Purpose of equipping the welder's workplace

Organization of a welder’s workplace is a procedure that provides for the provision of the most favorable conditions for welding. One welder or a whole team can be responsible for a section. Among the features the following points can be noted:

- As a rule, a certain area located in a structure or at the site of construction and repair acts as a welder’s place.

- When considering the requirements for a workplace, most attention is paid to the fact that it must be equipped with the required tools and equipment.

- Preparing the work area also includes removing unnecessary items that could compromise welding safety.

- The organization is carried out taking into account the size and type of structure being processed. Particular attention is paid to ensuring that the welder or assistants do not have to fix the workpieces. This is prohibited by accepted safety precautions.

Schematic illustration of a welder's cabin

In general, we can say that only with proper organization of the workplace in accordance with safety precautions can welding be performed efficiently. This takes into account the welding location, environmental conditions and many other points.

Welding tables

Welding booths must be isolated from outsiders. They house a welding table and other work accessories, so they are quite spacious. The size of the cabins is 2*2 or 2*3 meters, and the height is up to 2 meters. To improve ventilation, the walls are mounted so that there is a gap of 20 cm from the floor.

Welding tables are used for welding and assembling parts. They are located inside the welding cabin at a height of 50-60 cm if the post involves welding in a sitting position, or at a height of 90 cm if the work is performed while standing.

The table area is at least one square meter. The requirement for the welder's workplace involves the use of special bolts to which the wires from the welding machine are attached. To suck dust from the welding arc, it is not allowed to place an exhaust hood, since otherwise the flow of gases and dust will pass through the welder’s respiratory tract.

There should be sockets for electrodes on the table. If the desk has a drawer, then documents and tools should be stored there. There is one more requirement: there must be a rubber mat under the welder’s feet.

If the table is equipped with local suction, it can be installed both on the table and outside the room. The fan built into the desk creates noise that reduces productivity. The optimal design for a welder's table is one with lower-side suction and installation of a fan outside the room: then dust and gas do not enter the welder's breathing zone.

Additional amenities may be provided in welding tables . For example, many welders practice stripping the end of the electrode by touching it to the surface of the table. As a result, after a certain period of time, metal growths form on the table, which interfere with the movement of products on the table and worsen its aesthetic properties. To prevent this from happening, the table surface is edged with copper plates at the edges. As a result, the table surface is not contaminated by the electrodes, since the metal does not stick to the copper.

Local lighting may be provided in the table . For welding small parts, when seams are applied around the perimeter, it is advisable to use a rotating table, which is adjustable in height with screws. This allows the parts to be raised and lowered to a comfortable position. During such work, the welder gets less tired and is less exposed to harmful emissions.

To eliminate the awkward position, you need to provide the welder with a seat that is height adjustable.

What are the locations for welding work?

Safety precautions and many other regulatory documents determine the classification of the workplace into several types. An example is the information below:

- Stationary.

- Non-stationary.

The first type is most often associated with special premises in workshops, the second - mobile ones, required for traveling to the site of an accident or construction. The welder's cabin is equipped only once in accordance with safety regulations, after which attention is paid only to the technical condition of critical mechanisms and structures.

Text of the book “Occupational safety during welding work”

3.3. Workplace of a gas welder and gas cutter

To perform gas welding work, you need cylinders with oxygen and flammable gases, an acetylene generator, gearboxes, rubber hoses (sleeves), safety valves, welding torches, cutters, etc.

The workplace of a gas welder and gas cutter is a welding station. Under the term "welding post"

understand the workplace where gas-flame processing of metals is carried out. Work stations can be mobile or stationary.

Mobile work station

used, as a rule, for manual welding work performed in the workshop, as well as during installation and on construction sites.

Gas supply to mobile work stations is carried out according to the diagrams shown in Fig. 3.1. Oxygen and flammable gas cylinders with appropriate pressure reducers are usually used as power sources. Gases are supplied to the working tool (burner or cutter) through a hose at least 10 m long (Fig. 3.1, a).

Instead of an acetylene cylinder, a mobile generator with a safety shutter is sometimes used (Fig. 3.1,

b).

For ease of moving the mobile post, it is allowed to install the equipment on one trolley. The acetylene mobile generator must be no closer than 5 m from the oxygen cylinder during operation. Transportation of the generator in a charged state is prohibited.

A gas welder (gas cutter) must have at his workplace pliers, a hammer, a metal brush for cleaning the metal surface, needles for cleaning mouthpieces and a small crowbar for turning the workpieces (parts), as well as tools (keys) for fastening gearboxes and opening (closing) valves cylinders and eliminating minor malfunctions of burners (cutters).

Rice. 3.1.

Gas supply diagram for a mobile welding station:

a -

from cylinders;

b -

from an acetylene generator;

1 —

oxygen cylinder;

2 —

oxygen reducer;

3 —

cylinder with acetylene;

4 —

sleeves;

5 -

burner;

6 -

mobile acetylene generator

Welders (gas cutters) are supplied with special clothing in accordance with established standards and safety glasses (with filter density C-3 when working with cutters and C-4 when welding with acetylene consumption up to 2500 l/h).

When using mobile posts in enclosed spaces, it is necessary to ensure natural or forced ventilation.

Stationary work station

(Fig. 3.2) is intended for performing manual and mechanized work in a workshop, site or workshop.

Gas supply (gas supply) to stationary posts is carried out centrally: gas is supplied through gas pipelines to places of consumption if the number of posts exceeds 10. With a smaller number of posts, when the installation of gas pipelines is irrational, gas supply from individual cylinders is allowed.

Oxygen is supplied to stationary work stations via a gas pipeline from an oxygen plant, gasifier or bypass ramp, and acetylene is supplied via a gas pipeline from an acetylene plant, stationary generator or bypass ramp. In the latter case, acetylene is supplied directly to the workshop gas pipeline.

Rice. 3.2.

Stationary work station for a gas welder:

1 -

welding table;

2 -

cover;

3 -

box for storing materials;

4 -

filler material;

5 —

reducer for supplying oxygen to the burner (cutter);

6 -

oxygen line;

7 – safety shutter; 8, 9 —

hoses for supplying acetylene and oxygen;

10 -

economizer;

11 -

burner;

12 -

water box;

13 —

swivel chair; ventilation with local air suction in the amount of 1700–2500 m3/h is not shown in the figure

When using other acetylene power sources, a central (group) safety liquid or dry shutter is installed at the entrance of the acetylene pipeline to the workshop, designed to protect the inter-shop gas pipeline from backfire. The type of valve is selected depending on the pressure and flow rate of acetylene.

Directly behind the valve (along the gas flow) at the gas inlet into the workshop, an acetylene input cabinet with a shut-off valve and a pressure gauge is installed, which should be located in an accessible and convenient place. Shut-off valves are located on branches of acetylene pipelines intended for supplying acetylene to individual sections of the workshop.

A pipeline for discharging purge gases into the atmosphere is connected to the acetylene line through a shut-off valve. This pipeline is located at least 1 m above the ridge of the ceiling. Similarly, a discharge pipeline is connected to the oxygen line through a shut-off valve.

At the entrance of the oxygen pipeline to the workshop, as well as at each branch of the intra-shop gas pipeline distribution, shut-off valves are installed.

The height of the acetylene pipeline above the floor must be at least 2.2 m, and the oxygen pipeline - at least 1.6–1.8 m. The oxygen pipeline is laid at least 250 mm below the acetylene pipeline (if parallel). The distance between gas pipelines when crossing them must be at least 100 mm.

In places where gases are consumed, gas dispensing stations are installed on acetylene and oxygen gas pipelines, which include appropriate shut-off, control and safety devices that ensure normal operation of gas welding equipment. It is supplied with oxygen from the gas disassembly station reducer if the oxygen pressure in the gas pipeline does not exceed 1.6 MPa (16 kgf/cm2).

When the oxygen pressure in the gas pipeline cannot be more than 1.6 MPa and the oxygen consumption does not exceed 10 m3/h, a gas dispensing station with a network reducer is used. In this case, connecting the equipment to the gas pipeline is allowed directly (without a gearbox) through a shut-off valve and the gas dispensing station does not have a regulating device.

In all cases, a tool (torch or cutter) must be connected to an acetylene gas pipeline through a safety device: a liquid or dry seal.

When supplying workshop gas pipelines for acetylene from bypass ramps, when the pressure in the network can exceed 0.12 MPa (1.2 kgf/cm2), a gas dispensing station with a dry seal is used. If the pressure in the acetylene pipeline cannot exceed 0.07 MPa (0.7 kgf/cm2), gas dispensing stations with a liquid or dry seal are used.

Safety valves must correspond to the maximum possible pressure in the acetylene line and gas flow. To connect equipment (burners, cutters) to gas distribution stations, hoses are used: for acetylene - class I, for oxygen - class III.

When using acetylene substitute gases with a gas pressure of up to 0.15 MPa (1.5 kgf/cm2), to protect the gas pipeline from the flow of oxygen into it, a check valve is installed at each gas dispensing station instead of a stationary safety liquid or dry valve. In the case when the pressure of flammable gas in the gas pipeline may exceed 0.15 MPa, a reducer is installed that reduces the gas pressure and protects the gas pipeline from oxygen entering it.

The propane-butane mixture is supplied to stationary work stations through gas pipelines from a dispensing station or from bypass (discharge) ramps. A typical gas supply scheme for stationary work stations using oxygen and propane-butane differs from typical schemes using other acetylene substitute gases only in the composition of the equipment. Moreover, the oxygen pipeline is laid above the gas pipeline for flammable gas at a distance of 250 mm. The choice of power sources, shut-off and reducing equipment, as well as safety devices depends on gas flow and pressure.

The stationary work station for manual work includes:

♦ gas dispensing station for supplying gases to burners or cutters;

♦ table with devices for fastening workpieces;

♦ local exhaust ventilation system to remove harmful emissions generated during gas-flame work;

♦ lifting device for moving processed products;

♦ fire-fighting inventory and equipment.

Gas dispensing stations included in the work station are built into the table or placed on gas consumption pipelines.

Work tables for welding are covered with a metal plate or brick. Equipping tables with a general or local ventilation device is carried out taking into account the type of work performed.

Each work station must have a tool (keys) for connecting equipment to power sources and troubleshooting possible problems with the operation of burners and cutters.

There should be a bucket of water next to the welding table to cool the torches during operation.

When gas welding cast iron, in addition to the listed equipment, heating devices (furnace, forge, etc.) are installed at the work station - at a distance of at least 5 m from the work site. Boxes with sand should also be located nearby to cool parts prone to cracking.

The equipment of a stationary post for mechanized work includes a mechanism for moving tools and products (or one of them).

When using oxygen-flux cutting, the flux feeder should be located at a distance of at least 5 m from the cutting site.

Causes of accidents during gas welding work.

The main causes of accidents when performing gas welding work are:

♦ explosion of mixtures of flammable gases with air and oxygen;

♦ explosion of acetylene generators due to backfire and oxygen entering them;

♦ explosion of carbide drums when they are opened due to the presence of an acetylene-air mixture in them;

♦ explosion of oxygen reducers when solid objects in the form of individual grains of sand enter them and the valve of the oxygen cylinder is suddenly opened;

♦ explosion of cylinders and other vessels that are under high pressure during operation due to heating, falls, impacts and other violations of the rules for using cylinders, as well as fire;

♦ ignition of oxygen hoses due to backfire;

♦ self-ignition and explosion when high-pressure oxygen combines with fuels and lubricants;

♦ ignition and explosion of tanks with fuel and liquids during cutting when they are placed near a fire source and the hose supplying flammable gas is incorrectly secured.

In addition, poisoning is possible with combustion products of flammable gases or vapors of the material being welded in the absence of ventilation or personal protective equipment (gas masks, respirators, etc.).

Performing work without appropriate protective clothing and footwear, as well as without safety glasses, leads to body burns and eye disease.

3.4. Gases for gas welding and cutting

Oxygen -

a colorless, odorless gas, heavier than air (the density of oxygen at a temperature of 0 °C is 1.429 kg/m3). Oxygen does not burn, but supports combustion by forming chemical compounds with almost all substances. In gas cutting, oxygen is used to produce a high temperature preheating flame and burn the metal at the cut site. Oil and fat in a stream of oxygen spontaneously ignite as a result of rapid oxidation.

Acetylene

-

a colorless flammable gas, lighter than air, with a weak ethereal odor - it is a chemical compound of carbon and hydrogen.

Technical acetylene, used for gas welding and cutting metals, contains impurities that give it a strong, unpleasant odor. When acetylene burns in oxygen, the flame temperature reaches 3200 °C. Mixtures of acetylene with air and oxygen are explosive if they contain 1.5–82% and 1.5–93.0% acetylene by volume, respectively. They can explode from a spark, open flame or extreme heat.

When heated to a temperature of 450–500 °C and a simultaneous increase in pressure to 153 kPa, acetylene explodes, forming a blast wave in which the gas pressure is 10 times greater than the initial pressure of acetylene.

The explosiveness of acetylene is reduced if it is in thin (capillary) vessels. This property of acetylene is used when filling cylinders under pressure. The density of acetylene in relation to air is 0.9, and in relation to oxygen – 0.8.

The causes of an acetylene explosion can be:

♦ formation of an explosive mixture in the presence of an ignition source; the presence of a catalyst (copper, brass, copper and iron oxides);

♦ temperature above 530 °C and pressure 0.3 MPa (3 kgf/cm2), at which polymerization of acetylene occurs, releasing a significant amount of heat;

♦ strong shocks or impacts from acetylene cylinders; prolonged contact of gas with copper or silver, as a result of which acetylene copper (acetylene silver) is formed, which explodes upon impact or increased temperature (the permissible copper content in the alloys from which acetylene equipment is made does not exceed 70%).

The auto-ignition temperature of acetylene depends on its pressure and the presence of impurities in it.

Propane-butane mixtures

consist of technical propane (C3H8) with an admixture (5-30%) of technical butane (C4H10). Propane, butane and their mixtures are formed during the processing of oil and petroleum products. These gaseous substances are heavier than air, colorless and have a specific odor. At low pressure they liquefy, while at normal pressure the propane-butane mixture turns into a liquid state at a temperature of about -40 °C.

Natural gases

-

these are all flammable gases that are extracted from the bowels of the earth.

They can be found in oil fields and accompany oil during its production. The main component of natural gas is methane (CH4), the volume content of which is 85–98%. The remaining 2-15% comes from nitrogen, ethane, propane, hydrogen sulfide, etc. Natural gas is light, colorless, odorless, non-toxic, but is an asphyxiating gas. To give it a characteristic sharp unpleasant odor, an odorant is added (16 g per 1000 m3 of gas). Natural gas is dangerous because when it burns incompletely, it releases colorless and very poisonous carbon monoxide. When its content in the air is 0.5%, death occurs within 20–30 minutes; at a content of 1%, after several breaths, loss of consciousness occurs, and after 1–2 minutes, death occurs.

Gas MAF

(methyl acetylene-allen fraction), belonging to the group of liquefied gases, began to be used in recent years for oxy-fuel welding and cutting of metals. MAF gas is produced according to TU 38.102.1267; grade A – for gas-flame processing, grade B – for organic synthesis.

The main flammable components that determine the properties of MAF gas are methyl acetylene and alley. Their content in the mixture is 70–75%, the remaining 25% is propane and propylene. In terms of fire and explosive properties, MAF gas is similar to propane.

The combustion temperatures of acetylene (3200 °C) and MAF (2927 °C) are close to each other.

A characteristic indicator of the combustion process is the amount of oxygen that must be supplied to the cutter (burner). For acetylene and MAF, the amount of heating oxygen supplied to the cutter (burner) per 10,000 kcal is approximately the same: 0.95 and 1.04 m3, respectively; for propane – 1.68 m3. Thus, when replacing propane-butane with MAF, the consumption of heating oxygen decreases by 1.6 times. When burning 1 m3 of MAF, 1.3 m3 of heating oxygen is saved compared to working with propane-butane.

Gases are prone to explosive self-disintegration, therefore, to obtain a stable combustion process, it is necessary to ensure good mixing of the combustible gas and preheating oxygen supplied to the cutter (burner).

If oxygen and gas are not mixed well, the flame becomes smoky and has a “whisker” appearance.

MAF gas has its own characteristics, so its use requires modification of equipment (welding torches and cutters). The number of tips for MAF is increased compared to similar tips for acetylene.

To replace 1 m3 of acetylene, 0.62 m3 of MAF gas is required, or 1.06 kg (density 1.7 kg/m3). Thus, 1 kg of MAF gas replaces 3.2 kg of calcium carbide. One cylinder of MAF gas weighing 21.2 kg replaces four cylinders of acetylene (acetylene cylinder capacity is 5.5–6.0 m3).

One cylinder of MAF gas replaces two cylinders of propane-butane, and the oxygen savings is 22 m3. When working in winter, there is no need to heat cylinders with MAF gas; complete evaporation of the gas occurs at a temperature not lower than minus 27 °C.

When oxy-fuel cutting of metal, two processes are combined: heating the metal to an ignition temperature of 1050 ° C and burning the heated metal in a stream of pure oxygen. Heat transfer to the metal and its heating to the melting temperature at the beginning of the cutting process are carried out according to the same laws as during welding.

It is known that when switching from acetylene to natural gas or propane-butane, the heating time of the metal when cutting into a sheet from the edge or when punching a hole in the sheet increases by 30%. When using MAF gas this time is reduced.

When the metal is heated with a high-temperature MAF-oxygen flame, it becomes possible to cut into the sheet “on the fly” without stopping to heat the edge of the sheet and pass through counter cuts without stopping. Using propane-butane does not allow cutting at such speeds.

According to TU 38.102.1267, empty cylinders for refilling provided to the MAF gas manufacturer must have a residual pressure of at least 0.05 MPa, regardless of the time of year.

3.5. Operation of cylinders

Operation of cylinders for compressed, liquefied and dissolved gases.

Cylinders are designed for storing and transporting relatively small quantities of a certain type of gas: compressed (air, oxygen, nitrogen, hydrogen, etc.), liquefied (gaseous hydrocarbons, ammonia, chlorine) or dissolved (acetylene).

Data on cylinders for gases used in gas welding and cutting are given in table. 3.1.

Table 3.1.

Data on gas cylinders

The upper part of the cylinder has a neck into which a shut-off valve with a side outlet fitting is installed on the thread. If the cylinder is inoperative, then a plug is screwed onto the fitting. To protect the valve from damage, a metal or plastic cap is installed on the cylinder.

Strict labeling of cylinders has been introduced. The side fittings of valves for cylinders with flammable gases are made with a left-hand thread, and for cylinders with oxygen and other non-flammable gases - with a right-hand thread, in order to prevent misuse and the formation of explosive mixtures. Cylinders should be protected from impacts, as well as from high and low temperatures.

The maximum operating pressure in a cylinder at a temperature of 20 °C for compressed and dissolved gases is 15 MPa (150 kgf/cm2), and for liquefied gases – 3 MPa (30 kgf/cm2). If the cylinder temperature significantly exceeds the specified value, the gas pressure may exceed the permissible limit.

The following data is stamped on the upper, spherical part of each cylinder:

♦ trademark of the manufacturer;

♦ cylinder number;

♦ actual weight of an empty cylinder (for cylinders with a capacity of up to 12 liters inclusive - with an accuracy of 0.1 kg, from 12 to 55 liters inclusive - with an accuracy of 0.2 kg, over 55 liters - in accordance with the state standard or technical specifications for their manufacture) ;

♦ date (month and year) of manufacture and year of the next survey;

♦ working pressure;

♦ test hydraulic pressure;

♦ cylinder capacity (for cylinders with a capacity of up to 12 liters inclusive - nominal; from 12 to 55 liters inclusive - actual, with an accuracy of 0.3 liters; over 55 liters - in accordance with the state standard or technical conditions for their manufacture);

♦ the manufacturer’s quality control department stamp, round in shape with a diameter of 10 mm (except for standard cylinders with a capacity of over 55 liters); standard number for cylinders with a capacity of over 55 liters.

The height of signs on cylinders with a capacity of up to 55 liters inclusive must be at least 6 mm, and over 55 liters - at least 8 mm.

The weight of cylinders, with the exception of acetylene cylinders, is indicated taking into account the weight of the applied paint of the ring for the cap and shoe, if provided for by the design, but without the weight of the valve and cap.

The area on the cylinders where the passport data is stamped must be coated with colorless varnish and surrounded with distinctive paint in the form of a frame.

On cylinders with a capacity of up to 55 liters or with a wall thickness of less than 5 mm, passport data can be stamped on a plate soldered to the cylinder or applied with enamel (oil) paint.

Painting and marking of newly manufactured cylinders is carried out by manufacturing plants, and subsequently by filling plants, filling or testing stations.

The inscriptions on the cylinders are applied around the circumference, not less than 1/3 of it, and the stripes are drawn along the entire circumference, and the height of the letters on cylinders with a capacity of more than 12 liters should be 60 mm, and the width of the stripe should be 25 mm. The sizes of inscriptions and stripes on cylinders with a capacity of up to 12 liters depend on the area of the lateral surface of the cylinders.

It is prohibited to fill cylinders with gas if the periodic inspection period has expired, there are no established stamps, the valves are faulty, the body is damaged (cracks, severe corrosion, noticeable changes in shape), the cylinder is poorly painted, the coloring does not meet the standard, or the inscription on the cylinder is unclear.

Compressed gas cylinders are rejected if there is a weight loss of more than 20%, an increase in capacity of more than 3%, or the presence of other defects.

With a weight loss of 7.5–10% and an increase in capacity by 1.5–2.0%, the pressure in the cylinders is reduced by 15% compared to the originally set one.

With a weight loss of 10–15% and an increase in capacity by 2–2.5%, the pressure in the cylinders is reduced by at least 50%.

With a weight loss of 15–20% and an increase in capacity by 2.5–3%, the pressure in the cylinders should not exceed 600 kPa.

Cylinders in service are inspected at least once every 5 years. Cylinders intended for filling with gases that cause corrosion, as well as cylinders for compressed and liquefied gases used as fuel for cars and other vehicles, are subject to inspection at least once every 2 years.

Periodic inspection of cylinders is carried out by employees of filling plants, filling or testing stations.

If satisfactory results are obtained, each cylinder is marked with a stamp (round, 12 mm in diameter) of the filling plant where the survey was carried out, the date of the survey and the date of the next survey (on the same line with the manufacturer’s stamp).

The results of the cylinder inspection are recorded in the test log. Permission to inspect cylinders is issued to organizations by the local Promatomnadzor body.

Acetylene cylinders. Acetylene becomes explosive at a pressure of 200 kPa, therefore, for its safe storage and transportation at higher pressure, the internal cavity of the cylinder (2/3 of the volume) is filled with a porous mass - birch activated carbon, impregnated with acetone, which dissolves acetylene well. The cylinders are filled with porous mass and solvent in accordance with the state standard. Responsibility for the quality and quantity of the porous mass lies with the plant that fills the cylinders with it. Responsibility for the quality and quantity of the solvent lies with the plant that fills the cylinders with it.

After filling the cylinder with the porous mass and solvent, the mass of the container is knocked out on its neck (the mass of the cylinder without a cap, but with the porous mass and solvent, shoe, ring and valve).

To prevent solvent leakage (along with acetylene), filled cylinders must always be in a vertical position.

Inspection of acetylene cylinders must be carried out at the plant that fills them with acetylene at least once every 5 years. This includes external surface inspection, porous mass testing and pneumatic testing.

The condition of the porous mass in acetylene cylinders must be checked at the relevant filling plants at least once every 2 years. After checking the porous mass, each cylinder is marked with the year and month of the test, the mark of the filling plant and a mark (12 mm in diameter with the letters “Pm”) certifying the check.

During inspection, acetylene cylinders filled with a porous mass are tested with nitrogen under a pressure of 3.5 MPa, immersing them in water to a depth of at least 1 m. The purity of the nitrogen used for testing cylinders must be at least 97%.

In 1 liter of acetone at a pressure of 3 MPa (30 kgf/cm2) and a temperature of 20 ° C, 23 liters of acetylene are dissolved; With increasing pressure, the solubility of acetylene increases almost in direct proportion to the pressure.

Acetylene cylinders have a 1/2″ diameter valve with a left-hand thread. They are filled with gas under a pressure of 19 kgf/cm2. A cylinder with a capacity of 40 liters at this pressure contains 4–5 m3 of acetylene.

To store acetylene, cylinders with a diameter of 219 mm, a wall thickness of 7 mm, a capacity of 40 and 50 liters, a height of 1390 and 1700 mm, and a weight of 52 and 64 kg are used.

Oxygen cylinders.

A compressed gas cylinder consists of a cylindrical body with a convex bottom, an upper spherical part having a neck and a ring. A valve with a diameter of 3/4″ with a right-hand thread is screwed into the neck. To give the cylinder stability, a shoe is placed on the lower part of the body. A threaded ring is pressed onto the neck of the cylinder for screwing on a protective cap. Cylinders should be stored in an upright position, protected from shock and heat.

For oxygen, the most widely used cylinders are those with a capacity of 40 liters, having a body diameter of 219 mm, a height of 1390 mm and a wall thickness of 8 mm. The mass of such a cylinder is 67 kg. At a pressure of 15 MPa (150 kgf/cm2) and a temperature of 20 °C, it contains 6000 liters, or 6 m3, of oxygen. The cylinder is tested under a pressure of 22.5 MPa (225 kgf/cm2) once every 5 years.

The following requirements are imposed on oxygen cylinders: they must be in good working order, promptly inspected, painted blue and labeled “Oxygen.” The side fittings of cylinder valves with right-hand threads must be screwed in using foil or using liquid sodium glass, without using oiled parts and gaskets.

Storage and transportation of cylinders. IN

Under production conditions, compressed gas cylinders are stored with wrapped safety caps in special warehouses or under a canopy in a vertical position, in the nests of special racks. Due to the fact that compressed gas cylinders pose a great danger, no more than 50 cylinders are allowed to be stored together. The distance from the cylinder warehouse to buildings under construction and existing buildings must be at least 20 m.

Storing oxygen cylinders together with cylinders containing acetylene, propane, hydrogen and other flammable gases, as well as calcium carbide, paints and oils is strictly prohibited.

In the warehouse, the rules for the operation, storage and transportation of cylinders must be posted in a visible place. Storekeepers, loaders and other workers servicing cylinders must be trained in safety rules and instructed.

Warehouses for storing cylinders filled with gases must be one-story, with light-type coverings and without attics. Walls, partitions and coverings are made of fireproof materials of at least II degree of fire resistance; Windows and doors must open outwards. The height of storage areas (from the floor to the lower protruding parts of the roofing) must be at least 3.25 m.

The floors of warehouses must be level, with a non-slip surface, and the floors of warehouses for flammable gas cylinders must have a surface made of materials that prevent sparking when any objects hit them.

Lighting in warehouses for flammable gas cylinders must comply with the standards for hazardous areas.

The warehouse is divided by fireproof walls into compartments, in each of which it is allowed to store no more than 500 cylinders with flammable or poisonous gases and no more than 1000 cylinders with non-flammable and non-toxic gases (cylinder capacity 40 liters).

Compartments for storing cylinders with non-flammable and non-toxic gases can be separated by fireproof partitions at least 2.5 m high with open openings for the passage of people and mechanical equipment. Each compartment is equipped with an independent exit to the outside.

Cylinders are moved to gas filling and consumption points on special carts or using other devices. Cylinders filled with gas should be transported on spring vehicles or trucks in a horizontal position, with gaskets between the cylinders. Wooden blocks with cut-out sockets for cylinders, rope or rubber rings with a thickness of at least 25 mm (two rings per cylinder), etc. can be used as gaskets. All cylinders during transportation must be laid with valves in one direction.

When loading, unloading, transporting and storing cylinders, measures must be taken to prevent falling, damage and contamination of cylinders.

Standard cylinders with a capacity of more than 12 liters should be transported and stored with the caps screwed on. Filled cylinders can be stored at the filling plant until they are released to consumers without safety caps. When transporting and storing cylinders with poisonous and flammable gases, plugs are placed on the side fittings of the cylinder valves. Cylinders filled with gases must be protected from sunlight during transportation.

Stationary workplace

A stationary welder's position is found in various production workshops. They are suitable for welding small products. Among the features of equipping such premises, the following points can be noted:

- If the premises are properly equipped, unhindered access to workpieces is ensured.

- Explosive and flammable substances should not be located nearby.

- When using inverters that operate on flammable substances, cylinders should be located away from open flames.

- Unobstructed access should be provided to consumables, for example, electrodes and wire. This is due to the fact that during welding you need to quickly change some elements.

- The stationary location is prepared taking into account exactly which elements will be welded together. Safety precautions require that the welder's workplace ensures that the workpieces remain stationary during processing.

Stationary welding station

Training is carried out by following specific instructions, which are developed by an employee of the organization.

Other requirements

Also, do not forget about the following additional tools that make the welder’s work easier. This:

- screw clamps for tight contact with the product;

- wire brushes (manual and electric) - to remove slag and rust;

- narrow and wide steel brush for cleaning edges and seams;

- chisels, stamps and hammers - for cutting out places with defects, eliminating splashes, installing a stamp, etc.;

- a hammer with a pointed end for beating off slag;

- a set of templates for measuring the size of seams;

- canvas bags or glasses - for storing electrodes.

The welder should have easy access to consumables: electrodes, wire, flux, etc., so that he can easily change them during work. It is necessary to follow the labor protection instructions individually and generally.

If the welder works with a non-consumable electrode, then he must have a set of sharpened tungsten electrodes, pliers, wrenches, wire cutters, pliers, etc. The tool should be stored in a special box or bag.

Thus, the overall efficiency and safety of the work depends on how competently the workplace of a welder using the manual arc welding method was organized. The workplace is understood as an area assigned to the welder, which is equipped with equipment, tools and devices for welding. A properly organized place reduces injuries and accidents at work.

Mobile post

A mobile place can be created for a gas and electronic inverter. It is worth considering that a welding cabin is required for its installation in case of high ambient humidity.

The fewest problems arise when using gas welding. This is because electrical equipment must be reliably powered.

Mobile post

Welding wires: purpose, recommended cross-sections

The organization of the welding station involves the use of a cable of the most suitable cross-section. This indicator should be taken into account for the following reasons:

- If the cross-section is too small, the cable cannot withstand the load and begins to overheat. As a result, heat acts on the insulation, causing it to melt. If the damage is severe, a short circuit may occur.

- Large cables are expensive. At the same time, they are less practical to use; transportation and storage creates many problems.

Welding wires

Cable selection is carried out in accordance with regulatory documentation. The organization of the welder's workplace is carried out taking into account the fact that the cables should not be intertwined, all contacts should be fixed. Cable and other electrical equipment should not be located near flammable materials or water.

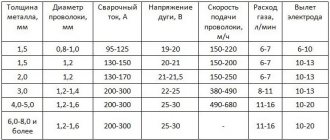

The optimal cross-sections of the welding wire are presented in the following table. As previously noted, the choice of wires is selected depending on the power of the equipment used by the welder. The optimal indicator is selected in accordance with the table.

Table of cable cross-sections depending on power

Using tabular data allows you to avoid quite a lot of problems. A high-quality cable has effective insulation, which eliminates the possibility of a short circuit.

Table

For convenient welding operations, it is practical to place the product on the table. This increases the speed of welding and the convenience of welding in hard-to-reach places. The welder's table is made to individual sizes, based on the dimensions of future products. The legs must be height adjustable to accommodate workers of different heights.

The table should include devices for:

- safe placement of the holder during the process of rearranging the product;

- quick access to consumables and easy electrode change;

- location of tools (hammer, file, flashlight, slag separator, metal brush);

- ignition of the electrode on the rough surface;

- installation of non-standard structures with protrusions in special holes.

How to choose an electric holder

When organizing your workplace, you also need to choose the right electrical holder. How safe the workplace will be and what labor productivity will depend on its technical condition. The welding station can be equipped with several types of holders, it all depends on the type of work being carried out.

When choosing such a device, pay attention to the following points:

- Weight should not be more than 0.5 kilograms. Excessively heavy versions complicate the welder's task. When welding for a long time, your hands will get tired, which will ultimately reduce your productivity.

- Attention is paid to how comfortable the grip is. To prevent the handle from slipping, its surface is often grooved.

- During operation, the structure should not become very hot. Otherwise, problems may arise during prolonged welding. Although the welder must use special gloves, high heat causes significant discomfort.

- The surface must be insulated, since such an element should become a barrier to electricity in the event of a malfunction. When organizing the workplace, attention is paid to the quality and integrity of the insulation.

- The fastening of the electrodes must be strong, since at the moment of contact with the surface they are subject to mechanical stress.

Electric holders

It is recommended to purchase original electrical holders recommended by the manufacturer for organizing the workplace. Before each work, the condition of the structure is checked.

Installation of gas equipment

The gas welder's workplace is set up according to a similar principle. The color of the walls of the protective shields does not matter here, since the gas flame does not emit ultraviolet radiation. The main thing is that the welder can clearly see all the parts in the workplace.

A significant difference is the location of the cylinders. Although a trolley is used for transportation, on which an oxygen and acetylene cylinder are immediately installed, before performing welding work they must be separated from each other by at least 5 meters. The same should be done with propane equipment.

In this case, it is important to maintain a distance of 5 m between the cylinders and the area to be welded. As a result, the arrangement should look like a triangle, with the element to be welded on one vertex and gas cylinders on the other two

It is important that there is nothing in the way of the acetylene generator or cylinders. This allows quick access to equipment in the event of a flashback.

This can prevent an explosion and serious injury. The hoses are located on the side so that they are not walked on or driven on. Otherwise, the flame will go out and rubber communications may deteriorate.

The welder's main tool is the holder. Productivity and quality depend on its convenience and thoughtfulness. The holder can be of two types: to clamp the electrode like a clothespin, or to tighten it by twisting the handle. Regardless of the type, it should allow the electrode to be changed in 4 seconds.

The structure is well insulated to prevent electric shock. The cable and the holder itself constantly exert their weight on the welder’s hand. Therefore, the mass of these elements should be minimal so as not to overwork the welder and not limit movement.

If work is carried out at high current (from 500 A), then the holder is equipped with a protective pad that prevents the welder’s hand from being damaged by high arc temperatures. When the welding current exceeds 600 A, the cable is passed to the electric holder, bypassing the handle that the worker grasps. The sides that secure the electrode are subject to the adhesion of molten metal splashes, making it difficult to replace a new consumable element. This slows down the entire process and the welder gets tired faster. To prevent this effect, the surface of the holder on which drops of metal fly is lubricated with a scraper and cleaned at the end of the day with a needle file.

For convenient welding operations, it is practical to place the product on the table. This increases the speed of welding and the convenience of welding in hard-to-reach places. The welder's table is made to individual sizes, based on the dimensions of future products. The legs must be height adjustable to accommodate workers of different heights.

The table should include devices for:

- safe placement of the holder during the process of rearranging the product;

- quick access to consumables and easy electrode change;

- location of tools (hammer, file, flashlight, slag separator, metal brush);

- ignition of the electrode on the rough surface;

- installation of non-standard structures with protrusions in special holes.

An important attribute of an electric gas welder’s workplace is a hood. It ensures the removal of harmful heavy gases from the melting metal and electrode coating. It is not practical to place it in the form of a large umbrella over the table, since part of the harmful mixture will pass through the welder’s respiratory system.

It is advisable to install a flexible side air suction system, which will immediately pick up harmful gases without allowing them to rise to the worker’s face. Such a line will ensure that the hood can be moved to any location within the welding cabin. At the same time, it is worth remembering that the noise of the engine disturbs the worker, so the power unit for pumping air is located outside the room.

Creating comfortable conditions for the welder improves the quality of seams and the process of producing finished products. Reducing passive harm at work and protecting personnel from injuries helps maintain a permanent team and harmonious interaction among employees.

Electric welder mask as a means of protection

Safety precautions for organizing a place for welders include the use of special shields and a helmet. When manufacturing them, the standards established in GOST 12.4035-78 must be taken into account. Among the main standards we note the following:

- The structure should not be heavier than 0.5 kilograms. Otherwise, it will be difficult to carry out the work.

- In order to protect the eyes, light filters are installed. They are divided into 13 classes, the choice is made depending on the power.

- When choosing a mask, attention is paid to ensuring that it fits comfortably. From time to time the welder has to open it for visual inspection of the seam.

Welder mask

There are a wide variety of protective masks available on the market. More expensive versions are characterized by greater efficiency. If you frequently carry out welding work, it is recommended to purchase a high-quality product, since ultraviolet and other radiation can be harmful to health.

Mobile welding station: equipment and fire safety requirements

Self-taught welders in most cases carry out welding work at home in places that are more or less suitable for such work.

Professional craftsmen know how important it is to provide the most comfortable and safe working conditions, so they organize special welding stations. After all, the characteristics of the workplace largely determine how safe it will be for a craftsman to use welding equipment in practice.

What is a welding post and what are its types?

A welding station is a kind of welder’s office with the entire complex of equipment, tools and consumables necessary for his work to ensure uninterrupted performance of welding work. That is, this is a welder’s workspace in which it is as comfortable and safe to work as possible.

If all work on arranging welding stations is carried out taking into account labor safety requirements, this will provide the foreman with the maximum level of safety when welding. At the same time, the level of fire resistance of the space will be maximum. But to achieve this, it is important to understand the specifics of different types of welding posts.

Stationary welding station.

Based on the type of equipment used in the work, welding stations are:

- Gas welding. The workroom for gas welding work is equipped taking into account the fact that the melting of metal in the process of organizing the joining of product edges in this case is based on the use of thermal energy from gas combustion in the burner. Therefore, the space must be equipped with the highest quality ventilation system, and surface finishing must be done with non-combustible materials.

- Electric welding. The workspace of an electric welder when working with electric welding is no less dangerous, but in this case it is important to pay more attention to ensuring a high level of human protection from electric shock.

Stationary post for manual welding.

Based on the capabilities, welding stations are:

- Stationary. They look like an open-top cabin, which is raised above the level of the floor covering, are located indoors and can be equipped with a moving tabletop.

- Mobile. They are mobile structures that can be moved to another place for work without much difficulty. Mobile stations for welders are relevant for welding large-sized structures in spacious workshops or directly in the open air on a construction site.

In a stationary welding station, it is convenient to weld small and medium-sized parts, but it is not suitable for large components and metal structures. The cabin is made of rolled metal with a zinc-containing coating, resistant to high temperatures and infrared radiation.

A special feature of a mobile workplace is that there is no need to carry out special events or create special working conditions. The mobile welding station is protected from precipitation by means of a canopy, and from wind by means of screens.

Tools relevant for welding work are placed in special cabinets, and lighting of the space is provided by local light sources.

Making a welding station with your own hands

The welder’s workspace with a set of necessary equipment, tools, consumables and the welding machine itself is called a welding station. You can organize it yourself if you carefully study the standards and safety requirements for such offices.

When organizing a mobile welding station, additional devices will be required, since the entire complex of items, equipment and tools present in it must be movable.

The stationary type of welder’s workplace does not need to be moved, so when organizing it there is no need for supports on wheels, etc.

Regardless of the type of welding station, the work will require non-flammable materials to eliminate the risk of fire: for both permanent and temporary use of welding, it is important to provide the craftsman with safe working conditions.

Current tools and materials

When setting up a workplace for welding work, it is important to select a full range of tools and equipment that are relevant for the job.

Welding booth layout.

The list may change at the discretion of the welder, but there are positions that are extremely difficult to do without:

- welding machine;

- a device for storing filler materials and other types of auxiliary devices;

- constant power supply of electric current;

- comfortable landing place;

- switch for turning the voltage supply on and off;

- high-quality ventilation system, exhaust chamber;

- storage systems for small equipment: portable baskets, drawers, shelves, etc.;

- electric holder

The above elements, with rational planning of the workplace space, will take up relatively little space.

Equipping a welding station yourself must be carried out taking into account all safety requirements. The optimal length of the working space is 2 m, width – 2.5 m, height – 2 m. In no case should you create a closed upper part of the welding station.

To organize the walls, it is worth using thin steel or plywood impregnated with a fire-resistant solution.

To perform assembly and welding operations of metal parts inside the master’s office, it is important to install a comfortable table. The optimal parameters of the welding table are as follows: the height is 50-60 cm when working while sitting and about 90 cm when working while standing, and the area is about 100 cm2.

Steel bolts should be welded to the table, onto which the current-carrying wire from the welding current source, as well as the grounding wire of the work table, are attached.

On the side there are nests adapted for storing electrodes and filler materials. Drawers can be used to store small hand tools or technological documentation.

The main type of equipment in welders' offices is considered to be single- or multi-station arc power sources.

Often, in the workspace, welders use single-station power sources, since in the case of power from multi-station sources, the welding current must be distributed throughout the cabins through the use of current-carrying wires or buses. Also, a switch must be installed in the cabin to turn the welding current on and off.

Step-by-step arrangement of a welding station

General view of a typical welding station.

Welding stations can be organized in a spacious garage, service station, construction site, etc.

In any case, all operations for their arrangement can be divided into the following stages:

- choosing a place to organize the master’s workspace, clearing it of foreign objects, cleaning;

- arrangement of the walls of the working area using steel or plywood impregnated with a fire-resistant composition;

- arrangement of a table with a table top and storage systems made of non-flammable material;

- providing access to a source of electricity for the operation of electrical equipment;

- organization of a reliable ventilation system;

- visual inspection of the work result before welding.

Basic requirements for arranging welding stations

Portable welding station.

Regardless of the type of equipment used, the basic fire safety requirements for organizing a welder’s workplace are almost always the same and have a single goal - to provide the worker with comfortable and safe conditions for welding operations:

- protect the welder’s workplace with screens made of fireproof materials, but do not equip it with a closed top;

- welding with a device in a shielding gas environment should only be carried out if the cabin casing does not reach the floor by 30 cm, and the height of the light shield exceeds 2 m;

- make the casing of the cabin and the light protection screen from fireproof materials;

- the cabin area should not be less than 4.5 m, otherwise there will not be enough space to accommodate welded equipment, assembly units, fixtures and parts storage systems;

- surround the plasma cutting machine with a continuous fence made of fireproof materials with a height of at least 2.2 m;

- There is no point in placing 2 or more welding tables in one cabin, but if necessary, they must be separated by a light-protective screen to avoid fire.

Separately, we note the special role of the ventilation system in arranging a welder’s workplace. This point must be strictly controlled by the foreman, as it directly affects the level of safety of the welding station.

Experts advise the following:

- It is worth organizing local and general exhaust ventilation. Local suction is provided for each unit and workspace if vapors of harmful substances are released into the air.

- Hoods are equipped with filters that clean the air from welding aerosols and release it into the workshop or atmosphere.

- The supply of supply air is carried out dispersed when welding in shielding gas or concentrated in the upper zone when welding by other methods.

- It is preferable to choose a matte finish for the walls so that their surfaces do not reflect welding glare during the operation of the welding unit. For the same purpose, the floors should be made of concrete.

If these requirements for the parameters of welding stations and the ventilation system of the master’s workspace are met, the welder can begin work.

Of course, different situations can happen in life, but the described precautions when assembling metal structures using welding machines significantly reduce the risk of injury to the craftsman and a fire from a welding spark.

Conclusion

The post for performing welding work must be equipped in such a way that the foreman is provided with high fire safety.

For this reason, it is worth using exclusively non-flammable materials when organizing walls, flooring, storage systems for equipment, do not forget about grounding and establish good ventilation of the workspace.

Share: Facebook

- Previous entryHow many types of welding are there

- Next entryDo-it-yourself metal welding products

No comments yet

Ventilation requirements

It is necessary to pay attention to the efficiency of ventilation when organizing the place, especially when working with a gas apparatus. Its purpose is to remove warm air and supply cold air, which is required for cooling tools and equipment.

During operation, quite a large amount of toxic gases can be formed. At high concentrations there is a risk of poisoning. If the concentration of gases is high, then there is a possibility of their detonation.

As a rule, artificial ventilation is represented by air ducts that supply and discharge air. To improve operating efficiency, a fan is installed. Problems with equipment cooling and gas pollution practically do not arise when work is carried out outdoors.

More about ventilation

Ventilation is one of the most important elements that must be taken into account when organizing a stationary post. This is especially true for those workplaces where gas is planned to be used. Ventilation is necessary to remove vapors generated during work.

When working at a stationary workplace, a huge amount of dangerous vapors and fine dust is generated. They negatively affect the health of the welder and in some cases can ignite or explode.

To avoid this, an air duct with forced ventilation is mounted above the work station. It works throughout the entire welding operation, and helps not only get rid of dangerous fumes, but also cools the equipment.

When working outdoors, special ventilation is not needed. Natural air movement is more than enough.

Requirements for special clothing

Special clothing can be considered personal protective equipment. It is manufactured taking into account the characteristics of metal processing, as well as the possible impact. The kit includes:

- Mittens.

- Special shoes.

- Jacket.

- Mittens.

- Trousers.

Welder's overalls

In most cases, they are made using tarpaulins to which asbestos is added. Due to this composition, the surface becomes much more resistant to the ingress of molten metal.

Advantages of welding curtains

Special curtains are very popular. They make it possible to significantly simplify work and divide the site into several sectors. The features of such equipment include the following points:

- Fire-resistant fabric is used in production.

- The material used can also withstand minor mechanical stress.

Variety of welding curtains

There are several versions of such equipment, each characterized by its own characteristics.

Solid standard curtain

Most often, a continuous curtain is installed. It is represented by a solid material that is attached to special load-bearing elements. Among the features we note:

- Visual protection and blocking ultraviolet radiation.

- Protects the environment from splashes and molten metal.

- The negative impact of side air flows is reduced.

Solid standard curtain

When choosing the most suitable curtain, attention is paid to the width of the seams, the thickness of the material and some other points.

Strip welding curtain

The protective curtain is selected taking into account various parameters. The main ones can be called:

- Thickness and type of material. Some fabrics are characterized by increased resistance to temperature.

- High-quality versions are stitched.

- Type of supporting structure.

Strip welding curtain

Such protection can be installed quickly; after the process is completed, it is quickly assembled. The supporting element is made of corrosion-resistant metal.