Passport (instructions) Resanta SAI 250PN .

Resanta SAI-250PN is a welding inverter, one of the most popular on the market.

All models of inverter machines " SAI-250 PN " received protective mechanisms against temperature overheating, and also have the anti-sticking function "ANTI STICK", the ability to adjust "ARC FORCE", and the hot start " HOT START ".

Resanta Sai 250

Packaging, power cables and appearance of the Resanta Sai-250

This device is easy to set up and operate. Thanks to the use of all the necessary functions such as: anti-sticking of the electrode, easy ignition of the arc, high VA value. These parameters greatly facilitate the process of joining metal, allowing even an inexperienced welder to achieve a good metal seam. The SAI-250PN inverter welding machine is lightweight and small-sized, and has a well-adapted carrying handle on top. It will be easy for the welder to install and will make him mobile on the job site.

Handle on top of the device

Characteristic features of Resant

Resanta SAI-250PN can weld at reduced voltage. In case of network fluctuations, the inverter shows its best side, providing high stability of the set parameters of the welding process.

The inverter machine is designed for manual welding with a coated electrode using direct current.

Resanta 250 professional is an energy-efficient welding machine due to its high energy conversion efficiency.

If we compare SAI 250 with conventional transformers, then this type will benefit from the ease of setting parameters and maintaining a weld.

Settings panel and protective glass

Features of operation

The scheme for preparing the Resanta SAI 250 welding inverter for operation is not difficult. It is recommended that you always follow these steps, as this will significantly extend the life of your equipment.

- Wires with a connector for the electrode and grounding are connected to the power connectors in compliance with the polarity necessary for welding;

- The current regulator is set to a minimum, after which the device is connected to the electrical network and only then put into operation;

- After completing the welding work, the current regulator is again moved to the minimum level zone. Then the inverter turns off and is disconnected from the electrical network;

- Lastly, the holder and ground wires are disconnected.

Important features of working with this inverter are contained in its built-in fan. Earlier units for arc welding do not have such features.

The device must be kept away from moisture and metal shavings!

The internal contents of Resanta are a board with electronics, in which large and powerful parts are mixed with smaller ones. It is the small parts that control the operation of the converter, and if they are damaged, the device will simply stop working.

The ventilation is designed in such a way that air flows are forced through the body of the device, thereby cooling it. The air currents are strong enough to draw metal shavings or other objects located in the immediate vicinity of the Resanta into the body. In this case, it makes no sense to close the ventilation holes - the device will simply overheat and the protection will work, which will turn it off.

A possible solution is to extend the standard wires of the unit yourself. Note that to maintain resistance, you will need to increase the diameter of the wires. For example, when doubling the length, you need to take wires 1.4 times wider. Such a cable will cost 4 times more than the original one.

Resanta SAI 250 can operate at reduced voltage, but this is fraught with the rapid failure of the device. The device can also be powered by an electric generator. The required power is 12 kW.

Resanta Sai 250: technical specifications

Possible voltage range, V 140-240

This will allow you to power the device from a regular household single-phase network.

Maximum possible current consumption, A 35

Possible open circuit voltage, V 80

Welding arc voltage, Volt 29

Current regulation range, A 10-250

Inverter load duration, % 70% 250A

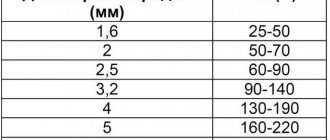

Electrode diameter, mm up to 6, which also sets the inverter apart from its competitors;

Device protection class IP 21

Device weight, kg 6.7

Dimensions Resanta 250 dimensions, cm: 25 x 13 x 40 cm

Packaging (HxWxD), cm 43 x 17 x 29 cm, weight 8 kg

Firm Resanta

Country of origin People's Republic of China

Convenient on/off switching of the welder

Trouble-shooting

The safety margin of the Resanta unit is quite large. In its class, this device is, without any hesitation, the best. If the operating procedures are followed, the unit can operate properly for years, but like any technical device it requires repair and troubleshooting.

Repair of the Resanta 250 welding inverter is recommended to be carried out in specialized centers that are authorized to work with Resanta equipment. Note that various devices of the company are in great demand in Russia, which does not create problems when finding certified workshops for the repair and maintenance of these products.

It is important to note that some problems of Resanta that arose during operation can be solved on your own:

- If overheating is frequently indicated, it is necessary to open the unit housing and clean it of dust and dirt;

- If the welding machine does not reach the maximum possible power, then it is necessary to dry the electrode;

- Another reason for the lack of power is the low voltage in the supply network.

Do you need a welding machine, but you have no experience in this field and are confused by the variety of models and brands? I will share my experience and tell you about one of the good options that has proven itself in work - the Resanta SAI 250. You will learn all the features of this model, and as a bonus, I will tell you how to properly prepare the device for work.

Appearance and dimensions

The Resanta 250 welding machine has the highest power among the range of similar inverters. In addition, its small dimensions make it extremely convenient for transportation. The inverter can easily fit into the trunk of a car. It won’t be a significant burden as hand luggage either. This is especially true if you compare it with a conventional transformer.

Cables and sockets "Resanta SAI"

The Resanta-250 inverter is designed in a classic metal case with dimensions of 25 x 13 x 40 cm.

The front panels have a standard group of indicators and adjustment knobs for modern inverters. There are also working connectors, which include:

— “device overheating” indicator;

— “network” indicator;

— power sockets for connecting various welding cables .

— setting the welding current ;

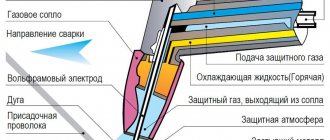

In order to avoid overheating of the Resanta SAI-250 welding inverter, the developers equipped it with a forced air cooling system, since welding generates a large amount of heat inside the device. From the outside it is easy to notice the fan grille of this cooling system.

Setting the welding current

"Resanta-250" is no different from its relatives from other manufacturers in terms of its operating principle. First, the alternating voltage coming from a regular household network of 220V is converted into constant up to 400V, which is subsequently converted to a modulated high-frequency voltage. After which the step-down transformer reduces the resulting converted voltage to the required operating setting.

To improve the quality of welding work, as well as ease of use, this Resanta-250 model received a number of additional functions to ensure a good level of work.

Add-ons included: Arc Force function - adjustable arc force, "Anti Stick" and "Hot Start".

In order for the user to get a durable and high-quality seam from the very beginning of work, the creators of the inverter implemented the “Hot Start” . The essence of the function is as follows: at the moment the arc is ignited, the device supplies increased welding current, which immediately returns to normal. This makes the task of igniting the arc easier.

In addition, “Anti stick” should be mentioned. This function helps well to protect the electrode from a fairly common problem among welders - sticking of the electrode to the base metal.

Do not ignore safety rules when working with the device. If there is high humidity in the room, work should be abandoned, taking into account the electrical housing of the Resanta Sai 250.

During operation of the device, shavings and various metal dust quite often get in, which often leads to a short circuit. You should stop using grinders and other similar tools to drive the inverter. Don't forget about power cables, they also need care. Power cable length - 1.9 m Cable length with electric holder - 3 m

Video repair and review of the Resanta-250 welding inertor:

Inverter Features

The welding machine is intended for use for domestic purposes, since the “Resanta SAI-250” circuit and its design ensure reliable and safe operation even with significant surges and surges in voltage. The inverter allows manual arc welding even at minimum voltage.

The maximum diameter of electrodes that can be used when working with Resanta SAI-250 is 6 mm. The current strength is adjustable over a wide range, but the upper limit is 250 A. The welding machine can withstand high loads for a long time thanks to protection systems. In terms of its characteristics, the Resanta inverter outperforms many similar models of welding machines offered on the market.

The inverter no-load voltage is 80 V. Built-in IGBT series transistors guarantee a long service life of the welding machine even if it is used frequently and under high loads. The protection level of this inverter model is IP21.

The mobility and compactness of the Resanta SAI-250 greatly facilitates its use. A convenient handle located on the inverter body allows you to quickly and easily carry it from place to place around the work site. Reviews of the Resant SAI-250 note the accuracy and ease of setting all parameters. The advantage of the device is that even with significant voltage surges, all specified settings remain unchanged.

Electrical circuit diagram of the welding inverter Resanta - 250

Resanta SAI-250 inverter circuit

Electrical circuit diagram of the welding inverter Resanta - 250

Cleaning the internal circuitry of the Resanta SAI-250

The welding inverter " Resanta - 250 " is made in a classic metal case and has on the front panel a number of indicators and adjustment knobs, as well as working connectors. These include: — “network” indicator; — “overheating” indicator; — adjustment of the current value; — power connectors for connecting welding cables.

Since when performing welding work, despite the inverter design of the unit, a significant amount of heat is generated, “ Rosanta-250 ” is equipped with a forced cooling fan, the grille of which is visible during external inspection of the product.

The principle of operation of the welding inverter "Resanta - 250" does not differ from similar devices from third-party manufacturers. The incoming alternating voltage of the household electrical network 220V is first converted to a constant voltage of 400V, which is subsequently changed to high-frequency modulated voltage. Next, a step-down transformer comes into operation, which lowers the converted voltage to operating voltage.

To improve the quality of work, as well as to obtain greater comfort during welding work, the welding inverter “Resanta - 250” “Anti Stick” and “Hot Start” functions

The “Anti stick” function, as the name implies, prevents the electrode from sticking to the surface of the materials being welded. That is, when the arc is ignited, the welding current automatically decreases, which is instantly restored after the electrode comes off.

And in order to get a beautiful and durable seam immediately after starting welding, the machine has the “Hot Start” function. In this case, at the moment the arc is ignited, there is a short-term increase in the welding current, which immediately decreases to the normal, required state.

Promotion of the resent with a screwdriver

When working with the Resanta-250 welding inverter, you must follow safety precautions. So, since the device is made in a metal case, it is strictly forbidden to use the latter in high humidity.

Do-it-yourself Resanta renovation

Chips and metal dust that get inside can damage the electronic part or even cause a short circuit. Therefore, the use of grinders and similar tools near the welding inverter is prohibited. And, of course, it is necessary to monitor the condition of the power and supply wires.

Safety precautions when operating welding equipment

Before starting operation, it is advisable to leave the inverter in a room at a positive temperature for several hours. This precaution will avoid the formation of condensation in the device, which can cause a short circuit. In addition, it is necessary to monitor the integrity of the insulation of the welding cable and connection wires. Damage to the insulating layer not only contradicts safety requirements, but can also cause the device to fail.

The Resanta inverter cannot be used in rooms where work is carried out, accompanied by the formation of small metal shavings and dust. Such inclusions can get inside the device and damage it. Also, do not use the inverter outdoors during rainfall or in rooms with high levels of air humidity.

When working with welding equipment, it is advisable to adhere to several basic rules:

- The place where welding work will be carried out must be well ventilated and have access to fresh air.

- Fire safety rules must be taken into account.

- During work, be sure to use special protective clothing, a welder’s mask, a hat and thick gloves. Such products will help protect your skin and eyes from burns.