Long-term and trouble-free operation of VSP elements is possible only when they are made of suitable material. And today we will look at what steel railway rails are made of, why this particular metal was chosen, and what properties it has. The information will help you choose the right rolled products for the actual construction of the track.

It is important to take into account the specifics of modern times. Over almost 100 years, the carrying capacity of railway transport has increased 8-10 times, and the speed of its movement along the roadway has increased 5 times. It turns out that the supporting structures experience completely different loads. Therefore, it is necessary that they are stronger, harder and more wear-resistant than they were a century ago.

Rail steel

It combines several types of similar metals, similar in method of application - used for the manufacture of elements of the VSP (superstructure of the track). Fine-needle perlite forms the basis of the phase structure for all variants smelted in converter or arc furnaces. After heat treatment, it becomes as homogeneous as possible, acquiring viscosity, sufficient hardness and high wear resistance.

According to deoxidizers, it is divided into 2 main groups:

I – harmful impurities are removed using ferromanganese or ferrosilicon;

II – aluminum inclusions are used to remove oxygen (considered more preferable due to their nature).

Basic materials for making rails

Much depends on the area in which the rental products will be used. VSP elements are made from converter steel, laid into the railway track and forming a wide or narrow gauge. But crane support metal structures need to withstand completely different loads, so factories use high-carbon alloys to produce them.

A completely different case is the so-called contact ones, installed to create a subway track. They do not accept huge voltages, but they must effectively remove current, so they are made of relatively soft metals.

Chemical composition and its advantages

For the main steel grades of railway rails, it is regulated by GOST R 554 97-2013. This interstate standard establishes that the main component is iron, but in addition to it, the alloy must include a number of other elements - in the following mass fractions:

- Carbon (carbon) – from 0.71 to 0.82%, increases the mechanical properties by approximately half. Its particles bind ferromolecules, turning them into carbides, which are much stronger and larger. And high-temperature effects become less critical.

- Manganese – from 0.25 to 1.05%, improves impact strength (by a quarter to a third), as well as wear resistance and hardness. Moreover, the ductility does not deteriorate, which has a very positive effect on the manufacturability of the finished rolled product.

- Silicon - from 0.18 to 0.4%, is required to remove oxygen impurities, and therefore to optimize the internal crystalline structure of the material. With this additive, the likelihood of segregation stains appearing is significantly reduced, and durability increases by approximately 1.4 times.

- Vanadium - from 0.012 to 0.08%, depending on the specific grade of steel for the manufacture of rails. Important for ensuring sufficient contact strength. In combination with carbon, it forms carbides that increase the endurance limit (namely, its lower threshold).

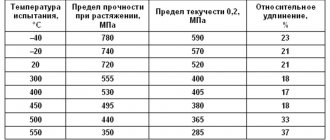

Mechanical properties

- Impact resistance - the hardness of the material alloyed with additives after volumetric hardening reaches 60 HRC on the Rockwell scale, viscosity - 2.5 kg/cm2. Thanks to this, it is difficult to accidentally damage already laid metal structures.

- Resistance to cyclic loads - rolled metal products are made from steel, because its tensile strength reaches up to 1000 MPa. In the climatic conditions of our latitudes, they do not deform for decades (especially with proper care).

- Moderate ductility - a hot-rolled product during production can be heated to a temperature of 1000 degrees Celsius. The indicator of its relative narrowing will not go beyond 25%. The result is a profile without voids and minor defects, which during operation could quickly turn into serious flaws.

The combination of such practical properties also determines the constant popularity and widespread use of I-beam guides made specifically from the alloy in question.

Rails, fasteners

View price list

Narrow gauge railway rails P18, P24, P33, P38, P43.

Rails P18, P24 are mounted on underground mine tracks and narrow-gauge railways. In terms of mechanical properties and assortment, they comply with GOST 5876-82, 6368-82. Rails R24, R18 are produced in accordance with GOST 5876-82 from steel grades H50, T60, PT70. Straightforward: in any section, local curvatures per 1 m should not exceed three millimeters, terminal curvatures of two millimeters. Both ends are cut at right angles to the longitudinal axis. The skew of the end does not exceed two millimeters in any direction.

R-43 rails comply with GOST R 51685-2000 and are intended for jointless and link tracks of broad-gauge railways, as well as for the manufacture of turnouts. They are made from electric furnace steel (continuously cast billets: E76, E76F, E76HSF) and open-hearth steel (casting into ingots: M76, M76F). Straightforward: with uniform curvature, the deflection of the rails should be no more than 1/2200 of the length in both horizontal and vertical planes. Thus, the deviation from straightness of the end of the rail in the horizontal and vertical plane with a base length of one and a half meters should not exceed 0.7 mm.

| Type | V, mm | В1,mm | N,mm | S,mm | Weight 1 m, kg | GOST |

| R 8 | 54 | 25 | 65 | 7 | 8,42 | GOST 6368-82 |

| P11 | 56 | 32 | 80,5 | 9 | 11,80 | GOST 6368-82 |

| P18 | 80 | 40 | 90 | 10 | 18,06 | GOST 6368-82 |

| P24 | 92 | 51 | 108 | 10,5 | 24,90 | DSTU 3799-98 |

| P33 | 110 | 60 | 128 | 12 | 33,57 | TU 14-2R-383-2004 |

| P38 | 114 | 68 | 135 | 13 | 38,416 | GOST 7173-54 |

| P43 | 114 | 70 | 140 | 14,5 | 44,653 | GOST 7173-54 |

Railway rails P50, P65, P65K, P75.

Rails P65, P50 are also intended for jointless and link tracks of broad-gauge railways and for the manufacture of turnouts. R 50 and R 65 meet the requirements of GOST R 51685-2000. Rails R 50 are intended for railways with a freight load of 10-25 million tons / km per year. R-65 rails are intended for railways with a freight load of 25-75 million tons / km per year.

| Type | V, mm | В1,mm | N,mm | S,mm | Weight 1 m, kg | GOST |

| P50 | 132 | 72 | 152 | 16 | 51,67 | GOST R51685-2000 |

| P65 | 150 | 75 | 180 | 18 | 64,64 | GOST R51685-2000 |

| R65K | 150 | 75 | 181 | 18 | 64,64 | GOST R51685-2000 |

| P75 | 150 | 75 | 192 | 20 | 74,60 | GOST R51685-2000 |

Crane rails KR70, KR80, KR100, KR120, KR140.

Rails KR-70, 80, 100, 120, 140 are intended for cranes and crane tracks. Manufactured from high carbon steel. They have a rounded head, a wider supporting plane and a thicker wall, which ensures uniform transmission of pressure from the wheelset to the upper belt of the crane beams. Crane rails are laid like railway tracks and attached to the crane beams. The movable fastening method is considered recommended. This method of fastening allows for leveling (straightening) of the track, and it is also relatively simple and convenient to replace worn rails.

Rails KR 120, 100, 80, 70 are produced in measured lengths: 9-12 m in increments of 0.5 m; unmeasured length - 4-12 m. Weight of one meter of rail: KR-70 - 47 kg 470 g; KR-80 – 64 kg 240 g; KR-100 – 89 kg 50 g; KR-120 – 118 kg 290 g; KR-140 – 146 kg 980 g. Technical characteristics and quality requirements are regulated by GOST 4121-96. Cracks, rolled films, sunsets, rolled dirt and flaws on the surface are not allowed. It is possible to remove defects by stripping or shallow cutting if the cutting depth does not exceed: - KR 80 and KR70 rails - 1.5 mm; — rails KR 100, KR 120 and KR 140 – 2 mm. Since crane rails are subject to high loads during operation, the wear rate is relatively high, despite the material of production - high-alloy steel. In this case, wear occurs both in the horizontal and vertical planes. Operation is permitted if wear does not exceed 15% of the nominal value.

| Type | V, mm | В1,mm | В2,mm | N,mm | S,mm | Weight 1 m, kg | GOST |

| KR70 | 120 | 70 | 75,6 | 120 | 23 | 47,47 | GOST 4121-96 |

| KR80 | 130 | 80 | 87 | 130 | 32 | 64,24 | GOST 4121-96 TU 14-2R-393-2005 |

| KR100 | 150 | 100 | 108 | 150 | 38 | 89,05 | GOST 4121-96 TU 14-2R-393-2005 |

| KR120 | 170 | 120 | 129 | 170 | 44 | 118,29 | GOST 4121-96 TU 14-2R-393-2005 |

| KR140 | 170 | 140 | 150 | 170 | 60 | 146,98 | GOST 4121-96 |

Railway rails RP50, RP65, RP75.

Designed for installation on broad gauge railways and turnouts of industrial enterprises.

Industrial rails are divided into

by type: RP50, RP65, RP75;

by hardening: heat-strengthened (T), non-heat-strengthened (N);

by the presence of bolt holes: with bolt holes at both ends, without bolt holes;

in length: measured - 12.5 and 25 m, with maximum deviations +/- 30 mm, unmeasured - from 6 to 25 m. Rails for welding are made at least 3 m long.

| Type | V, mm | В1,mm | N,mm | S,mm | Weight 1 m, kg | GOST |

| RP50 | 132 | 72 | 152 | 16 | 51,80 | GOST R51045-97 |

| RP65 | 150 | 75 | 180 | 18 | 64,88 | GOST R51045-97 |

| RP75 | 150 | 75 | 192 | 20 | 74,60 | GOST R51045-97 |

Frame rails P65.

Designed for making connections and crossings of railway tracks.

In terms of assortment, chemical and mechanical properties, the rails meet the requirements of GOST 24182-80. Rails are manufactured with and without bolt holes, 12.5 m long

Weight of 1 m of rail – 64.14 kg.

Counter rails RK50, RK65, RK75.

They are used in the structures of railway track superstructures.

The rails are made of steel M68 in accordance with GOSTs 18232-83, 9797-85, 9798-85, 26110-84.

| Type | V, mm | В1,mm | N,mm | S,mm | Weight 1 m, kg |

| RK50 | 70 | 19 | 172 | 18 | 36,57 |

| RK65 | 72 | 18 | 200 | 20 | 43,68 |

| RK75 | 71 | 19 | 212 | 22 | 48,60 |

Pointed rails OR43, OR50, OR65, OR75.

They are used in the structures of railway track superstructures. OR43 is used for the manufacture of railway turnouts for industrial enterprises and circular rails for slewing bearings of excavators.

| Type | V, mm | В1,mm | N,mm | Weight 1 m, kg |

| OR43 | 120 | 70 | 104 | 54,98 |

| OR50 | 132 | 74 | 112 | 64,30 |

| Or65 | 132 | 77,5 | 140 | 81,35 |

| OR75 | 140 | 72 | 152 | 89,58 |

Tram grooved rails T58, T62.

Designed for installation on tram railways.

The rails are manufactured with and without two bolt holes, 12.5 m long, maximum deviations along the length are +\- 10 mm.

| Type | V, mm | В1,mm | N,mm | S,mm | Weight 1 m, kg | GOST |

| T58 | 150 | 58 | 180 | 12 | 57,59 | TU 14-2R-320-96 |

| T62 | 150 | 62 | 180 | 12 | 62,05 | TU 14-2R-320-96 |

Guard rails UR65.

Designed for the manufacture of railway crosspieces with a continuous rolling surface.

In terms of assortment, chemical and mechanical properties, the rails meet the requirements of TU 32TsP-804-94.

Rail length is 12.5 m. Maximum deviations along the length do not exceed +/- 25 mm.

Butt bolt

| Material type | GOST or TU | Weight 1 pc. according to theory, kg. | Quantity per 1 t, pieces fact. |

| M 27x160 | GOST 11530-93 | 1,04 | 1220 |

| M 24x150 | GOST 11530-93 | 0,738 | 1695 |

| M 22x135 (for P43) | GOST 11530-93 | 0,471 | 2223 |

| M 22x135 (for P33) | GOST 11530-93 | 0,4 | 2500 |

| M 18 (for P18) | GOST 8144-73 | 0,262 | 5555 |

Terminal bolt with nut

| M 22x75 | GOST 16016-79 | 0,471 | 2083 |

Embedded bolt with nut

| M 22x175 | GOST 16017-79 | 0,761 | 1323 |

Butt nut

| Material type | GOST or TU | Weight 1 pc. according to theory, kg. | Quantity per 1 t, pieces fact |

| M 27 | GOST 11532-93 | 0,202 | 4545 |

| M 24 | GOST 11532-93 | 0,153 | 6250 |

| M 22 | GOST 11532-93 | 0,126 | 6250 |

Butt bolt complete with nut and washer (BGSh)

| BGSh 27 | GOST 11530-93 | 1,128 | 883 |

| BGSh 24 | GOST 11530-93 | 0,806 | 1222 |

| BGSh 22 | GOST 11530-93 | 0,61 | 1642 |

Terminal bolt assembly (BGSh+terminal)

| Terminal bolt assembly | 1,216 | 813 |

Mortgage bolt assembly

| BGS mortgage | GOST 16017-79 | 0,881 | 1182 |

Butt washer

| M 27 | GOST 19115-73 | 0,096 | 10752 |

| M 24 | GOST 19115-73 | 0,068 | 14706 |

| M 22 | GOST 19115-73 | 0,049 | 20366 |

Crutches

| K 165 (16x16x165) | GOST 5812-82 | 0,378 | 2645 |

| K 130 (14x14x130) | TU 14-4-1587-89 | 0,25 | 5555 |

Anti-theft

| P 65 | TU 32 TsP 811-95 | 1,1 | 909 |

| P 50 | TU 32 TsP 811-95 | 0,95 | 1020 |

| P 43 | GOST 14959-79 | 1,13 | 885 |

2-turn washer

| 2-turn washer | GOST 21797-76 | 0,124 | 8333 |

PC terminal

| PC terminal | GOST 22343-90 | 0,64 | 1515 |

Travel screw

| Screw 24x170 | GOST 809-71 | 0,56 | 1785 |

Crutch lining

| Material type | GOST or TU | Weight 1 pc. according to theory, kg. | Quantity per 1 t, pieces fact |

| D 65 | GOST 8194-75 | 7,66 | 138 |

| D 50 | GOST 12135-75 | 6,2 | 161 |

| SD 50 (pages) | GOST 12135-75 | 6,5 | 161 |

| D 43 | GOST 7056-77 | 5,26 | 190 |

| For P33 | GOST 8142-89 | 2,83 | 353 |

| For P24 | GOST 8142-89 | 1,86 | 625 |

| For P18 | GOST 8142-89 | 1,855 | 539 |

| DN 65 | GOST 8194-75 | 7,83 | 114 |

| DN 65-S | TU 1132-027-1124328-96 | 9,76 | 102 |

| DN 6-65 | GOST 8142-89 | 8,44 | 118 |

| DN 50 | TU 14-2R-393-2005 | 7,06 | 141 |

| SD 65 (p. trans.) | GOST 8194-75 | 7,22 | 138 |

Split Bond Lining

| KD 65 | GOST 16277-93 | 9,6 | 103 |

| KD 50 | TU 32 TsP 820-97 | 9,6 | 104 |

| SK 65 (page trans.) | GOST 16277-93 | 8,4 | 120 |

| KB 50 | GOST 16277-93 | 6,85 | 146 |

| KB 65 | GOST 16277-93 | 7,0 | 146 |

Overlays

| 1Р-65 (6 holes) | GOST 8193-73 | 29,5 | 33 |

| 2Р-65 (4 holes) | GOST 8193-73 | 23,78 | 42 |

| R-50 | GOST 19128-73 | 18,77 | 53 |

| R-43 | GOST 8193-73 | 16,01 | 62 |

| R-33 | TUUDP 14-2-1214-98 | 6,7 | 149 |

| R-24 | GOST 8141-56 | 4,22 | 277 |

| R-18 | GOST 8141-56 | 3,06 | 326 |

| KR-70, KR-80 | 8,0 | ||

| KR-100 | 9,0 | ||

| KR-120 | 9,5 |

Fastening crane rails to steel crane beams

| Set for KR-70, KR-80 (P1, U1) | GOST 24741-81 | 3,3 |

| Kit for KR100 (P1, U2) | GOST 24741-81 | 4,1 |

| Kit for KR120 (P1, U3) | GOST 24741-81 | 4,1 |

Applications and grades of rail steel

The main area of use of the metal (as is clear from its name) is the production of rolled products for laying VSP.

Now let's look at the most popular variations of alloys:

- 76 is the most popular. Profiles of the P50 and P65 series are made from it, constituting 3/4 of all supporting structures of wide-gauge railway tracks.

- 76F – already reinforced with vanadium, with an increased resource. Therefore, it is used for the production of rolled products, which will later be laid in lines for high-speed movement of locomotives and other fast transport.

- K63 – alloyed with nickel (up to 0.3%), has impressive hardness and better corrosion resistance. Crane rails are made from it; the grade of steel allows it to withstand loads that in other cases become critical.

- K63F – with tungsten additives, which means even higher cyclic strength.

- M54 – enriched with manganese and due to this has good viscosity. It has found its application in the production of linings for joints and turnouts.

- M68 – relevant for the production of specific elements of the superstructure of the track.

The need for mechanical properties in various combinations determined such a variety of options. Add here the relatively low weight and low cost, and you get a very practical design for the construction of transport lines and interchange nodes.

The type of rail steel is indicated on the marking, which can be either permanent or temporary. In the first case it is applied by branding, in the second - by paint. Other designations include compliance of the rolled product with GOST, as well as its additional features (shortened length, grade, location of technical holes, etc.).

The profiles can be used until the expiration of the service life specified by the manufacturer and calculated by the tonnage passed. Premature failure of VSP elements caused by the appearance of defects is also possible. Then they need to be replaced or repaired. You can read about different types of defects in this article.

So, we found out that for railway tracks the steel grade is 76 and 76F, with a high carbon content and with vanadium additives (in the second case). It is smelted in converter and arc furnaces, with deoxidation with ferrosilicon and aluminum, followed by dephosphorization and slag renewal, with vacuum and heat treatment. With this approach, the finished steel is distinguished by a high degree of purity and a low tendency to develop defects.

In a similar way, manufacturing plants produce not only structures for forming the fabric, but also other important elements used at railway facilities. Let's take a closer look at them.

Types of materials and their weight

If we consider the weight of the rails, it depends on their modification. The products are different in design, purpose, length, shape and other characteristics. Weight depends on a number of characteristics:

- type - rails are crane, railway, connecting, tram;

- degree of quality - products are presented as non-heat-strengthened and heat-strengthened;

- smelting method;

- grade used as a raw material base for steel;

- the presence or absence of niches specifically for bolted connections.

Conventionally, the weight of rolled products is determined by marking. The numbers that are added to the letters determine the approximate weight per 1 m of rails. But they are convenient only for approximate calculations, because the devices are created on the basis of steel, which differs in density. Consequently, the marking shows only the approximate weight, which is appropriate when organizing transportation and determining the carrying capacity of the required transport.

Common types of rails:

- Products of types R-65, R-43, R-75, R50 are railway. They are designed for turnouts and wide-gauge tracks.

- Devices of type RP-65, RP-50, RP-75 - equipping wide-gauge industrial tracks.

- Lines of types P-34, P33, P38 are intended for the development of such objects as mines and shafts.

- Devices of type R-18, R11, R-24 are designed for the construction of narrow-gauge lines.

- Rails of the RT-62 type are tram type and have longitudinal grooves.

- Products of the types KR-80, KR-70, KR-140, KR-100 belong to the crane category and are designed for operation with heavy equipment.

Wheel steels – for railway wheels

The rims of moving parts of transport simply must be wear-resistant (otherwise all the strength advantages of the superstructure of the track will be reduced to zero). Therefore, they are produced from those types of metal we are considering that are enriched with carbides. Then they fail less often, which means they provoke less emergency situations, and in the long term they also reduce the cost of operating locomotives and cars.

Attention, it is a mistake to assume that all risks are neutralized by suitable admixtures. Even useful additives should be introduced into the alloy in moderation - now we will explain why.

Carbon in wheel steels

Analyzing the chemical composition, we concluded that carbon inclusions increase the metal’s resistance to wear, but they also increase susceptibility to critical temperatures. In the case of rims, it is especially important to make them resistant to thermal damage. It must be remembered that premature wear (especially with careless maintenance) can lead to vehicles moving at an impressive speed going off the road.

Therefore, there is no point in focusing exclusively on high-carbon alloys - their strength in this case can be quite detrimental. Conventional rail steel may not be suitable for the production of wheels; the grade for their manufacture must meet the following standards:

- AAR M-107/M-208 – American;

- EN 13262 – European;

- JIS E 5402-1 – Japanese;

- GOST 10791-2011 – intersectoral.

The design solutions of the Land of the Rising Sun deserve special attention. The railway service there is quite well developed and today is at that modern level, which is worth emulating not only in the CIS countries. The locomotives there are advanced and move at impressive speeds. How do the moving parts of this transport withstand the most severe loads? Let's try to figure it out.

What steel are rails made from?

The first cast iron rails appeared in the middle of the 18th century; horse-drawn freight cars moved along them.

Gradually, cast iron rails were replaced by steel ones. A long evolutionary path has led to the emergence of technologies that make it possible to produce durable types of modern rail steel. High-speed passenger and heavy freight trains now rush along the railway lines. And due to the large loads exerted on the rails by rolling stock, new types of wear and defects arise, such as the manifestation of contact rolling fatigue and thin internal cracks. These problems have posed the task of creating new grades of rail steel with increased wear resistance. The open-hearth process was the main steelmaking technology until the seventies, including for the production of steel grades for railway rails. But it was replaced by a new technology for producing steel blanks. They are formed as a result of continuous bloom casting and do not have the inherent disadvantages of ingots, such as the presence of non-metallic inclusions, gas cavities and shrinkage voids. And in rails, such manufacturing defects manifest themselves in the form of vertical cracks in the head, networks of small cracks and shrinkage cavities.

Currently, rails are manufactured on rolling mills using technologies that effectively reduce the content of non-metallic inclusions. The applied vacuuming makes it possible to regulate the amount of carbon, hydrogen and oxygen. This technology makes it possible to reduce the level of hydrogen to the maximum permissible values and virtually eliminate the formation of flakes, leading to a decrease in the load-bearing capacity of rails.

Those who are interested in what kind of steel is currently used for the manufacture of rails should know that today steel grades are produced that allow heat treatment during the manufacture of rails, which significantly increases their quality characteristics.

Japanese wheel steels

About 90 years ago, local engineers and builders were faced with a global problem: experts discovered that the wheels of their vehicles were wearing out prematurely, although the service life was calculated for years to come.

An explanation was found and turned out to be simple: the alloy for the production of metal elements, made using borrowed European technologies, contained only 0.5% carbon. This mass fraction was clearly insufficient to provide the required wear resistance.

Scientists from Japan understood that increasing the percentage of carbon in the thickness of the profile could also lead to negative consequences (in particular, a tendency to thermal damage). Therefore, large-scale research was launched, the goal of which was to find the optimal concentration of the additive while maintaining all the beneficial properties. As a result, we settled on the level of 0.6-0.75%, which corresponds to the JIS E 5402-1 standard.

Higher carbon in the wheels - less wear on the rails

The search allowed us to draw another important conclusion: with a balance of impurities and the base metal, not only the moving parts of the transport, but also those elements of the VSP on which they travel last longer.

An explanation for this effect was also found: the smallest particles break off from the wheels, settle at the point of contact and have an abrasive effect on the rolling surface. As a result, scratches appear on the head, and over time, cracks.

These results prompted engineers to experimentally increase the carbon content - up to the level that the steel grade currently boasts for JIS E 5402-1 (that is, up to 0.75%).

Where are rails used?

Speaking of rails, we first of all remember night trains with their soothing sound of wheels or trams, which exist in many large cities of Ukraine and the world.

But according to the areas of application, narrow gauge rails, mine rails, crane rails, frame rails, counter rails, pointed rails, guard rails, etc. are also distinguished.

They are used not only for transporting passengers and cargo. For example, crane rails can be seen at almost any large construction site or industrial enterprise. They are used to form crane tracks for port, tower or bridge cranes.

But most of all in this segment of metallurgy, steel is smelted for rail transport. This is due both to the widespread development of the railway network and to the need to update those already built. The length of railway tracks in 151 countries of the world exceeds 1.37 million kilometers. In Ukraine – about 26 thousand km. In the USA and China, which top this rating, there are 257.7 thousand km and 154 thousand km, respectively.

In addition, in recent decades, high-speed passenger rail services have been actively developing in the world. It requires separate tracks that are not used by freight trains. And the struggle to improve the environment is leading to the development of electric transport in large cities, in particular, tram networks and subways.

Modern rail standards for railways provide the following lengths: 12.5; 25; 50 and 100 meters. The length of continuous lashes ranges from 400 meters to the length of the haul. Yes, the usual knocking of car wheels disappears, but significant savings are achieved during installation, and wear of the rolling stock is reduced.

Japanese wheels on a German railway

There was a problem in the German railway traffic: the moving parts of local trains (ICE) quickly deformed, which led to their failure, loss of traction quality, and the occurrence of emergency situations. When Deutsche Bann specialists learned that the locomotives of the Shinkan-sen company from the Land of the Rising Sun do not experience such difficulties even when moving at the maximum permissible speeds, they wanted to conduct comparative tests.

The German trains were equipped with both European wheels made of ER7 alloy (with a mass fraction of carbon up to 0.52%) and Japanese wheels made according to the JIS E 5402-1 standard. After 6 years of independent testing, from 2003 to 2009, the second option showed that it resists wear 1.5 times more effectively.

At the same time, metal structures laid in the track were also regularly checked. It turned out that they also erase more slowly - exactly 1.5 times. Fewer abrasive particles remain on the contact surface. Enriching the material with carbon gives a good increase in service life - thanks to the Japanese for this discovery.

Advantages of railway rails

Modern varieties of them have the following advantages (and a material such as rail steel helps to emphasize these practical advantages):

- distribute the tested loads evenly along the entire length of the web;

- provide a reliable surface for the wheels of vehicles, helping them develop and maintain high speeds of movement;

- have a significant service life (over 50 years), during which they can withstand severe stress and effectively resist wear.

Thus, they help to cope with the main task - they are the key to fast and safe transportation of passengers and cargo.

___________________

Now that you know what kind of material there is for the production of railway metal, its characteristics, chemical composition, as well as mechanical properties, it will be easier to choose a specific brand that is optimally suitable for arranging a railway facility. And it will always help you quickly obtain the required volume of metal structures at an attractive price - contact us to order.

What are rails and their types

Cherepovetsky is engaged in the production of metal structures for buildings and structures. We offer rails made of high-quality steel at an affordable price.

Rails are metal beams made of carbon steel. The structure is laid on specialized sleepers. Rails are used to build railway tracks.

They are manufactured in accordance with GOST for each type.

the design function is the direction of the wheels of railway transport. The rails take the load and distribute it to the lower elements of the track. In areas where electric traction is required, they play the role of a current conductor. In places with automatic locking, the rails serve as a conductor.

Material of manufacture

The most common material for the manufacture of metal structures is carbon steel. The quality of a metal depends on its chemical structure, micro- and macrostructure.

The presence of carbon in the rail increases its reliability and increases its service life, but excessive carbon content in the metal structure, on the contrary, increases the fragility of the rail.

Therefore, when adding this element, care should be taken to ensure maximum strength and reliability of the steel.

The quality of carbon steel can be further improved. For example, treat it with manganese. This will increase the service life of the rails, making them more viscous and resistant to mechanical damage. Silicon will increase the hardness of the material and its resistance to wear. To improve the quality characteristics of steel, titanium, zirconium and vanadium can also be used.

Sulfur or phosphorus should not be added, as they make the steel brittle and brittle. Rails made from these substances are susceptible to cracks and breaks.

For the microstructure of the material, pearlite is used, which is shaped like ferrite plates. A homogeneous composition of steel is obtained by processing it at high temperatures. This method increases the hardness, toughness, wear resistance, reliability and service life of the metal. The macrostructure should be homogeneous, without unnecessary elements.

Physical characteristics of rails

Throughout the existence of rails, they have been made in different shapes: two-headed, mushroom-shaped, corner and others.

Modern rails are made with wide soles. The design consists of a head, a sole and a neck, which connects the other two parts.

The central part is made convex so that it can take the load from the wheels of railway transport. The joints have a smooth shape. To relieve tension from the neck, it is made curved.

The wider the rail base, the greater its lateral stability.

For the Russian Federation, it is customary to make rails of standard length:

- 12.5 m;

- 25 m;

- 50 m;

- 100 m.

Constructions of shorter length are made for uneven sections of the railway. The longer the rail, the less its wear and resistance to railway transport.

When calculating the power of a material, its specific gravity per 1 meter of rail is taken into account.

Sleepers are an important fastening element in a structure. They are made from wood, reinforced concrete, plastic and steel.

When calculating the cost of a structure, its specific gravity, width, length, hardness and wear resistance are taken into account.

Rail requirements

- maximum length of the string - to reduce the load on the moving parts of the trains and track elements;

- rails for tracks with significant loads should be weighted - for ease of installation and replacement, as well as to save material;

- for effective resistance, sufficient rigidity and flexibility are needed to avoid breaking and flattening during strong impacts of the wheels;

- viscosity of the material - to prevent fragility and abrasion under mechanical stress;

- rough surface and smooth rolling - for high-quality adhesion between the vehicle wheels and track structures.

Rail types

The classification of rails depends on the congestion of the lines and the average speed of vehicles moving along them. For example, a massive, heavy rail reduces line maintenance costs (by increasing its service life) and has a beneficial effect on the wear resistance of sleepers.

The following types of rails are distinguished:

- Railway. The most popular and sought after type. 1 meter of such rails weighs 50-65 kg and has a length of 50 meters.

- Narrow gauge - to create a narrow space between the rails. This design is in demand in the mining industry and areas with difficult traffic.

- Mining. They are used for laying continuous railway tracks. Mine rails are used in industry.

- Trams. Used for tram tracks. The rails are not designed for heavy load on the line and are light in weight.

- Crane. They are used for railway tracks - for moving a crane.

- Crane The heaviest type of rails. They can be laid in several rows.

- Frame. Used for the construction of transfer mechanisms.

- Counter-rail. Used for upper structures of railway tracks.

- Witty ones. Also used for overhead track structures.

There are also other types of rails. They are classified by:

- smelting method (electric steel, converter, open-hearth);

- quality (heat-strengthened and non-heat-strengthened);

- type of source elements (ingots, cast iron);

- the presence of holes for connecting parts (bolts).

The price of rails depends on these characteristics.

Legend

Each rail must be marked. The marking consists of letters and numbers, each of which indicates a particular design characteristic. For example:

- the letter A means the type of rail;

- B – quality category;

- C – grade of steel used in manufacturing;

- D – length of rails;

- E – presence of holes for connecting elements;

- F – state standard.

The month of manufacture is indicated by Roman numerals, the year by Arabic numerals. The marking is applied with indelible paint of blue, pistachio, yellow or white.

You can purchase rails of any type at Cherepovets Metal Structures Plant LLC. We have been working for more than 55 years and during this time we have earned an impeccable reputation. For the production of structures we use only high-quality materials, which we process in our own workshops.

The team of the Cherepovets plant employs 120 experienced specialists who approach their work with responsibility. We manufacture parts using modern equipment, which allows us to guarantee high quality and reliability of our products. In the process of work, we strictly comply with all state standards.

Our factory offers each client:

- certified products;

- strict adherence to the deadlines specified in the contract;

- product warranty;

- affordable prices;

- the ability to control the production process online.

In addition to selling metal structures, we carry out equipment diagnostics, design technical documents, and deliver finished products to the customer.

You can place an order online or by calling 8-(800)-222-04-45.