Manufacturing of gasified models

The process of obtaining models in mass and large-scale production consists of two stages: preliminary foaming of the initial granules of expandable polystyrene in a free state and final foaming of the granules in a closed cavity of the mold - obtaining the model.

Pre-heat treatment

foaming polystyrene is necessary to obtain a subsequently gasified model with a given volumetric mass (density), which determines the strength of the model and the quality of the surface. The foaming ability of granules of a given dispersion is determined by the temperature and time of heat treatment (Figure 7.2).

Figure 7.2

– Increase in the volume of polystyrene foam granules (V) depending on temperature (numbers near the curves) and duration of foaming (t): solid lines – initial granule size 2.5 mm; dotted – 1.5 mm

With an increase in the duration of heat treatment, the volume of the granules increases and, accordingly, the bulk density of the foamed granules decreases. Increasing the processing temperature leads to a reduction in the time at which the granules reach their maximum volume. But at temperatures above 95°C the process becomes unstable and overexposure of the granules leads to loss of activity and shrinkage. This is due to an increase in the rate of deformation of the polystyrene shell of the granules with increasing temperature, as a result of which the walls of individual cells of the granules are destroyed and the loss of porogen occurs.

In enterprises with a small production volume, it is advisable to carry out preliminary foaming in hot water. To do this, the original polystyrene granules are placed in water at a temperature of 95 - 100 ° C and kept for 1 - 10 minutes with constant stirring to ensure uniform heat treatment and prevent the granules from sticking together. After the period of time necessary to foam the granules to a given bulk mass, they are removed and placed on racks with a mesh bottom for drying and exposure to air.

To heat the granules during pre-foaming, steam and high-frequency currents are also used. In large-scale and mass production conditions, superheated steam is most often used.

After preliminary foaming, the granules are kept in air for 6 hours to 2 days. During this period, the shell of the granules, cooling, again transforms into a glassy solid state, and isopentane vapor condenses, which leads to the appearance of a vacuum in the granules. During the holding process, air diffuses into the granules and the pressure equalizes. To reduce the holding time of foamed granules, you can use their holding at a pressure increased to 0.2 - 0.3 MPa.

Source materials

Paraffin is a mixture of limiting hydrocarbons with the general formula CnH(2n+2), a product of the sublimation of oil, brown coal and oil shale. It is a white mass with a crystalline structure. Paraffin gives the models plasticity and resistance to cracking. It is the cheapest and most abundant component of the model composition. The disadvantages of paraffin include: low strength, exceeding 28 oC, foaming ability in the molten state. Paraffin fuses well with stearin at a temperature of 70-80 oC and lignite wax at 100-110 oC.

Stearin is a mixture of fatty acids, a product of the processing of vegetable and animal fats. It is an amorphous whitish-yellow mass. Stearin increases the heat resistance and strength of models. This is a scarce and expensive material (8 times more expensive than paraffin). The disadvantages of stearin are interaction with ethyl silicate and saponification in water.

Lignite wax is a mixture of wax, resin and asphalt-like substances, a product of processing bituminous brown coal. It is a homogeneous mass of dark brown color. Serves as the main substitute for stearin. Lignite wax has high strength and hardness, significant fragility, and contributes to the formation of a hard, shiny surface of the model. The disadvantage of lignite wax is its carbonization during the burning process in a ceramic form with a lack of oxygen.

Ceresin is a mixture of solid high-molecular hydrocarbons of the methane series, obtained as a result of processing and purification of ozokerite or petrolatum. This is an amphora of light yellow color. Non-scarce material. Ceresin has higher ductility and heat resistance than paraffin and stearin. The disadvantages of ceresin are significant linear shrinkage, low strength and hardness. Ceresin fuses well with paraffin and stearin at a temperature of 70-80 oC, with lignite wax - at 100-110 oC, with rosin - at 140 oC.

The bottom residue of paraffin cracking is a mixture of high molecular weight saturated and unsaturated hydrocarbons. Used as a plasticizer (increases plasticity and elasticity). When more than 8% of the residual residue is introduced into the model composition, it reduces heat resistance and strength.

Ethylcellulose is a type of cellulose ether. It is a finely crystalline white or light yellow powder. Ethylcellulose is used as a plasticizer and hardener for paraffinostearin compositions, as well as compositions with rosin and ceresin. The content of ethylcellulose in the model composition should not exceed 5%, otherwise the model composition will stick to the equipment. Ethylcellulose mixes well with liquid stearin, but does not fuse with paraffin.

Peat wax is a mixture of high molecular weight hydrocarbons, a product of processing peat with various solvents. Compared to stearin and paraffin, peat wax has higher strength and heat resistance. The disadvantages of peat wax include fragility and increased viscosity in the molten state.

Polyethylene is a synthetic high-molecular compound obtained by polymerization of ethylene (CH2 - CH2)n under pressure (120-250 MPa). Polyethylene increases the heat resistance and strength of paraffin by 1.5-2 times. The disadvantages of polyethylene are significant shrinkage (up to 3%), increased viscosity in the molten state, which reduces the fluidity of the model composition. Polyethylene fuses well with stearin and rosin.

Rosin consists mainly of resin acids. This is a fragile glassy mass. It is used to give model compositions increased strength and heat resistance. With a high content of rosin in the model composition, it becomes brittle, sticks to the equipment, and loses its technological properties after repeated use.

Polystyrene is a thermoplastic material obtained by polymerization of styrene. It is used not only as an independent material for making models, but also as a component of the model composition, increasing its heat resistance and mechanical strength. The polystyrene model is difficult to remove from ceramic shells.

Expanded polystyrene is a thermoplastic material in the form of granules, obtained by suspension polymerization of styrene (C6H5 - CH = CH2) - in the presence of a volatile foaming agent. It is the starting material for making models.

Urea - CO(NH2)2 technical urea - a crystalline material obtained by heating ammonia and carbon dioxide at a temperature of 150 oC and a pressure of 450 MPa. When heated, urea does not go through the softening stage. It is the main component of water-soluble model compositions. Provides low linear shrinkage and high strength of the model.

Boric acid - shiny flakes or colorless small crystals - is a component of the water-soluble model composition.

Table 1. Basic properties of starting materials

| Material | Density, g/cm3 | Melting point, oС | Linear shrinkage, % | Compressive strength, MPa |

| Technical paraffin | 0,90-0,95 | 50-51 | 0,3-1,0 | 0,4-0,5 |

| Distilled stearine | 0,90-0,97 | 50-56 | 0,7-1,5 | 0,4-0,6 |

| Lignite wax | 1,00-1,03 | 82-90 | 0,8-1,3 | — |

| Ceresin | 0,91-0,94 | 67-100 | — | — |

| Bottom cracking residue | — | 35 | — | — |

| Ethylcellulose | 1,00-1,20 | 160-180 | — | 14 |

| Peat wax | — | 65-67 | — | — |

| Polyethylene | 0,92-0,95 | 104-115 | 2,0-3,0 | 12-16 |

| Pine rosin | 1,00-1,20 | 66-73 | — | — |

| Block polystyrene | 1,05-1,07 | 280-300 | 0,2-0,4 | 0,4-0,7 |

| Expanded polystyrene | 0,06-0,10 | — | 0,3-0,4 | 0,4-0,7 |

| Urea (urea) | — | 129-134 | — | — |

Note: Ash content (mass fraction of the tooling material after removing the model and calcining the mold) of the starting materials is in the range of 0.05-0.01% (no more). The ash content of polyethylene reaches 0.10%.

Organization of foundry production

Not everyone has the opportunity to have a whole arsenal of devices for doing their own casting. Therefore, you should not carry out complex foundry work with your own hands, at home, without the use of special equipment. Entrust them to professionals who have all the necessary skills, equipment and expert knowledge.

If you have planned to open your own foundry, but feel a lack of knowledge, it is better to entrust its organization to a progressive engineering company specializing in various technologies of the foundry industry. These are specialists with extensive experience in this field, providing all types of engineering services - from the design stages, commissioning of foundry production and until it reaches high design capacity.

Casting

Now the workpiece is ready for melting the wax from the mold. It is placed for 10 minutes in an autoclave filled with hot steam. The wax melts and completely flows out of the shell. The result is a ceramic mold that completely matches the shape of the part.

When the ceramic-sand mold has hardened, metal casting is carried out using lost wax models. The mold is first heated for 2-3 hours in an oven so that it does not crack when pouring metals (alloys) heated to 1200 ˚C.

Molten metal enters the mold cavity, which is then left to cool and harden gradually, at room temperature. Cooling of aluminum and its alloys requires 2 hours, for steels (cast iron) - 4-5 hours.

Brief historical information on technology

The world's historical practice has been marked by widespread use of a related process, precision wax casting. Modern precision investment casting technology has been used in industry for a relatively short period of time.

Thus, the use of precision wax casting in the field of dental prosthetics in 1907 did not touch other applications for quite a long time.

It wasn't until the late 1930s that jewelry manufacturers mastered the process of precision lost wax casting. And it took several more decades to accumulate technological experience.

It should be noted that the process now used in jewelry production owes little to engineering precision casting. The technologies used in these two areas have developed almost independently. Currently, jewelry casting is experiencing an era of significant changes.

It seems likely that the period of the last few decades of empirical development of materials and equipment is coming to an end. It is expected that the process will develop on a better technical basis than has been the case for some time.

Main stages of lost wax casting

- A sample model is created.

- The sample is attached to the center sprue.

- The sample and sprue are dipped into the refractory material several times, creating a shape around the sample.

- The sample is removed from the refractory mold. The mold is ready to be filled with metal.

- The metal is poured into the mold.

- After cooling, the mold material is removed by mechanical processing, chemical cleaning or dissolution in water.

- The parts are cut from the center sprue and lightly cleaned.

Creating new products, and especially foundry parts, is the most time-consuming and expensive part of the technological process. In standard production, a new iteration of a product often requires new foundry equipment, since upgrading the existing one is either too expensive or impossible.

It is not for nothing that additive technologies are called revolutionary: they have made it possible to reduce the production time of products for pilot production by several times and even tens of times. For example, a prototype of a car engine cylinder block can be 3D printed in just two weeks, while its production using traditional methods takes six months. 3D printing not only saves time, but also allows you to grow models and shapes of any complexity. Casting has limited possibilities in this sense.

When it comes to the precision of a part, the use of 3D printing is also unparalleled. This technology is most widespread in jewelry, dentistry, and instrument making - in those industries where small sizes and complex geometry of the product are a priority. When manufacturing objects such as small machine parts, jewelry, dental prostheses or implants, particularly high precision and quality castings are in demand.

Photo 1. Models created on a wax 3D printer

Vacuum casting using lost wax models.

Dear friends, current and future clients of our company and just random visitors to our website! We continue to publish a series of articles about casting - one of the main, most important and interesting technologies used to create a wide variety of products for many centuries to this day.

VACUUM CASTING BY LOST WAX MODELS.

There are a large number of casting methods used in the modern jewelry industry:

— casting into the ground (including using various equipment)

- ethyl silicate casting

— casting in disposable flasks

– centrifugal types of casting

— and, finally, vacuum types of casting.

This is what we will consider in detail, since today, as we have already found out, this is the most widely used casting method for the manufacture of jewelry and souvenirs.

So, vacuum casting using lost wax models.

And it all starts with a high-quality wax model or, as it is commonly called among jewelers, a wax model. Of course, it is impossible to obtain a high-quality wax without a well-made mold, which, in turn, must be removed from a well-designed and processed master model. However, master models and molds are a separate topic, which will not be considered within the framework of this article, due to the fact that the topic of casting is already very extensive and we, without overloading this article, will save it for a separate publication.

How are “waxes” made?

- using a mold and an injection tank

- cut by hand or on CNC milling machines from sculpted wax

— using other methods (poured, injected into metal forms, handmade using non-standard technologies)

— printed from burnable polymers on 3D printers

In the first method (and this is the main method for mass production), wax enters the mold using injection (injection, supply under pressure) from the filling valve of the injection tank. These tanks, in turn, can be divided into several types:

- with hand pump

- with connection to a compressor

— vacuum (with connection to air and vacuum compressors)

- semi-automatic

- automatic

A fundamental difference exists between vacuum and non-vacuum tanks, since the former, immediately before injecting wax into the mold, pump out air from it. While the air is squeezed out of the latter just during the process of wax injection through special technological cuts - vents. This also leads to the difference in the use of molds made in different ways - for a vacuum tank, the mold is made in a different way from molds designed to work with conventional, non-vacuum injection tanks.

Be that as it may, any mold is made detachable, so that after the wax injected into it has hardened, it is possible to remove it for subsequent use, and prepare the mold itself for further repeated operations.

What are the requirements for waxes made using molds?

1. There should be no irreparable deformities

2. No noticeable seams or displacements are allowed.

3. The presence of air bubbles or any other inclusions is not allowed, including inside the wax model (control for transmission)

4. The entire geometry of the outline of the wax model must completely repeat the master model from which the mold was removed

5. The quality of the surfaces of the wax must be reasonably similar to the quality of the surfaces of the master model from which the mold was removed

Once the wax model is ready and its quality has been checked, it is placed (by soldering) in a special wax block, often called, due to its external similarity, a “wax tree” or “Christmas tree”. There are several techniques for assembling Christmas trees, but there are several basic principles used in this process:

- smaller and lighter parts are soldered on top of the tree, and larger ones on the bottom

- parts on the tree are placed at an angle of less than 90 degrees relative to the main sprue (sometimes called a riser)

— waxes placed on the tree should not touch each other and the main sprue

— the waxes are soldered onto the tree in such a way that the places where they are attached to the sprue are as smooth as possible and do not have any missing solders or any gaps.

After assembly, the trees go to the molding area, where they are placed on special rubber stands - “shoes” or “soles” and placed in flasks - special metal cylinders, which allows them to be subsequently filled with molding mass.

The devices by which the process of mixing the molding sand and pouring it into prepared flasks are called vacuum mixers, since in modern conditions this entire process takes place completely in a vacuum. After pouring the molding mass, the flasks with the trees inside are left alone for several hours for the gypsum to harden properly and pre-dry.

If steam melting of wax is used in production, then after molding and settling, the flasks are placed in it. In it, most of the contained wax is melted from the flasks. After this treatment, the flasks need to settle again. And, after all the described procedures, the investment rings can finally end up in the muffle furnace.

For jewelry and souvenir production, a fairly large range of molding mixtures is used, the basis of which in any case is cristobalite - a mineral quite rare in nature, a high-temperature polymorphic modification of quartz that changes its structure when heated. In addition to it, molding mixtures contain gypsum, as well as a large number of various additives that perform adaptive functions. Selecting a suitable molding material for casting is one of the most important elements in the process of obtaining high-quality castings.

Jewelry muffle furnaces are designed in such a way as to ensure the totality of the necessary processes during the calcination cycle of the flask. Heating elements (usually spiral type) are located both in the walls and in the door (there are rare designs with heaters in the floor or ceiling of the oven), a programmer is required, paired with a thermocouple, which allows you to control the heating, as well as a gate hole required to remove fumes generated during wax burning. There are very different designs of furnaces, for example, which allow you to regularly place inside the flasks of several floors, cylindrical in shape and equipped with a rotating mechanism, with various systems for draining wax or forced air outflow, etc. All these improvements can, as a rule, have a positive effect on the result of calcination, however, in the minimum configuration, the presence of multilateral heating, a thermocouple with a controller and a gate hole is the norm, and the rest is considered desirable.

The calcination cycle in the furnaces is programmed in such a way as to achieve the best combination of two factors - removal of all wax residues from the flask and good polymerization of the molding sand. The schedule for calcining flasks in a furnace resembles a ladder in appearance: set the temperature, hold on a given “shelf”, set again, hold the molding sand again, that is, remove excess moisture from it. Further “shelves” stepwise bring the furnace to the maximum temperature of the program - most often 740 degrees Celsius, during which the mold mass polymerizes and acquires the properties necessary for pouring metal into it in a vacuum. Then, after going through the entire calcination cycle, the temperature drops to the set temperature. metal pouring. The entire standard calcination cycle usually lasts at least 12 hours from the moment the flask is placed in the furnace, and often much longer.

After passing through the calcination cycle, the flasks are ready for pouring metal into them. In modern injection molding shops and workshops, this process usually occurs using injection molding machines. The designs of these machines are very diverse; they can be conditionally divided according to the method of metal melting and the pouring method, the presence/absence and composition of the inert medium, and the degree of automation of the process.

According to the melting method, a distinction is made between machines with spiral heaters and an induction heating element; by filling method: bottom filling, “upside-down” filling, over-the-edge filling; for inert medium - one and two gas machines and machines without an inert medium; for process automation - manual filling, semi-automatic and automatic.

Metal pouring is carried out under the influence of a deep vacuum on a mold, at a temperature slightly above its melting point, if possible, either in a vacuum or in an inert environment, to prevent contact of the melt with atmospheric oxygen.

After pouring the metal into flasks, they are cooled under natural conditions, then placed in washing baths, after which, the casting semi-finished products in the form of “Christmas trees”, extracted from the flasks in the described manner, are processed in a water-jet booth in order to remove any remaining molding mass from them. If necessary, bleach in aqueous acid solutions. Cleaned cast trees can also be subjected to ultrasonic cleaning, steam treatment using a steam generator and, sometimes, tumbling in a magnetic tumbling machine. After cleaning, the “Christmas trees” are dried (most often either in a special chamber or using an industrial hair dryer). Then the “biting” process is carried out, i.e. the cast parts are cut off from the “Christmas tree”, the sprues are cut off from the excess length parts and the resulting products are delivered to the warehouse, where they are sorted, received and parts that have not passed the quality control department are rejected. The casting semi-finished products obtained in this way can be transferred to the jewelry workshop for further processing.

Author of the article: Ivan Gennadievich Skvortsov.

Founder and CEO of the production company 3D Avtozavod.

Varieties of lost wax models

Model casting is based on the removal of a special composition using one of the following methods:

- smelting;

- burning;

- dissolution.

Lost wax mixtures for precision model casting are low-melting materials (paraffin, wax and analogues). The composition is removed by heating with hot air, steam, hot water, the temperature of which is higher than the melting point of the model composition itself.

Burnt mixtures are made from ordinary or foamed polystyrene. In this case, the removal of the original shape occurs at the stage of calcination of the shell, since the temperature in this case is significantly higher than the melting of the polymers.

Soluble compositions for model casting are based on synthesized urea (urea), potassium or sodium nitrate, and a number of other materials that dissolve well in water. To remove the substance, use ordinary warm water.

Model materials and manufacturing methods

The most widely used materials for gasified models are dense foam plastic (foamed polystyrene) of small fractions.

Dense foam plastic for wood products

Depending on the size of the part, granules from 0.2 to 1.0 mm are used. The material has such key properties as:

- Low price.

- High strength.

- Easily processed.

The second important material for gasified models is non-stick coatings, which are used to lubricate the surface of the model before molding. Modern coatings are made on the basis of aqueous binders and are highly environmentally friendly.

Non-stick coatings for fuels and materials

Gasified models for LCM castings are produced in two ways. Small dies for mass castings are made by extrusion injection of liquid foam into aluminum molds. They are made, in turn, by casting or machining. Gasified models for the production of complex castings are cut out of a solid piece of foam plastic with hot nichrome wire fixed in a template or in a CNC machine.

Gasifying models for casting

Using gluing, you can create gasified models for casting large-sized parts and almost any configuration. Any number and depth of protrusions and depressions, internal cavities and variable surface slopes are no longer a challenge. The high skill of the designer and modeler and many hours of manual labor are not required. Now this is a simple sequence of operations.

Manufacturing methods

Depending on the type, purpose and technical features of future products, the production of a master model for casting can be carried out manually, by milling or on a 3D printer:

- Hand-made models made of clay, plaster or plasticine are usually used to make exclusive products of high artistic value.

- You can also make a master model on CNC milling machines. This equipment is suitable for working with various materials, including metal, wood, plastic, MDF, wax and others. However, milling modeling, as a rule, requires manual finishing: to obtain a smooth surface of the model, it is necessary to carry out abrasive processing. In addition, milling machines cannot cope with all small parts and complex shapes.

- 3D equipment allows you to simplify and speed up the process of creating models. The machine will print a layout of any configuration, with the most complex geometry, external and internal corners. At the same time, the 3D prototype is always impeccably accurate. Printed models are widely used in various fields: in mechanical engineering, foundries, light industry, medical, food industries, etc. There are various printing methods, including light processing, selective sintering, laser melting and others.

According to gasified models

The mold is obtained using a non-removable model, and the metal is poured into a permanent mold. In this case, the model is produced from foam plastic by foaming at high temperature. When metal is cast into a mold, the foam model burns out completely, freeing up the internal volume.

If models for small parts can be obtained by foaming the composition, then large ones are cut out from glued slabs. Cutting is done by hand. Nichrome wire is used for this. The applied voltage heats the wire, which makes cutting easier.

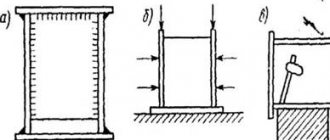

Forming during lgm is carried out using two methods. In the first case, for castings of simple shapes, vibrating tables are used, on which the molding sand is compacted using flasks. Then the lid is placed on the flask and the sprue receiver is mounted.

In the second case, when the product has a complex geometry, molding is carried out under vacuum. To prevent the closed mold from collapsing, it is subjected to reduced pressure until the end of pouring. The vacuum pressure value is low - about 4-5 GPa.

Blanks for casting using gasified models

The temperature of the poured metal is significantly higher than the beginning of foam gasification (560 °C). The gases released by the foam are easily removed from the mold by a vacuum system. At the same time, there is no smoke in the working area.

The main advantage of this method is the high quality of castings, which can be obtained by casting into an ordinary or lined chill mold. This became possible due to the fact that the shape is solid.

Casting using gasified models

At the present stage, casting using burnout models is used for casting:

- large and medium-sized products in small-scale production;

- workpieces with complex configurations and weighing up to 50 kg, which are subject to increased dimensional accuracy requirements, in medium- and large-scale production.

Development of technology for manufacturing castings by casting using gasified models

I. M. Tikhomirova, E. V. Klimenok, BNTU Scientific supervisor – Ph.D. tech. Sciences A. N. Krutilin, BNTU

The most significant changes in foundry production are associated with the improvement of existing technological processes and the development of fundamentally new special casting methods. One of the most important issues is the choice of the optimal casting manufacturing technology. It is necessary to pay attention not only to ensuring special requirements for the quality of the resulting castings, high physical, mechanical and operational properties, but also to the technical and economic indicators of the casting manufacturing technology, including mechanical processing. Unfortunately, at present there are no universal rules for choosing the optimal technological process for manufacturing a particular casting, since castings of the same quality can be produced in different ways. The choice of the most rational technological process for producing a cast billet is determined by the structural complexity of the part, its dimensions, quality requirements, operating conditions, type of alloy, volume and serial production, the degree of mechanization and automation of the equipment used at the enterprise. The main factor determining the choice of technological process is to ensure minimum allowances for machining, which in turn depends on the accuracy of the casting.

Among special casting methods, in recent years the technological process of producing castings using gasified models has become widespread both in industrialized countries and in the Republic of Belarus.

The advantages of this casting method are:

• use of bulk materials as mold material and strengthening of the mold with vacuum;

• use of a model that cannot be removed from the mold, ensuring the strength of the mold when it is filled with metal;

• core, molding and mixing equipment is significantly reduced and sometimes completely eliminated;

• there is the possibility of comprehensive automation of the entire technological process.

All of the above advantages, as well as an increase in the metal utilization rate, a decrease in the mass of cast workpieces, and a decrease in the labor intensity of casting production, determine the rational area for the use of casting using gasified models. The method can be used both in single and in serial and mass production of castings from various alloys weighing from several grams to tens of tons [1–4].

There are several types of technological processes for the production of castings using gasified models, which differ mainly in the method of manufacturing the casting mold. The choice of a particular technological process depends mainly on the production volume, the mass and configuration of the casting, and the technical requirements for the quality of the casting. For example, the method of casting using gasified models - Gamoliv - is most rationally used in the mass production of cast iron castings weighing up to 2000 kg. A distinctive feature of the Gamodar method is the use of vacuum and controlled pressure when pouring metal. The Policast technological process (models are assembled into a cluster on a riser, without a slag catcher and collector) is recommended for serial and large-scale production of castings, mainly from aluminum alloys. For serial and large-scale production of castings from ferrous and non-ferrous alloys, it is recommended to use the Replicast method. A distinctive feature of the Replicast - CS technological process is the use of a polystyrene foam model, which is first removed from the ceramic mold when it is calcined, the shell is molded in sand and the mold is evacuated. Combinations are possible in which part of the mold is made of polystyrene foam, and the main model is made of traditional materials, which can significantly expand the capabilities of the process.

In a single production, the selection of nomenclature for casting using burn-out models must be carried out on the basis of the structural complexity of the casting, the type of alloy, the labor intensity of making the model and mold, and the availability of the necessary equipment and materials.

In mass and serial production, it is most effective to use the method to produce castings from cast iron weighing up to 50 kg, steel up to 10 kg, castings should belong to the 2nd–5th complexity groups, the wall thickness of the part should be in the range of 5–20 mm, but not less than 3 mm at 10 times the length. It is not advisable to use the method for producing castings from low-carbon and alloy steels.

The final decision on the use of the method should be made after a feasibility study, taking into account the technical capabilities of production, capital investment and the environment.

The main role in the processes of casting formation during casting using gasified models belongs to the gas regime at the metal-mold interface. During the casting process, complex phase and chemical transformations occur, occurring during thermal destruction of the polystyrene foam model, accompanied by the formation of liquid, vapor and gaseous, as well as solid products; the completeness of the processes depends on the temperature of the metal pouring. As a result of the interaction between the metal and the model, an area of increased pressure is formed, which influences the formation of the structure and quality of castings from various alloys. The back pressure of the gaseous products of thermal destruction of the model against the hydrostatic pressure of the metal leads to a deterioration in the fillability of the mold when it is filled with metal.

The shrinkage of a casting is determined by the chemical composition of the metal, its overheating temperature above the liquidus line, the presence of impurities in the metal, and the intensity of heat exchange between the metal and the mold at all stages of casting formation. Unlike casting in sand-clay molds, shrinkage processes during the formation of a casting during casting using gasified models occur under conditions of constant close contact between the casting and the mold during the entire period of metal crystallization and cooling of the casting.

The most labor-intensive and critical part of the entire technological process of casting production is the production of a one-time model, since its geometric accuracy determines the quality of the cast part.

The material for gasified models at low density must have sufficient mechanical strength to eliminate the possibility of model breakage during manufacturing, transportation and molding; in addition, when pouring the mold with metal, the model must be completely gasified.

In a single production, both foundry grades (PSV-L and PSV-GM) and construction grades (PSV-65S and PSV-55S) of suspension polystyrene are used for the production of gasified models by mechanical processing from polystyrene foam boards.

In the serial production of models, at the first stage, suspension polystyrene is pre-processed and then the model is manufactured in a mold. In mass production, special model machines are used.

The quality of the model is determined by its dimensional accuracy, surface roughness, which is influenced by the cleanliness of the working surface of the mold, the activity of the foam granules, and the thermal and time parameters of the formation of the model in the mold. It is necessary to pay attention to the uniformity of the polystyrene foam structure, which affects the physical and mechanical properties of the model and the gas regime when pouring the mold with metal; the increased density of the model can lead to the appearance of defects on the surface of the casting. When producing high-precision castings, the total shrinkage of polystyrene foam models is assumed to be within 0.7–0.8%.

The quality of a model made of foamed polystyrene is significantly influenced not only by the monomer content, the amount of blowing agent in the granules, the humidity and size of the granules, the relative viscosity of polystyrene, but also by the mode of foaming of polystyrene granules, the activity and adhesion of polystyrene foam and the parameters of the final sintering of the model in the mold. The technological process of making models includes preparing the mold, filling it with polystyrene granules, heat treatment of the granules in the mold and its cooling, drying the models and quality control of the manufactured model.

The design of the cast part must be technologically advanced and must be linked to the method of manufacturing the model. The main attention should be paid to the possibility of manufacturing a model with a minimum number of its components. The number of components of the model depends on the method of its manufacture, which, in turn, is determined by the serial production. Models can be produced by autoclave or machine; in the first case, the mold may have several connectors and detachable parts; in machine production, as a rule, there is only one connector.

Models are assembled using liquid and solid adhesives; the latter are pre-melted at temperatures of 110–140 °C. In most cases, liquid glue is used for manual assembly of models, molten adhesives are used for machine assembly. For the manufacture of molds, aluminum alloys AMg5, 2.6 D16, 18K6 are used, which have good thermal conductivity, high corrosion resistance in a steam atmosphere and water, sufficient mechanical strength and are well processed.

Before molding, a non-stick coating is applied to the model or model block, which should well wet the model material, forming a strong adhesive bond with the surface of the model; in addition, the coating should increase the strength and rigidity of the model and elements of the gating system during molding. The non-stick coating not only ensures good quality of the casting surface, but also affects the fillability of the mold, the choice of the optimal speed of filling the mold with metal, and the melt pouring temperature. With an increase in the metal-static pressure and temperature of the metal being poured, as well as the porosity of the sand mold, the thickness of the non-stick coating must be increased. However, as the thickness of the coating increases, its gas permeability decreases, which leads to an increase in surface carburization of steel castings. The recommended coating thickness is 0.25–1.5 mm.

In mass production, the granulometric composition of the bulk refractory material after vibration should ensure high gas permeability and maximum shape density with minimal porosity. The content of fractions smaller than 0.05 should be extremely minimal (no more than 0.5%). The moisture content of the material is no more than 1%. When using quartz sands, these requirements are most satisfied by quartz sand of class 061K-063K and 1K-ZK with grain size of 0.2 and 0.16 (GOST 2138-74) of category A or B with an acute-angled or rounded grain shape. To increase the density of the mold, mixed sands of two fractions 0.315 and 0.16 mm are used in a 1:1 ratio; in this case, high gas permeability is maintained with low porosity. However, quartz sands have an increased expansion coefficient when heated, which affects the accuracy of castings.

Zircon sands are used in the production of steel castings; they have higher fire resistance, a low coefficient of thermal expansion and higher thermal conductivity compared to quartz sand.

Molding technology is determined by the serial production and the degree of mechanization and automation of molding. On automatic lines, it is rational to use pouring installations based on induction crucible and channel furnaces, which ensure constant temperature and weight consumption of metal. The metal temperature is selected taking into account heat loss due to thermal destruction of the model; deviation from the set temperature is allowed within 10 °C.

An important factor is to ensure the optimal and maximum permissible speed of filling the mold with metal, since failure to comply with these parameters leads to a deterioration in the quality of the castings. For the same reasons, it is necessary to pay attention to the minimum permissible speeds for lifting metal into the mold cavity. Obtaining a high-quality casting when casting using gasified models is influenced by good ventilation of the mold, which ensures free release of gas during thermal destruction of the model during the pouring process, as well as filtration from solid products (soot), the release of which when pouring the mold with metal is unacceptable, since this leads to significant deterioration environmental situation in the workshop.

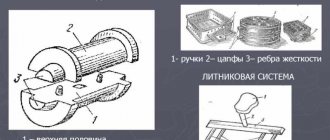

Rice. 1. Three-dimensional model of the casting “HDPE Suspension”

The standard casting “HDPE Suspension” was chosen as a part; the material was 35L steel. In Fig. Figure 1 shows a 3-dimensional model of the casting. In order to create a database of standard elements and be able to edit them, a 3-dimensional model of the gating system elements was developed separately. The connection of individual elements of the model into a 3-dimensional one was carried out using the SolidWorks computer-aided design system (assembly).

There are certain requirements for the design of the gating system, which are determined by the features of this technology. The parameters of the gating system depend on the type of alloy, casting configuration, its mass and molding method. It is necessary to ensure a flat front of interaction between the metal and the model, during which the model is gradually replaced by the melt, which is possible with a siphonic dispersed supply of metal into the mold cavity.

It is necessary to ensure that there is no vacuum in the elements of the gating system when pouring metal into the mold, and also to exclude the process of burning polystyrene in the mold cavity, otherwise the release of gaseous products and soot carbon increases, which leads to the formation of gas pockets in the castings, and when casting steel - to increase in volumetric carburization of the metal.

Depending on the production volume, weight and type of alloy, the gating system can be made of polystyrene foam, including the riser and bowl, or from refractory materials, and various combinations are possible. In Fig. Figure 2 shows a 3-dimensional model of the mold with assembled gating system elements. Based on the geometric dimensions of the casting and its configuration, it was decided to produce six castings simultaneously in one flask.

Rice. 2. Mold with gating system elements

The gating system parameters were calculated based on the recommendations proposed in [5].

The current stage of development of foundry production is characterized by the widespread use of automated systems for modeling foundry processes using computers. When developing casting manufacturing technology, technological decisions are usually made on the basis of many years of production experience and the intuition of experienced technologists. In a production environment, technology development is mostly done through trial and error, which leads to significant increases in production costs.

Currently, the first place comes to a preliminary assessment of possible options for manufacturing castings by mathematical modeling of complex hydrodynamic and thermophysical processes of casting formation. Work must be carried out not only in the direction of reducing material consumption, creating an optimal product configuration, based on the specific operating conditions of the part, but also from a technological point of view of foundry production.

The main task of mathematical modeling was to determine the places where porosity is likely to form in the casting body. The modeling process was carried out in the Polygon system. The heat transfer coefficient was taken to be 1000 W/(m2⋅C). For castings made of steel 35L when casting into sand molds, the linear shrinkage of the metal was taken equal to 2.2%. Recommended temperatures for filling molds when casting using gasified models with a wall thickness of 10–20 mm are 1595–1605 °C. The results of mathematical modeling are presented in Fig. 3.

Rice. 3. Modeling the process of porosity formation

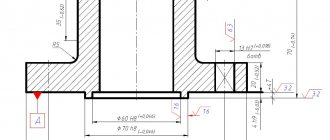

The results of the analysis of the process of filling the casting mold and solidifying the workpiece showed that the developed casting technology makes it possible to bring shrinkage porosity to profit. To carry out the process, a mold was designed to produce a model made of polystyrene foam (Fig. 4). In the process of repeated use of molding materials, the accumulation of products of thermal destruction of the model, residues of the non-stick coating, ceramic particles from the gating system, metal inclusions and a fine dusty fraction of quartz sand occurs in them, as a result of its thermal destruction. All this worsens the technological and physical-mechanical properties of bulk molding materials, in particular sand. Therefore, molding bulk materials must be regenerated. The regeneration process includes magnetic separation, sand sifting and heat treatment at a temperature of 650–700 °C. At the same time, during thermal regeneration in a fluidized bed, fine dust fractions are removed from the sand.

The use of regeneration of the mold material and catalytic afterburning of the products of thermal destruction of the model, as well as evacuation of the mold during the process of pouring metal and cooling the casting, makes it possible to create environmentally friendly production of castings [6].

Rice. 4. Mold for making the model

It should be noted that currently in the world market, leading companies have begun to use technological processes of rapid prototyping (RP-Rapid Prototyping), which have proven themselves most well at the initial stage of technology development. When testing the technology, the shortcomings of the proposed technology are revealed, which entails the production of new and improved model equipment, and this process is labor-intensive and takes a long time.

Of interest are models produced using SLS technology (Selective Laser Sintering) made from polystyrene powder. Such models can be produced on SLS machines from 3D Systems and EOS. The resulting polystyrene model is very fragile and requires careful handling, so after growing the model is impregnated with a special paraffin-based composition at a temperature of 80 °C. When heated, the model softens, becomes deformed and requires special measures to prevent deformations from leading to the loss of the model, which is a serious drawback of the proposed technology. CSoft offers Contex 3D printers – the full-color DesignMate Cx and the monochrome DesignMate Mx1. Using this equipment and special materials, it is possible to produce burnt models.

Contex offers two types of materials for the production of burnout models: zp14 and zp15e, both based on cellulose. The preferred powder is zp14, which produces lower ash content during the burning process, but its use is only possible on monochrome printers. Due to the design features of the printers, the use of zp14 powder on full-color DesignMate Cx is impossible, and monochrome printers have a noticeably smaller working area (250x250x200 mm).

RP technology can be used to quickly produce a burnt-out model without making special equipment. According to CAD data, a model is grown on a prototyping installation, which is equipped with a gating system, placed in a flask and filled with molding sand. After burning the model, the mold is calcined and filled with metal.

To obtain a burnt model, 3D printers such as ThermoJet, InVision, ZCorp or more expensive SLA machines such as Objet, NextFactory, Viper, etc. can be used. The main differences are related to the quality, purity and accuracy of the model and, accordingly, their cost.

High-quality castings with high precision and surface finish (Rz20 or less) can be obtained using the Quick Cast technology. When building a model on SLA machines using special software, a honeycomb structure of the model body is created; when it is burned, significantly less ash is formed. The SLA process (Stereo Lithography Apparatus, laser stereolithography) allows you to build models with a pitch of 0.1–0.025 mm, which ensures high quality surface quality of the model.

In the process of developing the casting technology for a specific casting, you can quickly change the configuration of the mold elements.

In modern foundry, in order to obtain prototypes and prototypes, it is possible to produce burn-out models without the use of expensive equipment. To build burnt-out models, three-dimensional printers from companies such as 3D System and Voxeljet are used, and polystyrene foam is used as a model material.

However, the technology for making models for mass or serial production on three-dimensional printers is very expensive, so it is used in single, small-scale production to create experimental samples.

Summarizing the technical and economic indicators of the production of castings using gasified models and comparing them with traditional casting methods, we can state that due to the absence of molding slopes and the reduction of allowance for machining, the weight of castings when casting using gasified models is reduced by 10–12%, while the accuracy production of castings increases by 2–5 times. The complexity of molding and finishing operations is reduced by 10–20% for single castings and by 40–60% for mass production of castings. The use of rods is reduced, and in some cases completely eliminated.

Thus, in the course of the work, the main parts of the casting equipment were developed. Based on methods of mathematical modeling of foundry processes, an analysis of the process of filling and solidification of the HDPE Suspension casting was carried out, and the locations of the most likely formation of porosity were determined. The main details of casting equipment and technological parameters of the process were adjusted.

The use of the obtained results in production will make it possible to obtain high-quality cast parts with a given level of properties with a significant reduction in casting defects.

Literature

1. Ozerov V.A., Shulyak V.S., Plotnikov G.A. Casting from polystyrene foam models. M.: Mechanical Engineering, 1970.

2. Stepanov Yu. A. et al. Casting using gasified models. M.: Mechanical Engineering, 1976.

3. Shinsky O.I. New in the theory and practice of casting using gasified models // Foundry production. 1991. No. 1.

4. Shulyak V.S., Rybakov S.A., Grigoryan K.A. Production of castings using gasified models. M.: Publishing house RIC MGIU, 2002.

5. Shulyak V.S. Casting using gasified models. St. Petersburg: Professional, 2007.

6. Shulyak V.S., Shinskiy O.I., Khvostukhin Yu.I. Environmental aspects of casting using gasified models // Foundry production. 1993. No. 7.

Under pressure

Injection molding technology involves the rapid supply of melt into a mold using compressor or piston mechanisms. Thanks to the automation of the process, injection molding is considered high-productivity.

In this way you can get details:

- complex geometric shape;

- with fairly thin walls;

- high precision;

- with increased roughness.

The injection molding method is used to produce parts in the automotive industry. They are light in weight and have sufficient strength, which helps reduce the total weight of the unit.

It is worth noting that the high pressure casting method has the following advantages:

- possibility of obtaining sizes of class 9 and coarser;

- achieved surface roughness - 1.25 microns;

- minimum wall size - 0.6 mm;

- minimum hole diameter - 1 mm;

- external thread formation;

- knurling, inscriptions on the outside.

The disadvantages include the following:

- the price of the forms themselves is high;

- spill of metals with low melting point;

- increased likelihood of the formation of internal defects in the form of cracks and stresses.

Die casting diagram

The widespread use of aluminum die casting is due to:

- low temperature values during the crystallization period;

- plasticity of the alloy;

- good fluidity;

- inertness to chemical reactions;

- low volume of shrinkage.

Considering ways to divide technology as follows:

- pressing chamber: hot;

- cold;

- horizontal;

- piston;

Process flow

The melt is fed into a special cavity. The piston pin forces liquid metal at high speed into the internal cavity of the mold. After which cooling occurs without removing the pressure. After hardening, the mold is released and the casting is removed. To facilitate extraction, the structure is equipped with pushers.

Manufacturing of molds

A mold is a complex engineering design that must ensure the quality of the resulting castings. In essence, this is a high-precision tool that consists of several parts, inside of which there are cavities into which the melt flows. The mold is installed in the unit in which the casting machine is closed. With each closure, a melt is supplied to the mold, then it is maintained under a certain pressure and after the time specified by the technology has passed, an opening occurs. The cooled castings fall into the receiving device.

This tool is designed and manufactured in several stages.

- Analysis of technical specifications. At this stage, the customer puts at the disposal of the contractor the technical requirements for the future form. The requirements must include data on operating conditions, in particular, there must be specified data on the material from which the castings will be made, and the production program for the month, quarter or year. Based on the data obtained, designers calculate the optimal shape characteristics. In addition, the customer must submit to the manufacturer either drawings for the product or sample planned for production.

- At the design stage, designers create a 3D model. It will help you visualize how it (the form) will work, how the material will be promoted. Modern software allows you to simulate the detailed operation of all mold components, temperature parameters and a lot of other information necessary for creating working documentation. It should be noted that designers have at their disposal software tools that allow them to improve the quality of working (design and technological) documentation, minimize errors and significantly speed up the design process.

- Modern molds are mostly produced on computer-controlled equipment. This allows us to minimize human participation in the production of mold elements and reduces the production of substandard products to zero. By the way, paperless technologies work successfully in serious industries. That is, the developer, after designing the form, using special software systems, is able to write control programs for CNC machines. After which, it can be sent to the machine via the factory LAN.

- After producing a prototype mold, the customer checks the quality of the resulting casting and decides on the production of a serial mold.

For the production of molds, alloy and tool alloys are used. Their use makes it possible to produce products that can withstand tens of thousands of closings and openings.

Making a master model for plaster casting on an FDM printer [CASE]

Hi all! Artyom Rodin aka Articoon is in touch and in this article I will share with you the experience of one order for printing and post-processing. Since I’ve been writing quite rarely lately, the case, in my opinion, stands out for its complexity among our other works. We are talking about creating a master model from plastic using FDM technology for plaster casting.

This project was carried out in collaboration with the creative workshop of KhNUM. Printing was carried out at the RODINLABS 3D Printing Studio.

However, the first time we didn’t succeed in fulfilling our plans and we will talk about how we got out of the situation...

Our workshop received a request to make a bust of Nefertiti to decorate a private home.

The original bust is in the New Museum (Berlin), and by coincidence, there is already a freescan of the model in good quality - https://www.myminifactory.com/object/3d-print-bust-of-nefertiti-at-the-egyptian -museum-berlin-2951

For greater tactile similarity to the original, the customer decided to make the bust from plaster. And we started printing the master model...

Since the project consisted of several technological operations, we jointly looked for ways to reduce the final cost, since the budget for the project is limited.

First of all, we printed a full-size bust from PLA plastic on a 3D printer developed by Vitaly according to our order - https://foxprinters.ru/professionalnye-3d-printery/3d-printer-bigfarm-1000

Material - PLA, layer 0.25 mm, nozzle 1 mm, printing time ~ 42 hours, plastic volume ~ 1800 cm3.

The result of the first print was satisfactory for us, but not satisfactory for the workshop, since the layering, seams and artifacts from the slicer distorted the real defects of the original. In other words, it was difficult to distinguish where the original bust defect was and where the 3D printer added them. The first pancake goes into the trash in a lump.

They realized their mistake after seeing the result - the bust was printed using a shell with 0% infill and a very high speed. Not at first glance, the rigidity of the walls was not enough and at a high altitude they simply lost stability... Although in this situation the result was most influenced by haste.

At this stage, we decided to change both the equipment and the material for production. Then it was decided to print the bust from carbon-filled plastic (ForMAX), which left virtually no print marks on the model. The printer was chosen PICASO Designer XL, since the model fit the dimensions, and as the “man with green hair” says:

The printer takes a long time to print, it’s expensive, it’s awesome!)

However, you can judge the result for yourself:

The printing took more than 100 hours. Material - Formax, printer - PICASO Designer XL, Layer 0.25 mm, this time the filling was chosen to be about 10% (to be sure).

The next stage is casting.

The printed master model from ForMAX was brought to a smooth state (processing of this plastic is one of the advantages) and a mold was made based on it. Next, the Bust was already cast from plaster, preserving all the chiseled original defects.

The photo shows a casting based on the master model from ForMAX.

The final. Artists recreated the image of Nefertiti using painting:

*** Friend, if the article was interesting for you, give it a thumbs up and subscribe to me on social networks. I will be glad to any comment

***

Sincerely yours, Artyom Rodin, RODINLABS Prototyping Laboratory.

More interesting projects - Instagram

Add to VK -

***

Technology

This method is used to produce products from various alloys. A quality indicator of up to ±0.005 mm is provided for every 25 mm of surface. This accuracy allows us to produce products that do not require additional processing. The key to the success of the technological process is that the model is made from a rapidly melting substance. Paraffin, wax, rosin or a mixture of them is used.

The technological process consists of the following actions:

- Production model:

- a special mold made of plaster, plastic, steel or cast iron is taken for the model;

- the substance forming the model is poured into it;

- you need to wait until it hardens completely;

- After this, the special mold is opened, the wax model is removed and placed in a container under cool water.

Assembling models into blocks:

- to produce a high-quality product, models are assembled into simple and complex blocks, each of which can include from 2 to 100 pieces;

- to increase strength, aluminum racks are installed in the block structure;

- they are covered with a layer of model substance up to 25 mm;

- block structures are combined into a gating system.

Applying a fire-resistant shell to the model:

- a block assembled from several models is placed in a container containing a suspension of ceramics (quartz dust, fine fractions of fireclay) and a binding component (ethyl silicate solution);

- during the day it is dried in a natural environment, this time can be reduced to 40 minutes under the influence of ammonia;

- Thus, 46 layers of fire-retardant shell are applied one by one to the specified block, with each of them thoroughly drying;

- the completed model in a fireproof shell is placed in heated water at 90°C;

- in a few minutes the model substance will melt and float to the surface of the water, where it is collected for the next use.

Preparing the mold for pouring:

- the empty shell is washed in water and dried in a cabinet for 2 hours at 200°C;

- the dry shell is placed vertically in a heat-resistant flask and compacted along the edges with quartz sand, placed in an oven for 2 hours at 950°C;

- the remaining moisture evaporates in the oven, the remains of the model composition burn out, the shell is sintered with the refractory material, increasing strength;

- molten metal is poured into a calcined hot mold.

Casting cooling:

- after the casting has cooled, the shell is destroyed;

- the product is cleaned of its residues, for which it can be chemically cleaned;

- Then the product is washed with water and subjected to final drying.

As a result, it is subject to heat treatment and taking control measurements. In this way, castings of the required size and configuration are produced.

Types of casting models and their properties

In the simplest case, the original product is used as a model for casting into the ground. However, due to casting shrinkage, it is impossible to maintain the exact dimensions of the castings.

Usually they make a model (or mock-up) - a scale copy of the future product, enlarged by the casting shrinkage value.

Model for casting in the ground

Materials for models should be easily molded to give the desired configuration and easily processed to convey relief details. Traditionally they are made from wood, wax, plaster and metals. Not so long ago, various plastics also began to be used. They are also printed on 3D printers.

Main properties of the models:

- Strength - necessary when compacting earth in order to maintain the configuration of the product and its dimensions.

- Easy to remove from mold. The surface of the model is carefully treated and coated with a special lubricant. For complex configurations, a collapsible model is used.

- Fusibility and volatility (in the case of lost-wax/burn-out models)

Based on the complexity of the design, the following types of models are distinguished:

- One-piece

- Detachable

- With detachable parts

- For hollow castings

One-piece models

Used for simple products, without noticeable protrusions and depressions. Removing such a model during molding does not cause any difficulties.

One-piece models

They are used for prototyping simple parts, as well as bas-reliefs, pedestals and other simple artistic castings.

CADmaster

according to burnt models

When throwing pebbles into the water, look at the circles diverging from them. Otherwise, this activity will be empty fun... Kozma Prutkov

Casting as one of the methods of metal processing has been known to mankind for a very long time. Once upon a time, a piece of copper ore fell into the fire of a primitive man and an observant ancestor discovered an ingot of metal in the cooled coals - this is how the copper (bronze) age of mankind began, which replaced the stone age. And if in those distant times casting was the only available metal processing technology, then today, for the production of certain products, casting remains the only possible manufacturing method when other methods are either technologically impossible or unreasonably expensive.

Casting has its undeniable advantages and obvious disadvantages, so when choosing this manufacturing method, you have to look for a compromise between the pros and cons. Casting parts have a very high material utilization rate (CMM), there are no fibers cut during machining, and sometimes very little machining is required. But with all these advantages, the mechanical properties of cast metals and alloys are lower, porosity is higher, internal defects are possible, etc.

Since the time of primitive man, casting technology has changed significantly. Today, metal casting is used in earth and sand molds, in metal molds (chill casting), centrifugal casting, pressure casting, burnt-out and lost-wax casting. Let's talk about the last method of shaping in a little more detail.

The essence of the method of casting metals and alloys using burnt/lost wax models (for now we will not make a difference between them) is as follows. First, a copy of the future product is made from a special material with the necessary allowances for shrinkage and subsequent machining. For lost-melt models, paraffin, stearin, wax or mixtures thereof are used, and for burned-out models, materials are used that burn in air or in an oxygen environment with little formation of smoke and dry residues (as professionals say, with low ash content). Then, ceramic powders with a silicate binder are applied in several layers (up to twenty) to the resulting model - no matter whether it is burned out or melted, drying the model after applying each layer. As a result, a strong heat-resistant shell is formed around the model - a crust, into which the molten metal will then be poured. But before pouring, the model must be somehow removed. If the model is lost wax, then the crust together with the model is placed in a bath of hot water, where the paraffinostearin mixture, the melting point of which is 60−70 ° C, melts and safely leaves the crust. Burn-out models are dealt with in the following way: the mold is placed in a furnace and kept for quite a long time at a high temperature either in air or with oxygen supply - for more complete and rapid combustion of the model (that is why, in fact, the model is called burn-out). To remove combustion products, the mold is blown with compressed air. If conditions permit, then before pouring the mold is allowed to cool to ambient temperature, and the ash residues are washed out with a stream of water or blown out. True, such removal of dry residues is not always possible: when it cools to room temperature, a web of cracks may appear on the crust.

Both highly artistic objects (for example, figurines) and mechanical engineering products - compressor wheels of pumps, pumping devices are cast using burnt/lost melt models: in both cases, production by other methods is impossible or more expensive.

One question remains - where did the lost-wax or burn-out model come from?! The malleability of wax or paraffin does not greatly simplify the process of forming a casting model. This is where the fun begins. It is clear that exactly as many models must be produced as the products will be cast, and to form these models, additional equipment is prepared into which the models will be cast (we are now talking about lost wax models). A mold is made from aluminum alloy or wood, and it is designed to be dismountable, from segments - sometimes it’s a Rubik’s cube, but this is the only way to extract the lost wax model. The process is not fast, so alternative methods of forming burnt/lost models are being explored.

With the development of rapid prototyping technologies (Rapid Prototyping - RP), the idea arose to produce injection molded models on special installations - three-dimensional printers. Without delving into the details of various rapid prototyping technologies, I will only say that today systems for producing samples using mathematical models obtained from CAD systems have been developed and are successfully used. Various growing methods and a wide variety of materials are used, but not all of them are suitable for the manufacture of lost-melt/burn-out models (either they do not melt easily, or they burn poorly - smoky and with a large ash residue). At one of the exhibitions I had a chance to see a 3D printer that grew a sample from a wax-like material layer by layer, but (apparently due to the fluidity of this material in a liquid state) the quality of the grown models left much to be desired, moreover, the model grew surrounded by supports from a special greasy wax, which had to be removed upon completion of the model formation.

Since the beginning of 2006, CSoft has been supplying Contex 3D printers to the Russian market - full-color DesignMate Cx and monochrome DesignMate Mx, the scope of which is not limited to the production of prototypes using mathematical models of CAD systems. Using this equipment and special materials, it is possible to both produce burnt-out models for foundry production (Investment Casting) and print sand casting molds themselves (!) for direct casting of non-ferrous metals and ferron-free alloys (Direct Cast technology). Both technologies were tested on samples provided by CSoft customers, which let me tell you about.

One of the customers, FSUE OKBM im. Afrikantova" (Nizhny Novgorod), proposed to test the casting technology using burnout models using the example of a real product - a turbopump wheel. Manufacturing this part by machining, even on modern multi-axis milling machines, is fraught with considerable difficulties. The reason here is both in the dimensions of the product (wheel diameter is about 300 mm) and in the rather complex shape of the blade channels. The company successfully uses lost-wax casting technology, but has little experience working with lost-wax models. It must be said that the invitation to such a pilot project was not spontaneous: metallurgists and engineers from OKBM, together with CSoft specialists, studied in sufficient detail the processes of filling a mold for casting a wheel using the LVMFlow package, which allows optimizing the design of the casting and gating system even before the production of experimental castings and a model equipment, select the metal pouring temperature, predict and minimize casting defects.

In Fig. Figure 1 shows the initial mathematical model of the product, generated in the Unigraphics NX package and built taking into account technological allowances, with calculated profits and a gating system. The dimensions of the printer's working area (350×250×200 mm) did not allow the entire wheel to be grown, so the product was cut into parts shown in Fig. 1 using CAD tools. 2 different colors. It was decided to abandon the idea of making the model thin-walled in order to save consumables, since in this case it would be necessary to take care of extracting the powder from closed cavities, and the dimensions of the product dictated fairly high mechanical properties of the model. After growing and drying, the component parts were glued together with a special glue. Another feature of the 3D printing technology is that all the sharp edges of the blades were rounded in a mathematical model with radii of 0.3-0.5 mm to protect them from chipping during subsequent impregnation with wax and during the crust production process.

A few words about the powder from which the model was grown. ]Contex[/anchor] (more precisely, its division Z-Corporation) offers two types of consumables for the production of burnout models: zp14 and zp15e, both based on cellulose (which looks like a mixture of starch and wheat flour). Zp14 powder is preferred, giving lower ash content during the burning process, but its use is only possible on Contex DesignMate Mx monochrome printers. Of course, the color of the burned models does not matter, but due to the design features of the printers, the use of zp14 powder on full-color DesignMate Cx is impossible, and monochrome printers have noticeably smaller working area sizes (250x250x200 mm). Zp15e powder with an appropriate binder is primarily aimed at the production of elastic, rubber-like objects (shoe models, rubber products, etc.), less suitable for the production of burnt-out models, but applicable for Cx printers.

The printing process involves layer-by-layer impregnation (printing) of uniformly applied layers of powder with a special binder. This procedure has already been presented in detail in our journal; Let us only add that in our case, it took about 10 hours to grow all the components of the model. Printing was done mainly at night: the printer does not require constant close attention. After printing, it takes some time to dry, then excess powder is removed in a special chamber - and the model is ready for gluing.

In Fig. 3 - two parts of the model (the wheel itself and the gating system with profits) before gluing. Here you can also see a special hole for the wooden holder on which the model was attached for molding the crust.

After gluing, the model left the walls of the CSoft company and went to OKBM, where work on forming the crust continued and the material was poured. To obtain a better casting surface and better conditions for removing material, the model was immersed in molten paraffin for several minutes before forming the skin.

Formation of the crust (Fig. 4−5) is a well-established technological procedure. Special powders of various grain sizes mixed with the emulsion are applied to the model in several layers, each layer is dried.

The crust is placed in a sand flask (Fig. 6) - a kind of temperature buffer that allows you to retain the heat of the mold when it is blown after the model is burned out. Next, the entire structure is sent to the oven for quite a long time (in our case, 40 hours), where the material of the burned model burns out.

The final stage, blowing the crust with compressed air, is a very responsible procedure: the charred remains of the model remaining in the mold can negate all the work. Of course, everything will be simpler if conditions allow, without the risk of destruction or cracking of the crust, to cool the mold to room temperature and then wash out the remaining material. But in this case, cooling the mold was a completely unacceptable option, so immediately after blowing it was poured into the hot crust.

After pouring, the mold cooled for 24 hours, and then the crust was mercilessly split and a casting was brought out into the light - exactly repeating the outlines of the model being burned out. Lost wax/lost wax casting is sometimes called fingerprint casting. Indeed, the casting reproduced all the smallest details - glue seams and even those very rounded edges with a radius of 0.5 mm (Fig. 7−8).

The pouring results confirmed the calculations previously performed in the LVMFlow package: no defects were found on the most critical blade surfaces.

After cutting off the sprues and profits, as well as preliminary mechanical processing, the product acquired the appearance shown in Fig. 9.

A few words about another project - the production of cast parts using Direct Cast technology by direct casting of aluminum alloys into molds prepared on a Contex DesignMate Cx 3D printer. The essence of the technology is this: an injection mold is grown from zp501 powder (which looks like ordinary quartz sand) with a special binder. Before pouring, the mold is dried for 6-8 hours at a certain temperature, after which it is filled with a melt of aluminum (or other non-ferrous, iron-free) alloy.

The initial data was contained in a mathematical model of the product with a profit and a riser, which was provided by MPO im. Rumyantsev (Fig. 10). And if in the technology of burned-out models a positive model is grown, then in the technology of direct casting the model of the product was “subtracted” from the rectangular block of the future injection mold using Boolean operations (Fig. 11).

For safety reasons, the printed and dried form was placed in a metal flask and covered with sand (Fig. 12). Metal at a temperature of 720 degrees was poured with slight smoking of the mold (Fig. 13−14).

- To get a general idea of Contex 3D printers, you can read, for example, the article by J. Erlandsen “A new dimension of GIS: Contex 3D increases the accuracy and efficiency of layout” (CADmaster No. 2/2006, pp. 98−100).

Vladimir Bankrutenko, Nikolai Gagarin, Kirill Komissarov, Alexander Poyarkov, Alexey Lazarev FSUE OKBM im. Afrikantova" Yuri Chigishev CSoft

Download article in PDF format - 365.3 KB |