The benefits of humanity include the use of water, so the sewer system is very significant in the modern world. The fecal pump has found its wide application both in industry for pumping wastewater and in domestic conditions.

What is a fecal pump?

It is equipment with high throughput properties, used for pumping contaminated water with large elements, characterized as a sewage pump. Depending on its structure, specifics of operation and installation rules, it is divided into several options. Each of the presented types has its own peculiarity, and will be needed when adjusting the liquid level in storm pits, sewers, pumping out flooded areas, in basements and any other large containers and reservoirs.

Fecal pump device

The device has a complex design when compared with other types of equipment. The package includes an impeller, stator and rotor, shaft, mesh, cuffs, sealing system and other components that perform their specific function. An essential element of the device is the oil chamber, because it protects the device from overheating.

The fecal pump for pumping out sewerage has a strong steel body that can withstand strong mechanical stress and fights the formation of corrosion. Modern variants such as Jeelex or Vihr have been designed to last for a long time without the risk of major malfunctions.

How does a fecal pump work?

Despite the fact that the sewer apparatus has a complex design, it works according to the simplest principle:

- Once the equipment has been installed and connected, it begins to dilute the impurity of the water;

- All solid elements that are located in liquids flow through the channels of the device and are crushed by a grinding mechanism;

- Water is directed to the outlet pipe of the device and moves to the sewer tank.

In a private home, sewage pumps often have a submersible function with a cutting mechanism. They must be located under strong pressure of the liquid that will be pumped. In situations where sewage processing occurs with the participation of surface units, they are lowered exclusively into the receiving pipe of the device.

Varieties

Depending on the type of object, its sewer system, as well as the volume of wastewater, there are several types of fecal pumps:

- Submersible type. Such devices are most often used for domestic needs, or in facilities with a small volume of wastewater. They are similar to conventional drainage pumps, but have improved technical characteristics.

- Submersible type dry installation. They are practically no different from the “submersible” type, with the difference that their design has a special metal casing. Used on small pump stations.

- Semi-submersible. Such devices are practically never found in retail sales. Most often they come as a spare part from a single pumping station system. They are attached to floats on the surface of the drains.

- Superficial. The most productive. They are used at large pumping stations. Most often, such pumps can be found in the city pumping station system. The apparatus itself is taken out separately from the tanks, with drainage hoses immersed in it for pumping wastewater.

All of the above pumps are used for industrial needs. At various sites and industries. In some cases, they can be used at home.

Why do you need a fecal pump?

A big threat to sewer lines is fecal immobility, as it can contribute to blockages in the pipes. To eradicate problems with improper movement of fluid, fecal water pumps should be used. Installation and further operation of the devices is necessary in the following cases:

- A high-quality fecal pump may be needed if the movement of parting waste passes below the level of the sewer riser.

- The use of the device is relevant when the pressure of the drains in the continuous channel, which is located from the outlet pipe to the septic tank, increases.

- If it is impossible to maintain the slope of the pipe in the desired direction, where is the central riser located.

Principle of operation

A fecal pump with a grinder for a toilet works according to the following scheme:

- The liquid is sucked into the working chamber.

- The cutting mechanism is located at the inlet, that is, the waste enters the pipe already crushed to small particles.

- The flow picks up speed and, under pressure, enters the pipes through which it is discharged outside.

When purchasing a unit, you need to pay attention to the labeling. The presence of certain letters determines what kind of waste and what size the device can pass through:

- if the abbreviation contains only numbers, the equipment can pump and grind waste up to 5 mm in diameter;

- if the letter “f” is present, the device crushes and pumps long fractions - rags, garbage - with a diameter of up to 35 mm;

- if there is a letter “n”, the unit is capable of operating in aggressive liquids for a long time, all its parts are made of appropriate materials.

Similar structures are installed on cesspool trucks, which are called to empty autonomous septic tanks.

Fecal pump - characteristics

The market provides a wide range of sewerage equipment that can be used with cold and hot wastewater at the same time. Between themselves they are divided into:

- devices with a cutting mechanism;

- devices without a grinding element.

A fecal pump for pumping out hot wastewater with a grinder is capable of fully functioning, even if the temperature exceeds 95°C. It is used in various fields, because it crushes waste with increased density. Devices without a cutting mechanism can withstand elevated temperatures and are necessary in cases of redevelopment of premises where there is an incorrect slope of the sewer system.

Selecting and connecting a drainage pump: recommendations from experts

Following the recommendations of our portal, many country homeowners have already installed a drainage system on their site and know how to drain water from the basement. We continue the series of articles devoted to drainage. Last time we explained the nuances of installing a drainage well, today we will tell you how to choose the right drainage pump.

From our material you will learn:

- Why do you need a drainage pump?

- How is it different from fecal?

- What are the types of sump pumps?

- How to calculate the required amount of pressure.

- Which hose to connect?

What is a drain pump used for?

Owners of suburban areas are often faced with the need for drainage. This problem usually gets worse in the spring, a time of heavy snowmelt. Excess water leads to flooding of the site, ditches, basements and has a detrimental effect on the root system of many plants. In this situation, a drainage pump comes to the rescue - equipment designed to pump out contaminated water and wastewater. With the help of a “drainer” you can drain a foundation pit dug under a foundation flooded by rain, “throw” excess water off the site, save a cellar from flooding, and eliminate the consequences of a pipeline break in the basement.

Moreover, as the experience of our users shows, the device will help out even if a full-fledged drainage system has not yet been installed on the site.

Barav FORUMHOUSE user, Moscow.

I needed the “drainer” to pump out water from the site and pump out a well 5 meters deep. I chose the most common pump - without any bells and whistles. When purchasing it, I was guided by the principle: price-quality. Anticipating the question of why I decided to pump the water out to pumps, rather than equip a full-fledged drainage system on the site and, thereby, save it from flooding, I will answer: doing something haphazardly is more expensive for yourself. I made a drainage project and calculated that the estimate would exceed 150 thousand rubles. For now, I put off its construction “for later”, and do what everyone else does - “budget” drainage - bury the money in the ground. I don’t want to redo it in 2-3 years.

Guided by these principles, Barav decided, as a temporary measure, until full drainage was launched, to drain the water with a drainage pump. To do this, he additionally purchased a hose 25 meters long, with a cross-section of 1 inch, and a reinforced rigid hose 6 meters long, with a cross-section of 1 ½ inches. According to our user, he had to tinker with connecting the hose because... the hose did not fit into the fitting. As a result, Barav managed to install a 31-meter-long system, which he decided to use to pump out water.

He dropped the “drainer” into the deepest place of water on the site and turned it on. The result of the work is visible in the following photos.

Flooded area

Working drain pump

Result of work

Barav

I “drove” the pump in full. I pumped everything out to them - the drainage well, the neighbor’s basement, and the drains from the kitchen. He “plowed” 5-8 hours a day all summer and autumn. Moreover, it worked so silently that I sometimes went up and checked if it had turned off.

In total, the drainage system worked for 7 months. This is approximately 800 hours and during this time it pumped about 8,000,000 liters of water, and the device even had to pump out a mixture of water and clay with sand from the pit.

Barav

I operated the pump in the harshest conditions, in very dirty water, even with “dry running”, which caused it to break. The “autopsy” showed that the engine was flooded with water, which got there due to the fact that the air outlet hole was clogged (it is located under the float mount), which had to be cleaned periodically.

Despite this ending, our user decided to buy a new “drainer”, but now strictly adhere to the rules of its operation .

Basic principles for choosing a drainage pump

We know that a drainage pump is designed to pump contaminated water from ditches, pits, drainage wells, basements, etc. It would seem that now all that remains is to go to a hardware store and buy it. This is where there are several pitfalls that you should be aware of in advance. The first of them is that the market offers a huge selection of drainage equipment. To choose the device that's right for you, you need to narrow your search criteria. To do this, you need to answer the following questions.

What is the difference between a drainage pump and a fecal pump?

Indeed: both drainage and fecal are designed for pumping dirty water and wastewater. Those. — liquids containing various inclusions. So why not pump out both the septic tank and the pit in the foundation pit with one. Not so simple. The purpose of the pump depends on the composition of the wastewater, its temperature, and chemical composition. Let's consider this aspect in more detail.

Drainage pumps are designed for pumping out wastewater containing solid impurities (inclusions) of a certain size - usually from 5 to 40 or more millimeters. The permissible size of solid particles that can pass through the mechanism is specified in the instructions . To protect the mechanism from the ingress of large solid objects - stones, gravel, etc., larger than those established by the design, the suction part of the device is protected with a metal mesh.

The fecal pump (if it is equipped with grinder knives intended only for grinding organic debris and fibrous inclusions) is used for pumping water that does not contain suspended solids , because it does not have a filter that delays such inclusions.

Most drainage pumps are designed to pump water with a temperature not exceeding 35-40°C. Therefore, if the device is needed to pump out hot wastewater (from the kitchen, bath, sauna, dishwasher), or you need to drain a basement flooded with hot water due to a break in the hot water supply system, you must choose a “drainer” designed to work in such “hard” conditions. » conditions. Those. with a temperature allowing its operation at 70°C and above degrees.

It is important to take into account the chemical parameters of the pumped water. If the pump will operate in an aggressive environment, the materials from which it is made will be subject to increased corrosion-resistant requirements. There are also drainage and fecal devices designed for both pumping fecal and wastewater containing solid inclusions.

Therefore, before purchasing, first carefully read the instructions - why, in what water and what inclusions (particle size) the device can pump.

You should not try to use the “drainer” as an element of the water supply system of a country house, because... pumps of this type do not create enough pressure.

We remember that submersible pumps designed to work in clean water (to supply water from a well) are not designed to work with dirty wastewater.

What are the types of sump pumps?

To simplify the choice, they can be divided into 2 groups:

- Working on the surface.

- Submersible.

From the names it is clear where the “drainer” works. The surface one is placed next to the place where water is pumped out. Then a hose is lowered to the bottom of the well or drainage hole, through which the waste is pumped out. The device operates in automatic mode. When the liquid level rises to a certain value, due to the float (rising along with the liquid), the pump turns on and begins to pump out water. But submersible devices have become more widespread, as they are the most convenient to use. They are completely lowered into the pumped liquid. Unlike a surface “drainer”, such a pump is not afraid of precipitation and moisture, which means it is better suited for work on the site and is not affected by negative atmospheric phenomena.

Important: the submersible pump (its motor) is cooled by the liquid in which it operates. To protect against “dry running” - “work without water”, submersible pumps are equipped with float switches. The float turns the device off and on when the liquid reaches a certain level.

When installing the pump, make sure that the float has the so-called. free “working stroke”. Did not cling to the walls of the well, branches, edges of the pit, etc. Another important characteristic of the “drainer” is the level of emptying (it is prescribed in the instructions). Those. what level of water can remain at the bottom of the container, after which the pump will stop pumping it out. This value can be ≈ 20-50 mm. A device with such parameters can be in demand when it is necessary to drain small flooded rooms and containers almost “dry”. The pumped water should not contain large abrasive particles.

What are the main criteria for choosing a drainage pump?

When choosing a “drainer” you need to pay attention to two main characteristics:

- Capacity l/min or m³/hour. Those. the amount of liquid pumped over a certain time.

- Pressure This value shows to what height (the difference in height between the installation site and the discharge point) wastewater can be pumped out. This parameter affects the ability to pump wastewater over a certain distance.

Let's look at the second parameter in more detail.

XxxlFORUMHOUSE user

I want to buy a drainage pump. I need it to pump water out of the pool. The height of the pool is about 1 meter. I began to study the technical characteristics of the pump I liked and saw the following parameter: maximum pressure - 14 meters. I want to understand what this parameter means and how far the device can drain water.

Andrey 203 FORUMHOUSE user

This parameter shows to what height the pump will raise water. We also take into account pressure losses when overcoming the hydraulic resistance of the pipeline.

Hence: for the calculation we need to convert the vertical to horizontal. Approximately the horizontal pressure loss ratio will be 1:10. Those. 1 meter of vertical pressure is equal to 10 m horizontally.

This coefficient = 0.1. Based on these data, we solve the following problem:

The “Drainer” was installed in a well at a depth of 5 meters, the length of the pipe for drainage is 20 meters, then the water will flow into the ditch. The minimum pressure is: 5 + (20 * 0.1) = 7 m. We need a pump with a pressure of at least 7 meters. To “insure” and obtain guaranteed pressure at the outlet of the pipe, you can add another 3 m to the resulting figure. That is. - a pump with a pressure of 14 m, this is ≈ 140 m horizontally.

It is also important to choose a hose of the appropriate diameter, because... By lowering its cross-section, we will “strangle” the pump by attaching a ¾ hose to it.

Andrey 203

If the pumping time is not working, then you can install a three-quarter ¾ (≈ 19 mm) hose; if you need to pump out water quickly, then an inch and a quarter 1 ¼ (≈ 32 mm).

Sergey N FORUMHOUSE user

If you need to quickly pump out water, then do not skimp on parameters (power) and think about a larger diameter pipeline.

Tip: if you need to connect the drainage temporarily - mobile, you can use a rubber reinforced hose. For a stationary, permanent connection, you can use 40 mm HDPE pipes.

Our article describes in detail the features of installing HDPE pipes.

Xxxxl

In the end, I bought a pump with a maximum head of 9 m and a max. productivity 12 m³/hour. It is suitable for hoses from 1 inch and above. I took a hose with a diameter of 32 mm and a length of 25 meters. I lowered the pump into the pool at 14 m³. It pumps well, but the hose is hard to carry. Then I left a 3-meter inch hose (the part that comes from the pump), and to it, through a tee, I connected a ¾ by 20 meter hose.

Our user needed an adapter to make another ¾ bend. It took about 3.5 - 4 hours to drain the pool and water the trees (with a ¾ hose). If pumping was carried out through a 1-inch hose, then, according to our user, the pool would be empty in 1.5 hours.

Conclusion: There is no one universal sump pump that fits all situations. Each situation must be considered individually and the appropriate equipment must be selected.

In the topic on the FORUMHOUSE website you can get advice on choosing a drainage pump and learn how to independently determine the groundwater level in your area. We also suggest watching a master class on installing a submersible pump and finding out how to choose a hose for a drainage pump.

Our video talks about how to build a basement with a high groundwater level; you can also see all the nuances of constructing a drainage system.

The difference between a drainage pump and a fecal pump

Despite the fact that contaminated liquid is pumped out using these devices, they have significant differences. Based on the difference between a drainage pump and a fecal pump, we can conclude that the first type has the task of removing liquids from sewage containing solid elements. However, their size should be small. This can be sand or other materials ranging in size from 5 mm to 12 mm.

The fecal pump is capable of processing viscous liquid with large solid particles, the diameter of which can reach 35 mm. In cases of using a shredder and other cutting mechanisms, the capabilities of sewerage equipment will increase several times. Another distinguishing feature of a fecal unit from a drainage unit is the minimal noise it makes.

Review of pump brands

Grundfos is a popular Danish brand. Known for the small size of the models and their excellent performance. Grundfos is manufactured exclusively from materials that are resistant to the working environment. The joints are completely sealed.

Grundfos fecal pump

SFA - introduced the first pump with a built-in chopper to the market. Their devices are capable of processing almost any solid particles, while they are small in size. Depending on needs, they can operate in automatic or manual mode. They need close proximity to a reservoir for disposal of waste water.

SFA fecal pump: appearance

Speroni is a popular industrial pump company in Europe. They work in a multi-drain system, i.e., they are equipped with two or more throughput channels, which can significantly reduce the time for processing feces, compared to other models.

Speroni fecal pump: work in real conditions

Types of fecal pump

When choosing sewerage equipment, it is important to understand the difference between industrial and household equipment. The first option must have a cutting mechanism, since it is often used when pumping out liquids. A fecal pump with a grinder may be needed when moving liquid through a pipeline to a septic tank. Household devices are necessary for regular use in residential buildings and apartments. They are divided into submersible, semi-submersible and surface categories. Each fecal pump for cesspools with a grinder has its own feature.

Submersible sewage pump

The unit takes its name from the principle of its installation. The device should be located at the very bottom of the cesspool. A distinctive feature of the submersible type is that it is easy to operate, highly productive and inexpensive. Unlike other types, the fecal pump interacts with the most aggressive environments, due to which it has a cast iron body.

The submersible sewage pump for a cesspool has a built-in switch that operates automatically if the level of contaminated liquid is below normal. Its operation is carried out on the principle of a float, because an emergency shutdown of the equipment may occur if the water in the sewer pit is higher than the permissible level.

Semi-submersible sewage pump

A less common model is the semi-submersible, since its suction pipe must be in contaminated water. As for the engine, it is located on a special platform that does not reach the liquid level. A household fecal pump has a cooling system, which means it is able to function with sewage whose temperature reaches 90°C. If we take into account the body, then expensive models can be made of cast iron and stainless steel.

Surface fecal pump

Unlike all other options, the surface unit does not come into contact with tanks and pits, but treats sewage using a suction hose. The external fecal pump has become very popular among users because it is mobile and small in size. Due to the fact that the units have virtually no contact with liquids, their housing is made of simple materials. When choosing, it should be understood that the pump housing will be exposed to external factors.

General information

Device structure

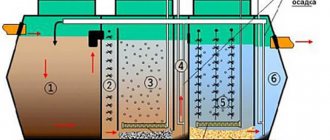

The mechanism for immersion in wastewater consists of:

1.pump unit to pump liquid.

2. an electric motor, with the help of which a shaft with blades rotates.

3.Double motor housing made of steel or plastic.

4.liquid moves between the walls of the housing to cool the engine.

5.knot for crushing large fragments of waste.

The devices have thermal protection, which is triggered when the pump is overloaded. An impeller in the form of a screw is attached to the axial shaft, which supplies water to the housing. When the pump turns on, rotating the impeller, water is drawn from the sump, passing past the walls to the outlet. Water flows in portions while the unit is running.

The float mechanism regulates the process of turning off the device. It controls the volume of liquid in the container. If the liquid level drops sharply, the unit turns itself off.

Frequent breakdowns

Pumps have various causes of breakdowns. They are of different nature. Common problems include:

1. The pump stopped working and hummed. When the pump is lowered, the float part floats to the surface, the cable is connected to the outlet, but there is no vibration. This means that the declared engine power does not correspond to the electrical network that is used to turn on the device. It is necessary to study the characteristics of the pump, power indicators, and efficiency of the device.

2.If the pump is in shallow water and the float does not respond. You need to remove the unit, lift the cushion out, then reconnect the device to the network.

3. The pump operates, but does not pump liquid. When the engine is running, water does not come out. There may be several reasons behind it. The protection grid that protects the body from debris and stones may become clogged. We need to raise the pump and clean the filter. Thick sewage may get into the discharge hose and clog it. They should be knocked out of the equipment. If this fails, the hose is disconnected and washed.

4. The impeller is broken. The part may have a broken bearing or screws. We need to disassemble the pump.

5. The pump creates strong vibration and overheats. The motor braid may be broken, liquid may get into the motor, or the shaft bearing may break. If the pump heats up and vibrates, the liquid flows in fits and starts or has stopped. The unit is disconnected from the network and taken out. The cause of the problem lies inside the case, which will have to be disassembled. The blades on the operating wheel may break. Rotation is carried out by means of an eccentric, hitting the body on one side.

6. When the engine is in good working order, the fluid flows weakly. The cause of the breakdown is a malfunction in the pump mechanism in the form of an impeller, or a bearing, a blockage in the discharge hose, or a filter device. The parts are washed with clean water or replaced.

7.When the pump is connected, the machine is activated. The power supply is cut off when shorted. It is necessary to check all electronic parts of the equipment. Using a tester, walk along the cable to find out the area of the short circuit and, if necessary, replace it. If the pump runs dry, the copper braid on the motor may be damaged. You can replace the braid or the engine in a special repair shop.

8.The unit works, but turns off on its own. The cable is plugged in, the pump operates, pumping liquid, and suddenly turns off. The reason may be a mismatch between the electrical network and the engine power. Voltage surges can cause malfunctions. It is necessary to study the features of the pump and install a voltage stabilizing device.

Attention! To pump out all the liquid from the container, you need to tie the float part to the cable vertically and lower it into the water. The operation of the unit is adjusted by disconnecting the cable from the outlet.

How to choose a fecal pump?

There are certain conditions, observing which you can select the required option. These include:

- Installation method

. If the device is purchased for regular work, you should pay attention to models of submersible or semi-submersible pumps. Surface options are suitable for short-term equipment functionality. - Liquid volume

. To understand which fecal pump to choose, you should decide on the volume of the tank itself. The wrong choice can lead to rapid breakdown of the device, since it will not be able to perform its certain functions if there is a lack of the required amount of liquid. - Immersion depth

. Each device model has instructions that indicate the permissible depth. If sewerage pumps are placed too low, they may not function properly and not perform their primary purpose. - Liquid temperature

is an important point to consider when purchasing a device. All information about the permissible temperature is indicated in the accompanying documents. - Chopper

. Most models have cutting mechanisms for crushing large elements. The presence of a chopper will significantly expand the scope of use of the device.

Rating of fecal pumps

According to experts, most of the models offered by the domestic and world markets have decent characteristics. They selected the TOP 5 fecal models that meet all the stated requirements and have an affordable price:

- Jeelex Fekalnik 150/6

. The Gilex fecal pump is recognized as an excellent submersible type. It has an affordable price. - Vihr FN-250

- a vertical unit, named the best economical model. It has an electric motor and a centrifugal pump. - Sturm WP9709SW

is a version with a chopper, complete with a single-phase electric motor and a single-stage fecal pump. - QUATTRO ELEMENTI

is a vertical device, recognized as an excellent balanced model. - Elpumps BT 4877

is a high-quality submersible unit, has a central pump and a single-phase electric motor.

Specifications

Such a unit is very different from a conventional household device.

The industrial fecal pump is designed for more severe operating conditions. It can be installed (embedded) directly into the sewer line, or immersed in a tank with wastewater. One of the basic principles when developing such equipment is compliance with the requirement of non-clogging. Therefore, such pumps are made with wider flow channels in comparison with pumps for pumping clean water. Also, industrial fecal pumps are equipped with a special grinding system.

A small cottage community of up to 30 houses can consume up to 100 cubic meters. m of water per day. This volume will pass through the entire system, including the fecal pump. Therefore, the parameters of this equipment must correspond to the design and operational characteristics of the pumping station.

For this equipment there are a number of requirements and technical characteristics that need to be taken into account when purchasing:

- Ph indicators: from 6 to 8.5 units;

- operating temperature: up to 90 °C;

- density indicator: up to 1100 kg/m³;

- the content of abrasive particles is no more than 1% by volume;

- large particle size (up to 3.5 - 5 cm).

Industrial sewage pumps can vary in installation method.

Installation of a fecal pump

In order to install the device, you should read the instructions and follow them completely. It is also necessary to have special equipment in the form of fasteners that have their own purpose:

- Vertical guide elements are used to fix the pump.

- Horizontal parts have an angular connection for the outlet pipe.

Installation of a fecal pump in a cesspool is carried out using special grips. To load the sewer unit, you must have a cable. The weight of the device will put pressure on the pipe, thereby securing it securely in the pit. If a specialist needs to carry out repairs, the pump can be lifted without much difficulty and all the necessary work can be carried out.

Criterias of choice

You can answer the question of how to choose a fecal pump by studying the following characteristics of the equipment:

- Power, performance. That is, the speed at which it can pump out wastewater.

- The body and main components must be made of durable materials, not susceptible to corrosion, and not react with chemicals.

- Protection. It is important that the motor is protected from overheating, and in submersible types, all structural elements are protected from waste.

- Availability of service in your or the nearest (accessible) locality.

It is also worth paying attention to reviews; they sometimes say much more than technical specifications.

As you can see, there are many options for which pump to pump out a cesspool or septic tank; you should choose based on the type of wastewater, installation conditions and financial resources. The frequency of use and transportability of the installation are also important.

How to use a fecal pump?

In order for the device to function smoothly, it is important not only to carry out installation work correctly, but also to follow the rules in further use. Sewage pumps are durable equipment, but their incorrect operation can lead to complete failure, so you should remember:

- The pump must always have access to water and the liquid level must be monitored.

- Do not allow air to enter the hose.

- Do not connect the equipment to the electrical network unless it has been grounded.

- The unit must not pump flammable or chemically hazardous liquids.

- Regular maintenance of the device is recommended.

Sewage pumps are often left in tanks to operate in automatic mode, but there is a reason why they have a float. Experts recommend removing the pump every 6 months. and immerse in clean water for cleansing. By observing such usual precautions, you can not only eliminate the possibility of troubles in the operation of the unit, but also increase the service life of the pumping equipment.

Scope of application of sewage pumping units

Industrial pumps, as a rule, are a separate unit of a single sewerage system. Its installation is included in the design and estimate documentation. Therefore, you need to think about purchasing this equipment in advance. Before you start building and commissioning a large facility. The pump station itself, together with the fecal pump, may be needed:

- When constructing a small, medium or large plant with a closed communications system.

- To meet the needs of a small private cottage or holiday village.

- In the conditions of the agro-industrial complex.

- Microdistricts or small urban settlements.

- Large shopping centers and malls that want to install an autonomous communications system.

- Cities. When constructing or modifying your own pumping station.

Industrial sewage pumps can also be installed by individuals. For example, if several houses decide to install one, common wastewater system. This option will cost less than purchasing, for example, three septic tanks and three household pumps. And it will last much longer.

Industrial sewage pumps not only pump wastewater, but also grind sewage. This makes it easier to maintain storage tanks and wells in the future. This advantage distinguishes this type of equipment from household pumps.

Installation features

If you plan to use a fecal pump only depending on the season, there is no point in buying expensive models and installing them permanently. It’s another matter if he works permanently in a private home. You can install according to two schemes:

- A concrete platform is made at the bottom, onto which the body of the product is fixed. Getting such a structure is problematic, since you will have to call divers-plumbers if repairs are needed.

- It is much more practical to install the pump so that you can get it out yourself if necessary. Usually a strong nylon cord or chain is attached to lift the pump from the depths. The disadvantage of this method is that it uses corrugated pipes, which have to be changed frequently due to contamination. Cleaning them is extremely unpleasant.

Sometimes waste needs to be pumped out of a common septic tank, but it is located in a place where a sewage truck cannot reach, so they equip an intermediate pit into which the waste is pumped using a pump and then order a machine with a regular hose. This is cheaper than looking for a sewer truck with a long hose, which costs half the cost of a mid-price sewage pump.