets.

- LiveJournal

- Blogger

For pipes with a polyethylene sheath, the steps look different:

- Liquid polyethylene is extruded into a special mold.

- A steel billet is placed there.

- The space between the steel shell and polyethylene is filled with liquid polyurethane, which hardens upon contact with air.

Pre-insulated pipes are indispensable for the operation of highways.

PPU insulation allows:

- Significantly reduce the level of heat loss during transportation, which means saving money.

- Thanks to the UEC, repair costs are reduced.

- Reduce costs for capital construction of water pipelines.

- Increase service life.

For this type of product there is a single standard - GOST pipes PPU 30732-2001. This document deals with the production of galvanized pipes. Compliance with many requirements is mentioned, in particular surface quality, elongation at break - 350%, change in length after heating to 110 degrees - 3% and more.

Conscientious manufacturers of polyurethane pipes apply additional layers of anti-corrosion coating. The fact is that the manufacturing technology came from abroad. Other climatic conditions, imperfect material and technical base and other reasons force us to take a new approach to the production process. Therefore, there is a need for additional treatment of products with anti-corrosion lubricants.

In addition to PPU insulation products with a galvanized or polyethylene surface, PPM insulation pipes are produced.

Advantages

Pipes with polypropylene insulation are a relatively new product on the market, but in comparison with classic products they are already considered to be much superior in their characteristics:

- When transporting coolant, heat loss can be reduced by 30-40%

- They have high reliability.

- Resistant to corrosion, rotting, and moisture.

- They can be successfully operated in a wide temperature range: from -80 to +130 degrees.

- Environmentally friendly.

- They ensure high speed of pipeline construction while simultaneously reducing financial costs for maintenance and repair of finished networks.

- Possibility of monitoring the condition of the pipeline (if there is a UEC system).

Technical parameters of other materials for insulation

In addition to polyurethane foam with UEC, pipes can be insulated with other materials. The table shows some technical parameters of such insulators in comparison with polyurethane foam.

Table 4

| Parameter | Coefficient of thermal conductivity | Duration of operation | Operating temperatures | Porosity structure | Density |

| Unit | W/m*K | Years | Degrees | — | kg/m3 |

| Hard polyurethane foam | 0,025 | 30-50 | -200 to +180 | Closed | 40-200 |

| Traffic jam plate | 0,050-0,060 | 3 | from -30 to +90 | Closed | 220-240 |

| Mineral wool | 0,052-0,058 | 5 | -40 to +120 | Open | 55-150 |

| Foam plastics | 0,040-0,050 | 5-7 | -50 to +110 | Closed | 30-60 |

| Foam concrete | 0,145-0,160 | 10 | -30 to +120 | Open | 250-400 |

Another fairly common material for insulation is expanded polystyrene (EPS). With the same shape and size, an insulation system made of polyurethane foam will have a higher density than one made of polypropylene foam. In other words, polyurethane foam is stronger than polystyrene foam.

Polystyrene foam insulation is inferior to polyurethane foam in strength

PPP is characterized by the following values of the main indicators:

- density: 25-50 kg/m3;

- thermal conductivity at 25 degrees: no more than 0.038-0.042 W/m*K;

- water absorption: no more than 1.0%;

- operating temperatures: -50-+75 ºС.

Expanded polystyrene can be used for all pipelines, except those carrying steam or superheated water.

Advantages of HDPE plastic pipes in polyurethane foam insulation.

- pipes are supplied in solid sections of the required length, which in 99% of cases allows you to do without joints at all. No bends, fixed supports or compensators are required during installation

- high degree of reliability

reduction of heat loss during coolant transfer by 35-40%

temperature resistance. Applicable in the range of external temperatures from -80 to +130 °C

moisture resistance

non-corrosive without additional treatment

high laying speed. Installation of polyurethane foam pipes is carried out above-ground, underground and channel methods. Underground channelless installation to a depth of up to 1 m is possible. This installation method involves installing the pipeline directly in the trench; there is no need to use reinforced concrete trays

environmental Safety

significant reduction in costs for construction, maintenance and repair of heating mains

anti-vandalism. Thermal insulation from polyurethane foam pipes is almost impossible to steal and reuse

increasing the service life of the heating main

That is why the housing and communal services of our country, when purchasing at their own expense, are increasingly choosing flexible polymer pipes.

Synonyms: HDPE pipe in PPU, HDPE in PPU, PPU insulation, thermally insulated pipes, flexible heat-insulated pipes, thermally insulated PPU pipes, uponor ecoflex, heating main pipe, uponor pipe, fuel pipe PEX, isopex pipe, isoproflex pipe, PPU pipes, PPU PE, PPU PE pipe

You can buy HDPE pipes in polyurethane foam insulation, as well as flexible heat-insulated pipes and ask any questions you are interested in, from our managers by making a request by e-mail or by calling the office by phone +7.

Pipes PPU OTs

PPU (polyurethane foam) - gas-filled plastic (foam) comes in two types: rigid and elastic.

When creating polyurethane foam OC pipes, a rigid variety is used, since it has a low thermal conductivity coefficient.

The production of polyurethane foam OC pipes takes place in the factory. First, a metal pipe is manufactured and placed in an outer shell of galvanized steel, which reduces the water permeability coefficient to a minimum and increases the service life of the pipe.

The outer shell protects the insulation from mechanical stress, fire and moisture. Polyurethane foam is poured into the gap between the steel pipe and the outer shell. After the insulation hardens, the finished product is obtained.

In essence, the product is a “pipe within a pipe”, and the space between the shells is filled with insulation.

After manufacturing, the pipes undergo a series of checks to ensure compliance with quality standards:

- Full check of welds for leaks, unless a seamless production method was used.

- Material axial shear compliance tests.

- Compliance of materials with GOST: the thickness of the insulation, the degree of polishing of the pipes, the diameter of the product must comply with the standards.

Properties and characteristics

The characteristics of finished products are regulated by state regulations. In this case, each element of the polyurethane foam OC pipe must comply with GOST.

The galvanized shell is moisture resistant, which expands the scope of application of the product. In combination with low thermal conductivity, polyurethane foam OC pipes become the best option for external water and heat supply.

The characteristics of the finished product must correspond to the table below:

| Properties | Measure | Index |

| Insulation layer density | Kg/m3 (kilogram/cubic meter) | Minimum 60 |

| Density at 10% radial compression | MPa (megapascal) | From 0.3 |

| Thermal conductivity at 50°C | W/m*K (watt/meter*Kelvin) | No more than 0.033 |

| Shear strength at (23±2)°С Shear strength at (140±2)°С | MPa (megapascal) | Minimum 0.2 Minimum 0.13 |

| Indicator of radial creep of thermal insulation with maximum temperature (140±2)°С | Mm (millimeters), within 100 hours Mm (millimeters), within 1000 hours | Up to 2.5 Up to 4.6 |

| Water absorption in boiling water over a period of 90 minutes | % by volume | Maximum 10% |

OC polyurethane foam pipes reduce heat losses to 1–2%, which is an excellent indicator that is superior to other types of insulation. The production cost is quite high, but the characteristics and durability allow the material to pay for itself.

Polyurethane foam is highly flammable upon contact with an open fire; in accordance with GOST 30244, it belongs to the highly flammable group G4.

OC polyurethane foam pipes are non-toxic and do not harm health or the environment, but polyurethane foam can release extremely toxic impurities when burned. However, the galvanized outer shell is a reliable means of protection against open fire.

The pipes are also equipped with copper indicator conductors with a cross-section of 1.5 mm2. These indicators allow you to monitor the status of communications remotely and find problem areas with high accuracy.

Shaped products for PPU pipes

Installation of polyurethane foam pipes is carried out using shaped products.

The most popular of these are:

- steel pipes PPU;

- bends, elbows, bends;

- PU shell;

- heat-shrinkable cuffs (allow you to ensure the tightness of the pipe junction);

- PPU pipe supports;

- fixed supports. Allows you to ensure the stability of the pipe on a straight section of the heating main;

- sliding supports. Used when installing pipes by air (ground) method. The sliding support allows the pipe to move, compensating for expansion caused by external factors.

This variety of shaped elements allows for the installation of systems of varying complexity and reliable connection of pipes to each other.

Production technology

PPU pipes can be produced exclusively in factory conditions.

Products with polyethylene and galvanized shells have similar production technologies. Differences exist only at the final stages of the production process.

The technological process sequence for products with a PE shell can be presented as follows:

- The accompanying documentation for all materials used is checked. These can be certificates of conformity, passports, etc.

- The steel working pipe and protective shell are carefully inspected. The pipe is shot blasted, shot blasted or brushed, followed by flame or chemical cleaning. This is necessary to remove contaminants (dust, rust, oil or grease stains, etc.) from its surface and ensure good adhesion with polyurethane foam coating.

- Centralizers are installed along the entire length of the working pipe at equal distances. They perform a dual task: they help place the pipe strictly in the center of the polyethylene shell, and also act as guides for the copper conductor of the SODK.

- A pipe section is placed into a waterproof polyethylene shell using a special track pulling mechanism. The technology ensures an equal distance between the surface of the working pipe and the shell at each point of the surface, and, consequently, a uniform thickness of the thermal insulation layer. Next, temperature stabilization takes place in a special chamber.

- At the next stage, flange-type filling devices are installed at the ends of the pipe. One of them is equipped with holes for injection of polyurethane foam under pressure and release of air. The pouring process takes place into a pipe located at a slope of 1-15 degrees.

- Polyurethane foam filler is obtained by mixing polyol and polyisocyanate in a casting machine. The result is a finely dispersed emulsion in which exothermic reactions are triggered, accompanied by an increase in temperature, gas formation and intense foaming of the mixture. Gas formation is compensated by the viscosity of the composition and the presence of a foam stabilizer.

- Even minor shaking and mechanical stress at this stage will lead to a sharp loss of quality of the PU foam layer. The pipes are kept stationary on special racks. Chemical reactions inside the insulation layer take place over several hours, while the product will be fully ready for transportation no sooner than in a few days.

- The technology for the production of products with a PE shell is described in detail in GOST 30732-2001 (for pipes with a galvanized steel shell it is not regulated by GOST).

Modern industry successfully produces various standard sizes of polyurethane foam pipes with a polyethylene sheath. Among them, it is easy to select those that will best meet the requirements of each specific project:

- Diameter of the internal (working) pipe: 25-1000 mm.

- Outer diameter of the working pipe: 32-1020 mm.

- Working pipe wall thickness: 2-11 mm.

- Product diameter: 90-1200 mm.

- PE shell thickness: 3.0-14.9 mm.

Processes during foaming and mixing PU foam components

When mixing the polyisocyanate and polyol components in the mixing compartment of the casting machine, a fine emulsion is formed. The increase in temperature and increase in viscosity of the mixture is explained by the exothermic reaction occurring in it. When the temperature reaches values greater than 25-28 degrees, intensive foaming of the composition and gas formation begins, which is recorded as the start time when insulating pipes.

Shells for pipes are made by extrusion, but their walls are much thinner than those of conventional pipes, so when pouring foam you must strictly follow the technology

READ ALSO: HDPE pipes for cables in the ground: underground laying of corrugated pipes, laying, in which pipes the cable is laid

The process of gas formation is stabilized by an increase in the viscosity of the polyurethane foam mixture and the presence of an organosilicon foam stabilizer in it. Additional growth of bubbles is also possible due to the reactions of the polyisocyanate and air moisture. Chemical processes lead to the emergence of a polymer structure (three-dimensional). The beginning of its formation is recorded as the gelation time.

Note! After this shaking, mechanical movements, and other influences on the assembly of the structure can cause the polyurethane foam layer of hardening foam to sharply lose quality.

For this purpose, the pipes are kept in thermal insulation on racks. At this time, there are many unreacted groups in the polymer matrix. Further polymerization is characterized by the time the surface of the polyurethane foam loses its stickiness and the time it takes to fill the space between the shell and the pipe. After a few hours, the chemical processes are completed, and after a few days, the mechanical relaxation processes are completed.

Types of pipes with PPU insulation

The wide scope of application and the possibility of using different materials to form the protective outer shell of the pipe makes it possible to manufacture two of the varieties. Information about the purpose and composition of the pipe is contained in the marking. There are types and types:

PPU pipe in a polyethylene sheath (PPU PE pipe). In this case, polyethylene is used to protect the thermal insulation material. Designed for installation in underground ductless and channel pipelines. Some manufacturers label this type as St PPU PE pipes, which means that the working pipe is a steel pipe with a polyethylene shell;

PPU pipes in a galvanized shell (PPU OTs pipe). The function of protecting the insulation is delegated to galvanized material, which is wound into a casing (shell, case). They are used for overhead laying of pipelines (aerial laying). In this case, polyethylene is unable to perform protective functions, because is destroyed under the influence of ultraviolet radiation and other external factors. A galvanized steel shell provides better protection in these conditions.

Pipes also differ depending on the thickness of the insulation used in them:

PPU pipe marking

Marking example:

PPU pipe st. 57x3-1 PPU-PE with ODK GOST 30731-2006

It stands for: pipe with polyurethane foam insulator, steel, outer diameter is 57 mm, steel wall thickness is 3 mm, PPU type - insulation of the first type (1 PPU), polymer shell (PE), the pipe is equipped with an operational remote control system (ODC). Manufactured in accordance with the requirements of GOST 30731-2006.

PPU pipe sizes

Metrological parameters of polyurethane foam pipes (dimensions, diameters)

PPU pipes - dimensions (diameter, wall thickness and shell)

Metrological parameters of polyurethane foam pipes (gradation by type)

Geometric parameters of polyurethane foam pipes GOST 30732-2001 standard shell (TYPE-1) and reinforced shell (TYPE-2)

Pipes in PPU insulation made of polyethylene (PE)

Size range. Outer diameter from 32 mm to 1020 mm, inner diameter 25-1000 mm, wall thickness 2-11 mm, PE shell diameter for 1-2 types of polyurethane foam 90-1200 mm, polyethylene shell thickness 3.0-14.9 mm.

Dimensions of polyurethane foam pipes in a polyethylene sheath (diameter, wall thickness and sheath)

Pipes in polyurethane foam insulation made of galvanized steel (OTs)

Size range. Outer diameter from 32 mm to 530 mm, inner diameter 25-500 mm, wall thickness 2-7 mm, diameter of the OC shell for 1-2 types of polyurethane foam 100-710 mm, thickness of the galvanized shell 0.5-0.7 mm.

Dimensions of polyurethane foam pipes in a galvanized shell (diameter, wall thickness and shell)

Pipe in polyurethane foam insulation

is engaged in the production of modern pipelines insulated with polyurethane foam (PPU pipes) in polyethylene (PE) and galvanized (OC) shells, with a system for operational remote monitoring (SORK) of the condition of pipelines.

The pre-insulated pipes (PI pipes) we produce and accompanying products in polyurethane foam insulation are made in accordance with the requirements of GOST 30732-2006, used for underground ductless and above-ground installation of heating networks with the design parameters of the coolant: operating pressure up to 1.6 MPa, temperature up to 150 °C .

Scope of application of pipes in polyurethane foam insulation

- hot and cold water supply systems (DHW and cold water supply);

- heating systems;

- sewerage systems;

- main, distribution and field oil and gas pipelines, oil product pipelines, pipelines of cryogenic systems and pipelines for transporting coolants or chemically active media.

Pipes in polyurethane foam insulation are a reliable way to reduce heat loss from pipelines and therefore they are most often used in the construction of new and replacement of old heating networks and hot water supply systems.

Classification of polyurethane foam pipes

- By type of shell: - Pipes in PU insulation with a polyethylene (PE) shell are intended for heating mains, which are laid underground, while the polyethylene (PE) layer protects the steel pipe and polyurethane foam from groundwater. - Pipes in PU insulation with a shell made of galvanized steel (GS) are intended for heating mains with an above-ground location.

- Depending on the thickness of the insulation layer, pipes are made of two types: - Type 1 is intended for installation in central regions with a temperate climate. - Type 2 is designed for operation in conditions of low temperatures (northern regions).

Depending on the temperature level in winter in the region of operation of the heating network pipeline, PPU insulation uses pipes of the first or second (reinforced) type of pipe insulation, which differ in the thickness of the thermal layer of polyurethane foam.

Thermal insulation PPU can be applied to steel oil, gas and water pipes (OGP) - electric welded, seamless, and also with a zinc protective coating (galvanized steel pipes). Galvanized steel pipes in polyurethane foam insulation are most often used in the construction of distribution pipelines for hot water supply networks (DHW systems), and zinc coating is an additional anti-corrosion protection for steel pipes, bends and other fittings.

The outer diameter of steel pipes d can be from 32 to 1420 mm. The length of steel pipes L for diameters no more than 219 mm can be from 8 to 12 meters, with a diameter of 273 mm and above - from 10 to 12 meters.

Construction of pipes in polyurethane foam insulation

Pipe design in polyurethane foam insulation in a shell made of polyethylene (PE) or galvanized steel (OTs) according to GOST 30732-2006

1 - centering support (centralizer); 2 - thermal insulation made of polyurethane foam (PPU); 3 - shell pipe made of polyethylene (PE) or galvanized steel (GS); 4 - steel pipeline pipe; 5 - copper wire indicator of the operational remote control system (ODC).

Advantages of pipes in polyurethane foam insulation

- Reduction of capital costs by 20-30%;

- Increasing the service life to 25 - 30 years at temperatures up to 150 degrees due to the prevention of external corrosion of the pipe;

- Reduction of heat loss to 2-3% as a result of the high thermal insulation properties of polyurethane foam, the thermal conductivity coefficient of which does not exceed 0.035 W/(m.K);

- Increasing service life to 30 years or more;

Stages of manufacturing products in polyurethane foam insulation

The process of manufacturing channels insulated with polyurethane foam can be divided into eight technological stages, each of which is carried out in accordance with regulatory documents:

- Quality control of materials and raw materials.

- Preparing the outer surface of a steel pipe.

- Installation of SODK and centering elements.

- Pulling a steel product with centralizers and a UDC conductor into a waterproof polyethylene sheath.

- Temperature stabilization.

- Filling of polyurethane foam components.

- Holding period.

- Quality control of finished products.

READ ALSO: Do-it-yourself snowmobile sled: sleds, drags, how to make them from plastic pipes

The main components for the production of channels and shaped elements in polyurethane foam are:

- pipes with an outer section of 5.7-102.0 centimeters, up to 12 meters long, which comply with GOSTs 8733, 10705, 550, 8731, 20295;

- steel transitions, bends, tees and other shaped products corresponding to GOSTs 17380, 17376, 17375, 17378;

- polyethylene casings made of black HDPE of high density grades not lower than 80 (according to document 18599).

Factories produce polyurethane foam pipes of different diameters for networks for various purposes.

The heat loss indicators of pipes in polyurethane polyurethane foam are reduced to the requirements of SNiP 2.04.14.

Types and markings

Polyurethane foam can be soft or hard.

Marking of soft PPU (foam rubber):

| Marking | Rigidity | Maximum load kg/cm2 (working pressure ) |

| ST | Standard | 60-100 |

| H.L. | Hard | 80-120 |

| H.S. | Soft | 60-120 |

| EL | Increased rigidity | 60-100 |

| HR | Highly elastic | 100-120 |

| CMHR | Highly elastic, fireproof Special purpose | 100-120 |

Marking of pipes covered with rigid polyurethane foam:

Pipe Cm 57×5-1-PPU-PE GOST 30732-2006 – steel pipe, outer diameter 57 mm, wall thickness 3 mm, PPU insulation type 1 in a polyethylene sheath.

Pipe Cm 57×3-PPU-OTs GOST 30732-2006 – in a galvanized steel sheath.

Pipe St 57×3-PPU-PE-B GOST 30732-2006 – in a shell reinforced with bandages.

Steel pipes covered with polyurethane foam can be produced without lining, in a shell made of galvanized steel, foil, polyethylene, kraft paper, glassine, fiberglass. Separate shells (two or more segments) are also produced for pipe insulation; they can be covered with foil or may not have an outer shell.

Without cladding

Budget shells with insulation without cladding are rarely produced - you cannot lay them under the sun's rays, if sufficient surface strength is required, you will have to additionally wrap them, for example, in galvanizing, and this is extra expense and extra labor. Such shells are usually used in dark rooms.

Kraft paper or glassine

These materials are used to protect polyurethane foam from ultraviolet radiation. Products with a shell made of kraft paper or glassine are not very common; they are used where a durable surface is not required - mainly indoors (usually industrial).

Fiberglass

Strong, durable coating, protects against ultraviolet radiation and mechanical damage. Such pipes are laid in the ground and on the surface - fiberglass tolerates mechanical loads well.

Galvanizing and foiling

Foil protects from ultraviolet radiation and does not protect very effectively from mechanical damage. Coverings can be made of fiberglass mesh or rubber-bitumen base. Such coatings are often used for hot water and steam lines with large differences in coolant temperature.

The galvanized sheet reliably protects the insulation surface from damage. Galvanized stainless steel pipes in such a shell are laid underground in channels or on the surface - galvanization is a durable anti-vandal coating.

Polyethylene

Polyethylene insulation PPU is made with a shell made of low-density polyethylene. Such products are designed for laying pipelines in the ground.

Shaped products

Separate shells (two halves) are also produced for insulating pipes; they can be covered with foil, plastic, polyethylene, or may not have an outer shell.

Related Posts

- Disadvantages of polypropylene pipes in home heating

- What kind of pipes are used for the gas pipeline?

- Which pipes for heated floors to choose: characteristics and installation methods

- How to use shell to insulate a pipe

- Thin-walled metal pipe for electrical wiring

- Features of using PVC sewer pipes with a diameter of 50 mm

- What sizes of sandwich pipes are best to use for a chimney?

- Effective methods of thermal insulation of sewer pipes

- How to choose high-quality pipes for water supply in an apartment

- Which rehau pipes are best for heating and water supply?

- Top 6 ways to competently make the transition from cast iron to plastic

- Trenchless pipe laying options

- Rules for laying sewer pipes

- Dimensions and installation of pipes for a bath

- Which pipes are best to choose for a water well?

- Dismantling of heating systems

- Cross-linked polyethylene pipes for water supply: material features, areas of application, installation technology

- Which pipe to choose for heating

- Which pipes are best for plumbing in an apartment?

- Copper pipes and their use in air conditioners

- How to insulate an outdoor water pipe

- How to assemble a simple stainless steel chimney

- Choosing between metal-plastic and polypropylene pipes

- Pragma sewer pipes

- How to weld heating pipes using electric welding

Read with this

- Disadvantages of polypropylene pipes in home heating

- What kind of pipes are used for the gas pipeline?

- Which pipes for heated floors to choose: characteristics and installation methods

- How to use shell to insulate a pipe

- Thin-walled metal pipe for electrical wiring

- Features of using PVC sewer pipes with a diameter of 50 mm

- What sizes of sandwich pipes are best to use for a chimney?

- Effective methods of thermal insulation of sewer pipes

- How to choose high-quality pipes for water supply in an apartment

- Which rehau pipes are best for heating and water supply?