What is manual MMA arc welding

Manual arc welding is called so because the process of igniting the electrode and maintaining the arc to form a seam is performed entirely manually. The electric arc was discovered a long time ago, but was first used to join metals in 1882. In 1907, the process was improved by coating electrodes and received the international designation Manual Metal Arc (MMA).

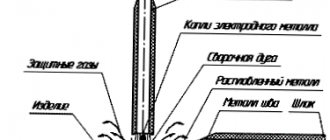

The essence of the manual arc welding process is to connect the current source to the network. There are two wires coming from the device (+ and -). One is attached to the product, and the second is equipped with an electrode holder. An electrode is inserted into it - a metal rod with a diameter of 1.6 to 6 mm, covered with coating. Tapping on the surface closes the circuit and initiates an electric arc.

The arc temperature is 5000 degrees, therefore, due to thermal energy, the edges of the metal being connected and the rod of the electrode itself melt. The molten metal is called a weld pool. To protect it from exposure to ambient air, a gas cloud is needed. This role is played by the electrode coating, which melts and creates a protective environment. Thanks to this, the metal hardens without pores. After crystallization, a slag crust forms on the surface of the seam, which is removed by lightly tapping with a hammer.

If you swap the wires (connect the minus to the product and the plus to the holder), you will get reverse polarity. In this case, the current will move from the product to the electrode, which reduces heat input and is in demand when welding thin products. With direct polarity (plus to the ground, and minus to the holder), the voltage moves from the electrode to the workpiece, which accelerates the melting of the edges and increases the welding speed.

To control the process visually, the welder must wear a protective mask with a light filter. It prevents damage to the retina by UV and IR rays, protects against bright light and prevents flying scale from reaching the face. Mandatory personal protective equipment is leggings, thick clothing and boots. There must be a headdress without a visor.

Detailed video lesson about manual arc welding

Pros and cons of gas and electric welding

Today there are quite a few ways to join metal, but the most popular is still welding, which can be carried out using electric current or gas. Both options involve the use of special equipment.

- Arc welding.

Electric arc welding is considered to be the process of joining metal products, which consists of melting sections of material and fastening them together under the influence of an electric arc. For this process, a special electrode is used, which either melts or simply heats the surface.Electric arc welding is carried out using direct current or alternating current, but in the latter case you will have to purchase a transformer to obtain a powerful charge that will ensure stabilization of the arc. In addition, a welding rectifier block is also attached to it.

- Gas welding.

In this case, welding is carried out thanks to a jet of burning gas coming out of the cutter or torch, that is, two cylinders are connected, one of which contains an oxidizing agent (oxygen), and the other contains propane, butane or methane. When using acetylene for the burner, an oxidizing agent is no longer required.If we talk about which welding is better - gas or electric, it should be noted that both options have their own advantages and disadvantages.

As for electric arc welding, it is better to use it in conditions where there is a good electrical network that can carry the voltage (working and starting) of the welding machine. In addition, in this case there are no gas cylinders that constantly need to be transported to gas stations. Another advantage is that the electric welding machine is much smaller than the gas welding machine. In addition to the advantages, this method also has negative aspects, one of which is the risk of electric shock. Therefore, the worker who will carry out welding must comply with all safety regulations and also have extensive experience.

We recommend articles on metalworking

- Steel grades: classification and interpretation

- Aluminum grades and areas of their application

- Defects in metal products: causes and search methods

What is good about gas welding? The first undoubted advantage is accessibility even where there is no electricity connection. In addition, gas welding is used when the electrical network is not able to withstand the load of the electric welding machine. Another advantage can be considered relative safety for humans, since it does not have such a negative effect on vision. The disadvantages include the fact that gas welding involves the use of fairly large equipment that has to be constantly transported. In addition, it is necessary to ensure protection against gas leaks, and the cylinders require periodic refilling. And, of course, there is always the risk that the gas could explode and lead to tragedy.

Advantages and disadvantages of manual arc welding

The MMA metal welding technology has a number of advantages and disadvantages that should be taken into account when choosing a method for specific tasks.

+ Advantages of manual arc welding

- Relatively low cost of equipment for RDS

- Possibility of welding metals in any spatial position

- Welds regular and high carbon steel, stainless metals

- Can cut at higher currents

- Can work in almost any temperature conditions

- A short electrode is convenient for reaching into awkward places

— Disadvantages of manual arc welding

- RDS is significantly inferior in welding speed to semi-automatic welding

- Smoke inhalation is hazardous to health

- It is difficult for a novice welder to distinguish metal from slag in the weld pool

- The quality of the seam depends on the skill of the user

- It is difficult to ignite an electrode on rusty metal

- The gap between the end of the electrode and the product is constantly changing (as the rod burns out)

Power supplies

For manual electric welding, the following types of current sources are used:

- Transformers. A thing of the past, a cumbersome and very heavy source. Converts high mains voltage to low voltage, proportionally increasing the current. Manual arc welding with alternating current requires high skill of the welder; the source is highly dependent on the stability of the parameters of the power supply network and causes interference and voltage surges in it. Not recommended for initial training.

- Rectifiers. It is the same bulky welding transformer, supplemented with a rectifier unit. Manual arc welding uses direct current, but at the same time retains the other disadvantages of the transformer.

- Inverters. Modern welding machine. In it, alternating current from the network is converted through repeated transformations into direct current, the voltage of which is stabilized. Its operation does not depend on changes in voltage in the supply network, and it itself also does not cause voltage surges. It is lightweight and small in size, easy to carry, and low-power models can generally be worn on a shoulder strap. This is very convenient when welding extended structures, such as fences. Equipped with electronic systems for stabilizing arc parameters and protecting against electrode sticking. Ideal for both initial training and further work. Affordable.

- Semi-automatic devices. An inverter is used as a current source. This class of devices uses welding wire fed into the working area by a special mechanism. Instead of flux spraying, direct gas supply from the cylinder to the working area is used. It is many times superior to the inverter in terms of performance and the range of metals and alloys available for joining. Several times more expensive than an inverter of equal power.

Semi-automatic welding

Transformer for welding

For initial training and small volumes of work, it is better to choose an inverter; for complex work or large volumes, a semi-automatic machine is more suitable.

Types of welding machines for manual arc welding

It is important for a novice welder to know the types of welding machines for manual welding, selected depending on the thickness of the metal being welded, the type of steel and the frequency of use of the equipment. The price of the models also differs, so it is worth delving into this issue in more detail in order to buy a device suitable for future activities. Equipment can be divided into three categories:

Inverters

One of the most compact devices with a connection to 220 or 380 V. It uses small transformers, a diode bridge and an electronic board with keys. The unit receives alternating current from the network with a frequency of 50 Hz and converts it into direct current, passing it through a special filter. Then the voltage again becomes alternating, but with an already increased frequency - 100 kHz. After this, the amplitude of the volts decreases to 48-90, and the current increases to 160-200 A.

Welding inverter with cover removed.

At the output, the current is again converted to direct current. There are universal inverters where, in addition to MMA welding, it is possible to install a spool of wire and connect a torch from a semi-automatic MIG/MAG welding machine. “3 in 1” models are also capable of cooking with a non-consumable tungsten electrode in an argon environment (TIG). Of course, the cost of universal inverters is higher than conventional ones, but their functionality is wider.

Universal welding inverter.

Rectifiers

These are installations for manual welding in industrial conditions. They convert alternating current into direct current without changing the oscillation frequency. Most often, 380 V is required for connection. They are distinguished by smooth seams created with a characteristic rustle. They are used for manual welding of critical products, but are expensive and not convenient to transport, so they are more suitable for stationary use.

Welding rectifier.

Transformers

Welding transformers are MMA welding machines at the most affordable price due to their simplicity of design. It is a coil with a primary and secondary winding. Due to this, the voltage decreases and the current increases. Changing the distance between the coils allows you to adjust the welding current. Work is carried out on alternating voltage. There are models for 220 and 380 V. There are compact devices for wearing on the shoulder and large industrial installations. Due to alternating current welding, they are suitable for non-critical structures.

Welding transformer.

What is needed for semi-automatic welding?

The electrode has less resistance compared to the arc. Therefore, when working with a metal surface, heat is generated, which leads to melting of the electrode or metal. At the same time, this method of fastening metal is quite reliable.

To carry out the work you will need a welding machine, a protective mask, gloves and some skills in this work.

- When vertical welding, it is necessary to move the electrode away from the seam. This is necessary to ensure uniformity and ensure quality of fastening.

- When welding horizontally, a continuous and spot weld is made. But, as a rule, the point one is considered more reliable.

Advantages of semi-automatic welding

Compared to a conventional welding machine, the work of the master is significantly easier.

- Instant arc ignition is ensured;

- there is no need to constantly replace electrodes;

- no need to rub the finished seam from slag;

- in many devices, the melting of wire under the action of an electric arc is automatically controlled;

- the welding inverter is connected to a regular household power source with 220V power supply;

How to choose a welding machine for manual arc welding

It is necessary to select welding equipment for manual arc welding based on the upcoming tasks of joining metals, including the maximum thickness of the workpieces, the location of work, the volume and type of steel. Here are the key equipment characteristics and recommended values for various activities.

Operating voltage

An important parameter that determines where you can cook with the device:

- Household models for 220 V, which can be connected to regular sockets. Suitable only for welding steel with a cross-section of up to 10 mm.

- Universal models designed for 220 and 380 V. They are suitable for both garages and production. They can weld metal up to 20 mm in thickness.

- Industrial installations with power supply 380-580 V. Designed for joining workpieces with a thickness of 10-50 mm.

Where the voltage often “sags” (a weak power line in a garage cooperative, a remote village, or a country house), it is advisable to choose a welding machine with an input current of 160 V. This will allow manual welding without installing a voltage stabilizer in the circuit.

Welding current adjustment range

The thickness of the penetration depends on the current strength. The adjustment range of some devices is 160-200 A, others 200-250 A. Industrial devices can have a maximum value of 400-500 A. If you buy an inverter with insufficient current reserve, then the metal from the electrode will not be able to fuse inside, but will stick on a surface. Such a seam will be weak and not airtight.

- For welding steel with a cross-section of 1-2 mm, a current of 60-100 A

- To cook workpieces 3-5 mm thick, choose an inverter with a rating of 160-200 A.

- If welding thick parts 6-20 mm is a priority, then a professional machine with a current of 250-400 A

| Metal thickness, mm | Welding electrode diameter, mm | Recommended welding current values, A |

| 1-2 | 1,0 | 20-60 |

| 3-4 | 1,6 | 50-90 |

| 4-5 | 2,0 | 60-100 |

| 5-6 | 2,5 | 80-120 |

| 6-8 | 3,2 | 110-150 |

| 8-11 | 4,0 | 140-180 |

| 12-15 | 5,0 | 180-220 |

| 15-18 | 6,0 | 220-260 |

Duration of activation

This characteristic is denoted by the abbreviation PV and is measured as a percentage. A PV indicator of 40% means that out of 10 minutes, the device will be able to cook at maximum current for 4 minutes continuously, and the rest of the time will be required for cooling. If you need to use the machine for a short time (welding with short seams, where there is often an interruption for subsequent marking and cutting of workpieces), then you can save money and buy a machine with a low duty cycle, since it will have time to cool down during downtime.

In cases of long-term welding, you need to buy an inverter with a duty cycle of 80 or 100%, which will allow you to weld almost without stopping. The second option is to purchase a device with a high maximum current rating (for example, 250 A). And although its duty cycle at maximum will be 40%, but at a value of 160 A, the duty cycle will be 100%. And this is enough for continuous welding of sheet steel with a cross section of 3 mm.

Open circuit voltage

Since the welder often holds or even stands on the workpiece while making a weld, it is necessary to ensure safety from electric shock. To do this, the voltage during arc closure is reduced to 12-48 V. This avoids electric shock. But as long as the arc does not burn (the circuit is open), the idle speed is maintained at higher levels.

This is necessary to make it easier to close the contact and initiate an electric arc. The higher the idle speed, the easier it is to ignite the electrode. This is especially noticeable when welding iron that is rusty or poorly cleared of paint. It is better for a beginner to look for devices with an indicator of 70-90 V. For more experienced welders, 60-70 V is enough.

Power consumption

The value varies in different models from 4 to 20 kVA. This determines how thick the cross-section of the wiring in the supply network should be. If the power of the device is too high for a household outlet, the wiring will melt. Therefore, for a dacha you need transformers with 5-7 kVA. If you plan to carry out welding work in the field using a gas generator, then it is better to find a 4 kVA machine. There are no restrictions for industrial versions, since in factories the connection of powerful equipment is included in the calculations when designing electrical networks.

Protection from dust and moisture

The characteristics of the welding machine indicate the protection of the housing from solid particles and water (IP). The first value is always "2". This means that the housing will not be penetrated by hard parts with a diameter of 12 mm or larger. This means that the jacket will not be sucked in by the fan blade, and your fingers will not get into live parts.

The second value can vary from "1" to "3". In the first case, the device is protected from vertical drops, and in the second from rain, even if the splashes fall at an angle of 60 degrees. If you work under a roof, then this does not matter, but for outdoor activities, IP23 protection will help you complete your work outside, despite the onset of rain.

Ventilation system

All devices for RDS are equipped with ventilation that removes heat from the transformer and board to the outside. The initial system is implemented in the form of a fan and perforations on the case. If it overheats, protection is triggered and the inverter turns off until it cools down. The presence of holes for ventilation leads to the fact that dust is drawn into the housing and periodic blowing is required.

Industrial models may have water cooling. In it, a mixture of alcohol and distilled water circulates through the channels using a water pump. The liquid removes heat from key electrical parts, extending the operating time of the device. But such products are more expensive, so the purchase is justified only by the need to continuously cook for 5-7 hours every day.

Temperature range for operation

If you have to work with manual welding in a heated room, then this characteristic is not important. But for those who work in cold buildings or outdoors, it's worth paying attention to the temperature range. Often, inverters are allowed to be used down to -10 degrees. There are special models that work properly at -20 degrees.

At positive maximum temperatures (which for most models is +40 degrees), the inverter’s thermal protection will work faster. Therefore, it is better to place the device in the shade in a ventilated area, then it will take longer to heat up.

Weight and dimensions

The dimensions and weight of the welding machine affect the mobility of the welder and ease of transportation. For stationary use in a garage or workshop, dimensions and weight are not important. Unless you need to provide space for a device 500x500x600 mm. But for field activities it is worth buying a transformer weighing 3-6 kg. It can be put on the shoulder and cooked at a height, which does not require long cables and a holder, but only an extension cord for the power cord. Dimensions of compact inverters range from 200x120x170 mm.

Availability of additional functions

The more additional functions a welding machine has, the easier it is to carry out manual welding and make a high-quality seam. A beginner should pay special attention to this. Here is a description of some additional capabilities of welding equipment:

- VRD - reduces idle speed to 9-12 V. This is necessary when welding work is carried out inside or on a metal structure to further increase safety. The function is especially useful if welding is performed in a humid environment that increases current conductivity.

- Antistick - switches off the welding current when the electrode sticks. Facilitates the moment of detaching a stuck rod from the product, saves time and simplifies the learning process.

- Hot Start - gives an increased current (voltage V) precisely at the moment of ignition of the electrode. Well suited for hand welding rusty or painted metal. Helps to start a seam in exactly the intended place, without leaving electrical marks from tapping with an electrode on the workpiece.

- Arc Force - at the moment the electrode sticks, gives a short-term increase in current strength (by 10 A) to prevent arc extinction. Useful for manual welding of thin sheet steel.

Video. How to choose a welding inverter for manual arc welding

How to set up semi-automatic welding?

Each master independently chooses for himself which mode he is going to work with.

- When working with gas.

Equipment settings can affect work speed and seam height. Some professionals with extensive experience can adjust equipment by ear. The gas supply should be uniform and not hiss. The gas is intended for high-quality blowing. The wire should be placed forward, which will not allow the arc to break. Correct settings will prevent the metal from boiling during operation. - When working without gas.

The technique of working without gas differs from that described above. Here it is necessary to use special cored wire. It consists of silicon and manganese. Metal powder is intended to create a protective environment. When heated, the powder burns out, protecting the seam from spreading. This method is most practical when it is necessary to ensure the best quality of welding joints without losing the original material for fastening. The ignition of powdered metal makes it possible to create a shell that protects from the temperature effects of the melting arc. - When repairing cars or to ensure high-precision welding.

Body welding is characterized by maximum precision. Loss of metal plane must be eliminated or minimized. The equipment used allows us to take into account all these requirements and eliminate unnecessary metal losses. Provides high quality even when used with the thinnest metals.

Therefore, this equipment is most often used in car body repairs. To work with body metal, instead of special wire, metal powder is most often used. The contents of such powder include: copper, manganese and silicon.

In order to ensure quality when working with the body, spot welding is used. This method allows you to create the strongest and most wear-resistant seam.

The best welding machines for manual MMA arc welding

Having considered the key characteristics, it will be easier for you to choose a device for the upcoming tasks. Next, we present a rating of the best models that have received the largest number of positive customer reviews. Perhaps among them you will find one that suits your needs.

The best MMA welding machines for 140-200 A

Transformers and inverters rated at 140-200 A are household models that are used in the country, in the courtyard of a private house, or in the garage. They are suitable for a small private workshop. They are called household because of their connection to a 220 V network and the ability to weld only thin iron up to 4-5 mm in cross-section. Here is a ranking of the best models in this category.

RESANTA SAI-140

Welding machine from a domestic manufacturer. The current range is 10-140 A. There is a rotary regulator with a drawn scale. Two indicators on the case indicate network connection and overheating. The inverter casing is entirely made of steel, which protects internal parts from shock. The 75V idle makes it easier to ignite the electrode. At maximum PV current, 70% is acceptable. The housing has a degree of protection IP21. The wide shoulder strap makes it easy to transport and work at heights. This is quite possible since the inverter weighs 4.3 kg.

Watch the product video

+ Pros of RESANTA SAI-140

- Full metal body.

- Comfortable shoulder strap.

- There are two additional functions (“Anti-stick” and “Hot start”).

- Easy ignition of the electrode.

- Weighs 4.3 kg.

- You can cook from a gas generator with a power of 3 kW.

— Disadvantages of RESANTA SAI-140

- No display.

- You can cook maxima with an electrode 3 mm in diameter.

- Flimsy mass clamp and holder.

- Short cables included.

Conclusion . This is one of the cheapest inverters for manual MMA welding. Its cost is explained by its simple configuration and maximum welding current of 140 amperes. The unit is notable for its ability to weld at a reduced voltage of 140 V. If your power line is weak, then this is the best option.

PATRIOT Max Welder DC-200

Second place in the ranking is given to an American brand produced in China. The inverter has a current of 10-200 A and an open circuit voltage of 75 V. A wheel and a drawn scale are provided to adjust the welding current. The front panel is equipped with two indicators that indicate connection and overheating. The device can be carried using a wide strap, which is not difficult to do with a weight of 4.5 kg. The holder included in the kit is equipped with multi-position copper plates for clamping the electrode at different angles.

Watch the product video

+ Pros of PATRIOT Max Welder DC-200

- The weight of the unit is 4.5 kg.

- Welding wire with a cross section of 25 mm².

- Compact dimensions 300x120x190 mm.

- Easy ignition of the electrode.

- Three additional functions at once.

- It works very quietly.

— Cons of PATRIOT Max Welder DC-200

- Sold without case.

- Short wires 1.8 m each.

- No screen for visual control of settings.

- The front and back walls of the case are made of plastic.

- Flimsy holder.

- The “crocodile” mass has a small contact area and heats up.

Conclusion. This is one of the best household-class devices in terms of price and performance. It is suitable for manual welding with electrodes up to 5 mm in diameter. Not every model is capable of this. The increased power allows you to use the inverter for welding gate hinges, greenhouse frames, and gazebos. They will also be able to cut a corner using electric welding, which does not require additional tools (grinders, hacksaws).