Classification of semi-automatic devices

The division of semi-automatic welding devices is carried out according to various criteria.

Device type

This mainly applies to the body of the device. If all the components are in one body, then it will be a single-body type. In two-body models, one block contains a welding torch, a wire feeder, and a control panel. In the second block there is a current source having equipment for regulating the start.

Type of wire

The semi-automatic machine can use two types of wire: aluminum or steel. There are universal devices that can work with any of these types.

Seam protection

This happens in three ways: with a layer of flux, in protective gases, and using flux-cored wire. The most common method is to use shielding gases. The caveat is that cored wire can also be used in a gas environment.

Nature of movement

For mass production, stationary devices are used. In everyday life and for field work, portable semi-automatic devices will be more convenient. Mobile devices move on a chassis with wheels.

Electrical connection

Single-phase semi-automatic devices with low power can be plugged into a regular outlet. Three-phase require special connectors.

Wire feeding

With the push type, the drive pushes the wire into the welding torch. In the pull-type design, the drive is located in the torch handle and pulls the wire from the spool on which it is wound. The hybrid is a pulling-pushing type.

Polarity when welding semi-automatically

Before welding, you need to decide which polarity you will use.

Plain copper-clad wire that is used with shielding gas should be used with reverse polarity when positive is applied to the wire. Straight polarity is used when the semi-automatic machine has flux wire installed, which is used without gas. In this case, a minus is applied to the wire, and a plus is applied to the metal being welded through the terminal. Thus, maximum heat generation is generated on the wire. This is necessary so that the flux in it can work properly.

If you use the wrong polarity for a certain electrode (in the case of a semi-automatic wire), then the strength of the weld will be poor. If the wrong polarity is used, there will be a lot of spatter, poor welding penetration and the welding arc will be difficult to control.

To change the polarity, you need to open the cover of the semiautomatic device and swap the terminals. Next to the terminals there is a table specifying the order of the terminals.

Welding wire

The semi-automatic machine can use two types of wires: plain copper-coated wire and flux-coated wire.

- Simple wire for semi-automatic welding is used with shielding gas and does not have any additives that can “resist” corrosion and contamination. Therefore, the surface must be prepared carefully.

- The second type of wire has a flux in the center, which, when burned, forms a protective gas. Thus, you can do without a gas cylinder. This wire creates deeper penetration when welding than conventional wire with gas. Flux-cored wire creates a lot of spatter and slag in the welding area, which must be cleaned up after welding is complete. When welding with such wire, minimal surface preparation is required, minor contamination is forgiven. This wire also works well when it's windy outside. For flux-cored welding, the machine must be set to straight polarity (see above).

- The greater the thickness of the metal being welded, the larger the diameter of the wire you need to use, since larger diameter wire conducts more electricity and gives more heat and better penetration.

Semi-automatic device

To better understand how to weld with a semi-automatic machine, you need to study its structure.

Main components of the device:

- Frame.

- Power supply.

- Control block.

- Burner.

- Bobbin with wire.

- Wire feed mechanism.

- The cable used to connect to ground.

- A hose designed to supply gas.

- Inert gas in container.

You can purchase additional accessories, such as a protective screen or a sleeve stand. Power sources for semi-automatic devices, usually operating on direct current, are inverters or rectifiers. Inverters are preferred, but their cost is much higher.

A welding hose is a hose that supplies gas, wire and cooling liquid to the work site. One end of it is connected to the apparatus, and the other to the gas burner. Inside the welding sleeve, in the center, there is a unit through which the wire is fed. Coolant is only available on some models. The longer the hose, the greater the possibility of welding in places where access is difficult. To connect the hose, a unified connector according to the Euro standard is used.

The large fitting in the center is used for the wire exit. The small one next to it is for supplying gas. The two contacts at the top are needed to switch modes. There are wires connected at the bottom that supply current.

A burner is connected to the hose, where all the wires and tubes are led out. The main components of the burner are the handle and the guide tube coming out of it.

There is a mode switch on the handle. A gas diffuser, a contact tip, and a nozzle are attached to the tube. The contact tip is a replaceable part because it is different for each wire diameter. The nozzle depends on the size of the tip.

The welding wire is wound on a spool, which can have different sizes. The wire feeding device includes a roller feed mechanism. The rollers have grooves for different wire diameters. The role of the electric motor is to perform rotation. The wire tension is adjusted manually.

Rollers are used for cored wires. There may be two or four. That's basically all you need for semi-automatic welding.

Technology and types

MIG/MAG welding

The technology of semi-automatic welding is based on approximately the same principle as in the conventional connection of metal parts using an electric arc.

This is where the similarities end and the differences begin:

- Firstly, unlike the traditional welding process using a conventional electrode, where the combustible coating of a metal rod forms a space free of oxygen, in a semi-automatic welding machine the role of the coating is played by the gas passing through the torch nozzle.

- Secondly, instead of a holder, a special device is used - a torch and a sleeve for simultaneous supply of both wire and gas.

- Thirdly, in addition to controlling the torch, in a semi-automatic machine you need to learn how to control the wire feed, since the adjustment lever is located on the torch handle.

Today's technologies use two main methods of joining metal in a protective gas environment:

- In an active gas environment (carbon dioxide) MAG (Metal Active Gaz).

- In an inert gas environment (argon or helium) MIG (Metal Inert Gas).

The third type of semi-automatic welding uses a special wire, but due to its high cost it has not yet become widespread.

Principle of operation

The theory of semi-automatic welding is as follows. The main feature is that instead of electrodes, welding wire is used, which enters the welding zone continuously.

Semi-automatic welding can be carried out in carbon dioxide (MAG) or inert gas (MIG). The technology of semi-automatic welding with carbon dioxide and inert gases involves setting the wire consumption value on the machine. At the exit, the wire has to pass through a hole in the contact tip. An arc occurs between the wire and the part being welded, and the metal begins to melt due to the high temperature, which leads to the formation of a weld pool. It begins to move after the burner. A weld remains behind, which gradually begins to cool.

A nozzle is used to form a gas cloud of a specific shape and density. Gas enters it through a diffuser, which is located at the point where the contact tip is attached. It is clear how a semi-automatic gas welding machine works. However, there is an option without using it. In this case, a special wire is used, which is a thin tube with flux inside.

Since the flux has a powder structure, the wire is also called flux-cored wire. When welding, flux, when burned, releases a gas that creates a protective environment. For beginners, semi-automatic welding without gas is a good and easier way to gain general information about the features of the process. For critical structures, gas welding is preferable.

Advantages and disadvantages

The popularity and widespread use of the technology are associated with those positive aspects that provide an undeniable advantage over other types of electric welding technologies.

This is largely explained by:

- The peculiarity of the operating principle is a narrow heating zone of the joined surfaces, while a small surface of the joined parts is subject to deformation.

- A fairly gentle effect on surrounding parts , including paint and varnish coatings; only a small area burns, and the rest of the surface does not suffer from thermal effects.

- A special wire of various diameters is used as an electrode , at the same time, the operating time of the device increases many times, and the costs of consumables are reduced.

Unfortunately, there are also obvious “disadvantages” of semi-automatic welding:

- The main thing is the complexity of the equipment; in addition to the welding machine itself, you must also have a gas cylinder with gas.

- Welding machines of this type are not entirely applicable in the household ; in most cases, an inverter is sufficient, but it is needed by those who are seriously involved in welding.

Welding wire

Following the widespread demand for semi-welding machines, the industry began to create various types of wires for them. Its correct choice increases the productivity of the welding process and improves the quality of the seam. An important aspect is increasing security. GOST 2246 contains requirements for the composition and quality of wire. Among the large number of types of brands, only a few of them are constantly used. The rest are narrow-profile.

The type, diameter and grade of wire depend on the chemical composition and thickness of the metals being welded. The composition of the wire must correspond to the same characteristics of the material. Therefore, wires are divided into three large types: low-carbon, alloyed and high-alloyed.

The type of brand is indicated on the label. Letters and numbers indicate the composition and percentage of the included elements. Wire, in which the content of harmful substances such as sulfur and phosphorus is reduced, has the letter “A” at the end of the marking. Two letters “AA” indicate highly purified metal.

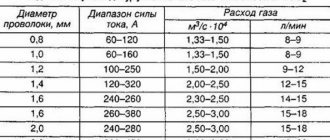

Wire diameters for semi-automatic welding range from 0.3 to 12 mm. The choice of diameter depends on the thickness of the parts. So, for example, if you are welding parts with a thickness of 3-5 mm, then the wire diameter should be no more than 2 mm. The choice of wire is also influenced by the selected amperage. To save money during the welding process, the consumption of filler material is controlled. It is influenced by the composition of the metal being welded, the diameter of the wire, and its quality.

Operating principle of semi-automatic machine

Semi-automatic welding machines are mostly simple equipment. Its main parts are an adjustable direct current source, which supplies the welding voltage, as well as a special mechanism designed to feed the welding wire into the welding arc zone, and the feed is performed at an adjustable speed.

The arc has reliable protection thanks to the gas flow created by the burner, where it enters from a cylinder with the same gas. The electrode feed speed and welding voltage are adjusted simultaneously.

As already mentioned, the welding wire must be fed into the arc zone at a strictly defined speed. Only in this case will the welding process proceed stably. Otherwise, at the slightest break in the wire feed, the arc breaks, and this leads not only to a decrease in the quality of the weld, but also to other more serious consequences, which include, first of all, burn-through of the seam, melting of the electrode tip and other failures and defects.

For high-quality feeding, it is necessary to check the drive rollers before work. It is necessary that the feed roller has a V-shaped groove, the size of which must match the size of the wire, and that this groove is in good condition, that is, not worn out.

Often when people experience poor feed, they will increase the clamping force on the drive rolls, which can only make the feed worse as the wire can become deformed. In addition, the burner guide channel can be damaged for the same reason.

During operation, the welding wire passes through the torch through a guide channel, which over time tends to become dirty and wear out. As a result, the resistance of the electrode feed increases, until the wire stops completely.

This should not be allowed; it is better to notice these changes in time and replace the guide channel with a new one, installing which you need to be very careful, since if its length, external and internal diameters do not match, serious feeding problems may arise. In other words, the whole point of replacement is lost and normal welding is still not possible.

In order to reduce wire contamination, as well as premature wear of the guide channel, it is better to choose a semi-automatic machine with a closed feed mechanism. This approach to wire feeding significantly better protects it from dust, moisture, oxidation, etc.

Now a few words about the contact tip of the torch, through which the actual welding current is supplied to the electrode (welding wire). It is clear that for high-quality welding, the wire must have high-quality and reliable contact with this tip. It is necessary to monitor the degree of wear of this part of the semi-automatic welding machine in order to replace it in a timely manner.

All these seemingly little things are of great importance for high-quality welding performed using a semi-automatic machine. Good condition of equipment is the key to success, and poor care of it is the first and surest step to the occurrence of all kinds of malfunctions.

Preparation

Before welding with a semi-automatic welding machine, it is necessary to carry out preparatory work. They begin with adjusting the semi-automatic welding machine. To do this, select the correct current value and set it on the device.

Then the wire feed speed and gas flow are adjusted, which is set using a valve on the cylinder reducer. You can evaluate the correctness of the settings on a small piece of metal. With proper adjustment, you should get a tight, even seam.

After this, the optimal gas flow rate is set. If it is insufficient, pores will appear in the weld seam. There is no limit to the upper value, but if it is unreasonably large, the gas will escape into the atmosphere uselessly, which will increase costs. If the seam is of insufficient quality, readjustment should be done.

Then you need to check whether there is a sufficient amount of gas in the cylinder to create working pressure. Working - pressure that allows for reliable protection of the bath in the work area. Then you need to decide on the polarity.

After selecting the polarity, you must connect to the appropriate terminal. Straight polarity will be ensured by connecting the welding cable to the positive terminal. Reverse polarity is used for very precise work.

Resanta SAIPA 165: main technical indicators

Let's look at the main indicators of Resant SAIPA 165 and the nuances of welding with it:

- Wire feed is directly dependent on current strength. This helps to avoid current short circuits and arc breaks during welding;

- The current strength is adjusted according to the selected cross-section of the electrode. The higher it is, the deeper the penetration of the metal;

- Welding speed allows you to control the quality and geometry of welding work. At high speeds, the wire has a chance to go beyond the protective sphere and oxidize. At low speeds, the weld pool increases and the likelihood of pores forming in the weld increases;

- The arc voltage is controlled by the selected current value. As this value increases, the penetration deepens and the seam becomes wider. Increasing the value too much leads to metal spattering and the formation of voids in the seam;

- The shielding gas and its quantity depends on the cross-section of the electrode, welding speed and air circulation around. If there is a need to increase gas protection, then the welding speed must be reduced and the nozzle should be brought directly to the surface to be welded;

- The polarity is set in reverse, the burner is connected to the “plus”, and the metal to the “minus”. Welding without gas is carried out in the straight polarity position;

- The inclination of the electrode affects the depth and quality of the seam. If the metal being welded is thin, then it is necessary to tilt the wire forward. With reverse tilting, the depth of the seam increases, and visual control over the progress of work improves.

Process technology

The peculiarities of semi-automatic welding are that wire is used instead of electrodes and the process occurs under gas protection. The semi-automatic welding technique involves maintaining a constant temperature. If the heating is insufficient, the edges will not melt normally and will not mix well with the filler material. If the temperature rises too high, the metal will begin to boil and evaporate.

There are two types of semi-automatic welding techniques. The first is that a continuous seam is made from start to finish. The second method uses spot welding. Welding points are placed at regular intervals.

Welding technology has features depending on the thickness of the metal parts, types of joints and their location in space. Thin parts are easier to weld semi-automatically if they are located in a vertical plane. If the thickness of the metal parts does not exceed 4 mm, then you do not need to cut the edges. It is better to weld thick parts in helium or argon. In this case, it is necessary to ensure that the burner axis does not deviate from the vertical.

When welding corner and T-joints with a semi-automatic device, the parts should be installed “in a boat”. Thin lap joints are made in one pass using a copper or steel backing. Parts whose thickness exceeds 1.5 mm can be welded in weight, making several passes.

Semi-automatic welding rules:

- Welding should be carried out in such a way that the weld pool is visible to the performer. This is possible when the wire is held straight or at a slight angle.

- The gap between the welded elements with a thickness of 1 cm must be at least 1 mm. Then it is calculated based on the formula - 10% of their thickness. The gap must remain constant throughout the welding process.

- If a backing is used, it is placed from below on the parts to be welded, ensuring density.

- It is necessary to control the current value and arc size. This will reduce the splashing of hot metal.

- A thin wire should be guided along the seam. With a large diameter, it is advisable to perform oscillatory movements, which contribute to heating the edges.

The setting depends on the specific equipment model. Before starting work, you should carefully read the operating instructions.

Welding in general and semi-automatic welding in particular is a complex art that requires patience. You should not immediately strive to set a record. The semi-automatic welding technique for beginners is to practice first on simple parts.

Working with thin metal

Working with a semi-automatic welding inverter, the best success can be achieved when welding thin metal. And, despite the complexity of the equipment, even beginners can do it.

But for such success you need:

- When welding such metal, it is recommended to adjust the feed of the welding wire.

- It is recommended to first clean the parts to be connected from dirt, dust and, if possible, from oil and greasy contaminants.

- When connecting thin metal, you should use special clamping devices, since the semi-automatic machine creates local heating points, the connection may not be completely tight.

- For large volumes of seams, it is recommended to first grab the metal in several places, and only then weld along the entire length.

Advantages

The advantages of semi-automatic welding include:

- ease of use;

- high performance;

- possibility of welding in all spatial positions;

- seam deformations are minimal;

- possibility of welding thin joints;

- slight sensitivity to dirt and rust;

- zinc coatings are not damaged when welding with copper wire;

- obtaining a high quality seam.

The disadvantage is that the gas protection evaporates in a draft. The relative ease of controlling the process makes semi-automatic welding possible for beginners.

Semi-automatic cooking rules

To learn how to qualitatively connect parts, you need to know the nuances of working with the device. Safety precautions are considered equally important. When welding semi-automatically, the following rules are observed:

- Wear a protective suit and a mask that neutralizes the negative effects of ultraviolet radiation on the eyes.

- Make a test seam on the rough parts. This will help you configure the device correctly. Before using the device, read the instructions.

- During operation, pauses are taken to prevent the unit from overheating.

Difference from automatic welding

Automatic and semi-automatic welding have much in common and are very different from the manual method. The main difference between automatic welding and semi-automatic welding is that the semi-automatic machine mechanically feeds the wire, which acts as an electrode, to the work site, but then it is moved manually. This allows you to correctly form the seam and monitor its quality.

It is advisable to use automatic welding in mass or large-scale production. On welding forums the question is sometimes asked: how to weld semi-automatically with electrodes. Experienced welders answer that for this they will have to radically redo the machine, but this does not guarantee a high-quality weld.

Characteristics of RESANTA SAIPA-200

The semi-automatic welding machine Resanta Saipa 200 is a universal inverter for semi-automatic MIG/MAG and manual arc MMA welding. That is, this semi-automatic machine can weld not only with a special wire, but also with an electrode whose diameter does not exceed 5 mm.

The power of the Resanta semi-automatic welding machine is 5.5 kW. The diameter of the wire that can be used in a semi-automatic machine ranges from 0.8 to 1 mm. The device can operate from a reduced voltage of 140 Volts, which is very important when the mains voltage is low in the house or country house.

The semi-automatic Resanta Saipa-200 is equipped with a reliable forced cooling system. It also has overheating protection, which is very important when working with a semi-automatic machine for long periods of time.

The arc voltage of the semi-automatic welding machine is 42 Volts, and the welding current range can be adjusted from 30 to 200 Amps. Thus, the semi-automatic welding machine can be flexibly configured to perform all kinds of welding work.

Education

Training in semi-automatic welding can be completed at special courses. The program includes theoretical and practical classes. You can choose individual training according to a schedule convenient for the student and also learn everything about semi-automatic welding. After graduation, you must pass an exam and prove that all knowledge has been acquired.

A certificate of the established form is issued, which lists the subjects taken, practical classes and indicates that the title “Electric and gas welder” has been awarded. It is possible to obtain an international diploma, which makes it possible to apply the acquired knowledge in other countries.

Training in semi-automatic welding gives an idea of the types of semi-automatic machines, the choice of welding mode and wire diameter, and the technology of the welding process. The lessons learned on the theory of “semi-automatic welding machines” will allow you to understand the designations of the materials used and the markings of the wire. The basics of semi-automatic welding include information about the design of semi-automatic devices, the principle of their operation, ensuring the safety of the welder, carrying out preparatory work, and choosing welding modes.

At the courses you can not only learn everything about semi-automatic welding, but also apply the acquired knowledge in practice. They are conducted under the guidance of a mentor, who will point out errors and explain how to eliminate them. Group classes have the advantage of being able to hear other students' questions and learn the correct answers. During practical classes, you should listen to the analysis of all situations, from which you can learn a lot of useful things.

Semi-automatic welding lessons are taught by professionals with extensive experience. The acquired profession is in demand and highly paid. Those who already have a welding profession, but who want to improve their skills, can also enroll in the courses. Training in a specialized course will help you understand what semi-automatic welding is. The knowledge gained will help you easily read drawings and understand technological materials.

Technology

With a semi-automatic welding machine you can independently weld stainless steel, non-ferrous metals, steel, and aluminum. To connect non-ferrous metal workpieces, you need to choose the right wire for welding work. For example, a flux containing magnesium, manganese and aluminum can be used to weld aluminum parts. This wire makes it possible to connect thin metal or thick sheets

For novice welders, it is important to follow all stages of preparation and technology of the welding process.

Before starting welding work, you must wear protective clothing and a welding mask. Work can be carried out provided that there are no flammable objects within a radius of 10 m. Unauthorized people without protective equipment are not allowed into the work area.

Preparation

The method of welding with a semi-automatic machine without gas equipment differs from the conventional welding method in that it has a different polarity: a terminal with a “plus” sign is attached to the work piece, while a “minus” will be connected to the electrode. This polarity is explained by the fact that with its help it is possible to achieve the highest temperature conditions that are necessary to melt the powder flux.

Another important stage of the preparatory work is the thorough pre-treatment of the surfaces of the workpieces to be joined together.

To set up semi-automatic welding equipment, you will need to perform the following steps:

- select the current setting for the operation, according to the thickness of the metal that needs to be connected;

- select the optimal feed speed mode for the welding wire so that it is not damaged by tension during welding;

- switch the device to direct current polarity;

- scroll the wire forward, open the flap at the flux feed funnel, press the start button and activate the electrode;

- perform test welding and, if necessary, adjust the machine parameters.

After the setup of the semi-automatic machine is completed, the wire will flow freely into the welding area, and the welding arc will be stable, you can begin to form the connecting seam.

Experienced specialists recommend installing the pressure rollers of the device in accordance with the thickness of the wire. If this condition is met, the fluxed wire will move freely through the pipeline without the risk of getting stuck in the supply channel or breaking.

Process

During operation of a semi-automatic welding machine without the use of bottled gas, the flux during the combustion process creates a cloud of protective gas. Such vapors tend to rise upward, so the welder needs to provide an exhaust system or ensure that the room is well ventilated.

After the semi-automatic welding machine is ready for operation, movements with the electrode must be performed along the connecting seam being formed. If thick sheets of metal are to be joined together, this process is performed in several layers. Moreover, in order to avoid the appearance of cracks in the seam, you need to boil the first layer at a low electric current. A seam is formed by filling the weld pool with molten metal. After the cavity of the weld pool is completely filled, it is necessary to turn off the wire feed, stop the welding machine and turn it off from the network.

So that the work can be performed as conveniently and efficiently as possible, it is recommended to start the welding process from the upper segment of the parts to be joined, gradually moving down. When the flux burns, thermal energy is generated and, rising upward, it makes it possible to constantly maintain the same level of temperature required for melting the metal. To maintain constant melting of the metal and form a weld pool, it is recommended to tilt the electrode holder handle slightly upward.

The torch of a semi-automatic welding machine must move quickly and smoothly along the connecting seam, while trying to prevent the appearance of molten metal deposits. For this purpose, the wire should go to the leading edge of the weld pool.

How to cook semi-automatically without gas, see below.

Features of wire welding

Features of welding with wire using semi-automatic equipment are as follows:

- the filler material must correspond to the chemical composition of the product being welded;

- the wire must meet government standards and be made from the correct components;

- The terms and conditions for storing filler wire must be strictly observed.

A review of the features of work using filler wire should begin with welding basics. Most metals welded in production or at home are steel and manganese. Wire for connecting such products is the most in demand.

Welding of ferrous metals is usually carried out using the following types of filler material:

- Wire Sv-08GS for joining low-carbon and alloy steels.

- Wire Sv-08G2s for welding high-carbon steel.

Flux-cored wire is often used for welding ferrous metal products. This filler material allows welding to be carried out without additional gas supply to the welding zone.

Self-fluxing wire is a low-carbon steel tube with a powder core. When the metal melts, powder is released, forming a gaseous environment to protect the weld. As a rule, the fluxing powder contains rutile and metal dust.

Stainless steel is welded with wire grades Sv.-06Х19Н9Т, Sv.-04Х18Н9 or Sv.-01Х19Н9. This filler wire provides good mechanical and physical properties of the weld.

The connection of aluminum parts is carried out using SV-AK5 wire. A characteristic feature of this filler material is the unique color of the weld. Immediately before joining aluminum products, preparation should be carried out.

Semi-automatic welding using flux-cored wire.

This procedure is divided into steps:

- Creating bevels or chamfers.

- Mechanical cleaning of surfaces.

- Washing with caustic substances to slow down the formation of a refractory oxide film on the surface of an aluminum product.

- Preparation of a Teflon channel to reduce friction of the filler wire on the walls of a semi-automatic welding device.

Step-by-step instructions for using carbon dioxide welding for beginners include the following subparagraphs:

- removing all foreign objects from the workplace;

- turning on maximum lighting;

- preparation of material and tools;

- checking cable connections and functionality of extension cords.

After completing the above points, you should proceed to preparing the electric arc welding machine.

To do this you need:

- unwind the welding sleeve;

- connect the gas cylinder;

- check the burner nozzle;

- conveniently place all the parts to be connected and fasten them securely;

- dress in welder's work clothes;

- connect semi-automatic equipment to the network;

- bring the torch to the intended connection site.

Upon completion of welding work using wire, you should:

- remove your fingers from the wire feed buttons;

- shut off the gas supply;

- turn off the power to the equipment;

- Allow the seam to cool for several minutes;

- If defects are found, repeat welding.

The semi-automatic welding machine allows you to use all types of filler wire.

When performing work, it is important not to forget about protective equipment.

Semiautomatic welding machine with thyristor control.

The most complete welder equipment consists of:

- Eye protection. The ideal equipment to protect a welder's vision is a mask, face shields and goggles.

- Respiratory protection. Special filter masks will help the master to significantly reduce the impact of harmful fumes on internal organs.

- Splash protection. Full body protection should include a flame retardant jacket and trousers. You can use overalls.

Safety precautions when performing welding work include the following rules:

- Carrying out work from wooden scaffolding. The use of metal protective masks and helmets is prohibited.

- Providing light flux from a 12 volt power source.

- Providing insurance for the welder using a string attached to the belt. The rope size must be at least 2 meters.

- Providing the workplace with a special hood that ensures the removal of harmful fumes from the work area. In cases where it is impossible to provide exhaust, the welder must work in a hose gas mask or respirator.

- Do not touch the workpiece to be welded with bare hands.

- It is prohibited to carry out work in open areas during precipitation.

Types of welds in semi-automatic welding

Semi-automatic welding technology allows you to obtain different types of seams, depending on the equipment settings.

According to the type of connection, seams produced by semi-automatic machines are divided into:

- butt;

- T-bars;

- overlap;

- corner.

Features of semi-automatic welding.

According to their spatial position, welds are usually divided into:

- horizontal;

- vertical;

- ceiling;

- lower ones.

Popular ceiling seams are usually made in two stages:

- Welding the root seam. The preparatory seam is usually performed with three-millimeter electrodes with low current.

- Full completion of the seam.

The second welding stage of the ceiling seam can be performed in two ways:

- Welding using short, jerky seams or spot welding. This welding method prevents drops of molten metal from falling on the operator. When performing such a procedure, additional welding may be required at the beginning and end of the seam.

- Cooking with the shortest possible arc. This approach will allow the metal to quickly harden, immediately after the electric flame is removed.

Bottom connections, made using semi-automatic or manual arc welding, are often used in factories and industries. Such welds provide high mechanical characteristics due to the uniform distribution of molten metal.

Semi-automatic welding modes when making corner joints can be different.

Table of characteristics of semi-automatic welding machine.

Semi-automatic gas welding of corner metal structures can be performed:

- With a perpendicular arrangement of two workpieces. This technique allows you to weld only the internal joint. Cooking perpendicularly located tubes should include making a concentric weld around the circumference.

- With an angle of less than 60 degrees between the parts being welded. The best option for performing a fillet weld. In this case, the workpieces are completely boiled.

The butt weld is the most popular method of joining pipelines or steel sheets.

This type of welding is divided into:

- one-sided welding;

- one-sided welding and processing;

- double-sided welding.

One-sided welding in shielding gases is used for product thicknesses of no more than 4 millimeters. If the parts have a thickness of more than 8 millimeters, it is necessary to perform double-sided welding.

The best method for ensuring high strength of a thick product when welding one side is to groove the edges. The cutting is carried out using a grinder or a file. During the processing of the joined ends, a bevel of 45 degrees is formed.

An overlap joint is usually performed to ensure high tensile strength of the product. The seam should be made on both sides of the contacting surfaces to avoid moisture accumulation.

A T-joint is in most cases used to secure the base of a metal structure. When the metal thickness is more than 4 millimeters, it is recommended to use a double-sided weld.

Vertical

The technology of semi-automatic welding of a vertical seam has several important principles:

- Molten drops of metal should solidify faster than with conventional welding. This condition is necessary due to the gradual flow of molten metal downward under the influence of universal gravity. The required droplet size can be ensured only by reducing the size of the welding arc.

- Vertical welding is done from bottom to top. The welding method ensures the absence of sagging and unevenness when making a vertical seam.

There are several rules that can be followed to guarantee a high-quality vertical connection when welding from top to bottom:

- use of a short arc;

- perpendicular position of the electrode at the beginning of welding;

- the location of the electrode at an acute angle relative to the weld seam.

Welding wire feeder.

Although such steps make it possible to obtain a vertical seam by welding semi-automatically from top to bottom, as the lessons learned by experienced welders show, such joints have much more meager characteristics.

There are three technologies for welding vertical seams using semi-automatic machines:

- Triangle. It is used when connecting parts with a thickness of less than 2 millimeters. The essence of the method is as follows: during the operation of the welding arc, liquid metal flows from bottom to top onto the already solidified metal. In this case, the flowing slag moves at a certain angle, depicting a triangle.

- Herringbone. Method used to join 2-3mm gaps. Welding begins from the plane of one of the edges. Then, using an electrode, the metal is melted throughout the entire thickness of the workpiece, after which the arc is drawn to the very depth of the gap.

- Ladder. The best option for eliminating large gaps between parts. The method involves performing welding work using a zigzag movement of electrodes from edge to edge.

Horizontal

Semi-automatic welding allows you to perform high-quality horizontal seams. Performing such operations is not much different from creating vertical connections. The welding process can be performed both from right to left and from left to right.

You can get a high-quality horizontal seam by taking into account these subtleties:

- the arc burning force must be equal to the gravity force of the metal drops;

- the speed of movement of the electrode must be selected separately for a horizontal seam;

- Welding work should be carried out continuously in order to keep the melt under control.

Arc welding sometimes makes it impossible to complete a seam in one go. In this case, you can use the welding technique with periodic arc extinguishing. When metal thickness is up to 4 millimeters, the use of various welding patterns is allowed.

Otherwise, the quality of making a horizontal connection using semi-automatic or manual equipment completely depends on the skill of the welder.

Semi-automatic welding machine.

The process of creating a horizontal welding seam can be divided into four stages:

- Creating a root roll. The root weld bead is made with a short electric arc. The angle of inclination of the electrode to the surface should be about 80 degrees. The primary roller, as a rule, is created with the maximum current allowed for the equipment.

- Formation of the secondary roller. The process begins with setting the average current strength. The secondary roller is made in one pass, in which it is advisable to use an electrode with a large diameter. The second welding bead should be formed using the forward angle technology.

- Getting the third roller. The tertiary bead can be created in two ways, depending on the success of the previous stage. If the secondary roller has a large area, then the third should lie exactly in the center. If the second roller turned out to be standard, then the third stage is performed in two approaches.

- Final welding of parts.

During the work process, you should carefully monitor the upper part of the seam being formed, since it is in this area that various welding defects appear.

How does a semi-automatic machine work?

To understand how semi-automatic welding works, it is worth considering the operating principle of the equipment. During processing, an electrode wire is continuously fed to the area to be welded. For this reason, the welder should not constantly install new electrodes.

During welding, the products being welded are heated and deformed. An electrical discharge is formed between the metal element and the electrode, which is energized, in the gas mixture. The quality characteristics of the connection are enhanced by the use of inert gas, which prevents the formation of oxides.

It is worth noting! Semi-automatic welding technology received this name because the wire is fed automatically, and the feed control and welding process is carried out manually by the welder.

Among the main features of the semi-automatic machine are:

- Semi-automatic equipment has two poles - with a positive and negative charge. The polarity of the connection is selected in accordance with the metal that is being welded. One clamp is attached to the workpiece being welded, the other is fed to the sliding contact of the torch.

- The current parameters are selected according to the characteristics of the material used for welding.

- To select optimal current values, welders use special tables and follow the recommendations of the welding equipment manufacturer.

- Feed speeds are set using a gearbox or gear.

- Gas semi-automatic equipment is designed to work with inert or carbon dioxide. To carry out welding work, welding wire is supplied for a semi-automatic device, which contains magnesium and silicon. Gradually, it melts and is subsequently supplied to the area to be welded.

- Along with the wire, gas is supplied, which protects the metal product and the electrode from the negative effects of oxygen.

- When using equipment for flux-cored wire, no gas is required. When semi-automatic welding is carried out without gas, the flux burns and gas is formed, which neutralizes the negative effects of air.

Setting up the welding machine

High-quality semi-automatic welding for beginners cannot do without fine-tuning the equipment.

Before using the device, the welder must install:

- current strength;

- wire feed speed;

- required shielding gas pressure.

Most semi-automatic welding machines are supplied with accompanying documentation containing optimal settings for certain operating modes. There are parameters that should be used as a starting point when fine-tuning the equipment.

You can check the correct settings of the parameters on separate unnecessary pieces of metal. To set the correct parameters when working in a protective gas environment, it is necessary to ensure that the weld is smooth and uniform, without drips or interruptions.

The optimal working gas pressure should generally be between 1-2 atmospheres.

Preparing the semiautomatic device for operation includes the following steps:

- Selecting the optimal wire radius. Most of these consumables come with a radius from 0.03 to 0.06 centimeters. The best choice for most materials is a wire radius of 0.04 centimeters.

- Pulling the wire until it exits the torch and adjusting the degree of its pressure.

- Preparation of optimal shielding gas. The two most commonly used gases are carbon dioxide and argon. The first option is cheap, common and great for welding steel parts. Argon is a more expensive shielding gas that ensures high stability of the electric arc and reduces the amount of metal splashes during work.

- Connecting the gas cylinder to the equipment.

Semi-automatic welding in a protective gas environment.

When setting up the equipment, you must adhere to certain rules that allow, if you have certain skills, to obtain an even and high-quality seam:

- ensuring uniform arc burning;

- installation of electrode wire forward direction;

- cleaning seams from accumulated slag.

The most optimal equipment settings are indicated in the accompanying documentation for the welding installation. However, you should not always completely trust the factory parameters.

Thus, the operating properties of the device can be affected by:

- various operating modes;

- quality of the electrical network;

- composition of the alloy being joined;

- ambient temperature;

- thickness and composition of filler wire;

- spatial positions of work;

- composition of the shielding gas.

The most common errors when setting up welding equipment are:

- Loud extraneous sounds resembling crackling. Similar symptoms can occur if the solder supply speed is insufficient. To avoid such misunderstandings, the feed rate of filler materials should be increased.

- Heavy splashing of metal droplets. The malfunction occurs when there is insufficient shielding gas. The problem can be resolved by checking the reducer or increasing the power of the gas flow.

- Poor penetration and low quality seam. Fault due to incorrect voltage and inductance settings.

- Uneven roller width. The defect may occur due to incorrect choice of burner speed.