Here you will learn:

- Purpose and principle of operation of the pumping station

- What is included in the pumping station device

- Operation and features of the control unit

- Interaction of the pump with the hydraulic accumulator

- Advantages of pumping stations

- What is good about a pumping station without a hydraulic accumulator?

- Which pumping equipment to choose

- Equipment installation rules

The operating principle of the pumping station and its comprehensive equipment provide protection from external factors and the possibility of uninterrupted water supply even during a power outage.

Water supply station design

For supplying water to a private home, stations consisting of a hydraulic tank, as well as an electric pump and an automatic unit are best suited. The main difference from surface pumps is the fact that water supply stations have a control system that depends on the pressure value.

We list the following functioning components of the station:

- Surface pump.

- A hydraulic accumulator equipped with a built-in rubber bulb.

- Pressure switch.

- Connection fittings.

- Pressure gauge.

To draw water, a suction pipe equipped with a check valve and a mesh filter must be connected to the station. A line should be connected to the outlet of the installation to transport liquid to water collection points. When the station is already equipped with a valve plus a built-in filter, then, in turn, a hose that suctions water becomes optional.

Design of an automatic pumping station

A membrane hydraulic tank together with a centrifugal pump can maintain a pressure level of 1.5 atmospheres directly in the water supply of your country house. This should be quite enough for the normal and stable operation of your household appliances. However, the maximum pressure for which the vast majority of hydraulic accumulators are designed - 4.5 atmospheres - should be more than enough for a solid two-story cottage.

A conventional automatic station is not particularly large in size, and its largest component is a water storage tank. Does not require a concrete platform. However, since the station produces a lot of noise during operation, a separate room should be allocated for its operation. Installation is traditionally carried out on the ground floor of the cottage or in its basement.

A more expensive option for installing an automatic station is a caisson, in which all equipment can be completely placed. A less expensive option is a special pavilion to protect the station from atmospheric influences.

Main operating components

A pumping station assembled in a factory is significantly superior to a set of independently selected elements at home.

This is due to the precise selection of technical parameters of each unit, the compactness of the single design, and the presence of a common control unit. Let's look at what a household pumping station consists of:

- surface type electric centrifugal pump;

- storage capacity;

- pressure gauge;

- pressure switch;

- check valve;

- inlet pipe with a mesh filter;

- outlet pipe for connection to the water supply.

This is all compactly installed on the common supporting frame of the entire structure. The average configuration is capable of automatically maintaining the pressure inside the water supply system at a level of 1.5 atmospheres. This is enough for the full operation of the plumbing of a private home.

More expensive designs are capable of producing a maximum pressure of 4.5 atmospheres, which is enough to power a three-story cottage. It does not require special conditions; a technical room will be sufficient for its operation and maintenance. An alternative for installation may be a caisson.

Control unit: design and features

The station’s automation serves to constantly monitor the pressure level inside the water supply system, plus to turn the hydraulic pump on and off depending on the situation. For this purpose, relays along with a pressure gauge were added to the control unit of the station. The pressure gauge is used to control the pressure, and the relay is used to control the pump.

If the use of your station involves a short-term shutdown of water, you should choose a control unit with a flow controller. It protects the station engine from overheating if there is no water at the water intake points. In such stations, the main task of the unit is not to monitor the maximum pressure, but to reduce the flow.

How does this system work?

To properly operate the water supply system, you need to know the operating principle of the pumping station. Water consumption in domestic conditions occurs periodically, so there is no need for constant operation of the pump. On the other hand, it is convenient for the resident to have liquid flow appear immediately after opening the tap. These problems are solved in a simple and effective way.

A running pump provides the consumer with water and pumps it into the storage tank. At the same time, the excess pressure increases throughout the system until it reaches the set maximum value. At this moment, the relay is activated and the electric motor is turned off. As the liquid is consumed, its pressure decreases until the control unit again gives the command to start the pump.

How does a hydraulic accumulator pump work?

Select the capacity of the membrane tank according to the volume of water consumption. For two people, a capacity of up to 40 liters is enough, and for a large family – from 100 liters and above. For seasonal country water supply, a tank with a volume of 15 liters is quite suitable. Due to frequent pumping of water, the tank membrane quickly wears out.

Pump with hydraulic accumulator

Consequently, tanks with a larger volume may wear out more slowly, since water is pumped less frequently. However, do not forget that such a tank will cost more. To accurately select a hydraulic tank, you should take into account the manufacturer’s calculations for pressure, turning the station on and off, and the actual water flow directly at the water intake points that are turned on immediately and simultaneously.

The volume of fluid reserve in the hydraulic tank is approximately one third of the total value. All remaining space is needed for compressed air, which maintains the water pressure in the water supply pipes.

If the accumulator is built into the water supply system, in order to reduce the risk of water hammer, a smaller tank should be selected. In such a situation, an important role will be played not by the container, but by membranes filled with air to absorb the force and consequences of water hammer.

The automatic water supply station has two cycles of operation:

- First of all, water is pumped from the water intake point to create excess air pressure in it.

- When the tap is opened, the tank is emptied, after which the moment comes when the equipment starts up automatically.

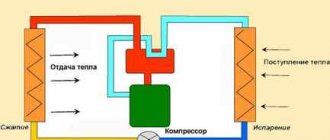

The station's hydraulic accumulator is constructed of a housing made of metal and a sealed membrane. It divides the internal space of the battery into two parts. In the first part there is air, in the second part water is pumped.

When the accumulator is full, the pump is turned off via a relay. At the moment the tap in the kitchen opens, air acts on the battery membrane, after which water flows into the water supply system.

After the tank is empty, the water pressure decreases, then the pump turns on, and the station’s operation returns to the first cycle. If the tank is empty, the membrane is pressed against the nozzle, after which it is straightened under the force of water pressure when the pump is turned on.

Some of the air is compressed under the influence of the membrane and the pressure inside it increases. Through a similar interaction between liquid and gas, through a barrier, the tank at the pumping station operates.

Advantages of a pump unit with a hydraulic tank

The pump is the main unit for delivering water from the water intake to the place of its consumption. Let's look at the design of a water supply pumping station and some advantages of using a hydraulic tank and accumulator:

To reduce the number of pump starts and provide water supply in case of power outage, a storage tank of significant capacity is used:

- it is installed at the top point, in the attic;

- in this way, water is drawn into it, and then flows by gravity to the places of consumption, while a slight pressure is formed;

- however, this method requires a durable overlap and additional costs for installation work;

- insufficient pressure in the system calls into question the full operation of the plumbing fixtures and can lead to their failure;

- There is a constant danger of residential flooding.

A more modern option is to use a hydraulic accumulator, which allows you to achieve constant pressure in the system:

- however, there remains a dependence on electricity;

- you can purchase an autonomous generator and make it automatically connect and start;

- however, this option requires additional financial costs.

As you can see, modern technologies make it possible to offer many options for solving the issue of arranging home water supply far from the central highway. It is possible to use both of the above options in one system.

This way, it remains possible to use sufficient pressure with available electricity, and use water with less pressure if it is not available.

Criteria for selecting pumping equipment

Pumping stations, which are completed directly at the factory, are supplied with a surface hydraulic pump with an ejector, internal or external. In addition, hydraulic accumulators can also be used with submersible pumps, in which case they will be called a “pumping system”.

When using a pumping station, tanks with membranes may have a smaller volume than hydraulic tanks in systems with submersible pumps. This approach is explained by the fact that submersible pumps have fewer starts and stops within an hour than surface pumps.

Design and principle of operation

In order to understand how a pumping station for a summer house or private home works, you should take a closer look at its structure and main functional elements. Let's consider their sequence in the direction of water movement.

- The water intake, located in a well or well, is equipped with a filter mesh that prevents relatively large particles of impurities from entering the system. A check valve is also located here to prevent reverse flow of water when the pressure drops or the pump stops working.

- The suction line is the section of pipeline from the water intake to the pump.

- The operation of a centrifugal pump creates a vacuum in the pipeline supplying liquid from the source, which contributes to its intensive rise, and excess pressure in the line leading to the points of water consumption to ensure the flow of water through communications. To optimize the operation of the system, the pump is equipped with a pressure gauge and a pressure switch , the settings of which ensure that the pumping unit is turned on and off when critical values are reached.

- The principle of operation of a pumping station for a summer residence would be incomprehensible without clarification - the relay settings are set taking into account the characteristics of the pump, the volume and required pressure in the accumulator and other parameters.

- The systems are equipped with reservoirs from which water is supplied to the pipeline.

The photo shows a diagram of a water supply device based on a pumping station with a hydraulic accumulator.

Thus, the principle of operation of a pumping station for a home in stages is as follows:

- When the pump is turned on, water rises from the source, fills the system and the hydraulic accumulator until a certain pressure value or level is reached. After this, the pump is turned off.

- When water is consumed (opening a tap, using a shower or water-consuming equipment), the pressure or level in the system decreases, which facilitates the supply of liquid from the accumulator/storage tank chamber. In this way, water flow from the storage tank is carried out until a critical pressure/level value is reached. After this, the pump is turned on again and the cycle repeats.

Pumping stations with internal ejector

Surface pumps with an internal ejector have significant limits regarding the depth of water intake - no more than 7-8 meters. This is compensated by the pressure of water that they ultimately produce - from 40 to 60 meters (about 4-6 bar).

If you use a pump with an internal ejector, you don't need to worry about air locks. Air pumping is carried out without negative effects for surface pumps. After pumping, the process of injection into the supply system with water taken from wells occurs.

Pumping stations with internal ejector

However, stations with an internal ejector also have their drawbacks. The main disadvantage is that they make a lot of noise. To supply water to a private home, it is better to install such stations in the utility room, having previously made good sound insulation there.

How to choose a pumping station

When choosing pumping equipment for a private home, you need to be guided by the following criteria:

- Power. It is important not to go too far. Too strong equipment drains the source and costs money. A weak station will not provide a supply of water for the home. The average power of equipment for private use is 900-1500 W.

- Water suction depth. Some models are capable of pumping water only from a level of up to 8 m - this means the distance from the surface of the earth to the liquid surface at the source.

- Hydraulic tank volume. For a family of 3-4 people, a capacity of 25-50 liters will be enough.

- Availability of additional protection. Many models are equipped with overheating systems. They prevent pump damage if the water level at the source drops.

- Pump housing material. Plastic is considered optimal. It dampens noise, is durable and environmentally friendly.

The list of selection criteria also includes the equipment manufacturer. Popular brands include Gilex, Metabo, Pedrollo, Grundfos and Gardena. Good equipment cannot have a low price. On average, you will have to pay from 500 USD for a pumping system.

Pumps with external ejector

When using a pump with an external ejector, you can draw water at a depth of 50 meters. Despite the economical use of this pump, their efficiency is not all smooth – it is a maximum of 40%. On the other hand, unlike pumps with an internal ejector, they make almost no noise during operation.

Station with remote ejector

What is good about a pumping station without a hydraulic accumulator?

A pumping station without a hydraulic accumulator is located in many summer cottages. Its main difference from pumps with a hydraulic accumulator is, as you may have correctly noticed, the absence of a hydraulic accumulator.

If the pump does not have one, then most likely it works with a storage tank. This is the second type of pumping stations. This is an old design, but it is still used in summer cottages. The amount of water in the tank can be estimated by the float that is placed in the tank. When the volume of water has decreased to the limit values, at that moment the sensor is triggered. At this moment it sends a signal to start pumping water.

The storage tank is very large, so it is used less and less.

Among the disadvantages of the system are:

- Low water pressure;

- Large tank sizes;

- Difficult to install;

- The storage tank must be installed above the pump level;

- If the sensor that signals overflow breaks down, water can flood the house.

The main advantage of such a pump is its low cost. A hydraulic accumulator is not cheap, so you can save money without it.

A pumping station without a hydraulic accumulator with a storage tank is a thing of the past. Summer residents do not recommend buying it if it is possible to buy a pump with a hydraulic accumulator. Despite the low cost of such pumps, you risk flooding your home with water. Therefore, it is better not to purchase such pumps.

Choosing a location for a water supply station

This choice largely depends on the parameters of the hydraulic pump. Every ten meters it passes through a horizontal pipe, its suction characteristics decrease. For example, for pumping water from a depth of more than 10 meters, only certain pump models may be suitable.

An automatic water supply station should be installed in the following places:

- in a caisson, next to the well;

- in a separate pavilion for pumps;

- in the basement.

If you chose an external stationary pump, lay a pressure pipe from the caisson to the cottage. Moreover, the pipe must lie below the frozen soil. This really makes sense if the pipeline is used all year round. If you need to lay pipes only for the summer, a depth of 40-60 cm will be quite enough, or the laying can be done completely on the surface.

If you are planning to install the station on the ground floor or even in the basement, you don’t have to worry that the pump may freeze in the winter cold. It is necessary to lay the pipe below the frost line of the soil, and the problem will be solved.

Drilling a well can also be done right at home to reduce the length of the pipeline. The only question is about the possibility of such a step in various private houses and cottages.

If you want to install the station in a special separate extension, keep in mind that this is only suitable for warm seasons. Otherwise, a separate heating system will have to be installed in this extension, and it is better to immediately install the equipment in the heated house.

Pumping stations for water supply at home: device, installation, connection, principle of operation

Many private homeowners have to decide on connecting the water supply to their home. The remoteness of the house from the centralized water supply forces residents to use water from local sources: wells and wells. Using these alternative sources, homeowners sooner or later are faced with the problem of choosing pumping equipment to supply water to their home. An automatic water supply pumping station is exactly the equipment that will ensure the supply of water to all water collection points, automatically and with the proper pressure.

Let’s try to figure out what to consider when choosing equipment and how the pumping station is connected to the water supply.

What is a pumping station

The design of a water supply pumping station consists of a hydraulic accumulator, a pump and an automation unit. Before you start installing a water supply, you need to have at least a little idea of how the system works. At the place of installation, water supply pumping stations are classified as submersible and surface. In submersible units, some of the elements, including the pump, are located in the water; at the top there is a hydraulic accumulator and an automation unit.

An automatic water supply pumping station is a fully factory-ready product, but nothing prevents you from assembling such a station yourself with your own hands.

Types of pumping equipment

When choosing, you first need to decide on the heart of the pumping station - the pump. For surface automatic water supply pumping stations, pumps can be divided into:

- vortex, centrifugal;

- multi-stage or sectional.

Pumps with vortex and centrifugal operating principles are structurally similar; at first glance, they may not be distinguishable. The main thing is the principle of operation: centrifugal ones create pressure due to centrifugal force, and vortex ones due to the pressure created by the impeller blades during turbulence.

The main advantage of both is their simple design, which makes their repair and maintenance easier.

Multistage or sectional pumps, these types of units are made up of sections as liquid passes through each section, the pressure increases. The main advantage of such a pump is its ability to create a strong output pressure; they are less noisy.

The depth from which they are capable of lifting water is usually from 7 to 10 meters.

The next type of pumps is submersible, which in turn can be divided:

- borehole;

- well

Wells and boreholes, their principle of operation for pumping water into submersible water supply stations is centrifugal - due to an impeller with blades and vibratory through the vibration of a diaphragm. The main advantage of these pumps, of course, is their noiselessness.

1. Pump power cord, 2. Pressure gauge, 3. Power cord, 4. Pressure switch, 5. Tee, 6. Hydraulic accumulator, 7. check valve, 8. water pipe, 9. Cable, 10. Submersible pump, 11. Well

Submersible units are usually installed where the water is too deep.

Important! The performance of the pump depends on the conditions: the depth of the intake, the height of the water rise and the pressure in the system.

Stations can be divided according to the type of water intake:

- direct action;

- ejector

When drawing water directly, the suction of water occurs due to the discharge of the pump created in the chamber; in simple words, it is simply a pipe extended from the pump to the water source. This method is inconvenient because the station has to be located in close proximity to the source. Although submersible pumps can be classified as this type, they stand separately in their own category.

1. Permissible water level, 2. Pressure height, 3. Water pipe, 4. Pressure gauge, 5. Pressure switch, 6. Power cord, 7. Surface electric pump, 8. Hydraulic accumulator, 9. Tee, 10. Non-return valve

Intake using ejection, when a vacuum is created due to the flow of water which, passing through the ejector, forms a reduced pressure and sucks in water along with it.

The advantage of this method of water intake is a greater depth of water intake; the station can be located at a distance from the source.

Automation block

Automatic water supply pumping stations are equipped with an automation unit that turns the pump on and off.

The automation unit monitors the pressure in the tank and the speed of water flow, which protects the pump from dry running (operation without water) and significantly extends the service life of the pump.

Often stations are equipped with one control element. The name of the pressure switch speaks for itself; it allows you to adjust the water supply station to a certain pressure, upon reaching which the pump will turn off and turn on at the minimum pressure in the system.

Setting, pressure regulation is set by tuning springs “The more compressed the springs are, the stronger the pressure and vice versa.”

The pumping station is also equipped with a check valve.

The check valve prevents the pump from being left without water by stopping the reverse flow.

Hydraulic accumulator for station

It is important to consider the volume of the accumulator. A large volume is capable of providing water to a home for a long time in automatic mode, that is, in the off state.

This, firstly, will allow you to save on electricity, secondly, provided that the lights are turned off, the house will be provided with water for some time, how long will depend on the volume of the hydraulic accumulator, thirdly, the operation of a pump with a hydraulic accumulator is much longer than without him. When choosing, the large volume of the hydraulic accumulator is a plus, and the cost is a minus.

Equipment installation rules

For the equipment to operate, it is necessary to have a power supply. It is necessary to draw a line to where the station will be installed; it is advisable that your connection point (socket) has a degree of protection of at least IP44.

Connect and configure the equipment after you have read the manual supplied with this unit.

For a home with year-round use, we will consider the optimal installation schemes for an automatic water supply pumping station. To do this, there are a number of other criteria that must be taken into account before installing the equipment:

- Place where it will be installed.

- And how it will be used.

If operation is planned in winter, then the room where the station will be installed must be insulated and have ventilation. Regardless of the installation location, the room temperature should not be lower than +5 degrees.

The equipment should not be affected by temperature changes or frosts; the room should be ventilated, since the accumulation of condensate also has a bad effect on operation.

You can also make a caisson - this is a small structure for pumping equipment in which waterproofing is done, insulation is done, and the walls are sheathed with soundproofing materials.

Under the caisson, a depression of up to 2.5 meters is dug in the ground, where the pumping station is installed. This is a good option for installing a water supply station - the equipment is located below the ground freezing level, and a positive temperature will be constantly maintained inside the installation.

If water is drawn from a well, the casing pipe is cut slightly higher than the bottom of the caisson. A pump is lowered into the well pipe, which lifts water into the accumulator.

The pipes are laid in trenches below the freezing depth of the soil in this region; also, to reduce the depth of the trench, the pipes can be insulated, which will allow less digging