Universal welder template USHS-3: how to use correctly

For operational visual inspection of welding joints, a special meter with several graduated scales has been developed. A welder's template is necessary for independently checking important parameters that affect the strength of seams: bevel angle of edges, gap of joints between workpieces, parameters of the seam bead. This is the simplest instrument for non-destructive testing, made of stainless metal, the marks are applied with wear-resistant paint.

UShS-3. Universal welder template

In the practice of welding work (especially with critical parts, for example, pipes operating under pressure), it is often necessary to measure certain parameters of the weld. You can also use a caliper, but this is labor-intensive and inconvenient. It is much more expedient to use specialized measuring tools, one of which is the universal welder template UShS-3.

Detailed product description

The universal welder template UShS-2 is designed to control the legs of fillet welds in the range of 4-14 mm and fully complies with the requirements of STB 1133-98 “Welded joints. Method of control by external inspection and measurements. General requirements".

Inspection is carried out using a stepwise method to determine the minimum gap.

The welder's template UShS-2 consists of 3 blades and 1 connecting ring. Each of the petals has precisely made grooves of a certain leg. For ease of control, next to each groove the size corresponding to the radius of the seam leg is stamped. Control of the weld leg is carried out by sequential contact (selection) of the petals with the parts connected by welding. The size is considered established if the long side of the petal and the jumper between the legs of the petal are adjacent to the parts without visible gap, and the gap between the arcs of the petal and the seam is minimal. If it does not coincide with any size level in the specified range, the value of the leg is determined empirically.

Delivery set of welder template UShS-2:

- Template UShS-2, consisting of 3 separate petals with 4.14 mm legs; 8.10 mm; 6.12 mm

- Connecting ring

- Passport (one per 10 templates)

- Package

If after this you still have questions, you can try the equipment in operation at the ITS-Ural production site (the service is provided for goods that are available at the warehouse in Yekaterinburg).

For details about the Equipment Test Drive service, call +7 (343) 222-1-999.

Own production

ITS-Ural LLC is part of the ITS group of welding equipment factories. JSC Nauchno-Proizvodstvennaya is a leading Russian manufacturer and supplier of welding equipment and consumables. This large specialized financial and industrial group unites developers, industrial enterprises and centers for the sale and service of welding equipment.

was founded in 1991 and today is a large industrial and financial group, which includes JSC Elektromashinostroitelny (Simferopol), JSC ELEKTROSVARKA (JSC ESVA) (Kaliningrad).

The fundamental activity of ITS-Ural LLC is a comprehensive solution to problems to ensure welding production in the Ural Federal District. The company's head office, retail stores, production and warehouse are based in Yekaterinburg.

Own service center

The official service center is located on the territory of the company’s production and warehouse complex. Maintains and repairs equipment for welding, cutting and surfacing of the SELMA and ESVA plants, brands BIMArc, Svarog, Resanta, Kedr, Aurora, etc.

Usherov-Marshak pattern

You can see how it is used in the picture. The size of the cut is 60°. Accordingly, each side is 30°.

In addition to the angle, you can measure the bluntness of the edges, the height of the reinforcement, the amount of convexity - “convexity” (not to be confused with the leg).

The width of the seam can be determined approximately. You can also measure the depth of defects: inter-roller depression, undercut, lack of fusion of edges.

Structurally, it consists of three parts:

- Base , with measuring scales printed on it.

- The engine is a rectangular strip of metal. It also has measuring marks and scales. It is connected to the base by a special axis.

- Pointer - has a pointed tip, attached to the slider in a certain place.

The measuring device must be protected from shock, corrosion, and chemical contamination. Before work, you need to check its integrity, the absence of bends, dents, abrasions or damage to the measuring scales.

Nine types of measurements can be carried out by the universal welder template UShS-3. Let's look at how to use it in detail for each type:

- For whatever types of measurements the universal welder template UShS-3 is used (how to use it in each specific case was previously discussed in detail), it should always be positioned strictly perpendicular to the surfaces of the connected parts.

Universal welder templates

A welder's template is a tool that allows a worker to control the geometric parameters of a weld, and also, in some cases, check the preparation of edges for welding and other characteristics.

Template measurements are a visual method that is part of any welder's job. It is necessary not only to weld the part, but also to check the size of the leg and the absence of defects (lack of penetration, undercut, etc.). In practice, welders rarely use templates, since professionals in their field usually determine all the necessary characteristics of a seam without a special measuring tool. However, the template will be a useful thing for novice welders to understand the basics of welding and acquire skills that will later allow a person to become a specialist who has knowledge and understanding of basic issues, and not just poking an electrode into the metal. The template can be useful for students of vocational schools, quality control department employees, it may be required for certification, and the tool can also be used by a wide range of interested parties (again, for educational purposes).

Welder templates differ from each other both in appearance and have functional differences. Let's look at some of them in more detail.

What can this instrument measure?

- Bevel angle The image shows a one-sided bevel of the edges. The template is installed on the part, and the arrow is rotated at an angle, which in our case is 45 o.

- Blurring edges

Measured using the lower scale.

This way you can also determine the thickness of the metal.

- Gap between parts

It is measured using a scale in the form of a wedge that is placed in the gap. In our case, the gap is approximately 3.5 mm.

Determined by inserting a needle. Using the appropriate scale, we determine the reinforcement of the seam. Using the same method, you can measure the drop between rollers and check the “difference in thickness” of the parts.

By the upper grooves you can find out the diameter of the electrode (4-2 mm) or wire for semi-automatic welding (1-1.2 mm).

The disadvantages of this template include the impossibility of measuring the suture leg; for this you will have to buy an additional cathetomer.

Template for control of seam legs UShS-2

Universal welder template USHS-2

Template UShS-2

| Price on request |

The price is inclusive of VAT. Payment is made by bank transfer.

We deliver throughout Russia, Kazakhstan and Belarus using courier services and transport companies.

More detailed information can be obtained from our managers.

Equipment type : universal template

Manufacturer : Russia

Series : UShS

Models : UShS-2

Description : device for monitoring seam legs.

Warranty for universal welder template UShS-2 : 12 months.

Template purpose:

The template for testing the legs of welds UShS-2 is designed for checking the legs of fillet welds in the range of 4-14 mm and fully complies with the requirements of STB 1133-98 “Welded joints. Method of control by external inspection and measurements. General requirements".

Inspection is carried out using a stepwise method to determine the minimum gap.

Design of the universal welder template UShS-2:

The technical device (template) consists of 3 petals and a connecting ring. Each of the petals has precisely made grooves of a certain leg. For ease of control, next to each groove the size corresponding to the radius of the seam leg is stamped. Control of the weld leg is carried out by sequential contact (selection) of the petals with the parts connected by welding. The size is considered established if the long side of the petal and the jumper between the legs of the petal are adjacent to the parts without visible gap, and the gap between the arcs of the petal and the seam is minimal. If it does not coincide with any size level in the specified range, the value of the leg is determined empirically.

Technical characteristics of the UShS-2 template:

| Range of controlled legs of a butt weld, mm | 4 — 14 |

| Type of control | stepped |

| Number of steps | 6 |

| Precision manufacturing | ±0.3mm |

| Mean time between failures | at least 1,000 conventional measurement cycles |

Delivery set of template UShS-2:

- Template for monitoring seam legs UShS-2, consisting of 3 separate petals with legs 4.14 mm; 8.10mm; 6.12mm;

- connecting ring;

- passport (one for 10 templates).

*Technical specifications and delivery package of the device are subject to change by the manufacturer without prior notice.

Additional information on templates and measuring tools can be obtained by contacting our specialists by calling the numbers listed in the “contacts” section.

We deliver instruments for visual and measuring control throughout Russia by courier services and transport companies.

Template UShS-2

The universal welder's template UShS-2 (cathetomer) is designed to control the legs of fillet welds of welded joints in the range of 4-14 mm when carrying out visual and measuring inspection. Inspection of UShS-2 is carried out in a stepwise manner until the minimum gap is identified. The UShS-2 template consists of 3 petals with legs of 4 and 14 mm; 8 and 10 mm; 6 and 12 mm. Each petal plate has 2 recesses of a certain leg size, and each of these recesses is marked in accordance with the radius of the seam leg. Control of the leg of the weld is carried out by sequential contact (selection) of the petals with the parts connected by welding. The size is considered established if the long side of the petal and the jumper between the legs of the petal are adjacent to the part without visible gap, and the gap between the arcs of the petal and the seam is minimal. If there is a discrepancy with any size step in the specified range, the value of the seam leg is determined experimentally.

The UShS-2 template is made of stainless steel and is resistant to a variety of chemicals. The material from which the template is made does not have magnetic properties and, accordingly, does not require demagnetization after long-term use. The universal welder template UShS-2 is manufactured in full compliance with the requirements of STB 1133-98 “Welded joints. Method of control by external inspection and measurements. General requirements". To expand the range and the ability to measure not only the radius but also the dimensions of the legs, the UShS-2 template can be supplemented with a KMS-3-16 cathetometer and radius templates. Calibration of UShS-2 templates should be carried out using the methods and means specified in the UShS-2MK calibration methodology 10.2017. The calibration interval of the UShS-2 welder template is set by the consumer, depending on the intensity of use of the template.

Welder template UShS-2. Specifications:

| Range of controlled legs | 4-14 mm |

| Number of steps | 6 pcs |

| Material | steel |

| Precision manufacturing | ±0.3 mm; |

| Dimensions | 115x50x5 mm |

| Mean time between failures | 1000 cycles |

| Template size | 91x22x4 mm |

| Weight | 0.07 kg |

Contents of delivery:

- Universal welder template USHS-2;

- Passport;

- Connecting ring or chain;

- Certificate of calibration (on request);

- Package.

Related products:

- VIC kits (Expert, Attorney, Transneft, Basic, VIC-1, etc.);

- Roughness meters (TIME, PCE, Elcometer, roughness samples and kits, etc.);

- Luxmeters and radiometers (TKA, Testo, CEM, PCE, etc.).

Our production

Universal welder template UShS-3 with calibration RUB 825.00.

The universal welder's template UShS-3 (hereinafter referred to as the template) is designed to control weld preparation elements, electrodes and weld elements.

Set of radius templates (UShS-2) with calibration 415.00 rub.

Designed for measuring fillet weld legs in the range of 4−14 mm, meets the requirements of STB 1133−98, EN 970: 1997, RD 03−606−03

Universal template A.I. Krasovsky UShK with calibration 415.00 rub.

Used when inspecting welded joints, T- and lap welded joints, butt welded joints, and measuring the gap between the edges of parts

Set of welder cathetometers (KMS-3−16) with calibration RUB 1,245.00

Designed for measuring fillet weld legs in the range of 3−16 mm. and complies with the requirements of STB 1133−98 “Welded joints”.

Universal welder template V-WAC with calibration RUB 1,250.00

Used for visual and measuring inspection of welded joints

Covering tape "UFM" for precise measurement of diameters (circometer)

Rulers are designed to accurately measure diameters. Used in mechanical engineering and other industries.

BUY VISUAL AND MEASURING CONTROL TOOLS

Universal welder templates USHS-3, USHS-2, USHK, V-WAC, sets of welder cathetometers KMS-3-16 and circometers can be purchased by filling out a special form on our website by clicking the ORDER button. Or contact us in any way convenient for you by phone, via instant messengers or write to us by email. We will receive your application and will contact you to clarify the details.

How to use the welder template?

A template should only be used that has been previously cleaned of grease and oil contaminants, scale, etc. To determine the height and depth parameters of the weld g, the tool is applied to the area being measured with the installation plane A (see Fig. 2), after which the slider is turned until its pointer contacts measured surface. The counting is made by combining the marks K with a certain scale indicator G. The depth of undercut of the seam ho and the distance Δ2 between the heights of the beads of adjacent seams are determined in a similar way. To measure the height of the weld e, use the E scale.

The angle of inclination of the measuring plane to the surface of the part does not matter, however, for short seams it is advisable to install the template perpendicular to this surface.

Figure 2 – Measurements using mounting plane A of the tool

Determination of the absolute displacement of bevels or mounting edges on the elements being welded is carried out as shown in Fig. 3. The count is made according to the indications of the pointer, using the G scale.

Figure 3 – Measuring displacements of welded parts

To determine the actual values of the gaps, the tool is turned strictly perpendicular to the line of the intended seam (see Fig. 4), after which the slider is inserted into the gap until it makes full contact with the metal of the parts.

Figure 4 – Measuring the gap between the connected products

To control the values of the weld cutting angles, the tool is turned over so that the dimensional plane B is at the bottom (see Fig. 5). The upper plane of the slider is applied to the surface being measured, and the result is measured on the D scale.

Using technological grooves Ж, it is possible to measure the thickness of the welding wire and electrodes, as well as the thickness of the metal in the welding zone.

Figure 5 – Measuring bevel angles of welding edges

After using USS-3, it is necessary to degrease and wipe with soft flannel.

The price of the tool included ranges from 950...1000 rubles. for domestically produced products, up to 1500...1600 rubles. – for imported products (made in China). If the template will not be used for a long time, it is advisable to preserve it in the sequence provided for by GOST 9014.

How to work with uss-3

Structurally, it consists of three parts:

- Base , with measuring scales printed on it.

- The engine is a rectangular strip of metal. It also has measuring marks and scales. It is connected to the base by a special axis.

- Pointer - has a pointed tip, attached to the slider in a certain place.

The measuring device must be protected from shock, corrosion, and chemical contamination. Before work, you need to check its integrity, the absence of bends, dents, abrasions or damage to the measuring scales.

Nine types of measurements can be carried out by the universal welder template UShS-3. Let's look at how to use it in detail for each type:

- Blurring the edges of parts. The device is applied to the edge, its length is measured using a scale at its base.

- Seam width. The UShS is located on the part - the width is determined by the scale located at its base.

- Angle of cutting edges of parts. In this case, it is placed on the surface of the part upside down. The engine is lowered until it comes into contact with the plane of the edge. The values are read from a scale around the axis of rotation of the engine. With the template in this inverted position, it is on its right side.

- The height of reinforcement of seams (both butt and corner). It is placed on the surface of the part and the slider is carefully lowered until its pointer touches the highest part of the weld. Readings are taken from the right scale.

- Displacement of the edges of parts when they are connected. To do this, place the device with its left base strictly on one of the parts. It’s more convenient to use the same one that is located to the left of the person measuring. The engine is carefully lowered down until it touches the surface of another part. Measurements are read from the scale on the far right.

- Recesses or undercuts between seam beads. It is placed with its base on the part, the slider is lowered down until its pointer comes into contact with the undercut or recess. Its value is read from the scale located on the right side of the device.

- The amount of convexity or concavity of seam undercuts. The UShS is placed on the base of the part. Then lower the slider down until its pointer touches the maximum point of convexity or concavity. The values are read from the measuring scale on the far right.

- The gap between the parts to be connected. The wedge-shaped part of the slider is placed in the space being measured, and the values are read from the corresponding scale.

- Diameter of the electrodes used. This is done by simply attaching electrodes to rectangular grooves on the upper plane of the base of the device.

- For whatever types of measurements the universal welder template UShS-3 is used (how to use it in each specific case was previously discussed in detail), it should always be positioned strictly perpendicular to the surfaces of the connected parts.

What can this instrument measure?

- Bevel angle The image shows a one-sided bevel of the edges. The template is installed on the part, and the arrow is rotated at an angle, which in our case is 45o.

- Blurring edges

Measured using the lower scale.

This way you can also determine the thickness of the metal.

- Gap between parts

It is measured using a scale in the form of a wedge that is placed in the gap. In our case, the gap is approximately 3.5 mm.

- Seam width

- Seam height

Determined by inserting a needle. Using the appropriate scale, we determine the reinforcement of the seam. Using the same method, you can measure the drop between rollers and check the “difference in thickness” of the parts.

By the upper grooves you can find out the diameter of the electrode (4-2 mm) or wire for semi-automatic welding (1-1.2 mm).

The disadvantages of this template include the impossibility of measuring the suture leg; for this you will have to buy an additional cathetomer.

Description

The universal welder's template is produced in accordance with the descriptions of GOST 15150 from high-quality tool steel . An anti-corrosion coating is additionally applied to the elements of the device. The manufacturer ensures that the functionality of the device is maintained without reducing accuracy for at least 10 thousand measurement cycles.

The tool consists of the following elements:

- Main measuring panel.

- A slider with variable thickness throughout the element.

- Pointer arrow.

- Slider rotation axis

The following planes and measurement areas are highlighted on the central part of the device:

- A - installation plane, used for laying on straight surfaces of the connected product to determine the characteristics of the seam.

- B – plane for measuring the angle bevel for welding.

- B – moving pointer.

- G – scale for measuring seam dimensions in height.

- D – ruler for setting the angle of the beveled edge.

- E – ruler that determines the bluntness and total height of the seam.

- I is a linear scale used to establish the distance between the products to be welded.

- F – recesses to reveal the thickness of the metal in the welding area.

- K – index line on the slider, used to read the measurement result along the G ruler.

The measuring panel must be straight. Concavity and dents are unacceptable. The axis for turning the slider must allow the element to move smoothly without jerking.

Our production

Universal welder template UShS-3 with calibration RUB 825.00.

The universal welder's template UShS-3 (hereinafter referred to as the template) is designed to control weld preparation elements, electrodes and weld elements.

Set of radius templates (UShS-2) with calibration 415.00 rub.

Designed for measuring fillet weld legs in the range of 4−14 mm, meets the requirements of STB 1133−98, EN 970: 1997, RD 03−606−03

Universal template A.I. Krasovsky UShK with calibration 415.00 rub.

Used when inspecting welded joints, T- and lap welded joints, butt welded joints, and measuring the gap between the edges of parts

Set of welder cathetometers (KMS-3−16) with calibration RUB 1,245.00

Designed for measuring fillet weld legs in the range of 3−16 mm. and complies with the requirements of STB 1133−98 “Welded joints”.

Universal welder template V-WAC with calibration RUB 1,250.00

Used for visual and measuring inspection of welded joints

Covering tape "UFM" for precise measurement of diameters (circometer)

Rulers are designed to accurately measure diameters. Used in mechanical engineering and other industries.

BUY VISUAL AND MEASURING CONTROL TOOLS

Universal welder templates USHS-3, USHS-2, USHK, V-WAC, sets of welder cathetometers KMS-3-16 and circometers can be purchased by filling out a special form on our website by clicking the ORDER button. Or contact us in any way convenient for you by phone, via instant messengers or write to us by email. We will receive your application and will contact you to clarify the details.

You can pay for your order to the bank account of our company Arvil LLC in Russia.

Delivery of products is carried out from Minsk to any point in Russia by courier company, to a warehouse or to the customer’s office. Delivery of orders worth RUB 50,000. and we will pay more ourselves.

A flexible system of discounts is provided for the entire range.

Products undergo double output control.

Control of linear-angular measurements (calibration) is carried out in accordance with the MK Control Methods developed for each product.

The products are made of high-quality steel, have a special galvanic coating, which ensures a long service life and are packaged in polymer cases.

At the customer's request, we can apply their company logo to any type of our products in quantities starting from 500 pcs.

Detailed product description

The universal welder template UShS-2 is designed to control the legs of fillet welds in the range of 4-14 mm and fully complies with the requirements of STB 1133-98 “Welded joints. Method of control by external inspection and measurements. General requirements".

Inspection is carried out using a stepwise method to determine the minimum gap.

The welder's template UShS-2 consists of 3 blades and 1 connecting ring. Each of the petals has precisely made grooves of a certain leg. For ease of control, next to each groove the size corresponding to the radius of the seam leg is stamped. Control of the weld leg is carried out by sequential contact (selection) of the petals with the parts connected by welding. The size is considered established if the long side of the petal and the jumper between the legs of the petal are adjacent to the parts without visible gap, and the gap between the arcs of the petal and the seam is minimal. If it does not coincide with any size level in the specified range, the value of the leg is determined empirically.

Delivery set of welder template UShS-2:

If after this you still have questions, you can try the equipment in operation at the ITS-Ural production site (the service is provided for goods that are available at the warehouse in Yekaterinburg).

For details about the Equipment Test Drive service, call +7 (343) 222-1-999.

Own production

ITS-Ural LLC is part of the ITS group of welding equipment factories. JSC Nauchno-Proizvodstvennaya is a leading Russian manufacturer and supplier of welding equipment and consumables. This large specialized financial and industrial group unites developers, industrial enterprises and centers for the sale and service of welding equipment.

was founded in 1991 and today is a large industrial and financial group, which includes JSC Elektromashinostroitelny (Simferopol), JSC ELEKTROSVARKA (JSC ESVA) (Kaliningrad).

The fundamental activity of ITS-Ural LLC is a comprehensive solution to problems to ensure welding production in the Ural Federal District. The company's head office, retail stores, production and warehouse are based in Yekaterinburg.

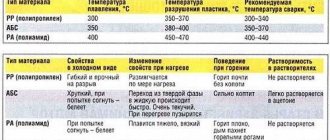

Specifications

The performance of the welding welding system is guaranteed when operating in a temperature range of ±45°C.

When purchasing an instrument from specialized trade organizations and carrying out periodic checks , the accuracy of measurements is guaranteed in the following ranges:

- According to linear depth values, including undercuts and seam defects, 0...15.0±0.5 mm.

- According to angular parameters 0…450±2.50.

- Height 0…4.0±0.5 mm.

- According to the value of the seam bluntness along the welding joint line, 0...50.0±0.25 mm.

- The gaps are 1.0...4.0±0.25 mm.

- The thickness of the elements connected by welding (with grooves F, in steps) is 1.0 to 5.0 mm.

- According to the concavity value of the weld along the connecting line 0…15.0±2.50

The tool can be used for welding work using electrodes of 1-5 m. The error of the measured values is ±0.1 mm for rods with a cross-section up to 3 mm, ±0.12 mm for electrodes up to 3.25 mm in size, ±0.3 for elements larger than 3.25 mm.